A method for continuously producing high-stability triacetonamine using melt crystallization technology

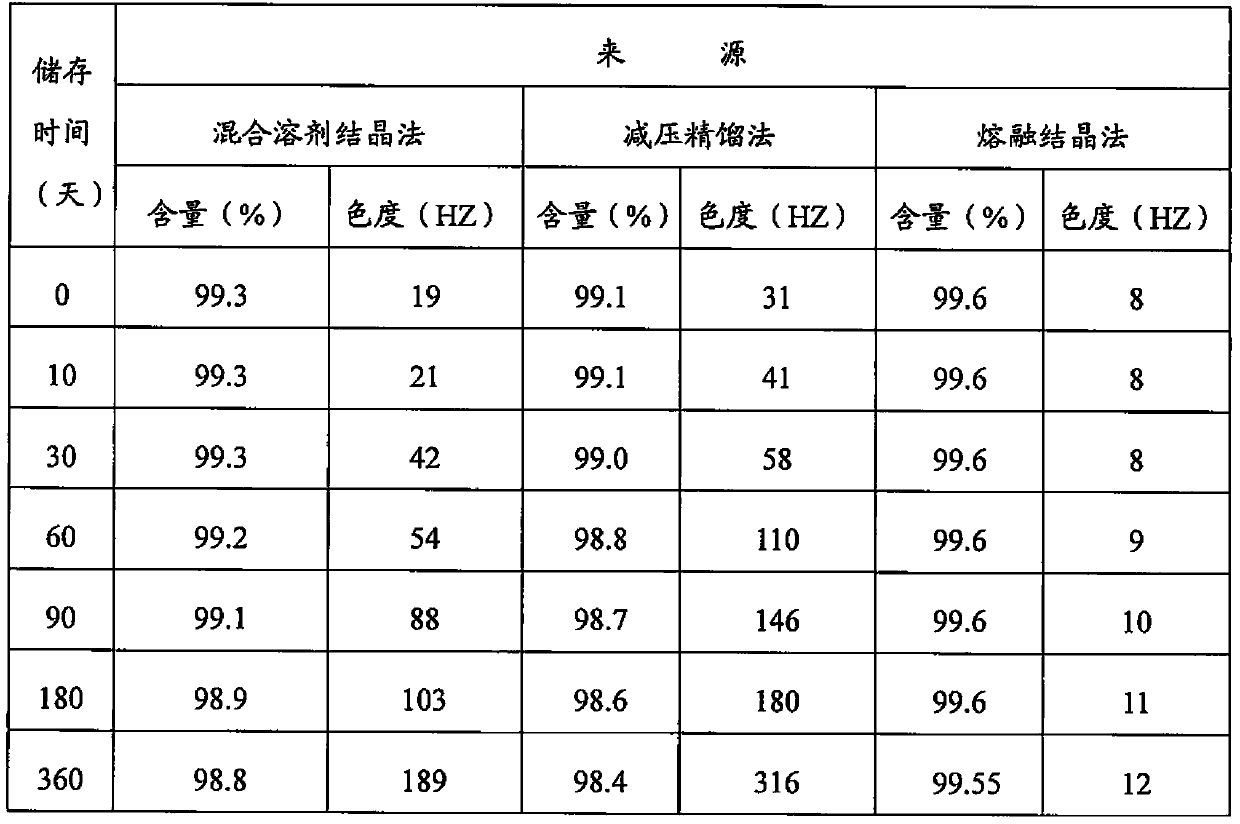

A technology of triacetone amine and melt crystallization, applied in the direction of organic chemistry, etc., can solve the problems of poor product stability, increased post-peak impurities, decreased yield and other problems, and achieves the effects of stable quality, reduced residual impurities and less waste residue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

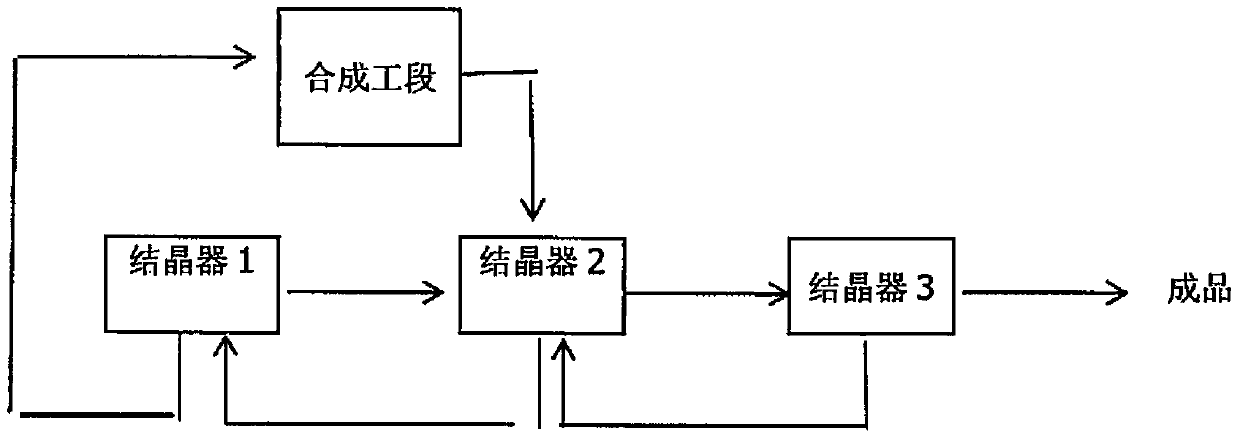

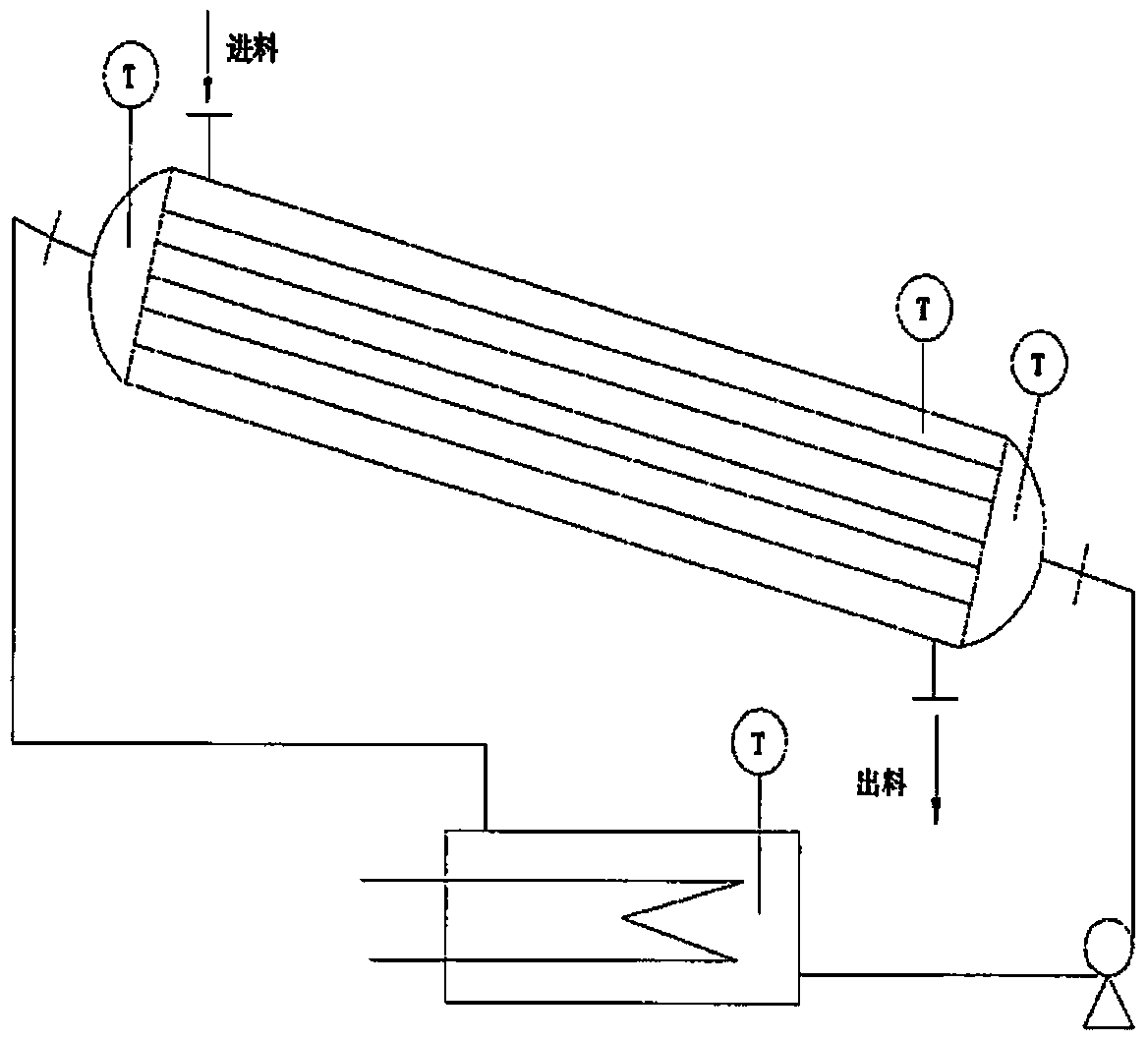

[0039]Such as figure 1 As shown, under the protection of nitrogen gas, 5 liters of glass melting crystallizer 2 is preheated to 60 ° C, and the content of injecting 3.5 kg in the melting crystallizer is 73.8% molten triacetone amine crude product (produced by Suqian Zhenxing Chemical Co., Ltd. , batch number 20140703), lower the temperature at a rate of 0.5°C per minute, drop to 20°C and keep for 1 hour, press out the unattached liquid with nitrogen to obtain 1.68kg of dark brown crystalline mother liquor B with a content of 55.1%, and press it into the crystallizer 1. Reheat the attached solid to 55° C. to melt, press out with nitrogen, measure, detect by GC, and enter to obtain 1.81 kg of light yellow triacetonamine semi-finished product with a content of 92.5%.

[0040] Then heat the above 1.81kg semi-finished product to 65°C, inject it into the 3-liter glass melting crystallizer 3 that has been preheated to 65°C under the protection of nitrogen, cool down at a rate of 0.4...

Embodiment 2

[0042] Such as figure 1 As shown, under the protection of nitrogen gas, 50 liters of stainless steel melting crystallizer 2 is preheated to 60 ° C, and 35 kg of molten triacetone amine crude product with a content of 74.1% is injected into the melting crystallizer (produced by Suqian Zhenxing Chemical Co., Ltd., batch number 20140705) , lowered the temperature at a rate of 0.5° C. per minute, dropped to 20° C. and kept for 2 hours, and the unattached liquid was depressurized with nitrogen to obtain 16.95 kg of dark brown solution B with a content of 55.7%. Then heated to 55° C. to melt the attached solid and press out with nitrogen to obtain 18.01 kg of light yellow triacetonamine semi-finished product with a content of 91.6%.

[0043] Then add the above 18.01kg semi-finished product into the 30-liter stainless steel melting crystallizer 3 preheated to 65°C, lower the temperature at a rate of 0.4°C per minute, drop it to 25°C and keep it for 2 hours, and press out the unattach...

Embodiment 3

[0045] Such as figure 1 As shown, under the protection of nitrogen gas, 3 liters of glass melting crystallizer 1 is preheated to 60°C, and 2.1kg of crystallization mother liquor B with a content of 55.1% is injected into the melting crystallizer 1, and the temperature is lowered at a rate of 0.3°C per minute. Keep at 15° C. for 2 hours, press out the unattached liquid with nitrogen to obtain 1.04 kg of dark brown crystalline mother liquor C with a content of 37.3% (the crystallized mother liquor C with this content is pressed into the synthesis section for processing). Then the temperature was raised to 55° C. to melt the attached solid and blow out with nitrogen pressure to obtain 1.05 kg of light brown crude triacetonamine with a content of 73.2% (the crude product with this content directly enters the crystallizer 2) for circulation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com