Preparation method of dimethyl hydroxyl silicone oil adsorbent for fabric synthesis

A technology of dimethyl hydroxy silicone oil and synthetic fabrics, which is applied in the direction of chemical instruments and methods, and other chemical processes, can solve the problems of friction resistance and heat resistance, fabric products should not be in contact with the skin for a long time, and achieve long service life and adsorption The effect of fast rate and less residual impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

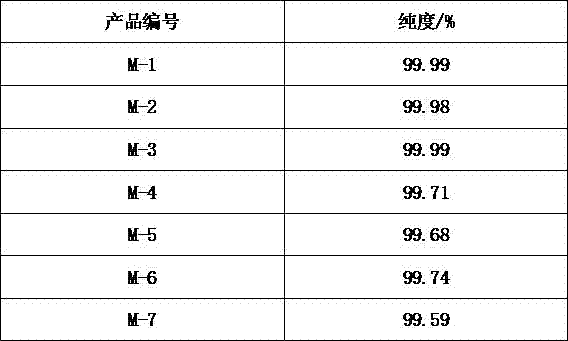

Embodiment 1

[0015] Add 100Kg of recombinant protein series high flow rate agarose gel, 0.5Kg of 2,3-dihydro-1,4-benzodioxy-5-carboxylic acid, and N-sulfonic acid propyl-3-methyl into the stirred tank. Pyridine p-toluenesulfonate 0.5Kg, 2-amino-1H-imidazole-5-carboxylic acid ethyl ester hydrochloride 1Kg, 300Kg toluene, then reacted at 77°C for 12h, the product is separated and dried to obtain the present invention The adsorbent product. Product number M-1.

Embodiment 2

[0017] Add 100Kg of recombinant protein series high flow rate agarose gel, 0.1Kg of 2,3-dihydro-1,4-benzodioxy-5-carboxylic acid, and N-sulfonic acid propyl-3-methyl into the stirred tank. Pyridine p-toluenesulfonate 0.1Kg, 2-amino-1H-imidazole-5-carboxylic acid ethyl ester hydrochloride 0.5Kg, 200Kg toluene, then reacted at 60℃ for 6h, the product is separated and dried to obtain the The adsorbent product of the invention. Product number M-2.

Embodiment 3

[0019] Add 100Kg of recombinant protein series high flow rate agarose gel, 1Kg of 2,3-dihydro-1,4-benzodioxy-5-carboxylic acid, and N-sulfonic acid propyl-3-methylpyridine into the stirred tank. P-toluenesulfonate 1Kg, 2-amino-1H-imidazole-5-carboxylic acid ethyl ester hydrochloride 2Kg, 500Kg toluene, stirred at 300rpm for 1h, and then reacted at 100℃ for 21h, the product was separated, After drying, the adsorbent product of the present invention is obtained. Product number M-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com