A p-type delafossite structure cusco 2 Crystal material and its preparation method and use

A technology of crystal material and delafossite, which is applied in the field of p-type delafossite structure CuScO2 crystal material and its preparation, can solve the problems of less crystal powder material preparation and performance research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

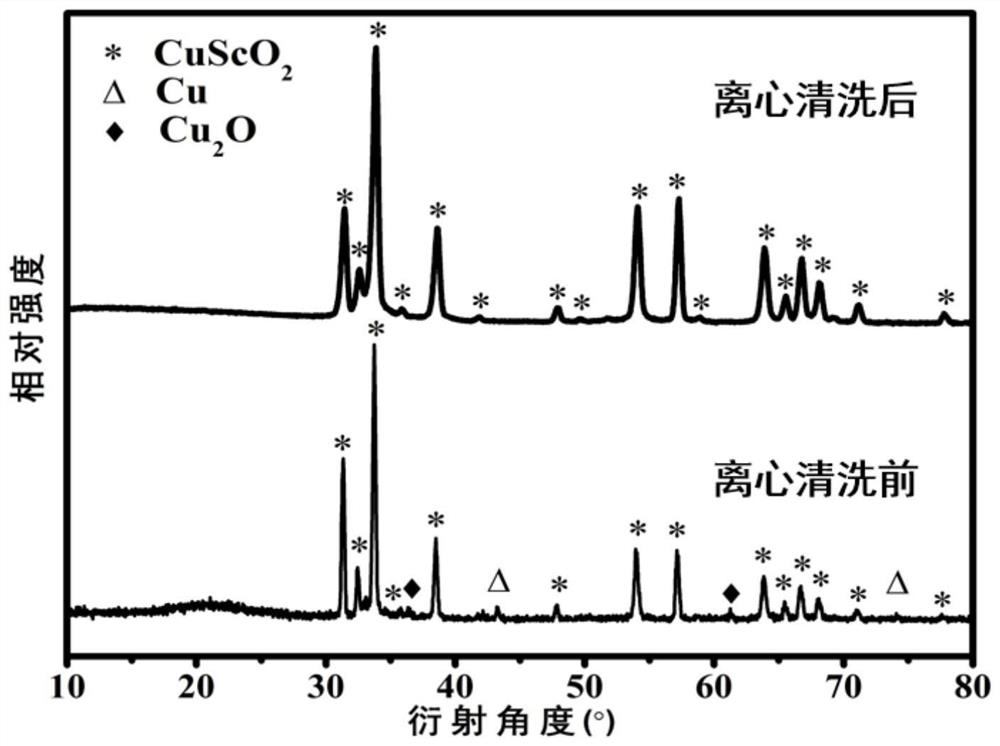

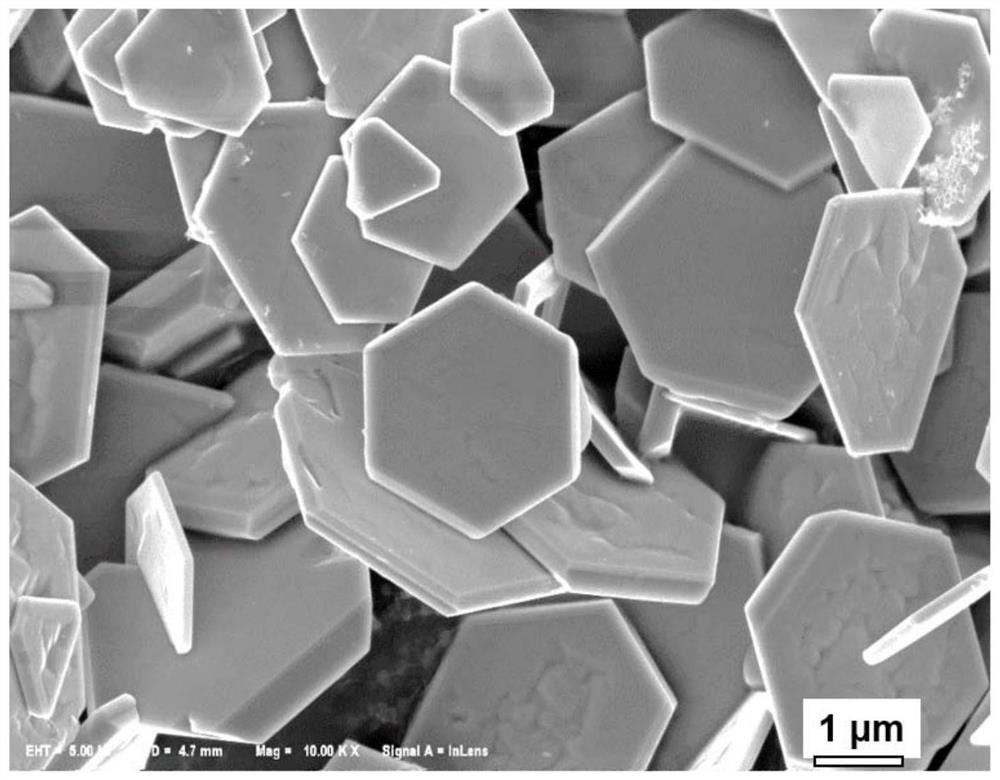

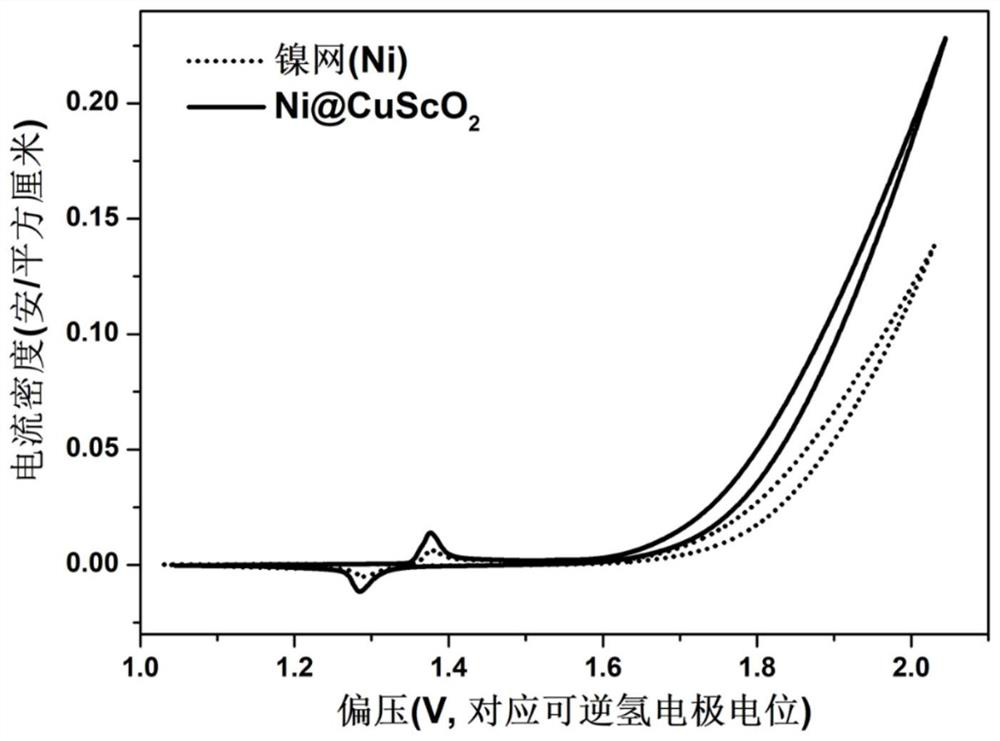

[0031] This embodiment provides an electrolytic water oxygen evolution catalyst delafossite structure CuScO 2 A crystal material and a preparation method thereof, comprising the steps of:

[0032] First prepare the reaction precursor (or hydrothermal reaction precursor): the Cu(NO 3 ) 2 and Sc(NO 3 ) 3 According to the molar ratio of 1:1, add to the reaction solution, stir with a magnetic stirrer for 10 to 15 minutes to dissolve, then add Cu(NO 3 ) 2 NaOH with 10 times the molar number is used as a mineralizer, and finally 0.5 ml of ethylene glycol is added, and the stirring is continued for 10 to 15 minutes until it is completely dissolved to obtain a reaction precursor.

[0033] The above reaction precursor was transferred to a hydrothermal reactor (generally polytetrafluoroethylene), the resistivity of deionized water was 18.24MΩ·cm (25°C), and the filling rate was about 70%. After sealing the kettle body, place it in a programmed temperature-controlled oven for hydro...

Embodiment 2

[0036] This embodiment provides an electrolytic water oxygen evolution catalyst delafossite structure CuScO 2 A crystal material and a preparation method thereof, comprising the steps of:

[0037] First prepare the reaction precursor (or hydrothermal reaction precursor): the Cu(NO 3 ) 2 and Sc(NO 3 ) 3 According to the molar ratio of 1.5:1, add to the reaction solution, stir for 10 to 15 minutes with a magnetic stirrer to dissolve, then add Cu(NO 3 ) 2 NaOH with 10 times the number of moles is used as a mineralizer, and finally 1.0 ml of ethylene glycol is added, and the stirring is continued for 10 to 15 minutes until it is completely dissolved to obtain a reaction precursor.

[0038] The above reaction precursor was transferred to a hydrothermal reactor (generally polytetrafluoroethylene), the resistivity of deionized water was 18.24MΩ·cm (25°C), and the filling rate was about 65%. After sealing the kettle body, place it in a programmed temperature-controlled oven for ...

Embodiment 3

[0041] This embodiment provides an electrolytic water oxygen evolution catalyst delafossite structure CuScO 2 A crystal material and a preparation method thereof, comprising the steps of:

[0042] First prepare the reaction precursor (or hydrothermal reaction precursor): the Cu(NO 3 ) 2 and Sc(NO 3 ) 3 According to the molar ratio of 1.25:1, add to the reaction solution, stir with a magnetic stirrer for 10 to 15 minutes to dissolve, then add Cu(NO 3 ) 2 NaOH with 6 times the molar number is used as a mineralizer, and finally 1.0 ml of ethylene glycol is added, and the stirring is continued for 10 to 15 minutes until it is completely dissolved to obtain a reaction precursor.

[0043] The above reaction precursor was transferred to a hydrothermal reactor (generally polytetrafluoroethylene), the deionized water resistivity was 18.24MΩ·cm (25°C), and the filling rate was about 75%. After sealing the kettle body, place it in a programmed temperature-controlled oven for hydrot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com