Method for preparing permeable reactive barrier for relieving passivation of zero-valent iron

A technology of permeable reactive walls and zero-valent iron, applied in chemical instruments and methods, water pollutants, water/sludge/sewage treatment, etc., can solve the problems of low efficiency and easy passivation of permeable reactive walls, and achieve The effects of avoiding microbial loss, alleviating passivation, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

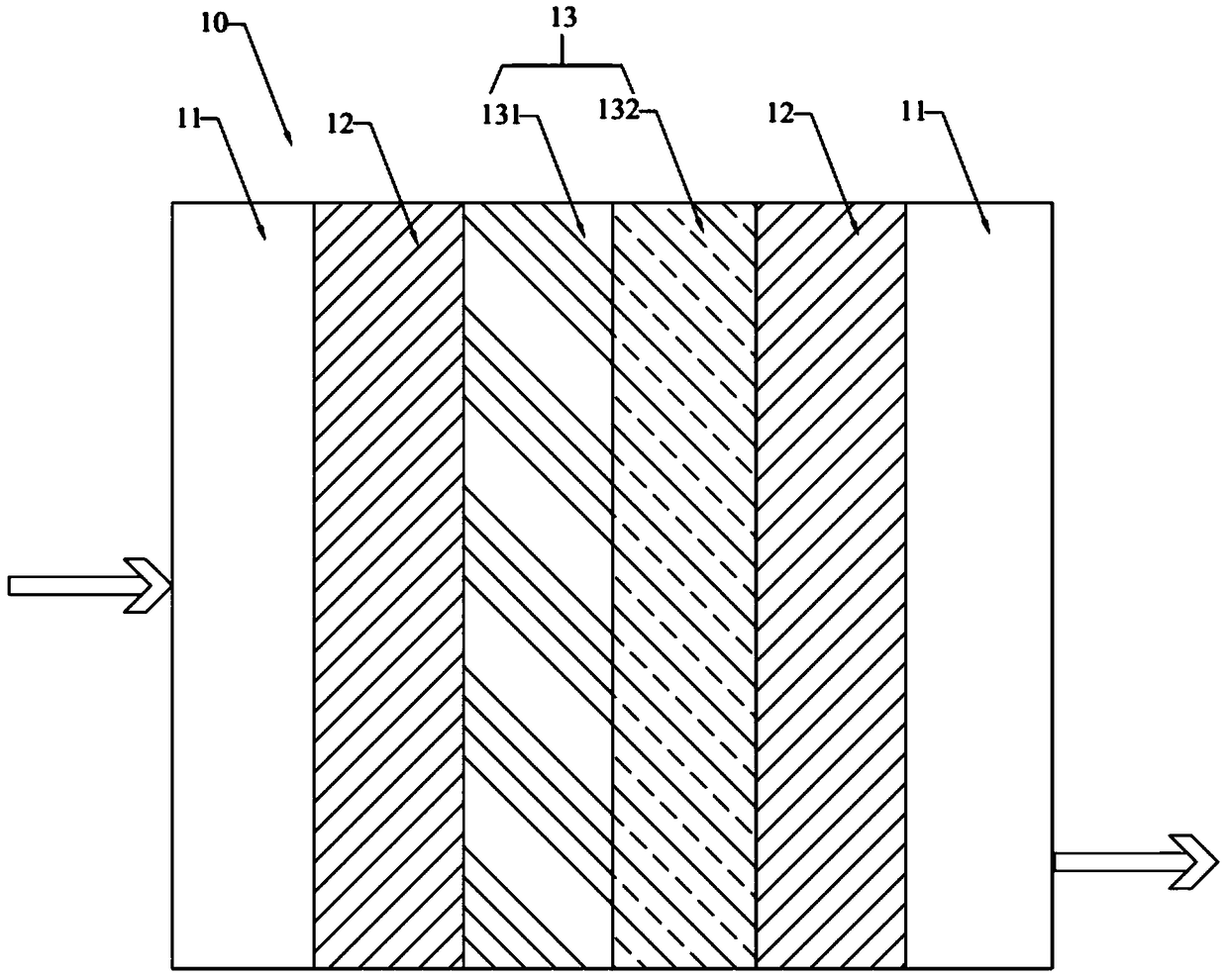

[0024] Embodiment 1: Preparation of double-layer permeable reactive wall 13 fillers:

[0025] CaO 2 The granules and Woshibao granules are evenly mixed at a volume ratio of 3:2, and packed into the first layer to form the oxygen-releasing nutrient layer 131 .

[0026] Cut the corn stalks to 1-3cm with a cutting machine, burn them under anoxic conditions at 300°C for 2 hours, soak them in 1mol / L hydrochloric acid for 12 hours, wash them with deionized water to remove the ash, wash them until the pH value is constant, and dry them in an oven at 105°C. Grind, pass through a 40-mesh sieve, and pass through a 60-mesh sieve for the undersieve, and the oversieve is biochar.

[0027] Prepare 10L of sterile suspension activation medium, inoculate L.acidophilus, and culture with shaking for 24 hours. Concentrate to 1L by aseptic centrifugation (bacteria concentration 10 8 ). After 12 hours, configure 1 L of sterile suspension activation medium, inoculate L.acidophilus, and culture w...

Embodiment 2

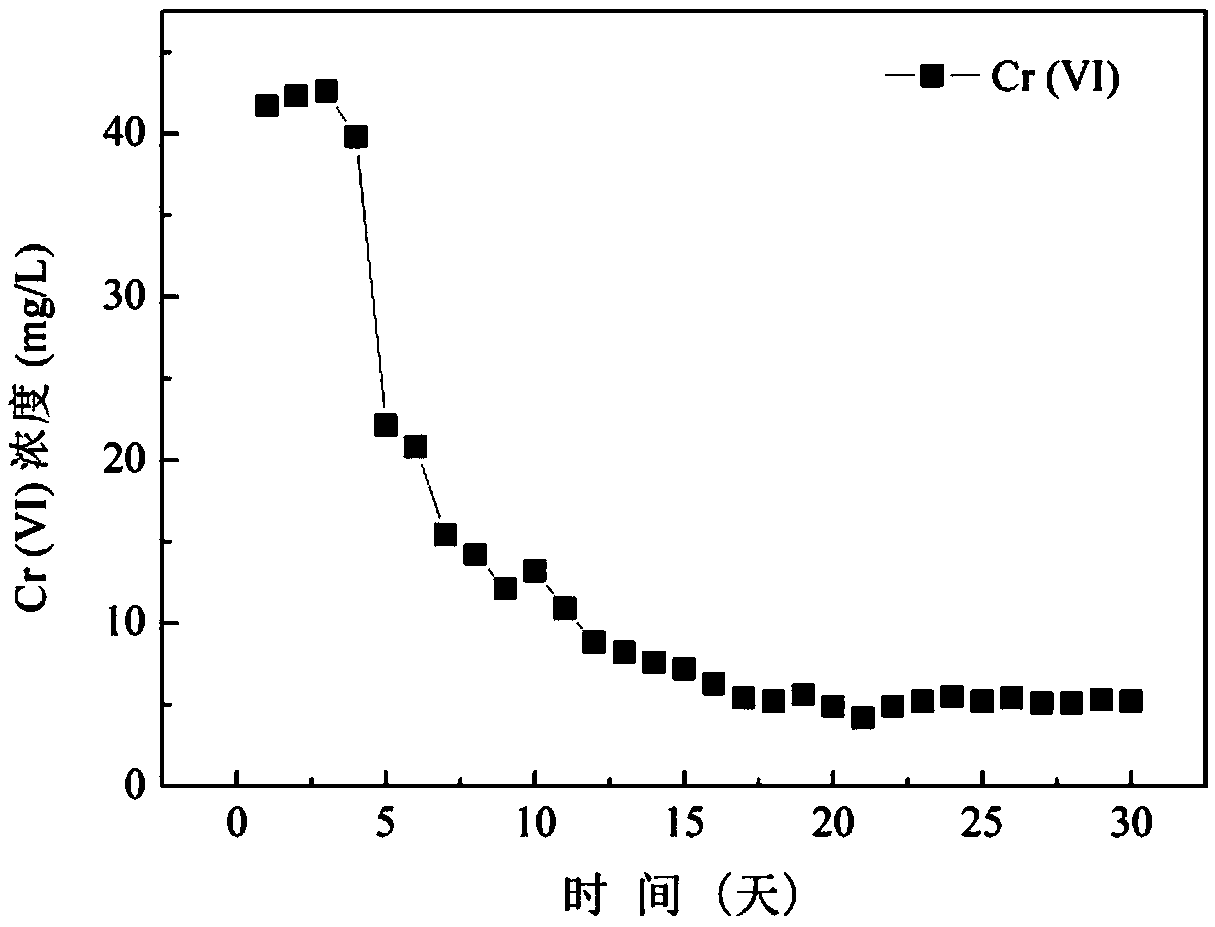

[0031] Example 2: The prepared permeable reaction wall 13 repairs Cr-polluted groundwater.

[0032] my country is the largest producer of chromium salts in the world, and chromium and its compounds are widely used in metallurgical industry, electroplating industry, leather making, printing and dyeing and other industries. In recent years, the disorderly accumulation of chromium slag has seriously polluted soil and groundwater, posing a great threat to animals, plants and human health. Due to the close combination of chromium and soil minerals, the harmless treatment of chromium is difficult. Therefore, how to effectively control and control the chromium pollution in soil and groundwater is a very important and urgent task. The toxicity of Cr(VI) is extremely strong. In contrast, Cr(III) is less toxic and less harmful to the environment. Therefore, converting Cr(VI) into Cr(III) is an important way to reduce the harm of Cr pollution. How to effectively reduce Cr(VI) to Cr(III...

Embodiment 3

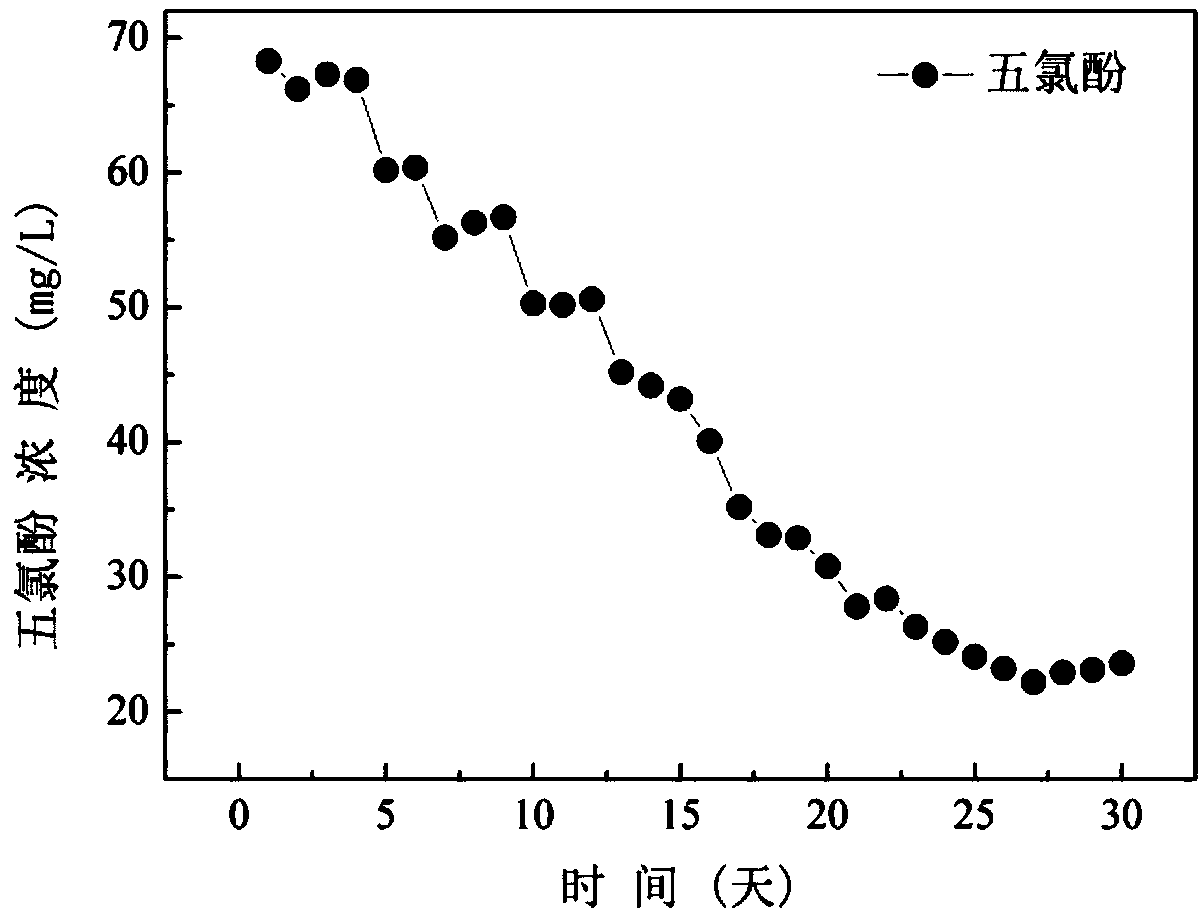

[0035] Example 3: The prepared permeable reaction wall 13 treats chlorophenol pollutants.

[0036] Chlorophenol pollutants are bioaccumulative, refractory to biodegradation, and have "three causes" effects, so they are a class of pollutants that are prioritized for control. Aiming at the treatment of chlorophenol pollutants in water bodies, a lot of research work has been carried out in related fields at home and abroad, and a variety of treatment technologies have been developed. Among them, the reduction of zero-valent iron is a class of methods that has attracted much attention.

[0037] Raw water containing 100mg / L pentachlorophene was configured (configured using sodium pentachlorophenate). Use a peristaltic pump to feed water at a speed of 10rpm for 30d ( figure 1 ), every 24h high performance liquid chromatography measures the concentration of pentachlorophenol in the water. See the test results image 3 .

[0038] At the initial stage of operation, due to the pass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com