Preparation method for tellurium electrolyte

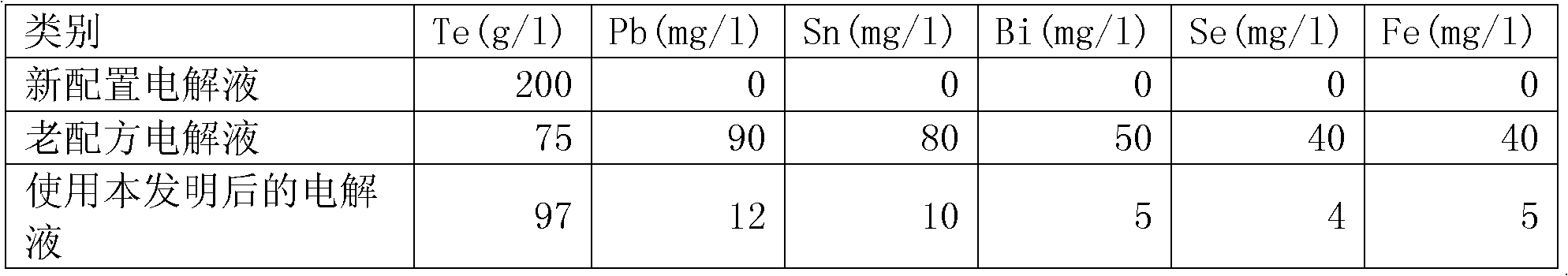

A preparation method and electrolyte technology, which can be applied to the improvement of process efficiency, photographic technology, instruments, etc., can solve the problems of difficult removal of potential, long time and high cost, and achieve low impurity content, low residual impurity, and long service time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0022] Add 1000 grams of tellurium dioxide with a purity of 99.99% to 500 grams of sodium hydroxide with a purity of 99.99%, and then add 5 kg of pure water, and dissolve it in a container at 80°C to obtain an initial tellurium electrolyte with a concentration of 200 grams per liter Then, add 200 grams of solid sodium oxalate and 20 grams of solid potassium iodide in turn, and dissolve to obtain the final tellurium electrolyte.

example 2

[0024] Add 500 grams of tellurium dioxide with a purity of 99.99% to 250 grams of sodium hydroxide with a purity of 99.99%, and then add 2.5 kg of pure water, and dissolve it in the container at 80°C to obtain an initial tellurium electrolytic solution with a concentration of 200 grams per liter. Liquid; Then, add 100 grams of solid sodium oxalate and 10 grams of solid potassium iodide in turn, and dissolve to obtain the final tellurium electrolyte. All the other are the same as example 1.

example 3

[0026] Add 250 grams of tellurium dioxide with a purity of 99.99% to 125 grams of sodium hydroxide with a purity of 99.99%, and then add 1.25 kg of pure water. After dissolving in the container at 80°C, an initial tellurium electrolytic solution with a concentration of 200 grams per liter is obtained. Then, add 50 grams of solid sodium oxalate and 5 grams of solid potassium iodide successively, and dissolve to obtain the final tellurium electrolyte. All the other are the same as example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com