Water quality electrolyzer and cleaning machine

An electrolyzer and water quality technology, applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of slow contact and circulation of electrode components, affecting electrolysis efficiency, and small area of electrolytic sheets. Achieve the effect of stable function, simple principle and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

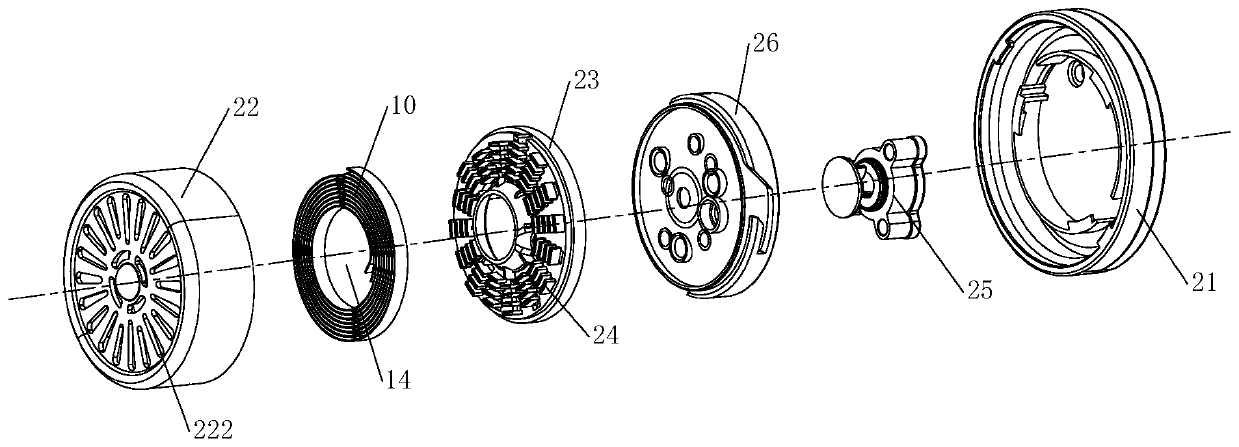

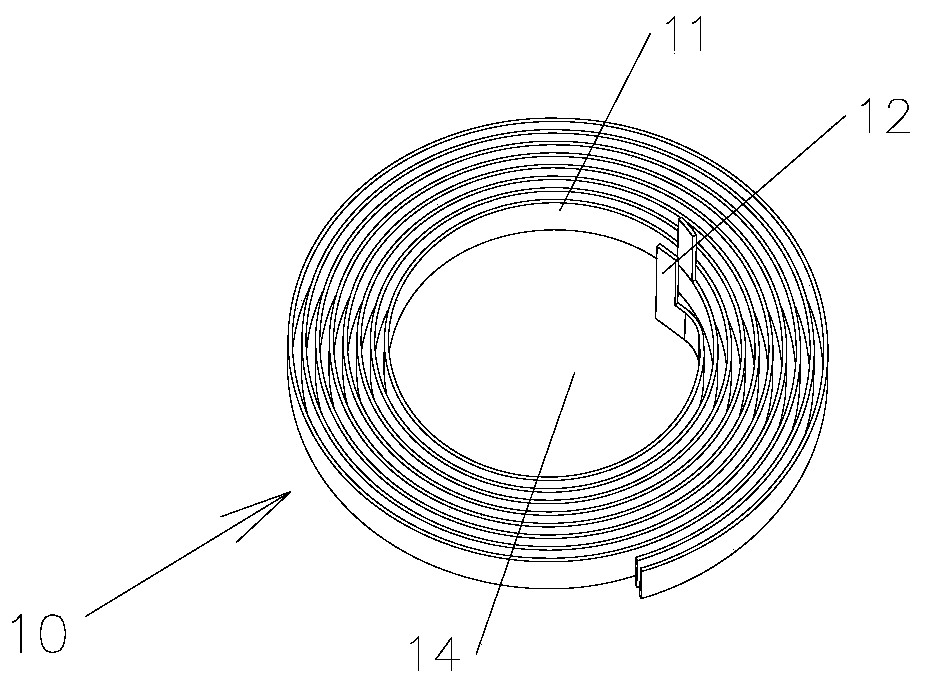

[0060] The electrolytic sheet 10 of the water quality electrolyzer 20 of the first embodiment is spiral and adopts a bipolar structure to increase the contact area between the electrolytic sheet 10 and water and reduce the contact resistance. Specifically, such as Figure 3 to Figure 5 As shown, the spiral electrolytic sheet 10 includes two strip sheets 11 and two conductive polar points 12; the two strip sheets 11 are parallel with an interval 13 between them, and the two strip sheets 11 are bent synchronously into spiral. Two conductive polar points 12 are respectively formed on the two strips 11, and the two conductive polar points 12 are arranged opposite to each other so as to facilitate the introduction of electric current.

[0061] The electrolytic sheet 10 of the embodiment of the present invention changes the shape of the traditional electrolytic sheet 10 so that it forms a spiral electrolytic sheet 10 with only two conductive polar points 12, and both sides of the s...

Embodiment 2

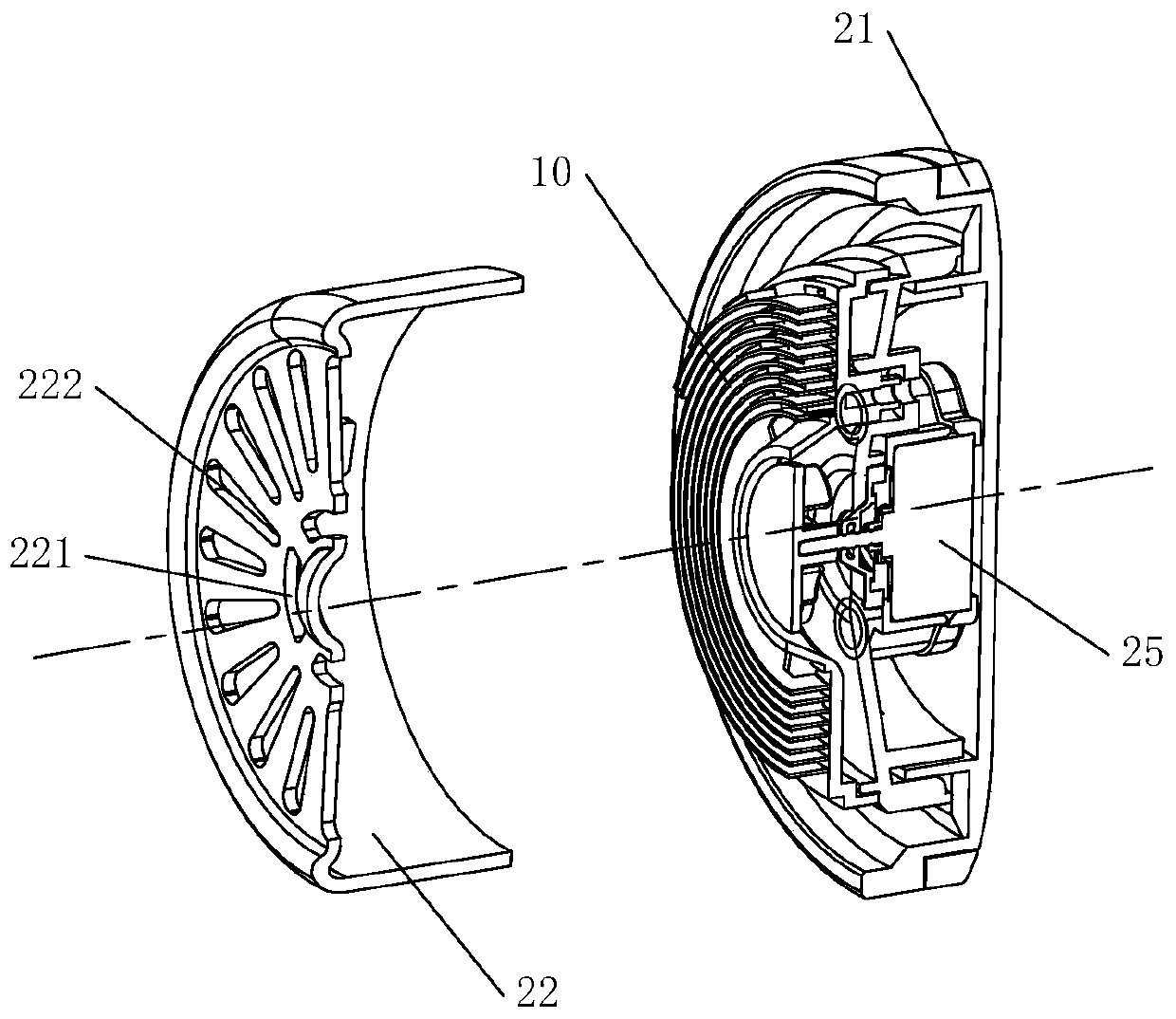

[0075] The electrolytic sheet 10 of the water quality electrolyzer 20 of embodiment two is mesh shape, as Figure 9 to Figure 12 As shown, the electrolytic sheet 10 is in the shape of a mesh with an inner hole 14, and the electrolytic sheet includes two sheets arranged relatively parallel to each other. The two sheets are respectively provided with a conductive polarity point, so as to guide the current pair of the two sheets. Water is electrolyzed. Figure 9 , Figure 11 and Figure 12Shown in is an electrolytic sheet 10 of an integral structure formed by combining two sheets. The electrolytic sheet 10 is provided with a plurality of connection holes 15 surrounding the inner hole 14 . The housing includes a top cover 22 and a motor base 21. The top cover 22 in the second embodiment has the same structure as the top cover 22 in the first embodiment, that is, the top cover 22 is cylindrical, and one end surface is sealed to form the top surface. The other end surface is pen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com