Insulin-loaded sugar-sensitive phenylboronic acid-based epsilon-polylysine particle and preparation method thereof

The technology of polylysine and phenylboronic acid is applied in the directions of non-active ingredients medical preparations, active ingredients-containing medical preparations, pharmaceutical formulas, etc., and can solve the problems of high scale production cost, complex synthesis process and the like, Achieve the effects of low production cost, simple synthesis process and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

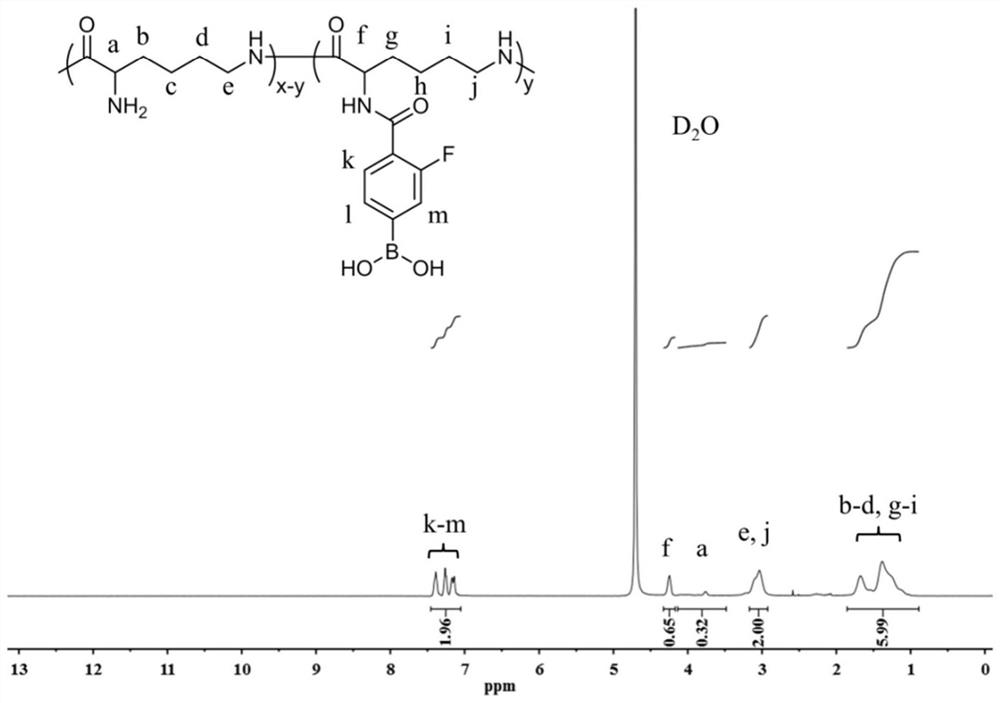

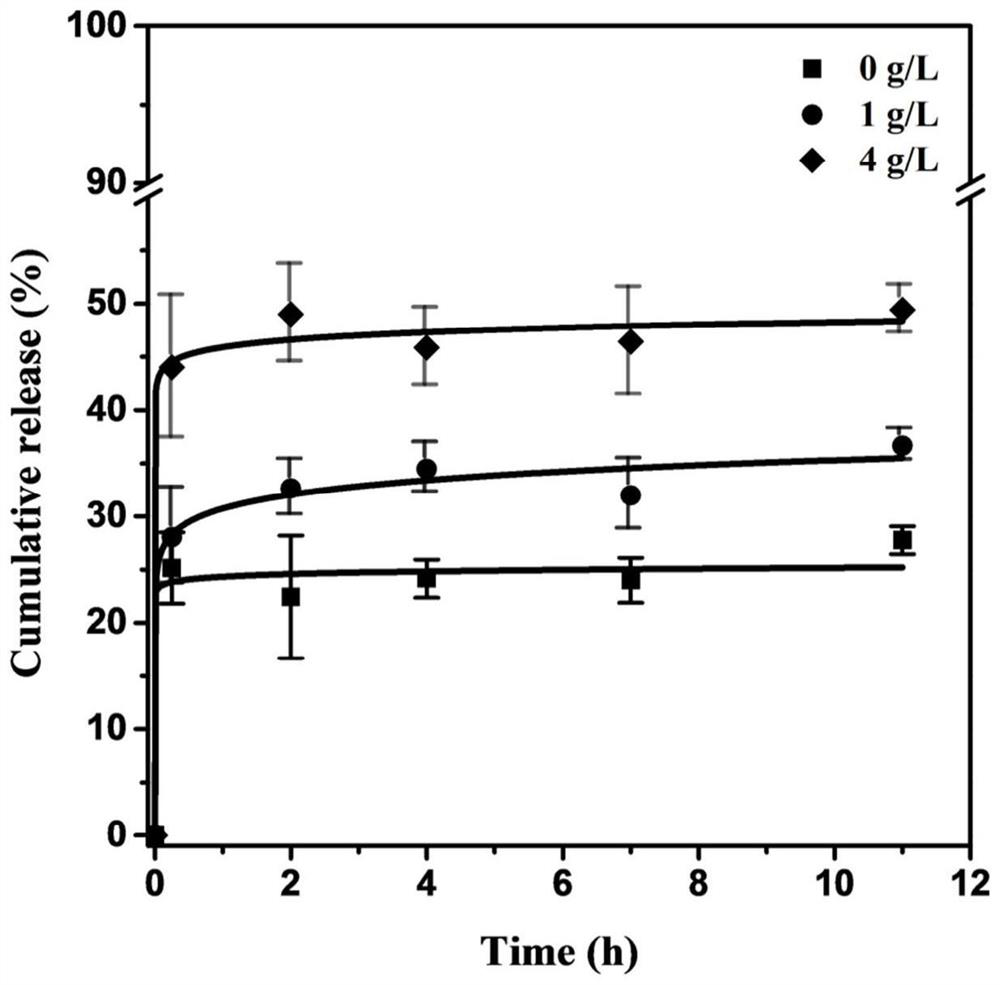

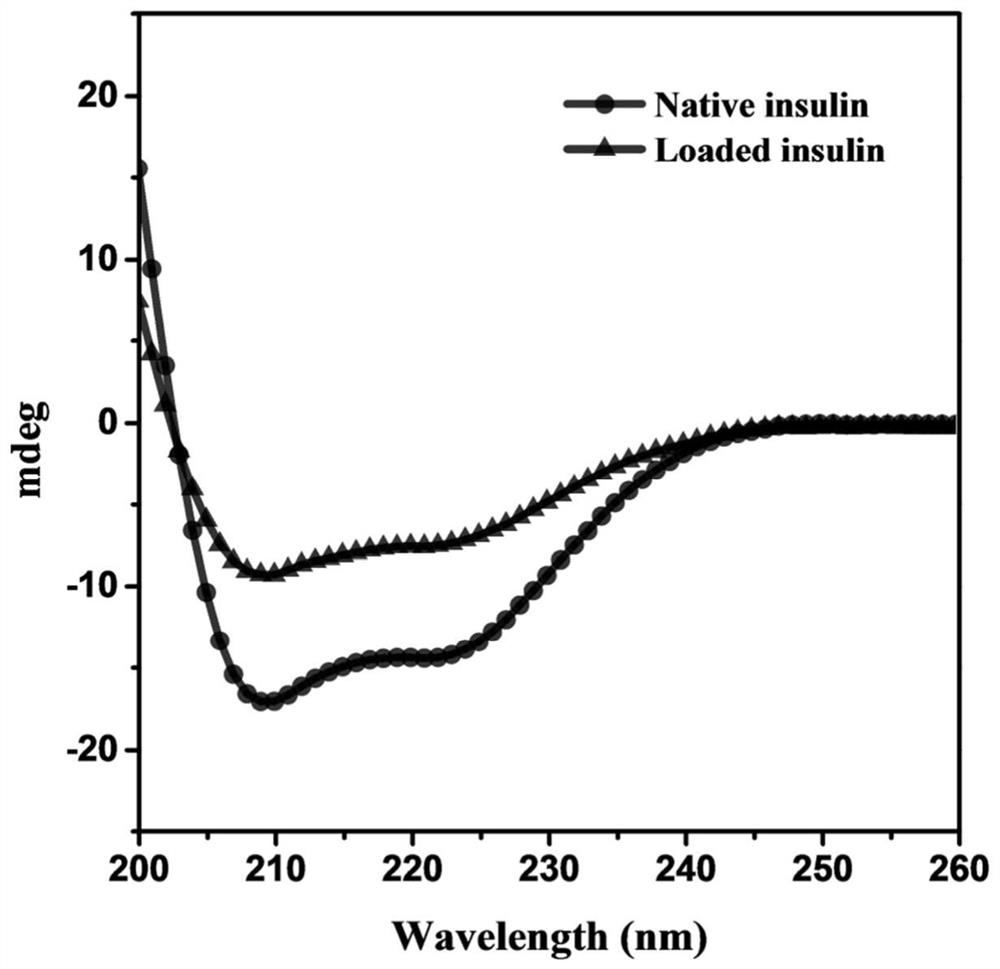

Method used

Image

Examples

Embodiment 1

[0044]Put 1.0780g of 4-carboxy-3-fluorophenylboronic acid, 1.1245g of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and 0.6739g of N-hydroxysuccinimide into Stir in 100 mL of dimethyl sulfoxide to obtain mixture A, the stirring rate is 400 rpm, the stirring time is 90 min, and the stirring temperature is normal temperature. Put 1.0001g of ε-polylysine into 10mL of water and stir at a stirring rate of 400rpm for 10min at room temperature to obtain a mixture B. The mixture A and the mixture B were mixed and stirred, the stirring rate was 500 rpm, the stirring time was 2000 min, and the stirring temperature was 30° C. to obtain the mixture C. Put the mixture C into a dialysis bag, the dialysis bag has a molecular weight cut-off of 1000Da, place the dialysis bag containing the mixture C in water for dialysis, and replace the dialysis water with fresh water every once in a while, and the time interval for each water change is 6h. The number of times is 9 times. Afte...

Embodiment 2

[0047] 1.3345g of 2-carboxyphenylboronic acid and 1.5087g of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride were dropped into 50mL of water and 150mL of N,N-dimethylformamide, To obtain mixture A, the stirring rate was 0 rpm, the stirring time was 0 min, and the stirring temperature was normal temperature. Put 1.2010g of ε-polylysine into 10mL of water and 2mL of N,N-dimethylformamide and stir at a stirring rate of 400rpm for 5min at room temperature to obtain a mixture B. The mixture A and the mixture B were mixed and stirred, the stirring rate was 300 rpm, the stirring time was 300 min, and the stirring temperature was normal temperature to obtain the mixture C. Put the mixture C into a dialysis bag, the molecular weight cut-off of the dialysis bag is 3500Da, place the dialysis bag containing the mixture C in water for dialysis, and replace the dialysis water with fresh water every once in a while, and the time interval for each water change is 8h. The number o...

Embodiment 3

[0049] Put 1.0001g of 4-carboxy-3-chlorophenylboronic acid, 0.9122g of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and 0.7397g of N-hydroxysuccinimide into In 50 mL of water and 150 mL of N,N-dimethylacetamide, a mixture A was obtained, the stirring rate was 200 rpm, the stirring time was 60 min, and the stirring temperature was normal temperature. Put 1.0212g ε-polylysine into 15mL water and 1mL N,N-dimethylacetamide and stir at a stirring rate of 200rpm for 15min at room temperature to obtain a mixture B. The mixture A and the mixture B were mixed and stirred, the stirring rate was 200 rpm, the stirring time was 1200 min, and the stirring temperature was normal temperature, and the mixture C was obtained. Put the mixture C into a dialysis bag, the molecular weight cut-off of the dialysis bag is 500Da, place the dialysis bag containing the mixture C in water for dialysis, and replace the dialysis water with fresh water every once in a while, and the time inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com