Aluminum anode material for seawater power battery

A technology of power battery and aluminum anode, applied in the field of chemical power source material, can solve the problems of easy passivation of pure aluminum, reduced corrosion resistance of aluminum alloy, voltage hysteresis, etc., and achieves good storage performance, wide application range and convenient use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

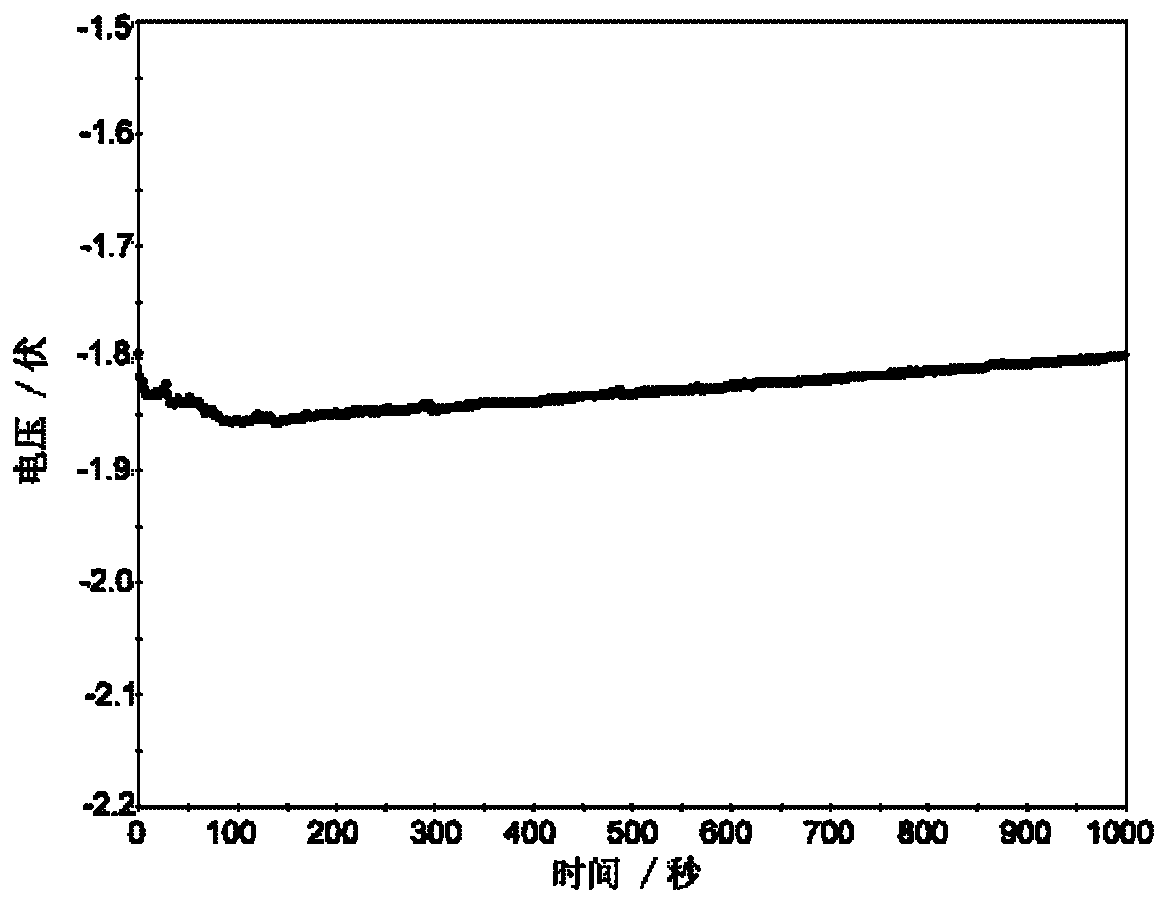

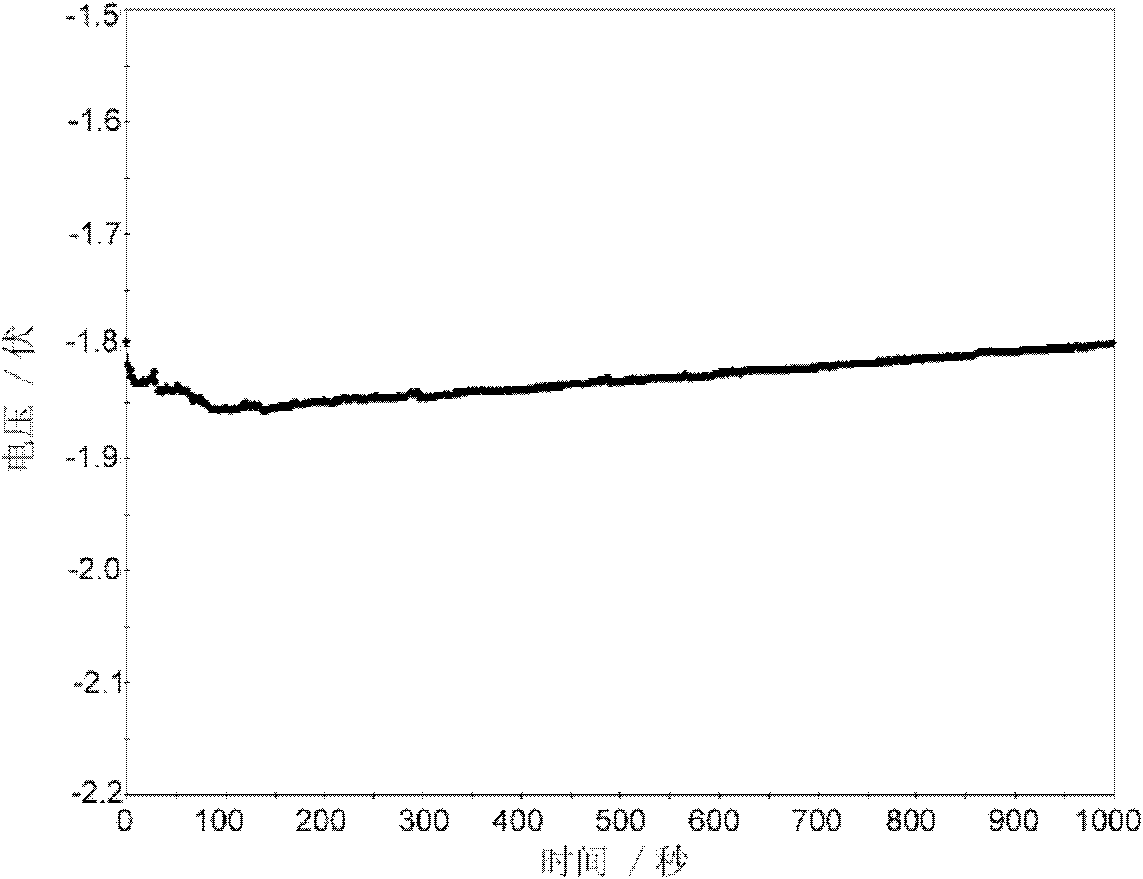

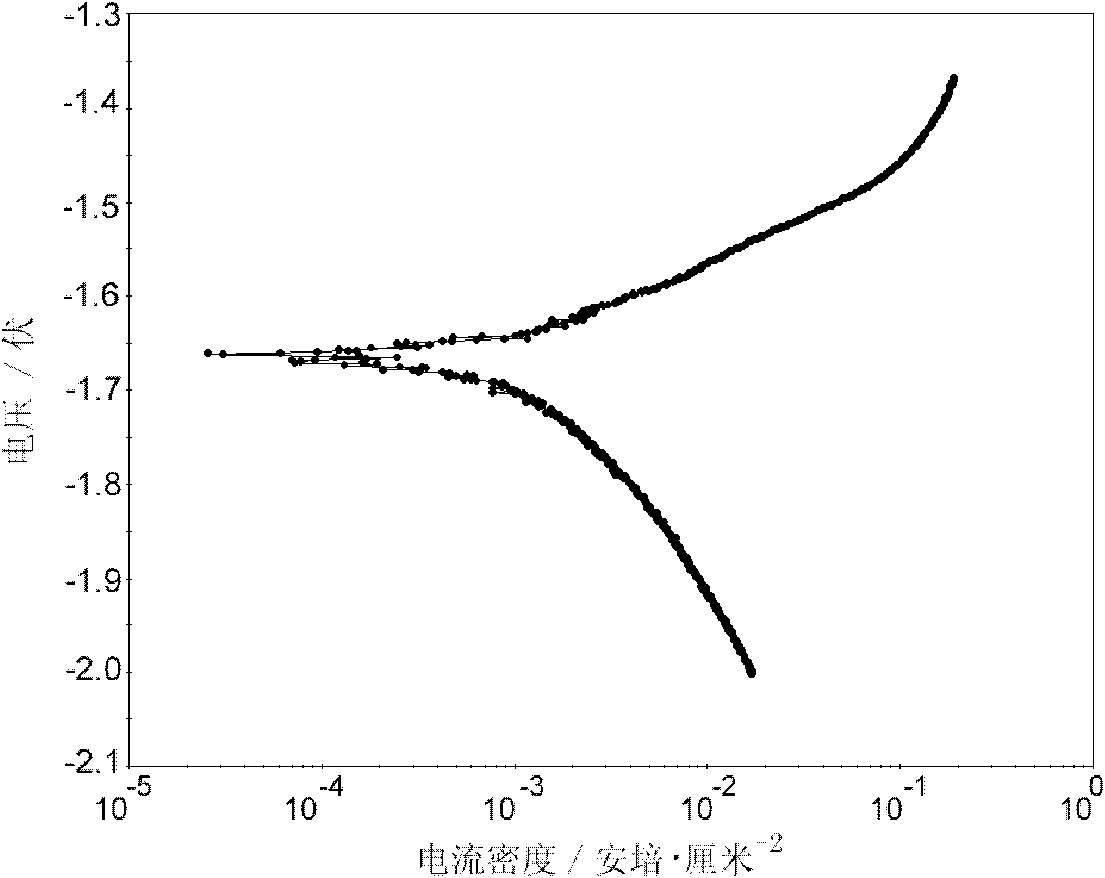

[0022] See Figure 1, Figure 2, Figure 3 and Figure 4, based on aluminum and containing 0.01wt% activated element mercury, 0.05wt% gallium, 0.05wt% magnesium, 0.01wt% tin and 0.01wt% zinc.

[0023] Adopt the same structural form as the zinc-manganese laminated battery pack, and use the aluminum battery anode plate as the anode plate of the aluminum / silver oxide laminated battery pack.

[0024] The parts not described in this embodiment are the same as the prior art.

Embodiment 2

[0026] It is based on aluminum and contains 0.1wt% activated element mercury, 2.0wt% gallium, 2.0wt% magnesium, 0.1wt% tin and 0.1wt% zinc.

[0027] The aluminum anode material for the seawater power battery of the present invention can be used as the aluminum alloy anode of the aluminum-air battery.

[0028] The parts not described in this embodiment are the same as the prior art.

Embodiment 3

[0030] It is based on aluminum and contains 1.0wt% activated element mercury, 1.0wt% gallium, 1.0wt% magnesium, 1.0wt% tin and 1.0wt% zinc.

[0031] The aluminum anode material for the seawater power battery of the present invention can be used as the aluminum alloy anode of the aluminum-hydrogen peroxide half fuel cell.

[0032] The parts not described in this embodiment are the same as the prior art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com