Patents

Literature

48 results about "Delafossite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

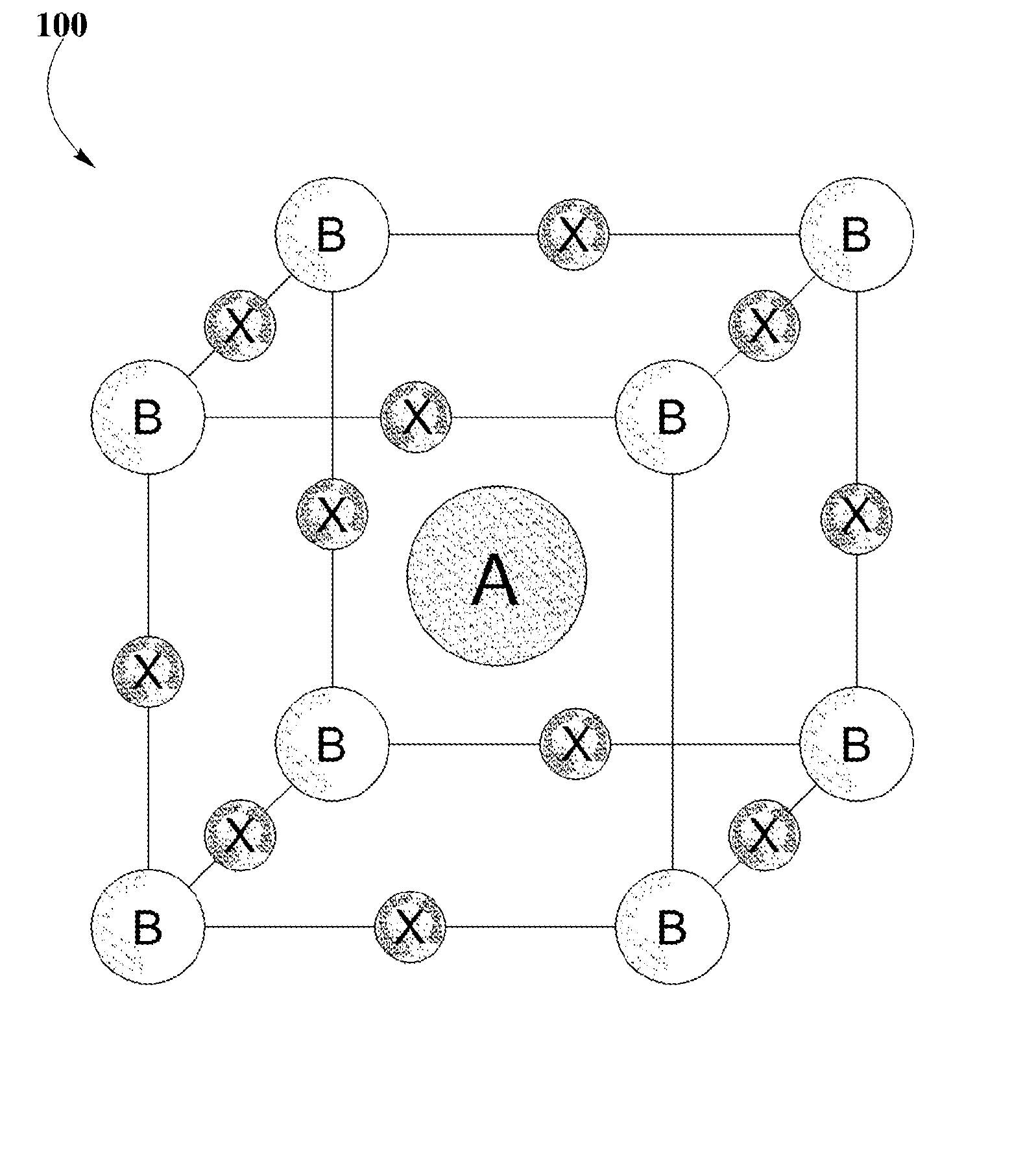

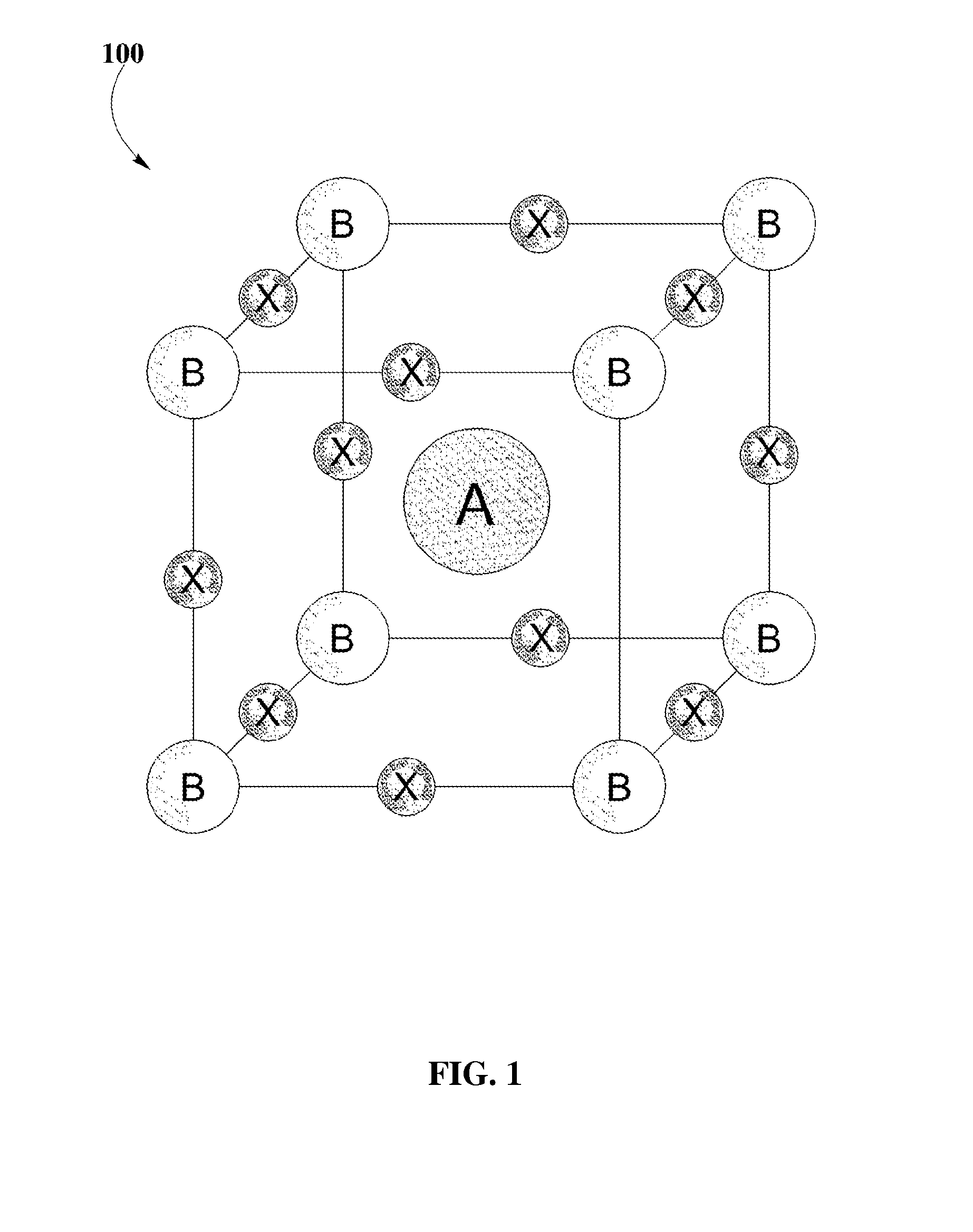

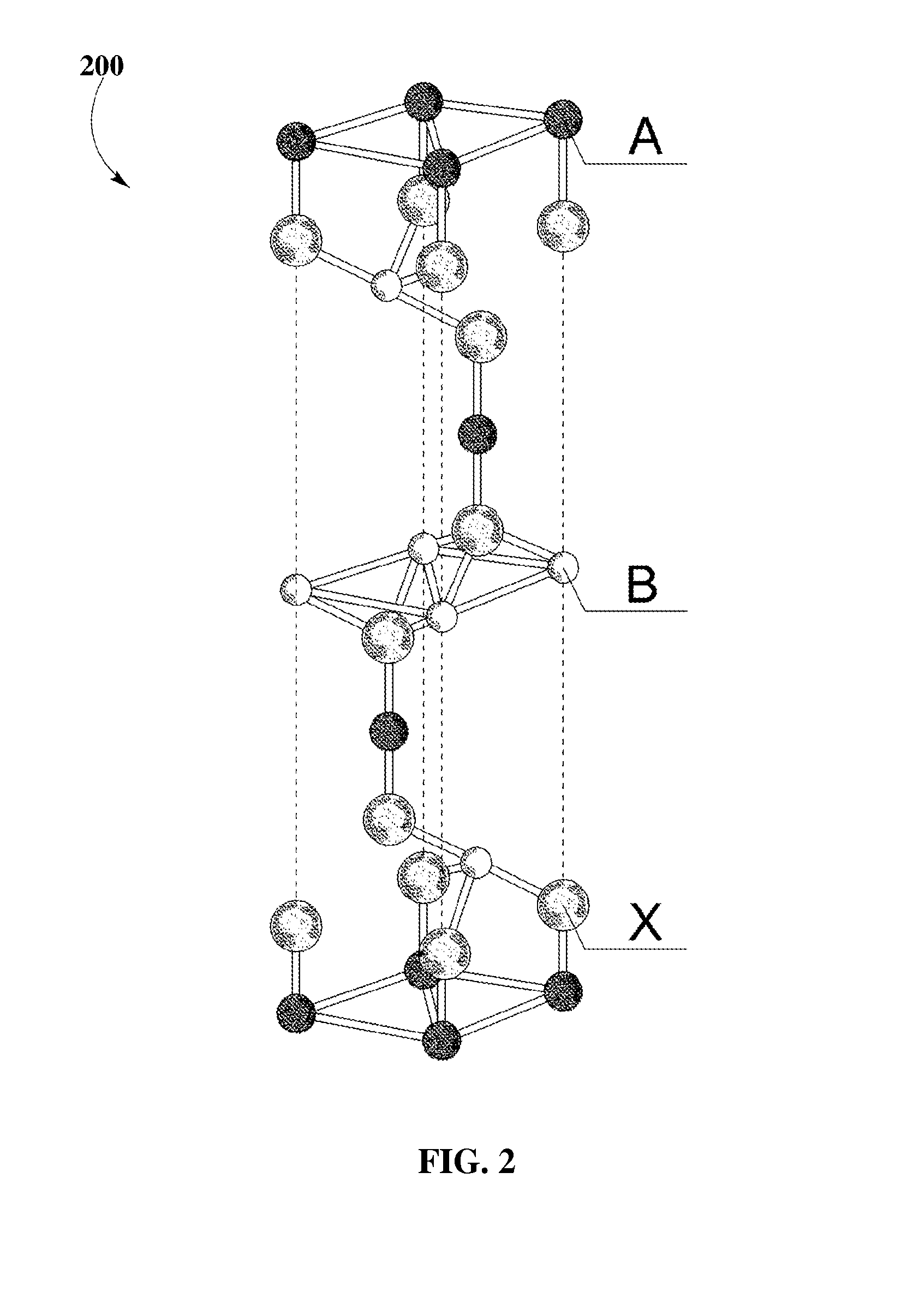

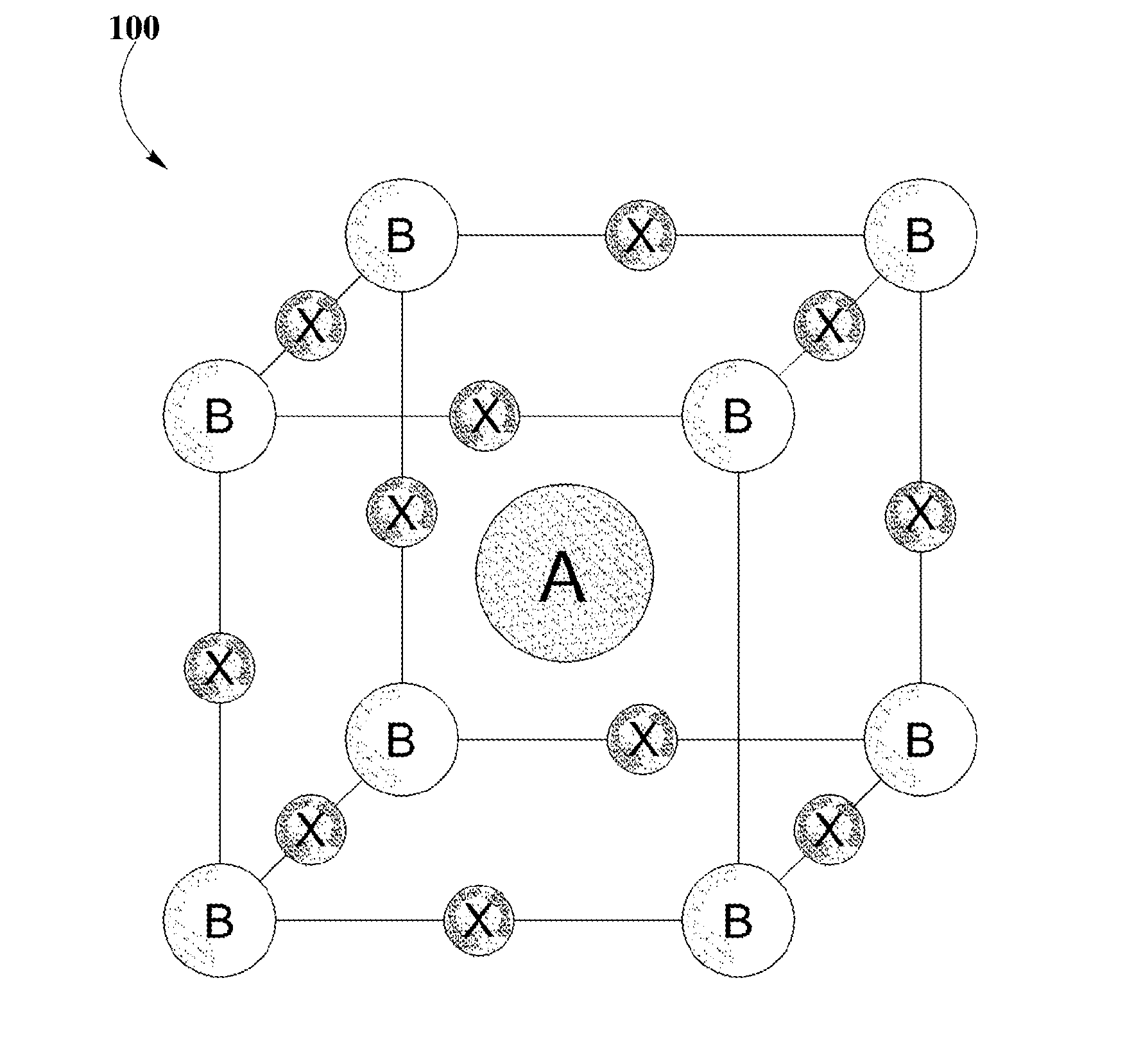

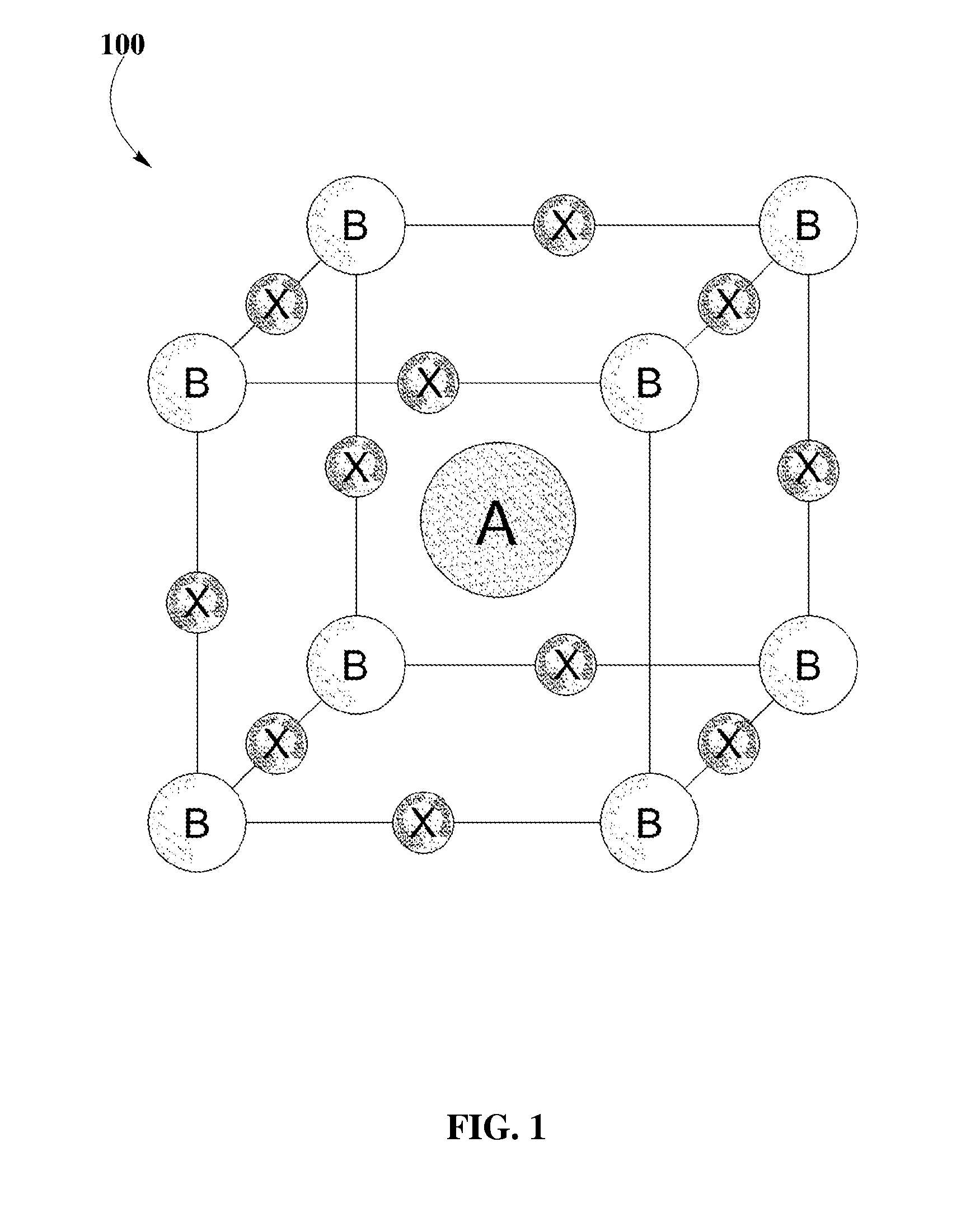

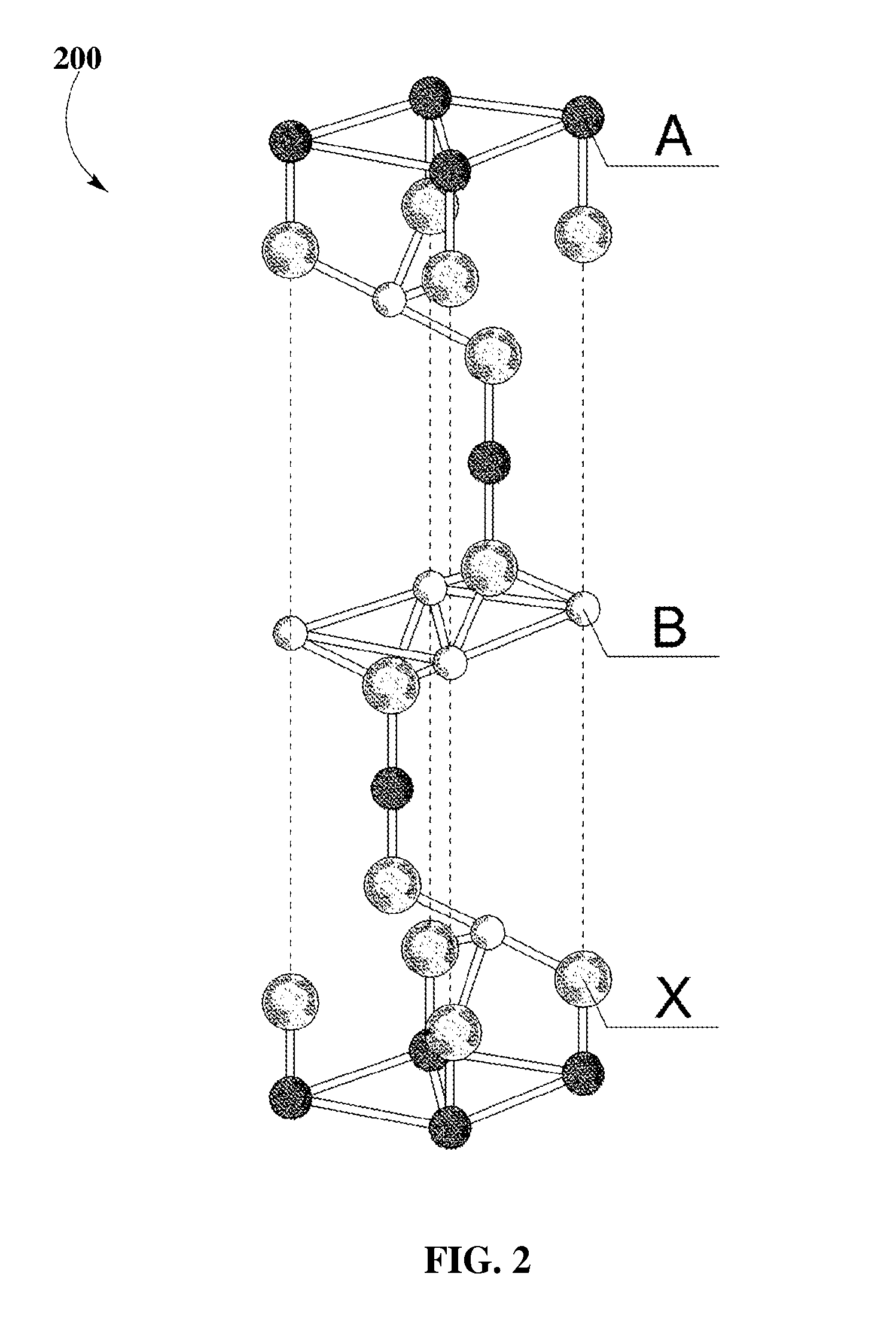

Delafossite is a copper iron oxide mineral with formula CuFeO₂ or Cu¹⁺Fe³⁺O₂. It is a member of the delafossite mineral group, which has the general formula ABO₂, a group characterized by sheets of linearly coordinated A cations stacked between edge-shared octahedral layers (BO₆). Delafossite, along with other minerals of the ABO₂ group, is known for its wide range of electrical properties, its conductivity varying from insulating to metallic. Delafossite is usually a secondary mineral that crystallizes in association with oxidized copper and rarely occurs as a primary mineral.

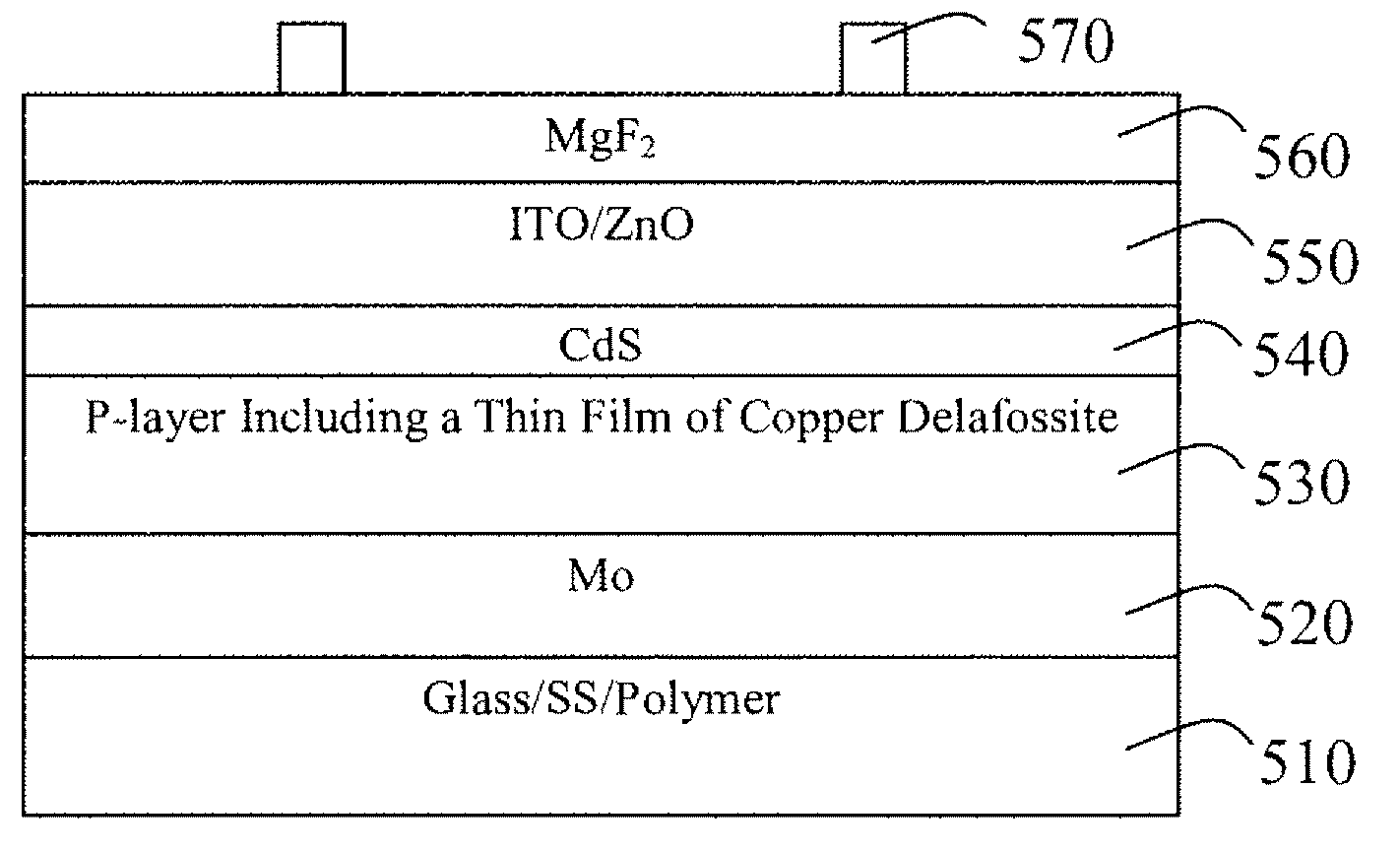

Copper delafossite transparent p-type semiconductor thin film devices

InactiveUS20100175755A1TransistorElectrolysis componentsPulsed laser depositionSemiconductor thin films

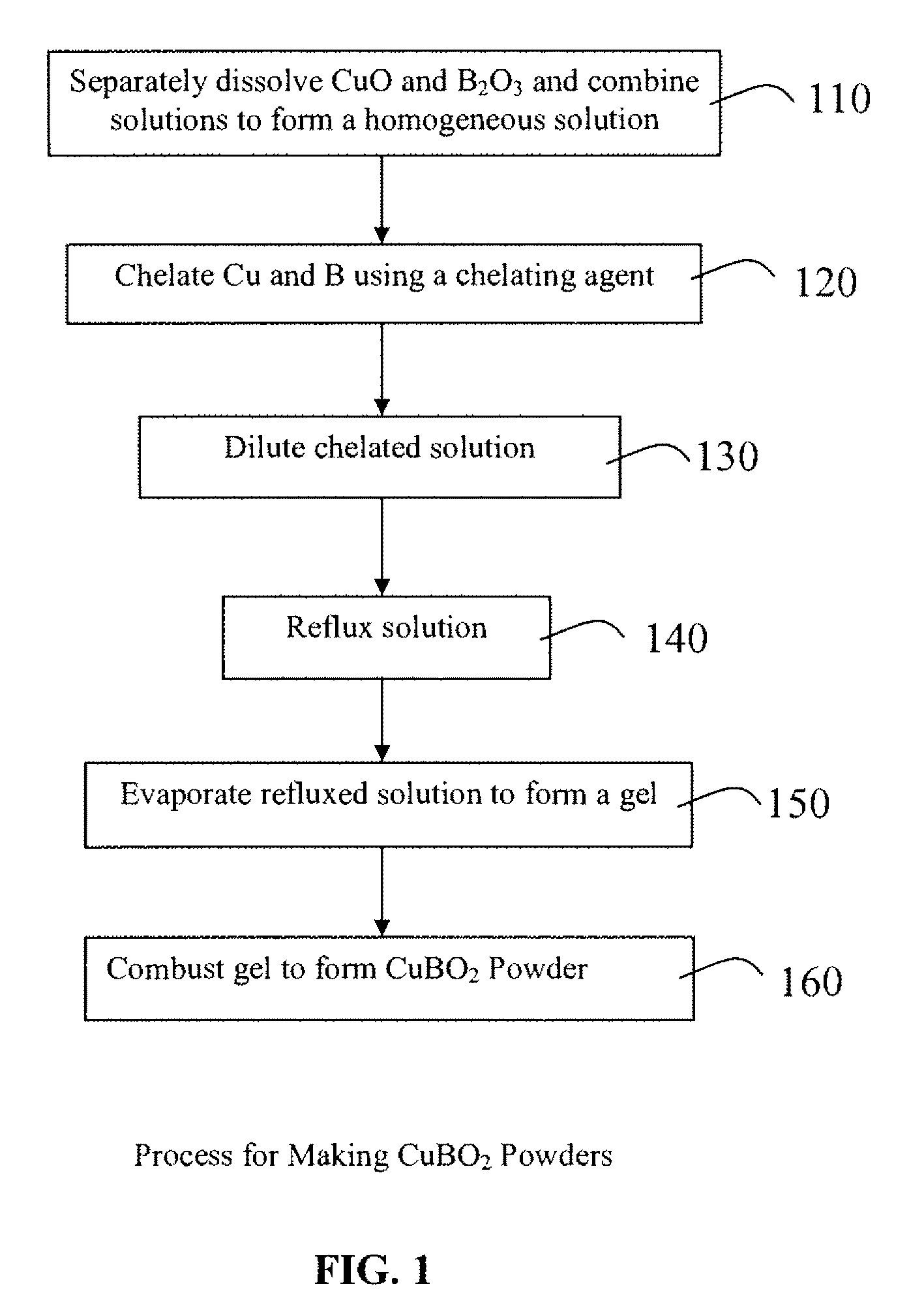

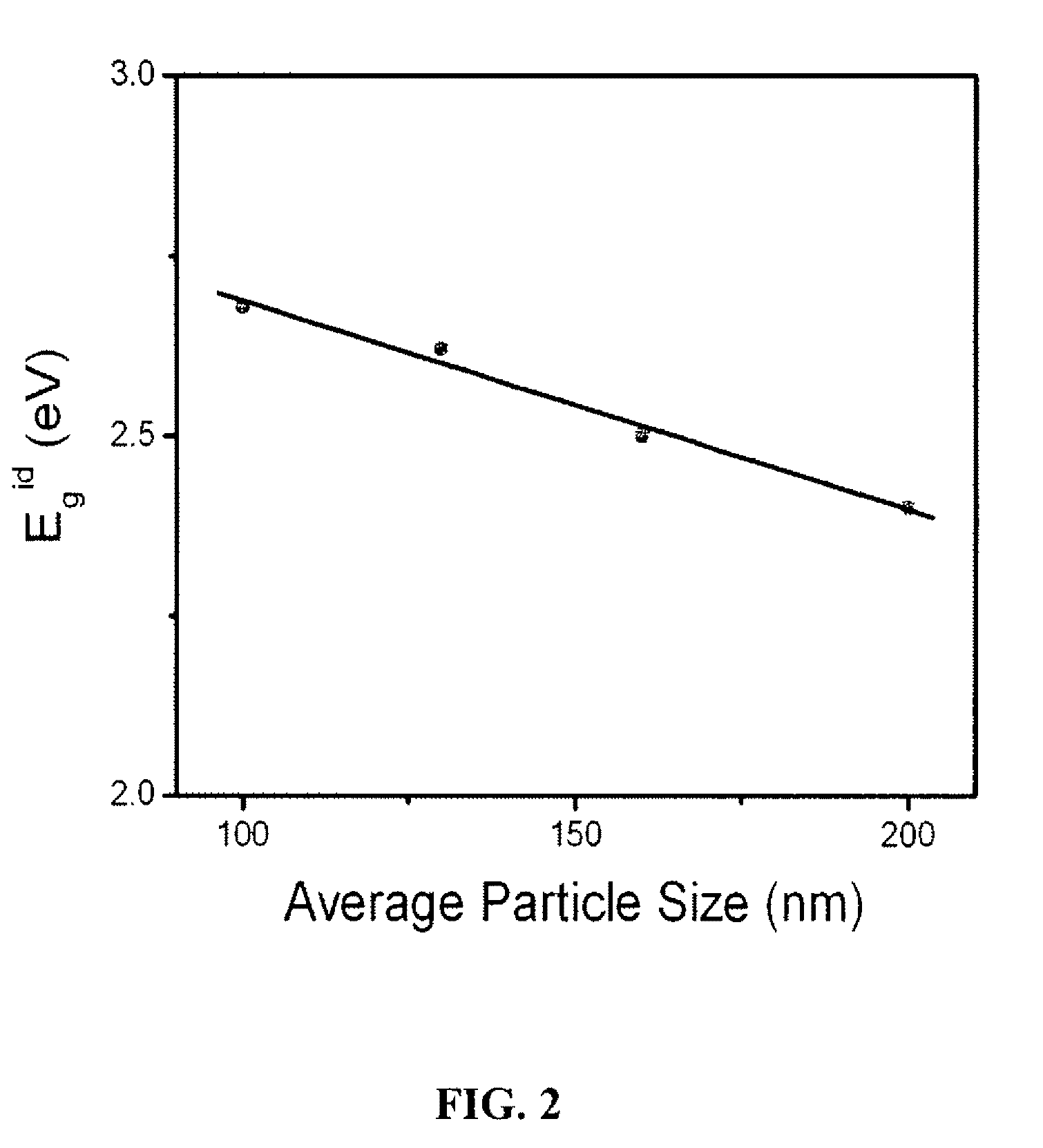

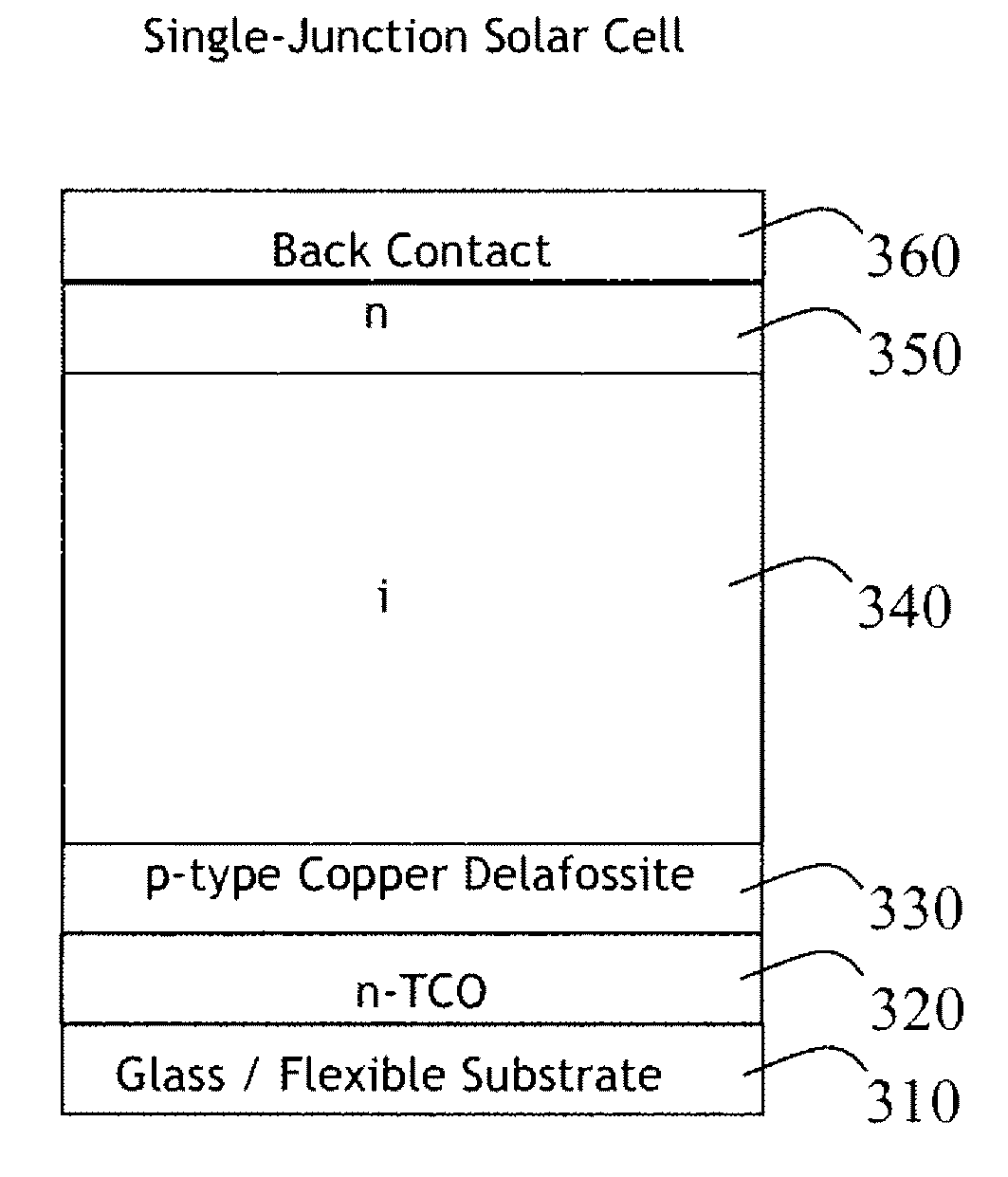

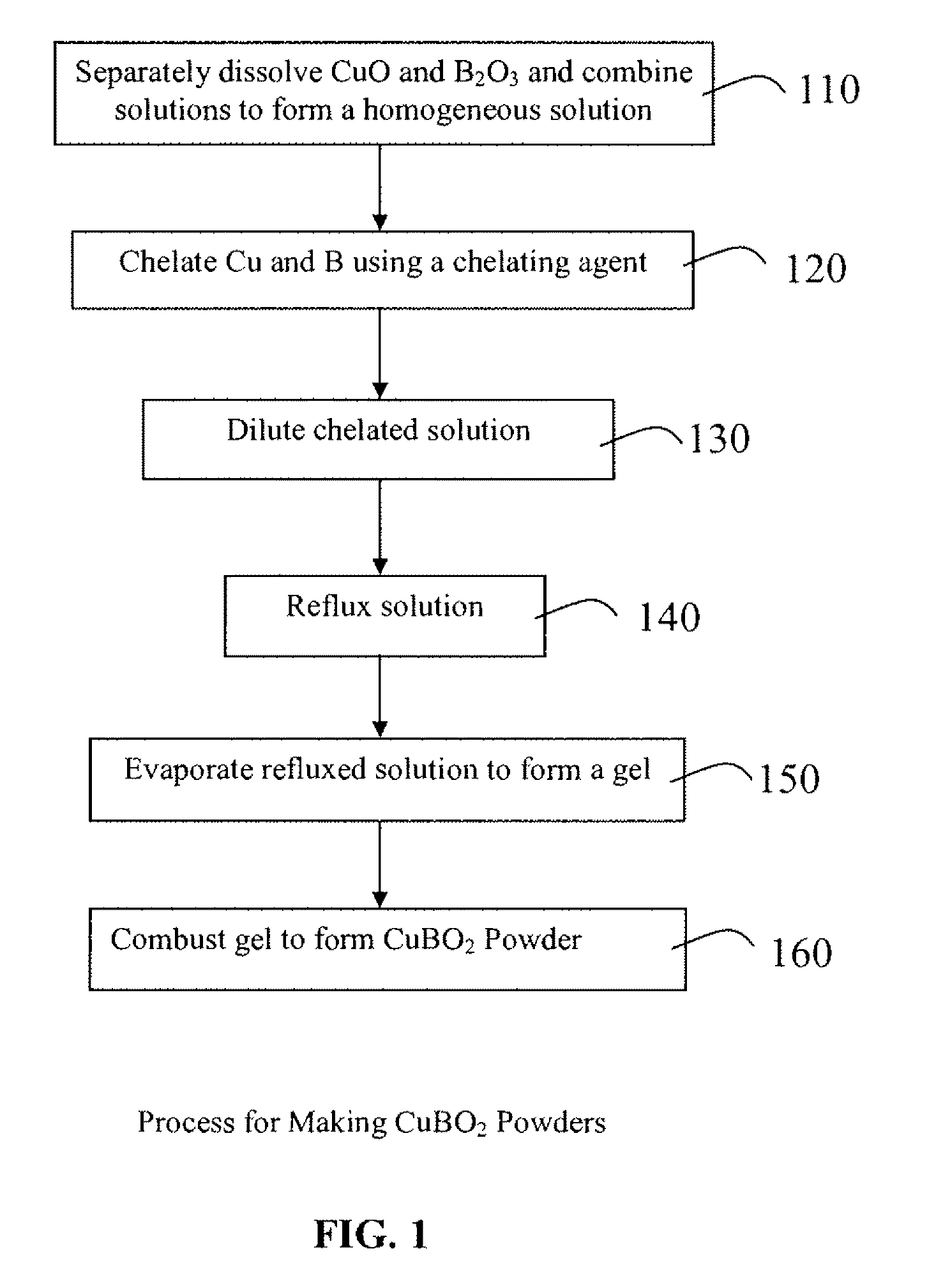

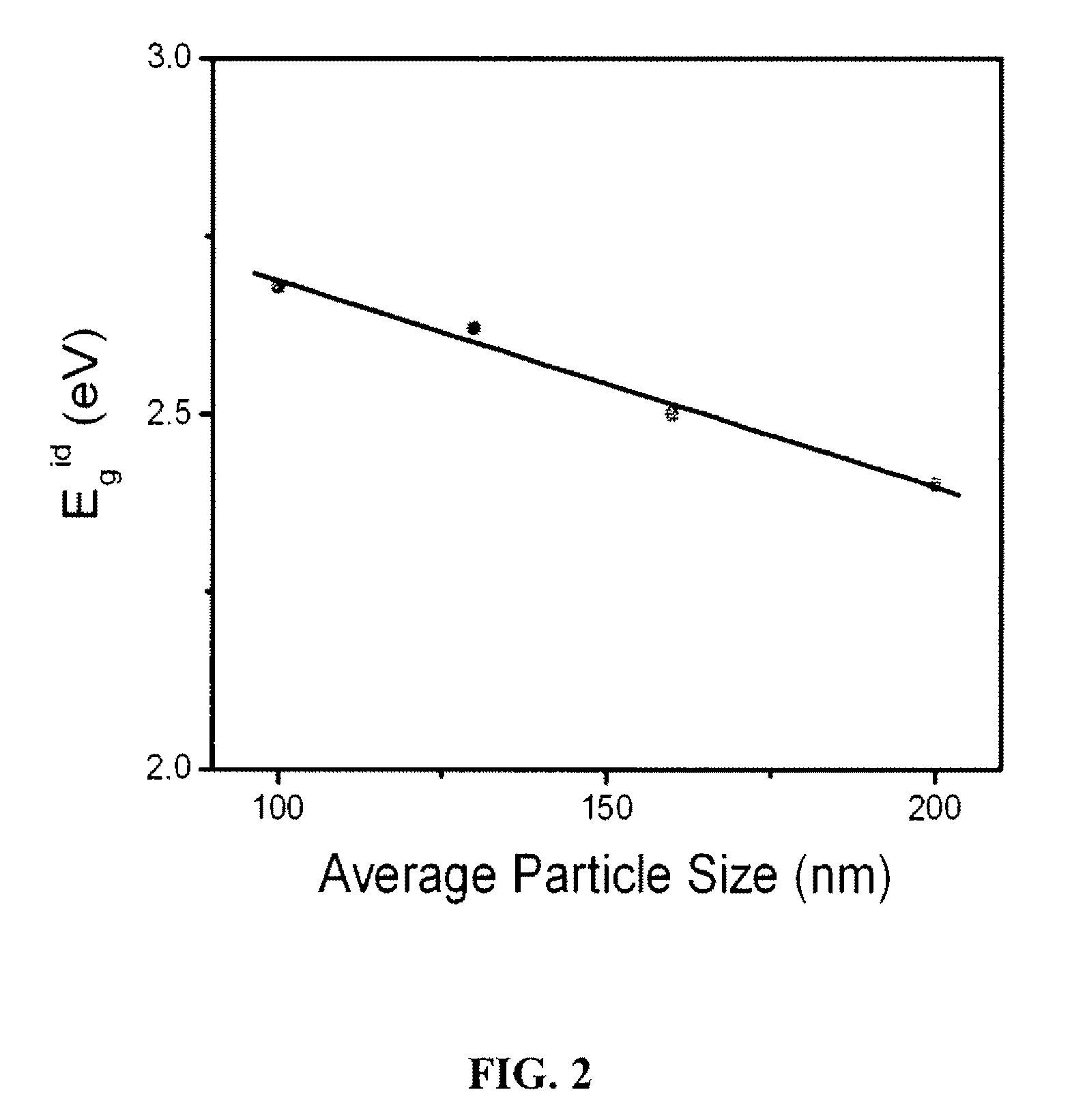

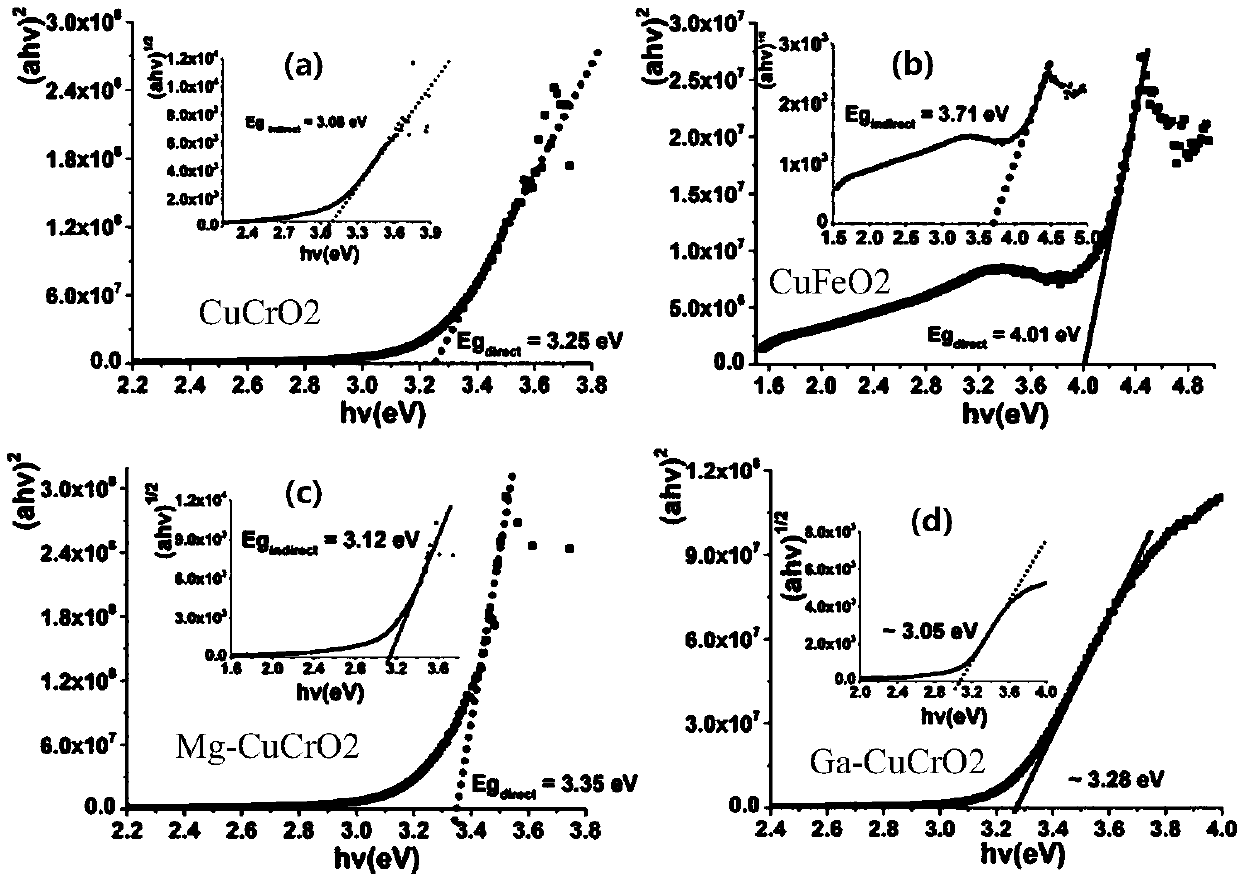

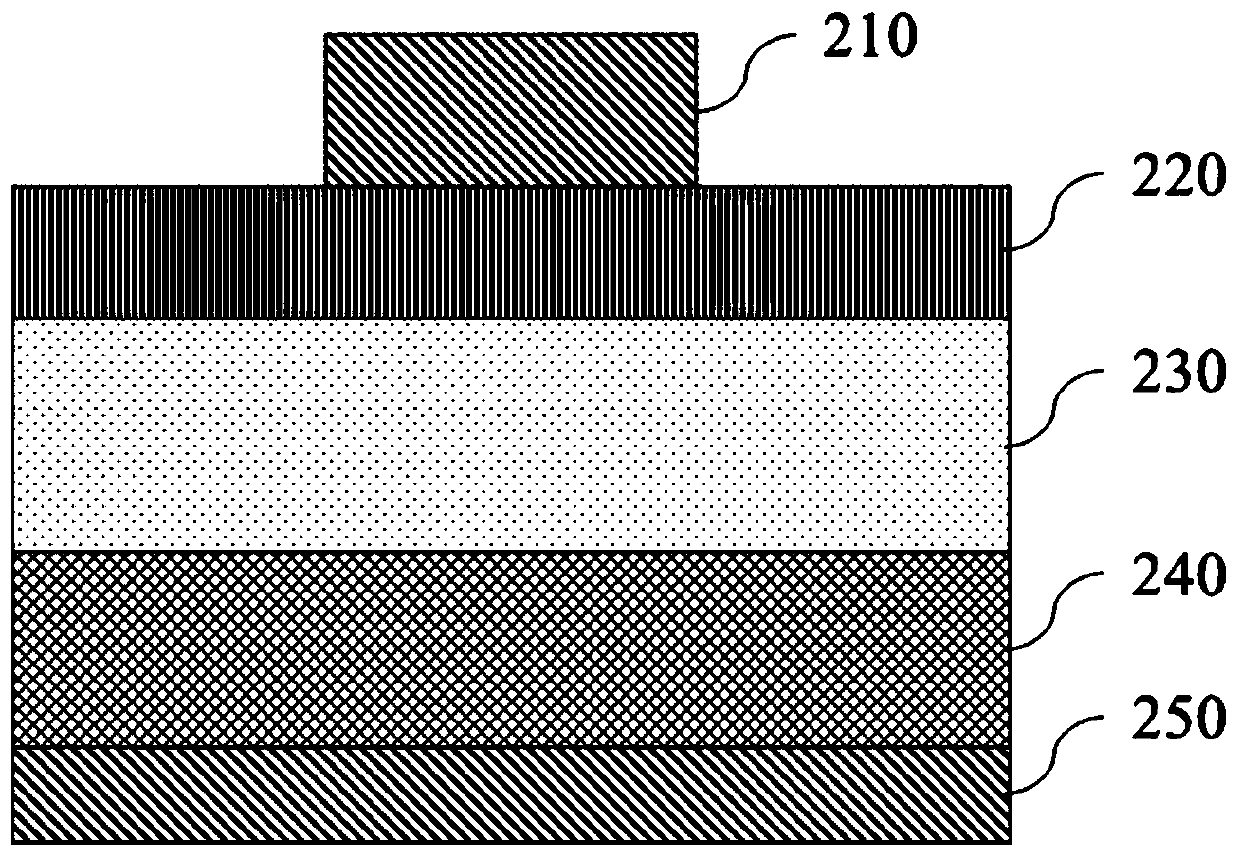

Methods for fabrication of copper delafossite materials include a low temperature sol-gel process for synthesizing CuBO2 powders, and a pulsed laser deposition (PLD) process for forming thin films of CuBO2, using targets made of the CuBO2 powders. The CuBO2 thin films are optically transparent p-type semiconductor oxide thin films. Devices with CuBO2 thin films include p-type transparent thin film transistors (TTFT) comprising thin film CuBO2 as a channel layer and thin film solar cells with CuBO2 p-layers. Solid state dye sensitized solar cells (SS-DSSC) comprising CuBO2 in various forms, including “core-shell” and “nano-couple” particles, and methods of manufacture, are also described.

Owner:APPLIED MATERIALS INC

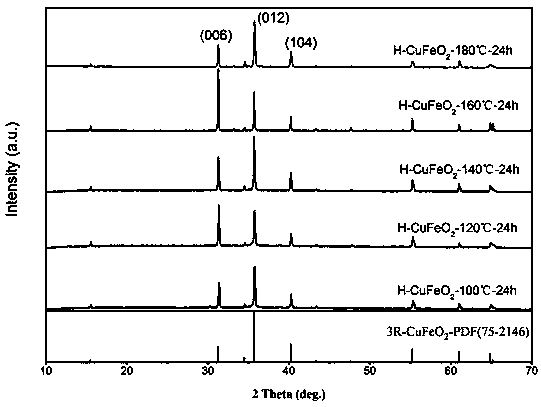

Low-temperature preparation method for CuFeO2 crystal material of delafossite structure

ActiveCN104058461APromote application developmentLow costMaterial nanotechnologyIron compoundsFilling rateReaction temperature

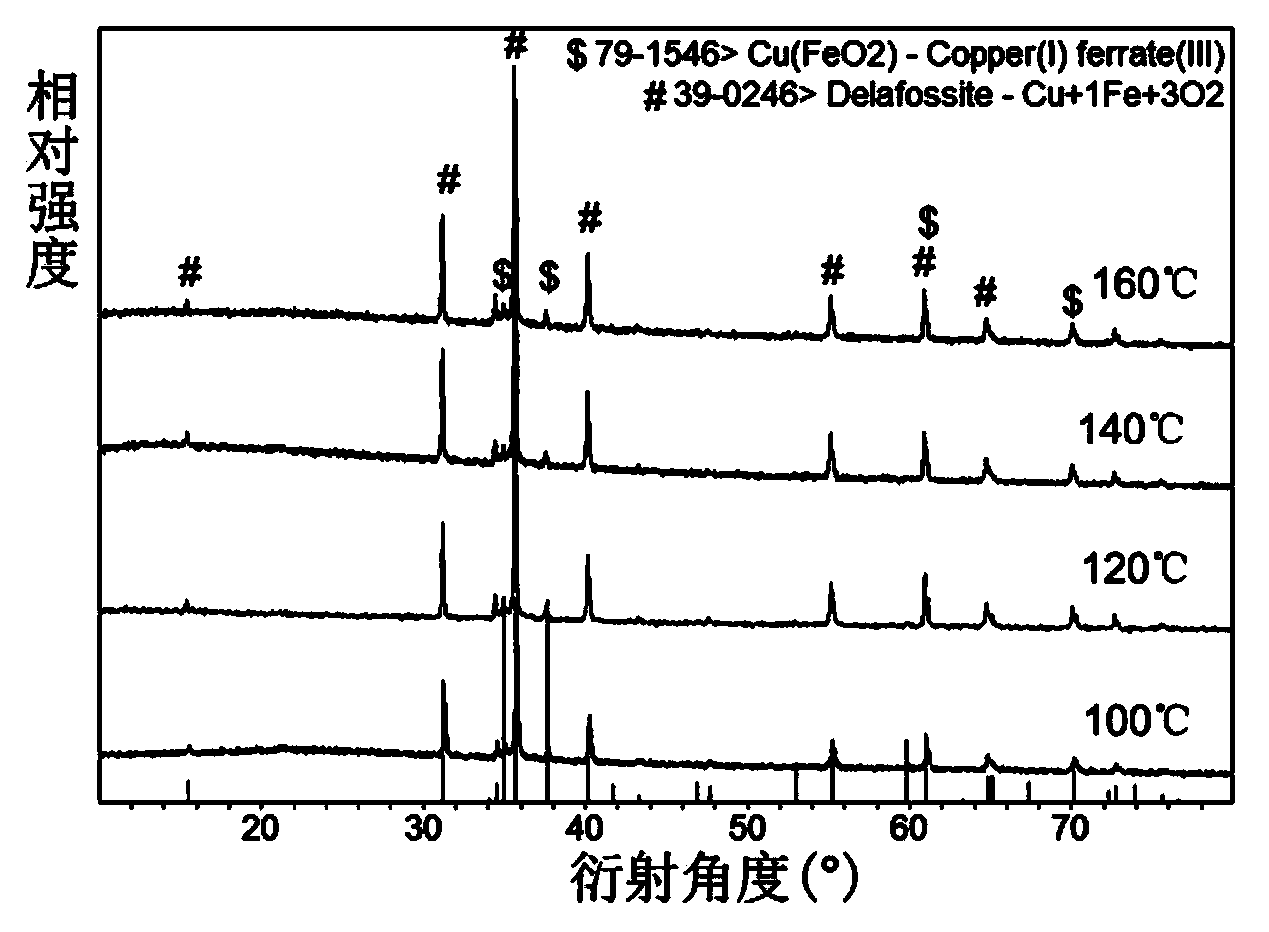

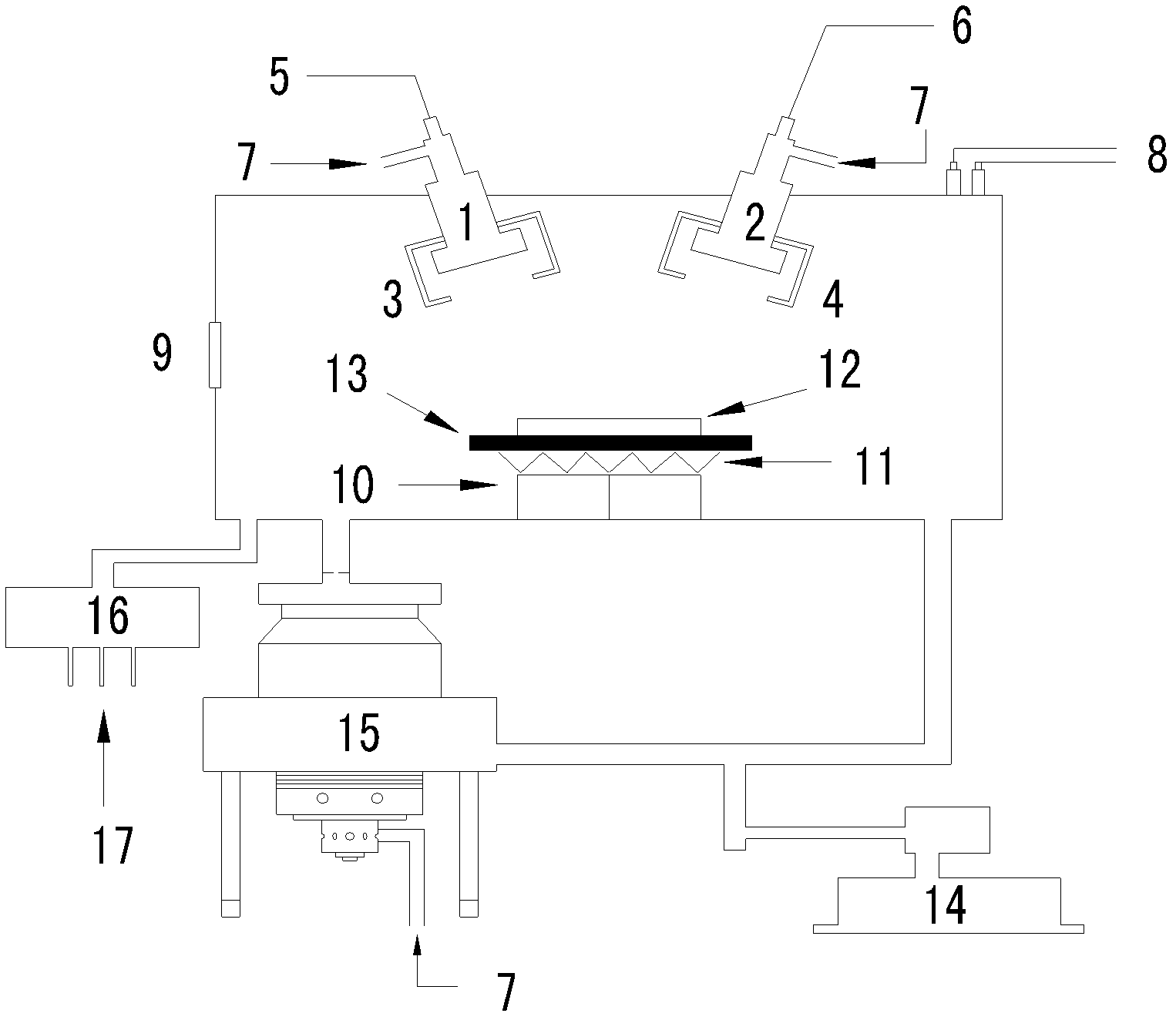

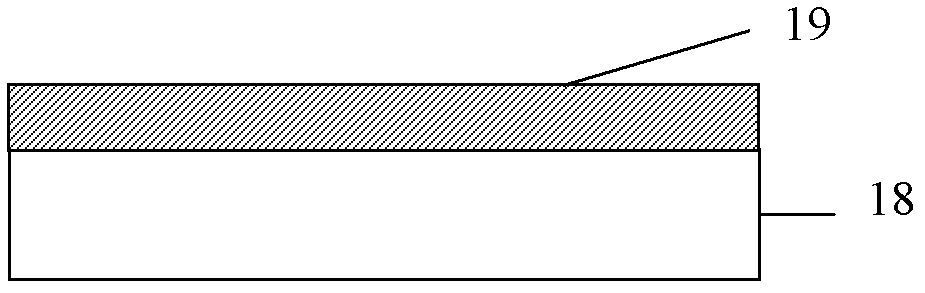

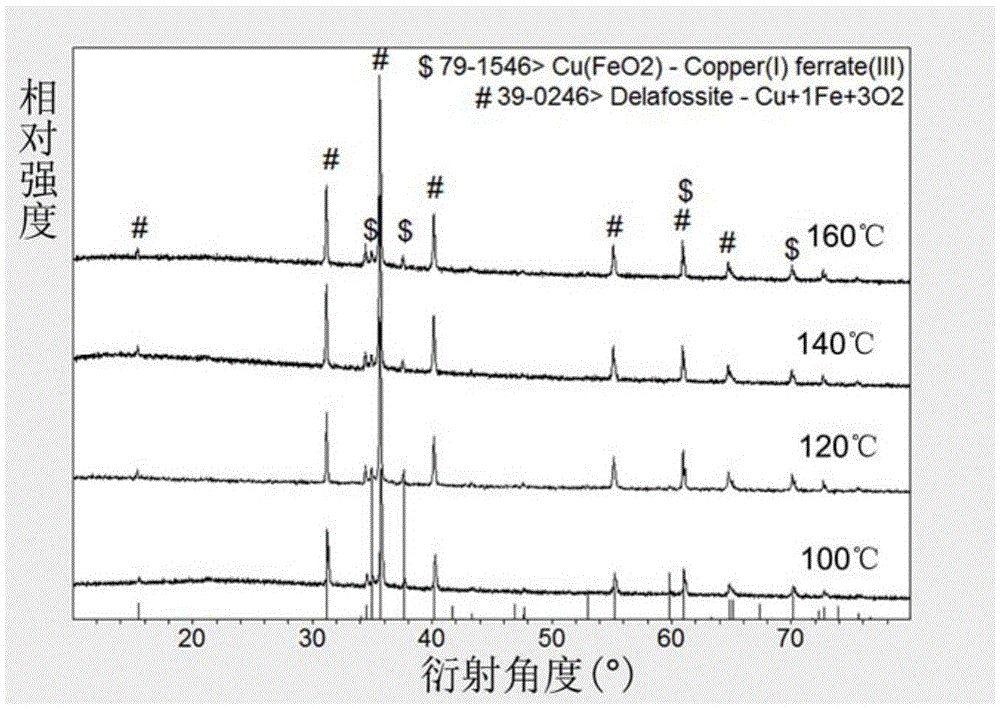

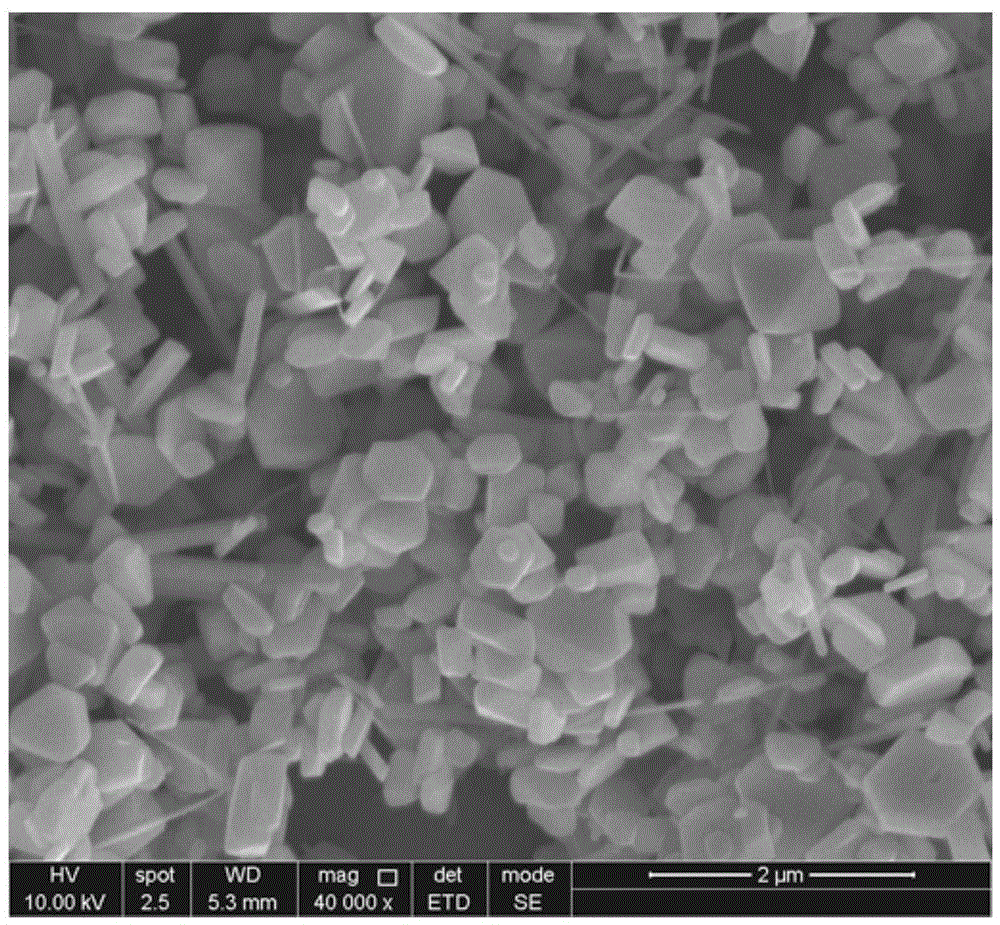

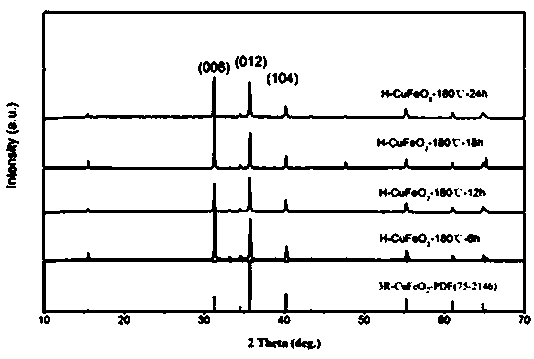

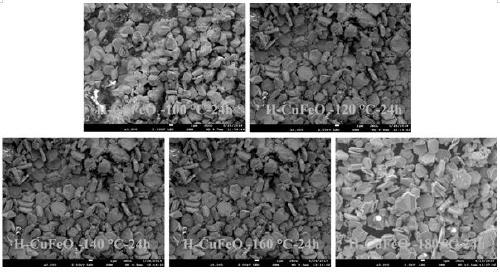

The invention discloses a low-temperature preparation method for a CuFeO2 crystal material of a delafossite structure, in particular to a low-temperature hydrothermal synthesis method for rapidly preparing the CuFeO2 nanocrystalline material of the delafossite structure. The method comprises the steps that parameters including reaction precursor components, the reaction temperature and the filling rate of a reaction solution in a hydrothermal reaction kettle are regulated and controlled through a low-temperature hydrothermal reaction, reactants including Cu(NO3)2 and FeCl2 react for 12 hours to 48 hours at the temperature ranging from 100 DEG C to 160 DEG C, and then, after a reaction product is processed through centrifugal cleaning and dried, the nanoscale CuFeO2 crystal material is obtained. The low-temperature preparation method for the CuFeO2 crystal material of the delafossite structure is easy to operate, the technological parameters are easy to control, no pollution is caused, the yield is high, and the method can be widely used for photoelectricity functional devices such as transparent conducting oxide.

Owner:WUHAN UNIV OF TECH

Systems and Methods for Using Pd1+ in a TWC

ActiveUS20140364303A1Low costImprove availabilityMolecular sieve catalystsInternal combustion piston enginesDelafossiteCopper

Stabilized palladium (+1) compounds to mimic rhodium's electronic configuration and catalytic properties are disclosed. Palladium (+1) compounds may be stabilized in perovskite or delafossite structures and may be employed in Three-Way Catalysts (TWC) for at least the conversion of HC, CO and NOx, in exhaust gases. The TWC may include a substrate, a wash-coat and, a first impregnation layer, a second impregnation layer and an over-coat. The second impregnation layer and the over-coat may include palladium (+1) based compounds as catalyst.

Owner:CLEAN DIESEL TECHNOLOGIES

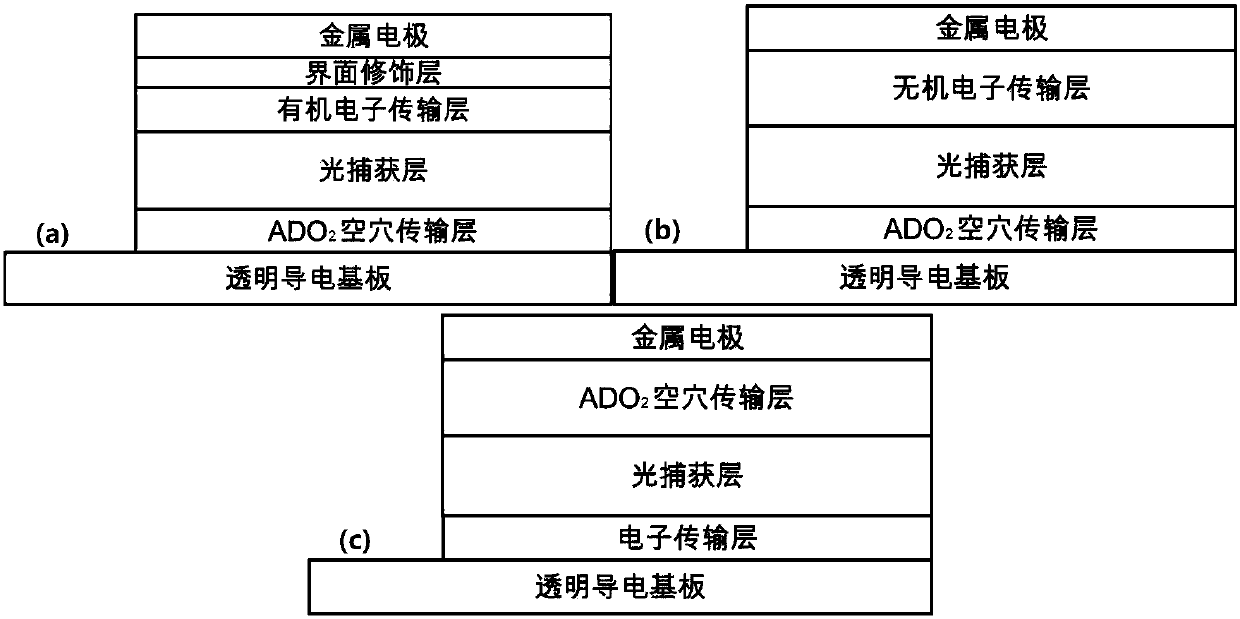

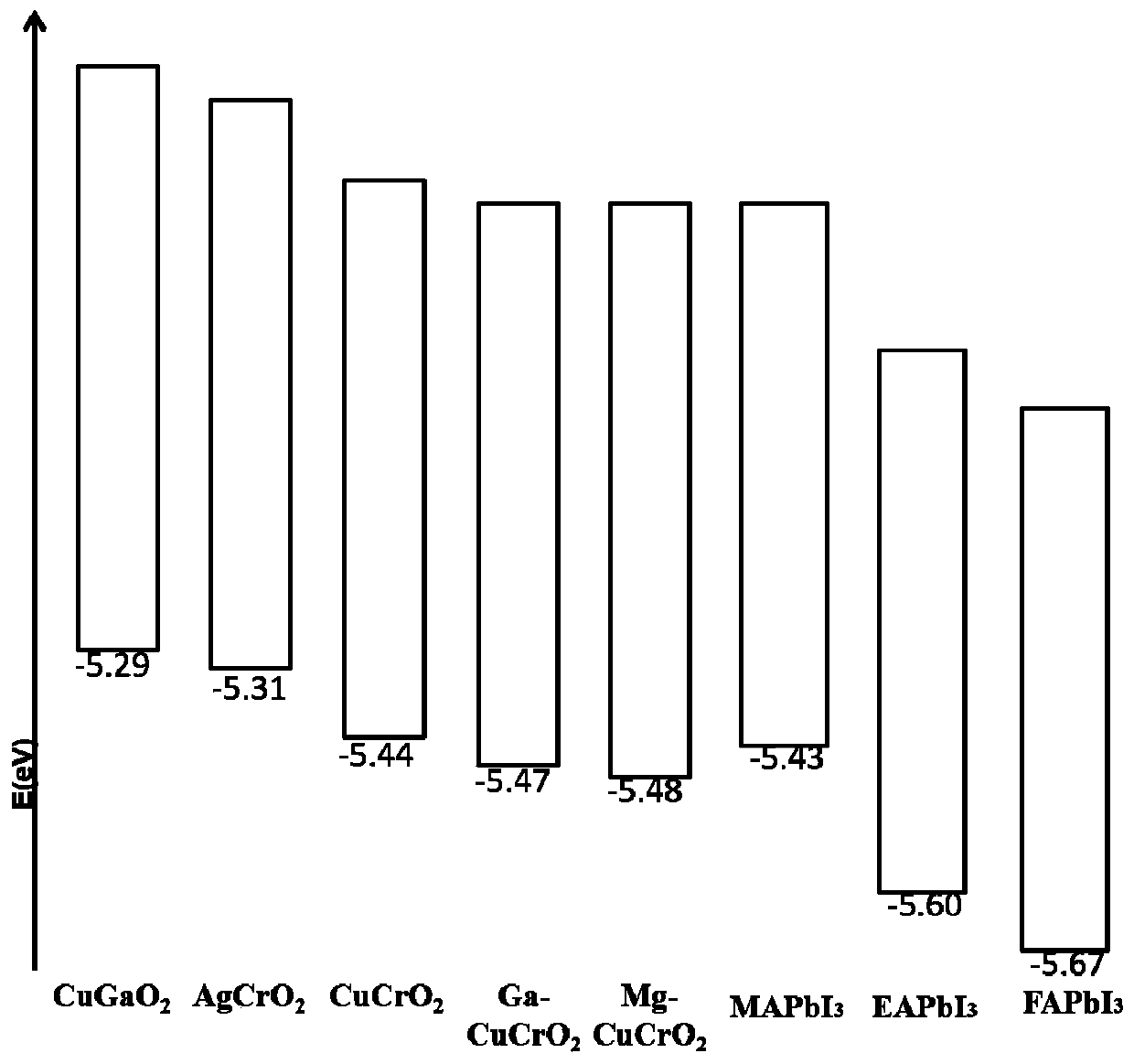

P-type delafossite structure semiconductor material-based plane structure perovskite solar cell and preparation thereof

ActiveCN105679941AGood repeatabilityLow costFinal product manufactureSolid-state devicesSemiconductor materialsPerovskite solar cell

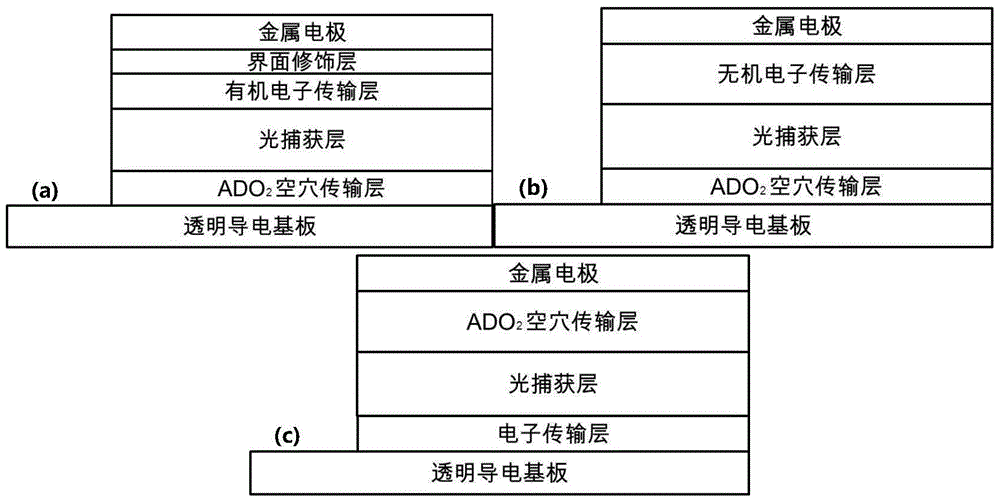

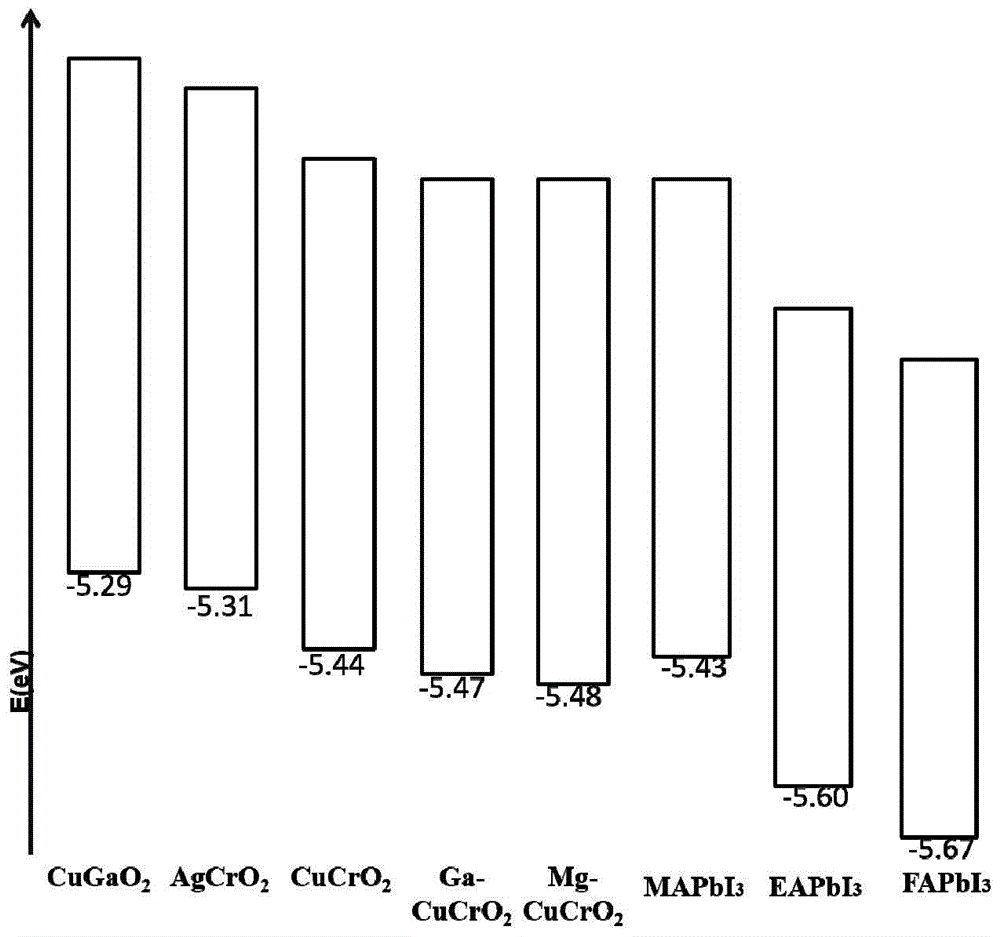

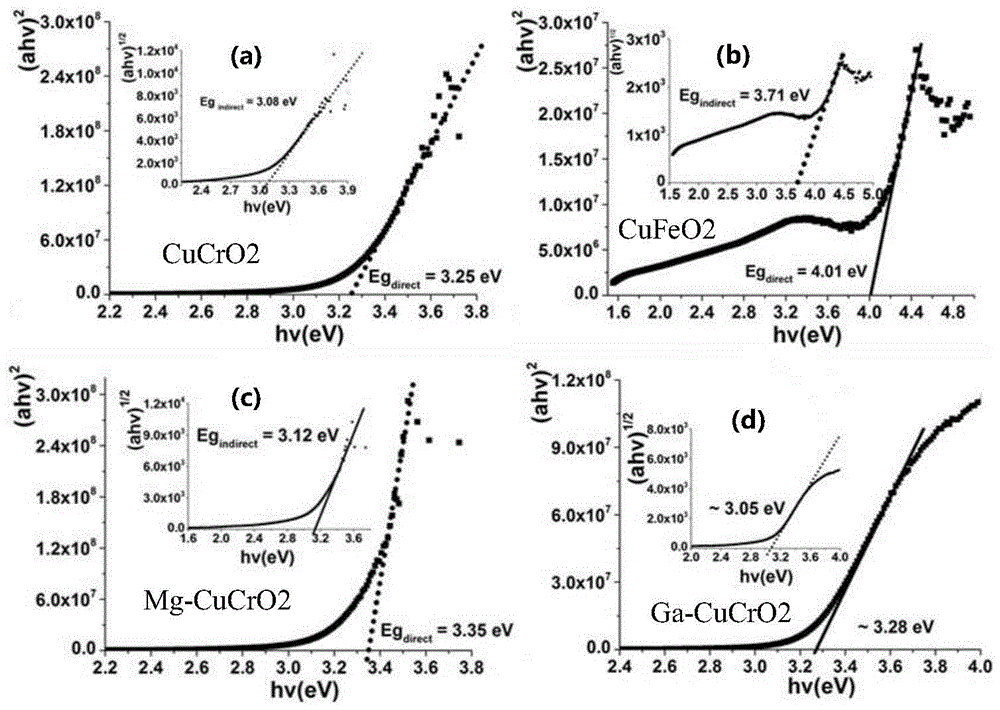

The invention relates to a plane structure perovskite solar cell and a preparation method thereof. The cell comprises a hole transport layer and a light capture layer, wherein the light capture layer is prepared from an MXZ3-type perovskite material; M is selected from Cs<+>, CH3NH3<+>, CH3CH2NH3<+>, CH(NH2)2<+> or a mixture thereof; X is selected from Pb<2+>, Sn<2+>, Ge<2+> or a mixture thereof; Z is selected from Cl<->, Br<->, I<-> or the mixture thereof; the hole transport layer is prepared from a doped or un-doped ADO2-type semiconductor material with a p-type delafossite structure; A is selected from Cu or Ag; D is selected from one or more of Cr, Ga, Sc, In, Y or Fe; and a doping element is selected from one or two of Mg, Ca, Sr or Ga. A film of the hole transport layer provided by the invention has good electrical conductivity, proper energy level position, high transmittance and low cost; a solar cell device with excellent and stable performance can be obtained; and propulsion of industrialization of the perovskite solar cell is facilitated.

Owner:HANGZHOU ZHONGNENG PHOTOELECTRIC TECH CO LTD

Copper delafossite transparent p-type semiconductor materials for dye sensitized solar cells

InactiveUS20100252108A1Electrolysis componentsElectrolytic capacitorsSemiconductor materialsDelafossite

Methods for fabrication of copper delafossite materials include a low temperature sol-gel process for synthesizing CuBO2 powders, and a pulsed laser deposition (PLD) process for forming thin films of CuBO2, using targets made of the CuBO2 powders. The CuBO2 thin films are optically transparent p-type semiconductor oxide thin films. Devices with CuBO2 thin films include p-type transparent thin film transistors (TTFT) comprising thin film CuBO2, as a channel layer and thin film solar cells with CuBO2 p-layers. Solid state dye sensitized solar cells (SS-DSSC) comprising CuBO2 in various forms, including “core-shell” and “nano-couple” particles, and methods of manufacture, are also described.

Owner:APPLIED MATERIALS INC

Systems and methods for using Pd1+ in a TWC

ActiveUS9216410B2Low costImprove availabilityInternal combustion piston enginesHeterogenous catalyst chemical elementsDelafossiteCopper

Stabilized palladium (+1) compounds to mimic rhodium's electronic configuration and catalytic properties are disclosed. Palladium (+1) compounds may be stabilized in perovskite or delafossite structures and may be employed in Three-Way Catalysts (TWC) for at least the conversion of HC, CO and NOx, in exhaust gases. The TWC may include a substrate, a wash-coat and, a first impregnation layer, a second impregnation layer and an over-coat. The second impregnation layer and the over-coat may include palladium (+1) based compounds as catalyst.

Owner:CLEAN DIESEL TECHNOLOGIES

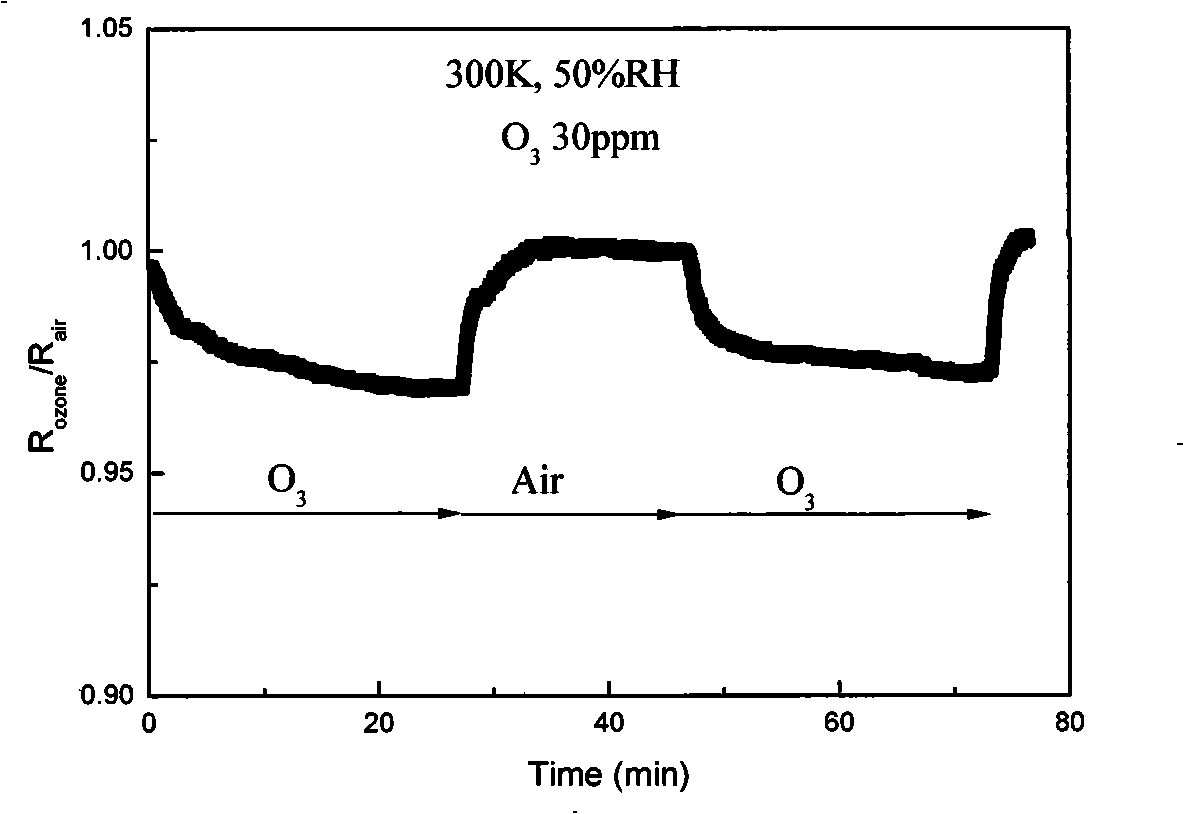

P -type delafossite base oxide ozone gas sensory semiconductor material and method for making same

InactiveCN101308109AGood reversibilityImprove stabilitySemiconductor/solid-state device manufacturingMaterial resistanceSemiconductor materialsDelafossite

The invention discloses a p-type delafossite base oxide ozone gas sensing semiconductor material and a method for the production thereof, the ozone gas sensing semiconductor material is a mixture of p-type delafossite base oxide CuM(1-x)AxO2, 0<=x<=0. 30, or the oxide and other materials by arbitrary proportion, and M is a trivalent metal ion of B, Al, Ga, In, Fe, Cr, Sc, Y or La; and A is bivalent metal ions of Mg, Ca, Ni, Sr and Zn. The gas sensing material of the invention has advantages of good selectivity, reversibility and stability to the response of ozone at the room temperature, a gas-sensitive element made by the gas sensing material of the invention need not carry a heater, and the ozone gas has good sensitivity characteristics in the concentration range of 1ppm to 1000ppm at the room temperature. The semiconductor material and the method can provide the room temperature ozone gas-sensitive element with low power consumption, long service life and low cost of manufacture.

Owner:ANHUI INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

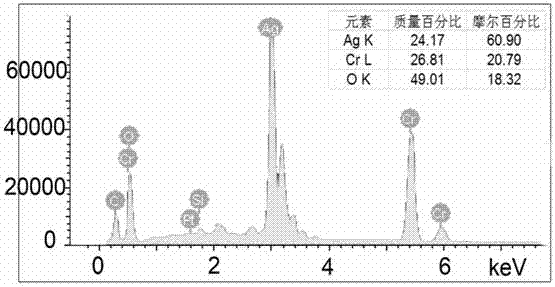

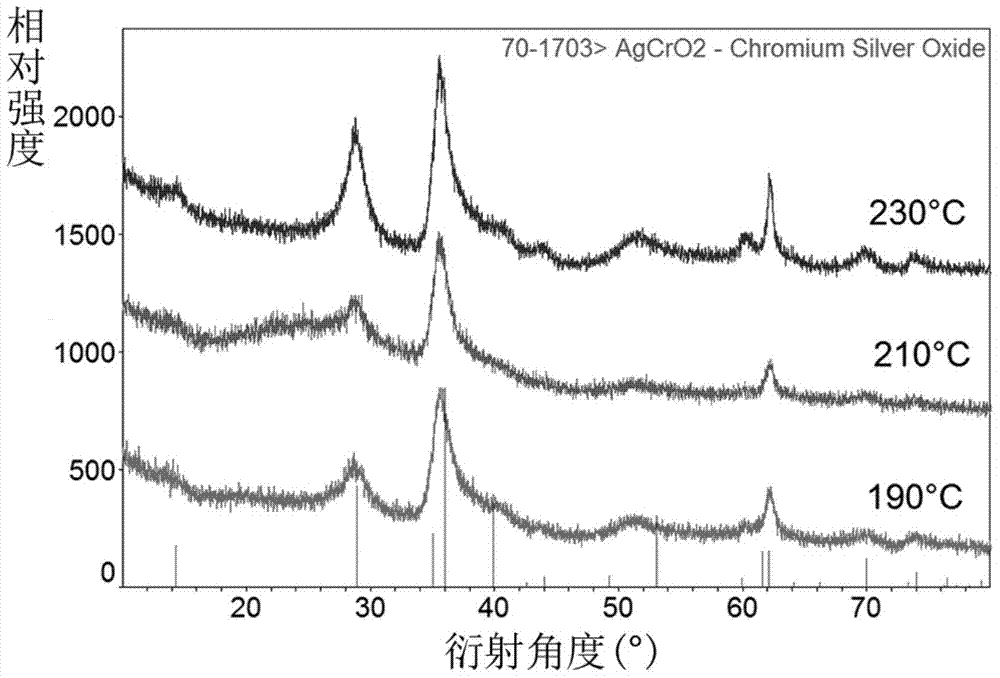

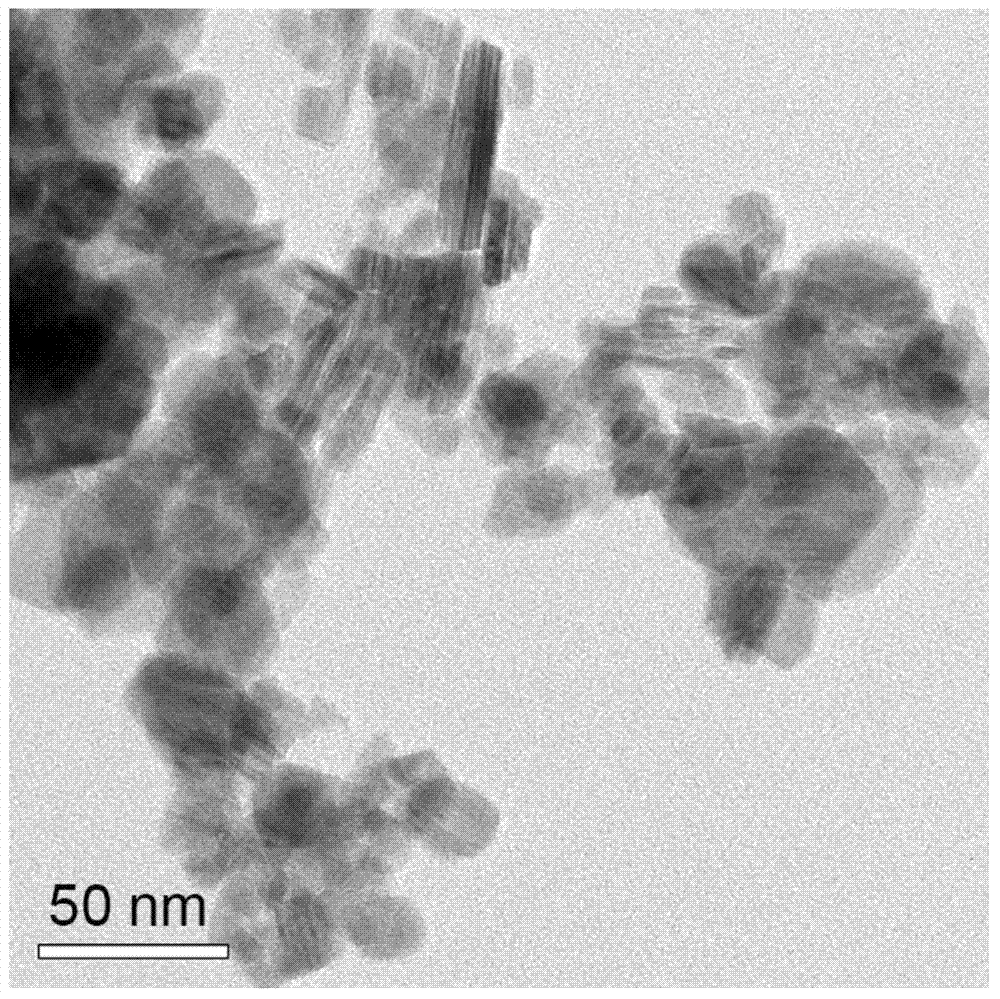

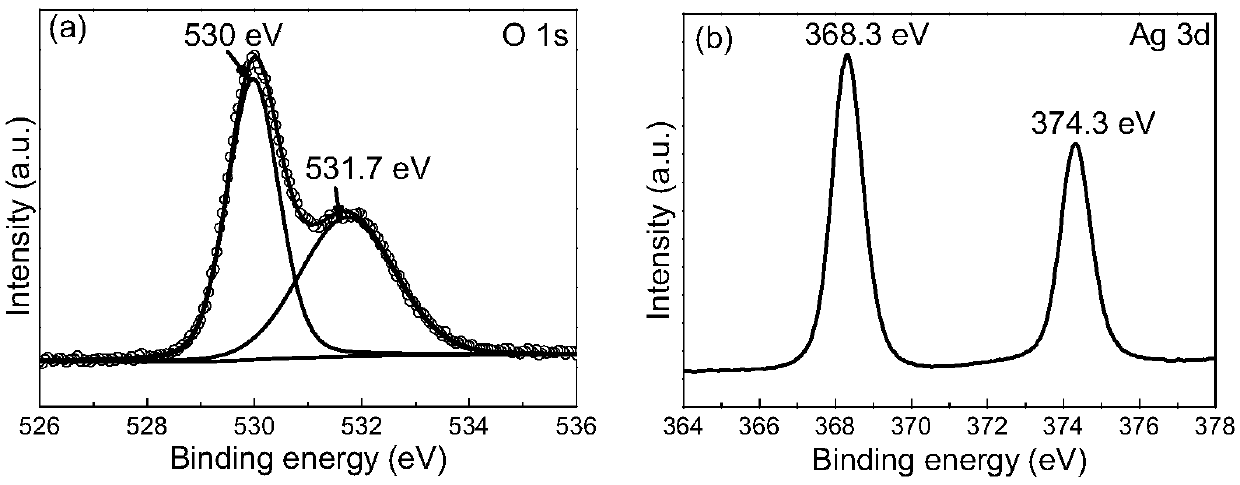

Preparation method for delafossite-structure AgCrO2 nanocrystalline material

ActiveCN103880081AHigh yieldLow costMaterial nanotechnologyLight-sensitive devicesDelafossiteSynthesis methods

The invention discloses a preparation method for a delafossite-structure AgCrO2 nanocrystalline material, in particular to a low-temperature hydro-thermal synthesis method for rapidly preparing a delafossite-structure AgCrO2 nanocrystalline material. The preparation method comprises the following steps: regulating a reaction precursor constituent, a reaction temperature and the filling rate parameter of reaction solution in a hydro-thermal reaction kettle, reacting at 190-230 DEG C for 36-60 hours, carrying out centrifugal cleaning treatment on the reaction product for multiple times, and drying at 60 DEG C in a vacuum drying oven for 24-48 hours, thereby finally obtaining the AgCrO2 nanocrystalline material with the size of 10-20 nm. The method is simple to operate, easy in control over process parameters, pollution-free, high in yield, and capable of being widely used in photoelectric function devices such as transparent conductive oxides.

Owner:WUHAN UNIV OF TECH

A delafossite-structured CuCoO2 crystal material and a low-temperature preparation method thereof

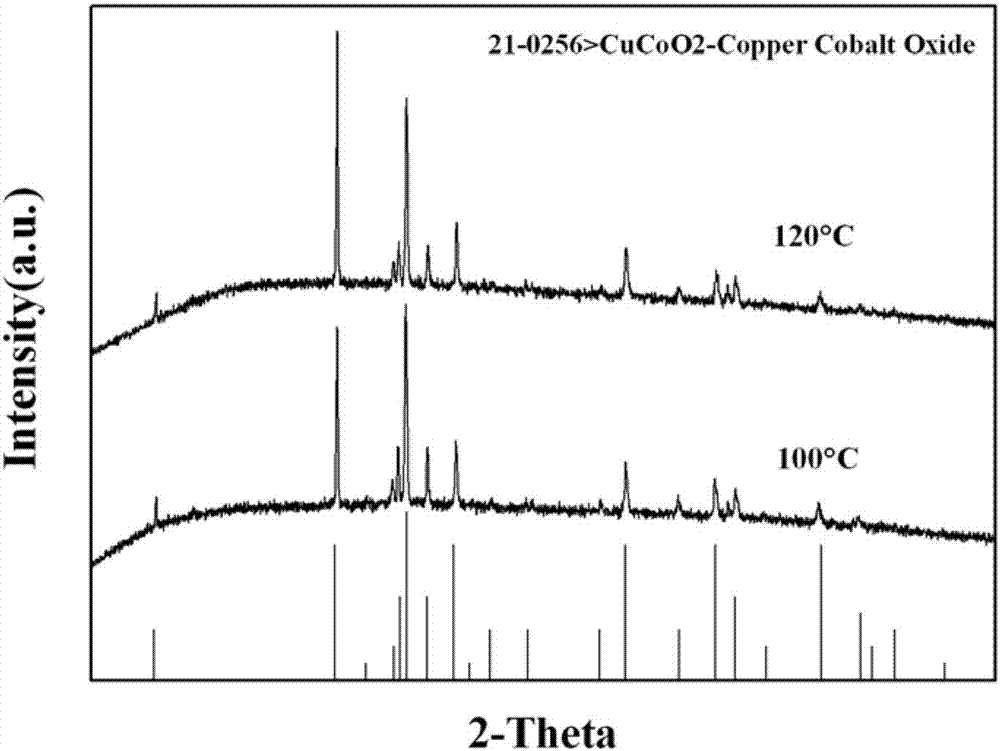

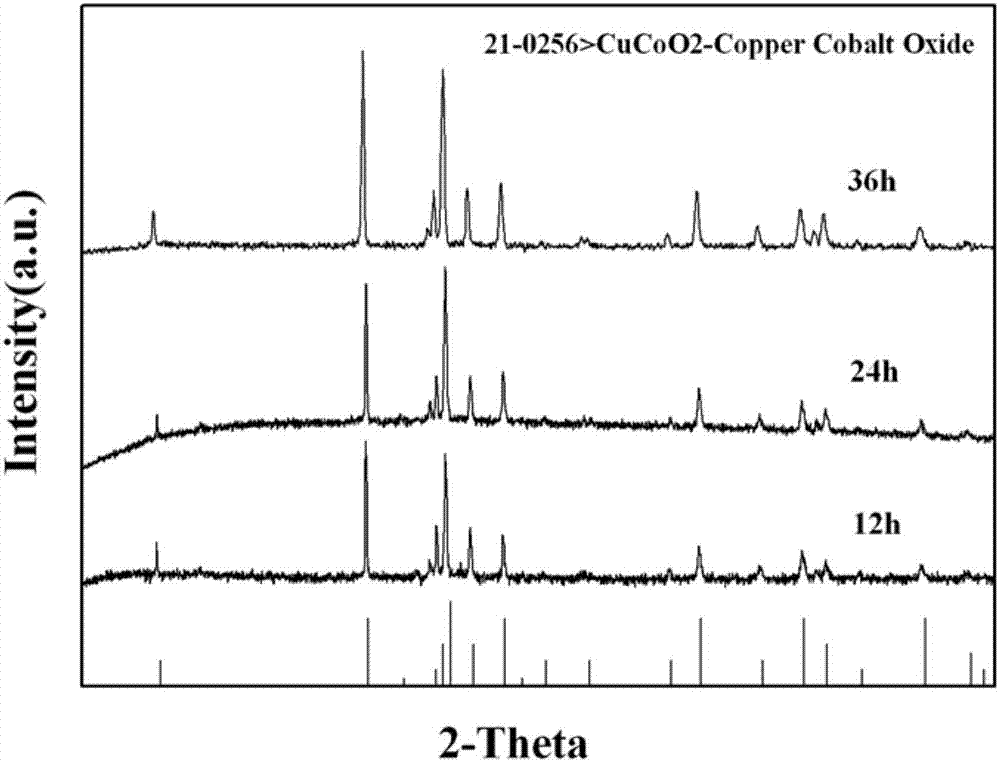

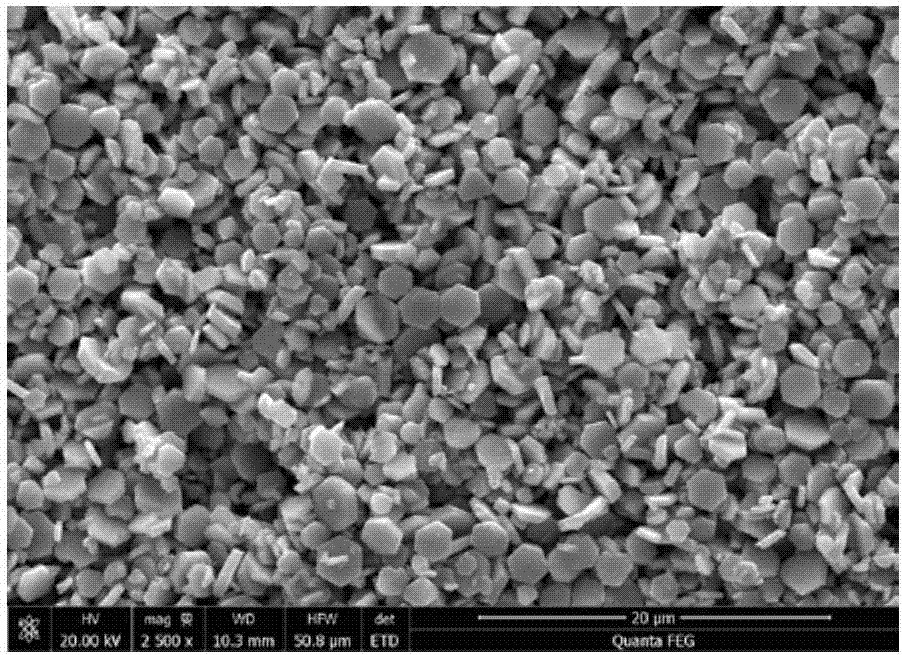

ActiveCN107098401ASimple preparation processGood experimental repeatabilityCobalt compoundsDelafossiteReaction temperature

The invention relates to the field of preparation of delafossite-structured crystal materials, particularly relates to preparation of a CuCoO2 crystal material at a low temperature by utilizing a hydrothermal process, and more particularly relates to a low-temperature preparation method of the delafossite-structured CuCoO2 crystal material. The method is characterized in that a low-temperature hydrothermal reaction is utilized, reaction precursor components, the reaction temperature and the filling coefficient of a filling liquid in a hydrothermal reactor are regulated, and after Co(NO3)<2>.6H2O and Cu(NO3)<2>.3H2O are reacted at 100-120 DEG C for 12-36 h, a reaction product is subjected to centrifugal cleaning treatment and drying to obtain the crystal material the particle size of which is 1-4 microns. The method when compared with other CuCoO2 crystal material preparing methods has advantages of an ultralow temperature, a high yield, a low cost and low pollution.

Owner:WUHAN UNIV OF TECH

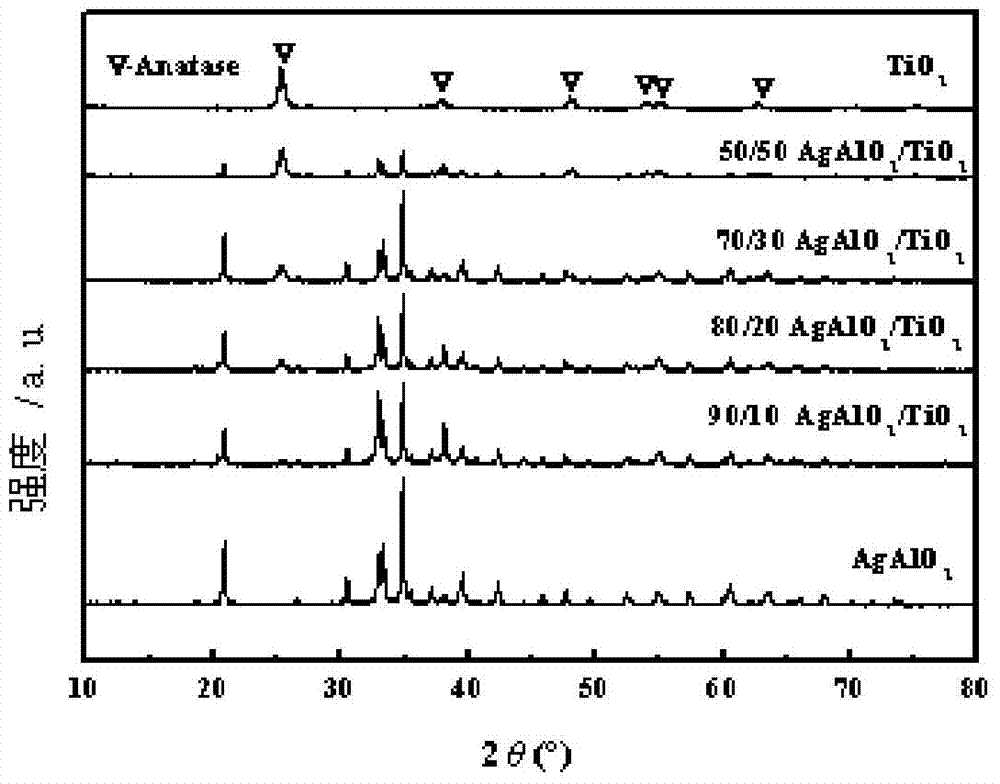

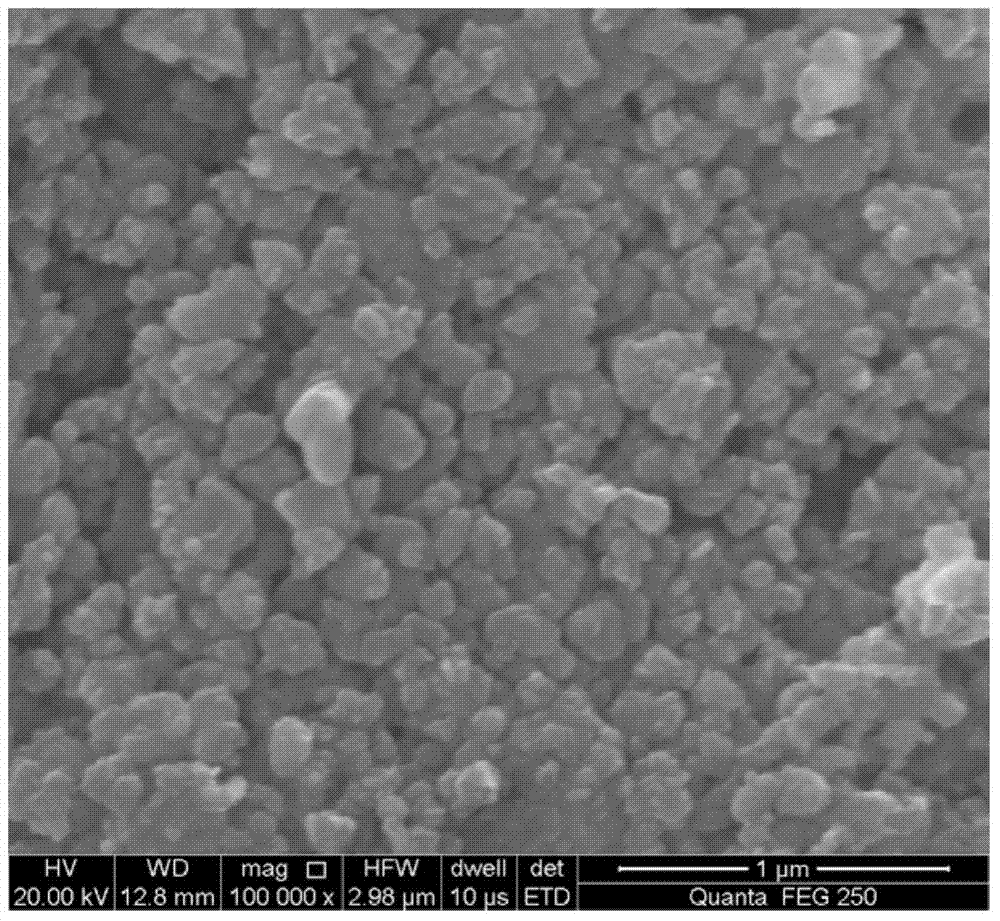

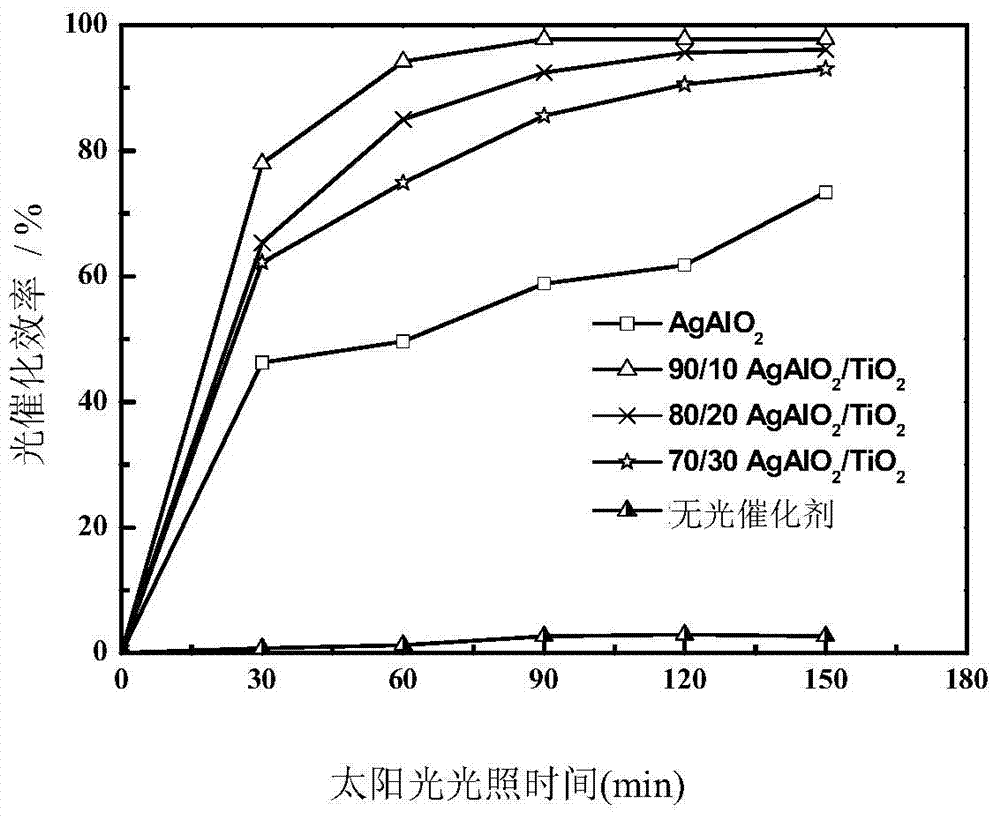

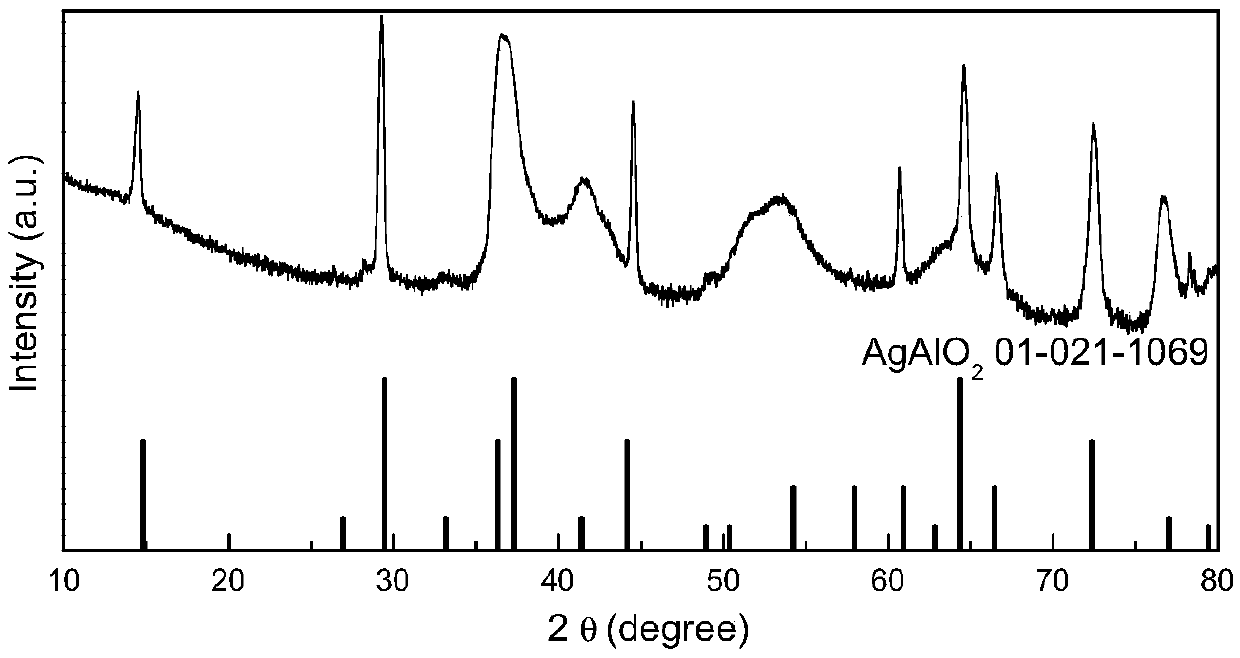

Preparation method of AgAlO2/TiO2 photocatalytic material

InactiveCN103480372AAvoid recombinationHigh outputMetal/metal-oxides/metal-hydroxide catalystsQuantum yieldElectron hole

The invention relates to a preparation method of an AgAlO2 / TiO2 photocatalytic material. The preparation method comprises the following steps: 1, preparing TiO2 through a sol-gel method; 2, preparing NaAlO2 through the sol-gel method; 3, preparing AgAlO2 / TiO2 through an ion-exchange method. According to the invention, P-type delafossite type AgAlO2 and n-type TiO2 are compounded to form an alloplastic photocatalytic material, so that under the condition of improving the yield of photoinduced electron-hole pairs of the material, the electron-hole pairs can be effectively prevented from compounding again, the quantum yield is improved, and then visible light catalytic activity better than that of single AgAlO2 can be represented. The preparation method provided by the invention is mild in reaction conditions, easy to operate, and good in repeatability; and a prepared product is high in crystallinity and uniform in particle size, and the particle diameter is about 100 to 200 nm.

Owner:CHANGSHA UNIVERSITY

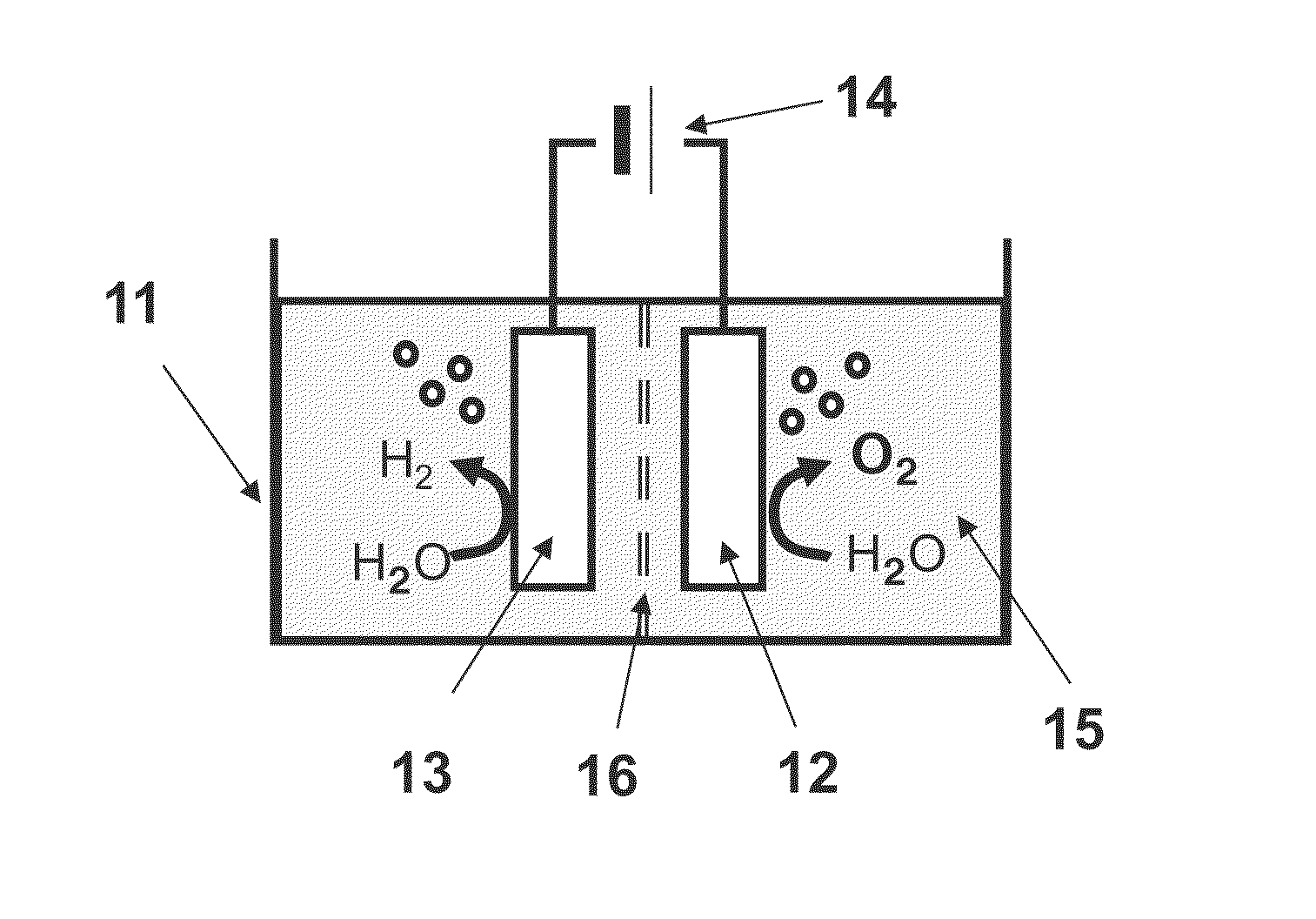

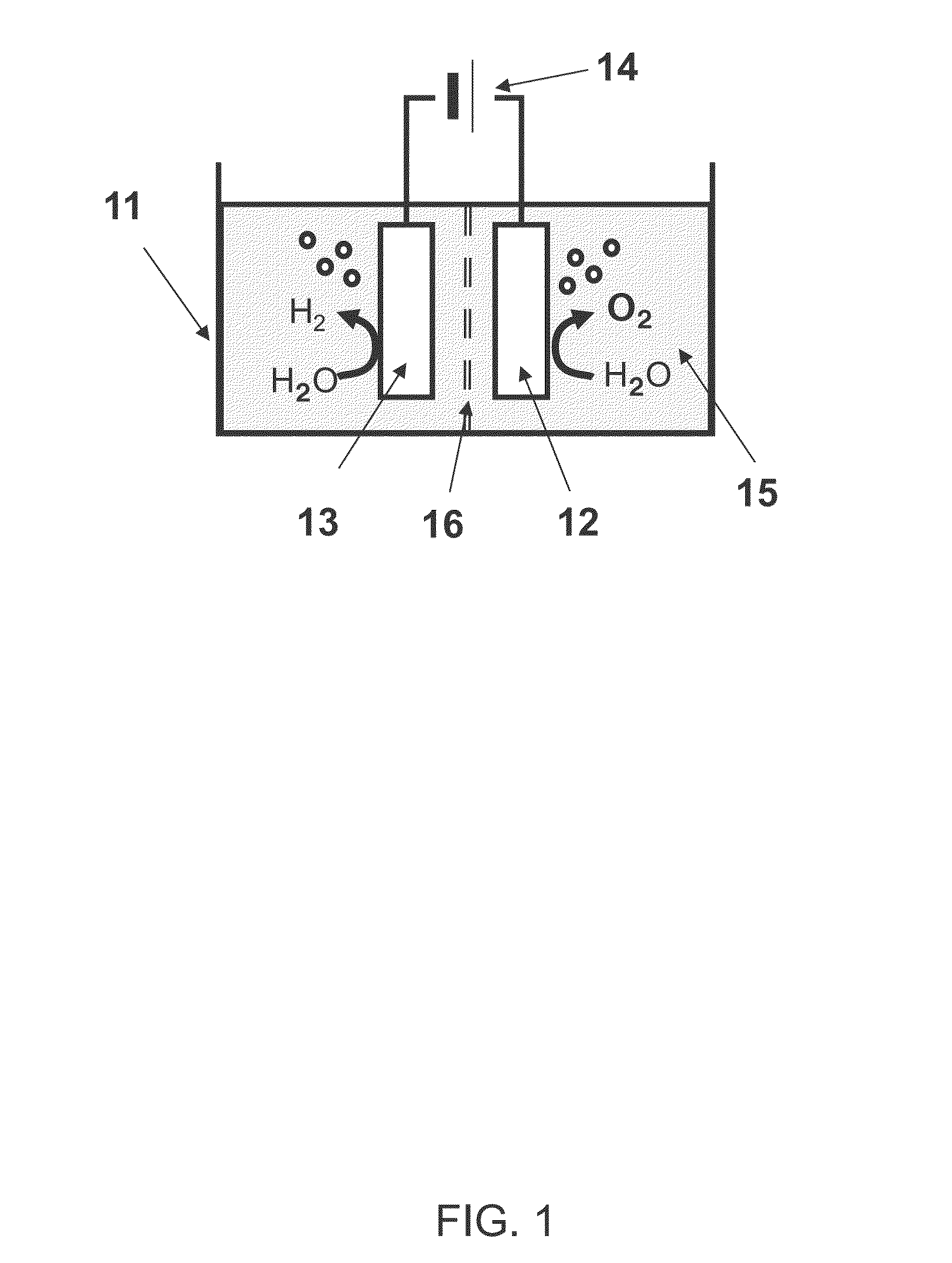

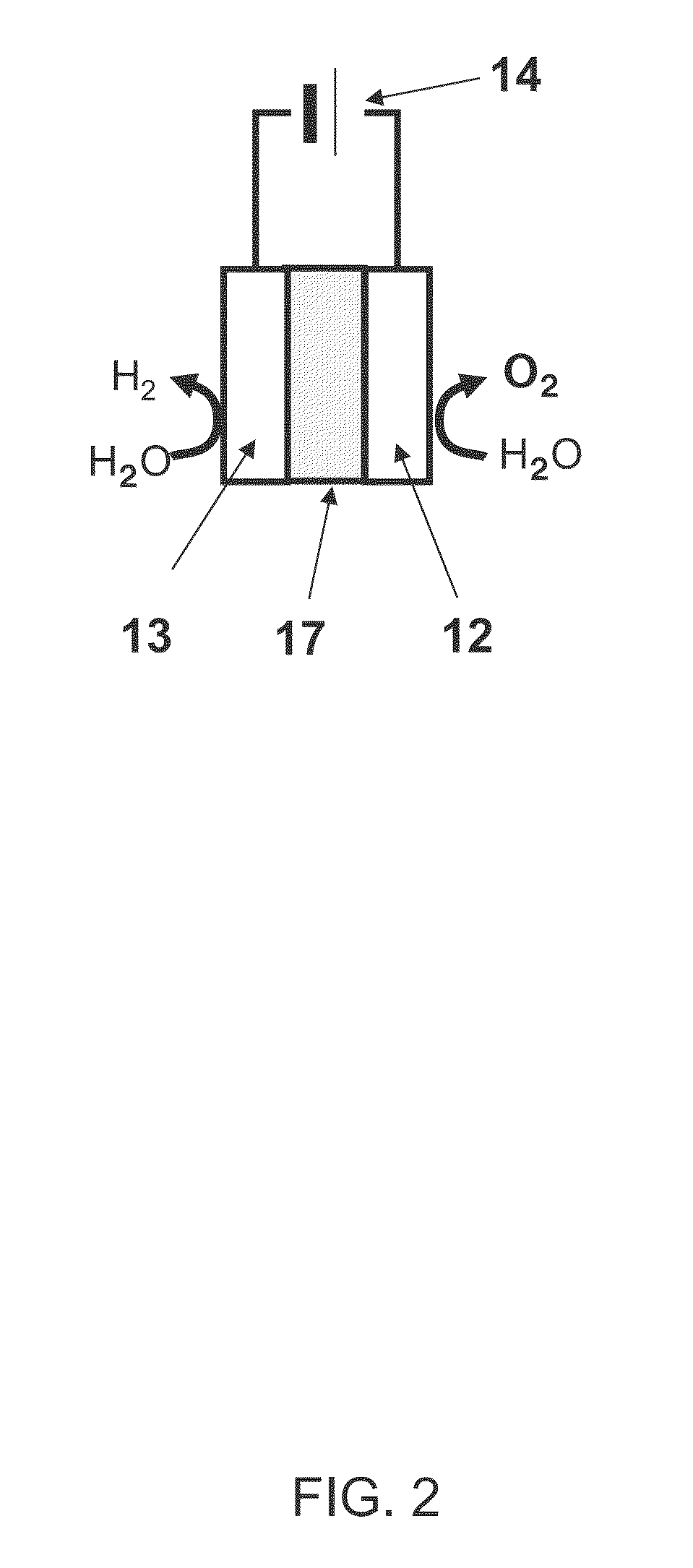

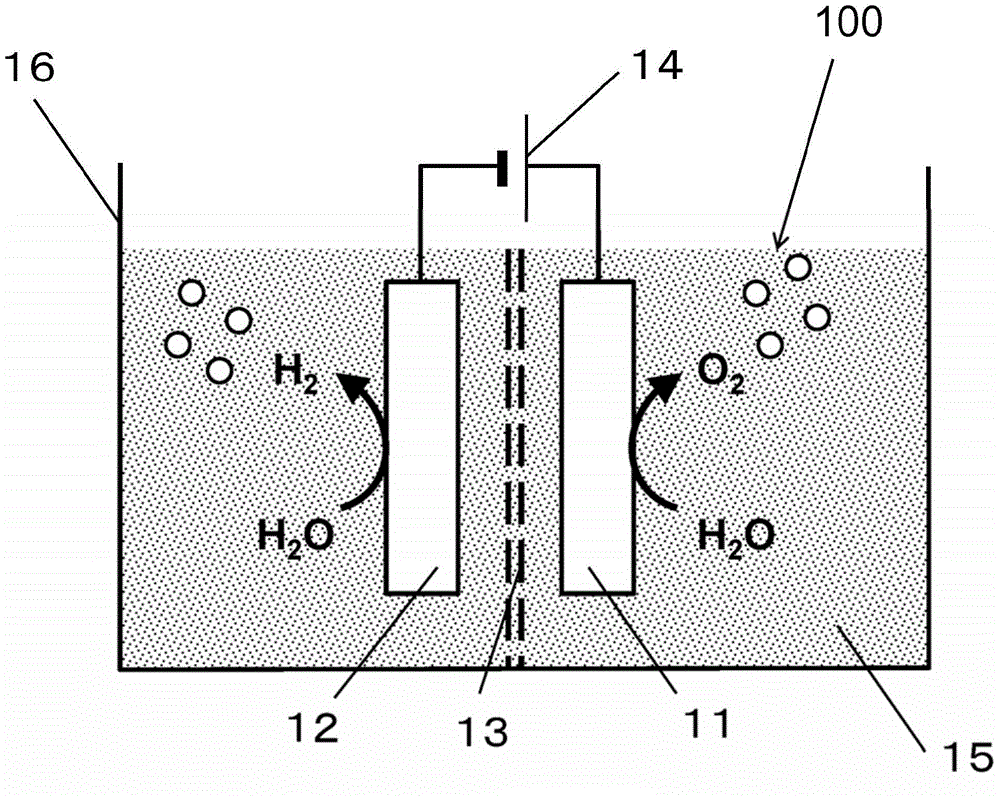

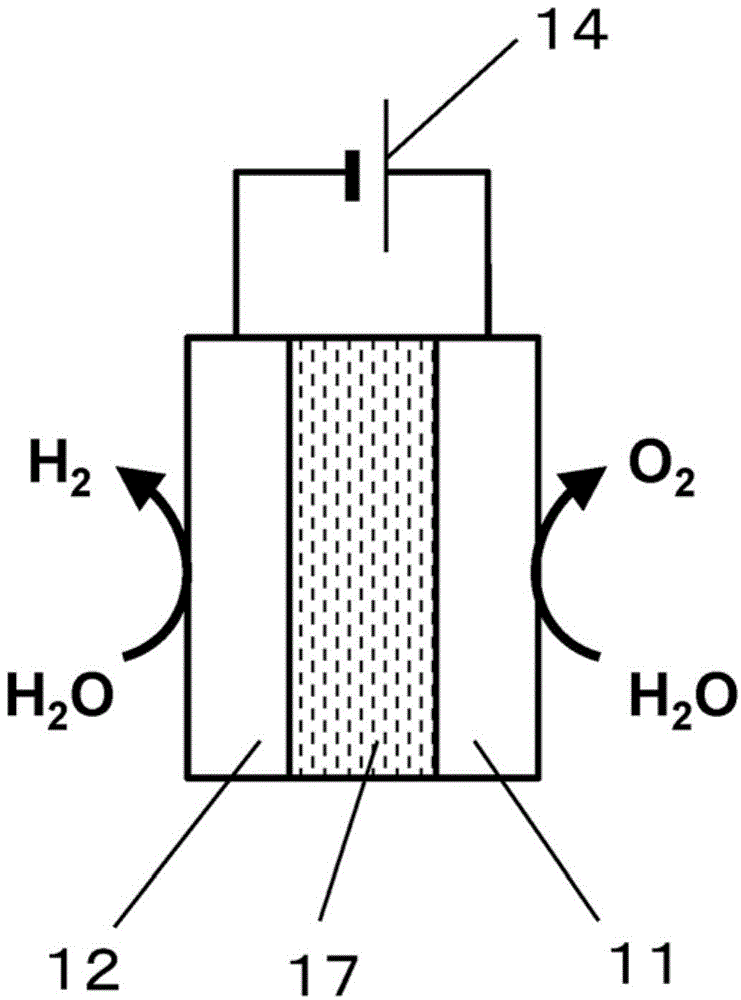

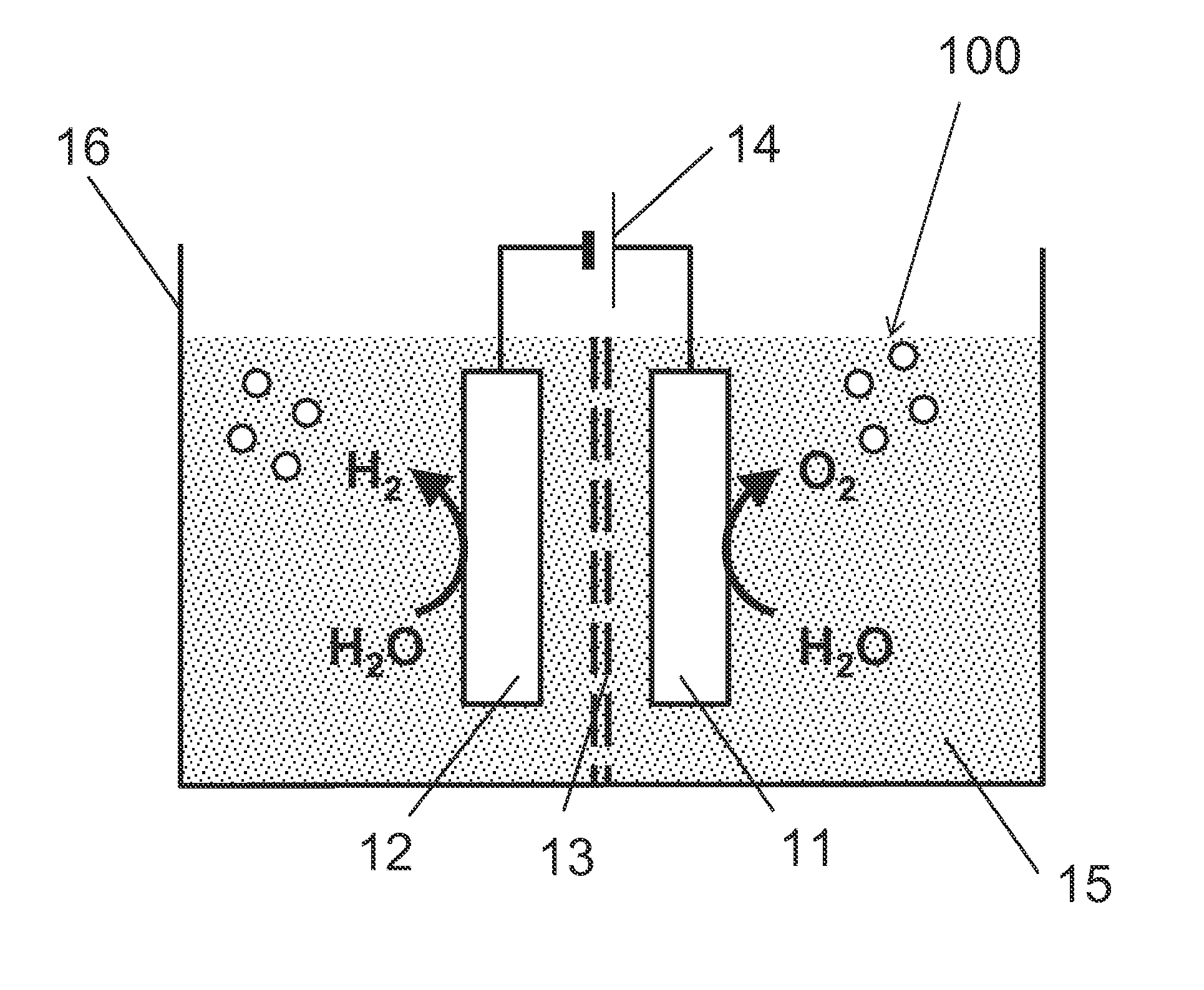

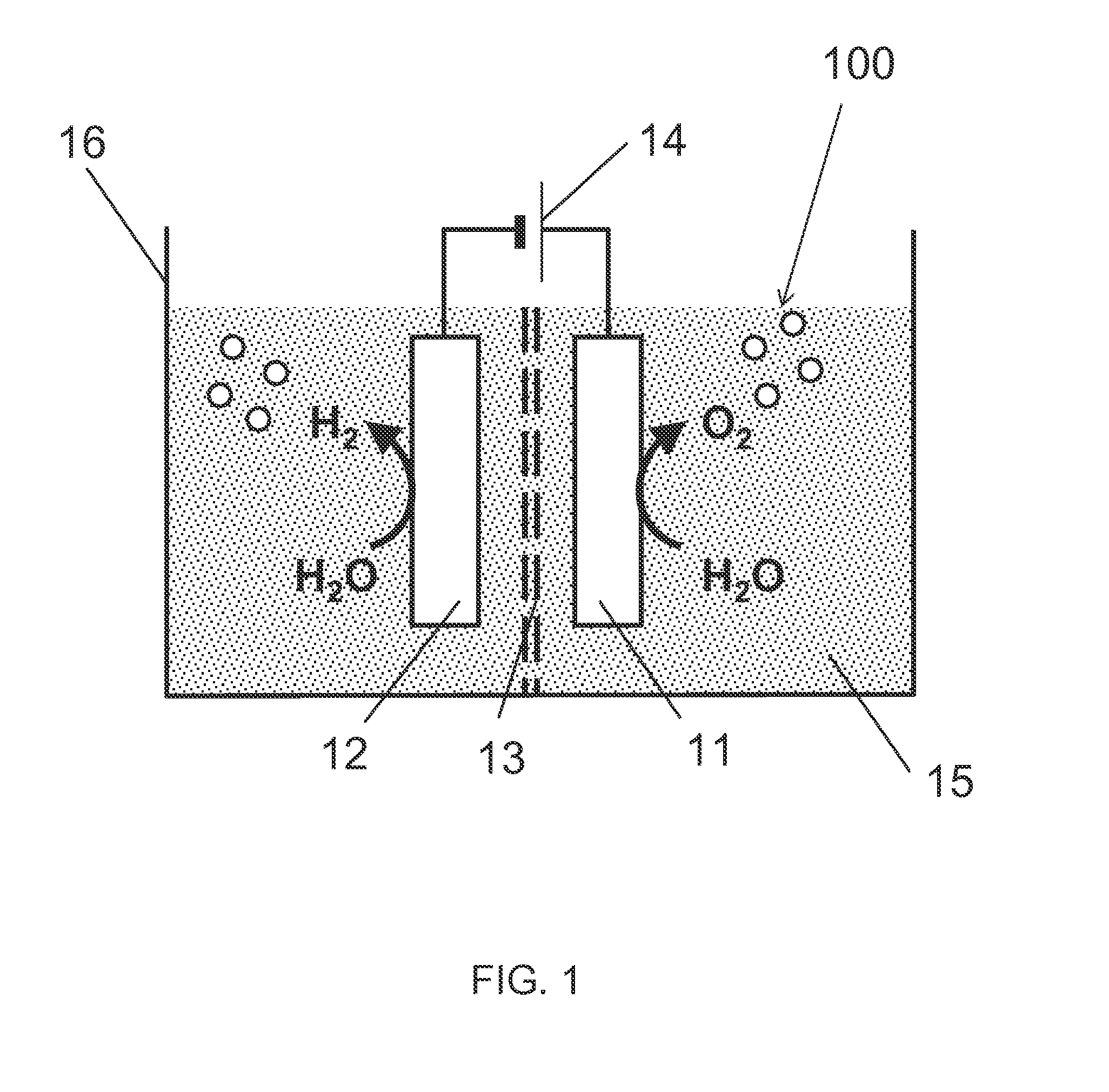

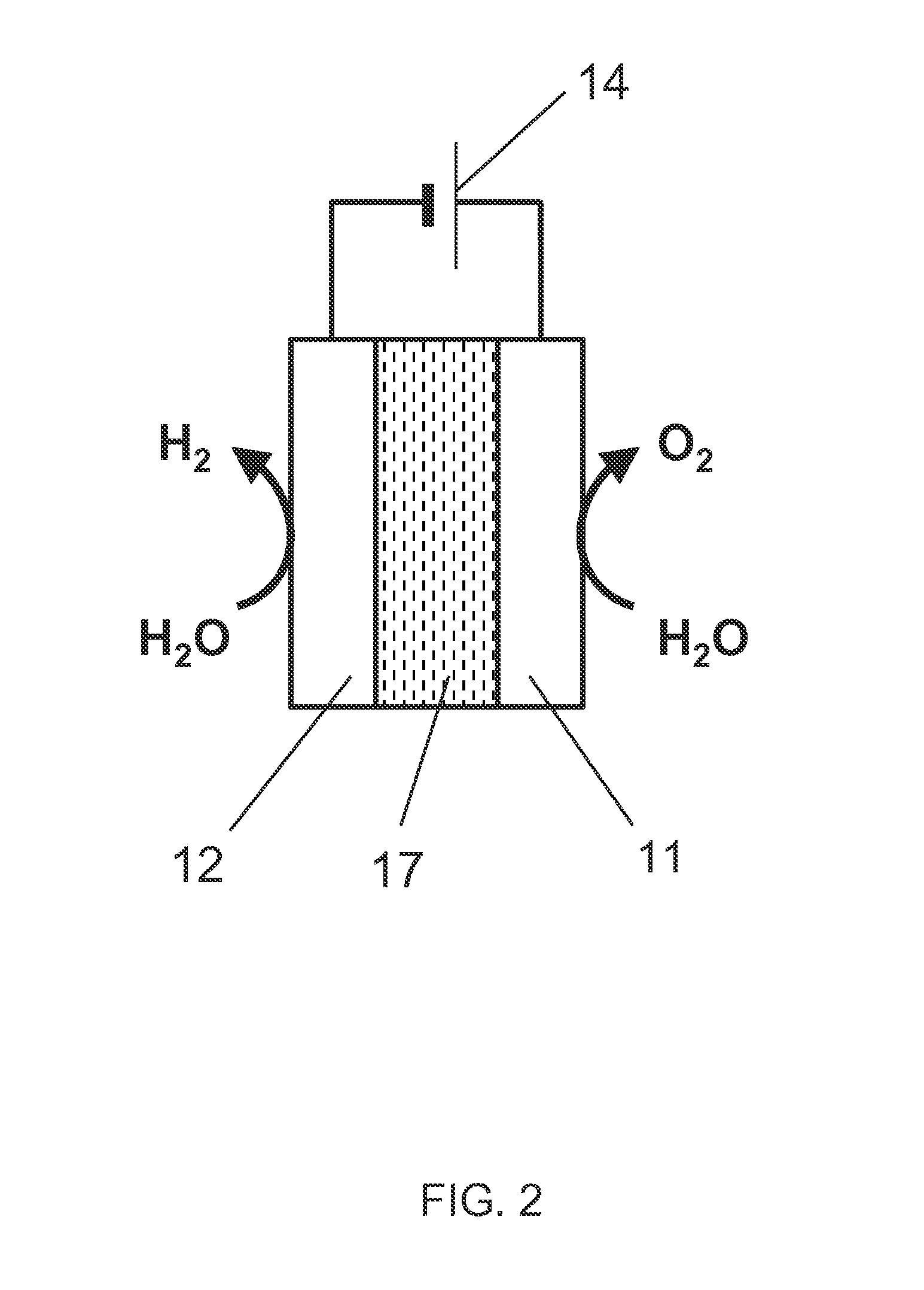

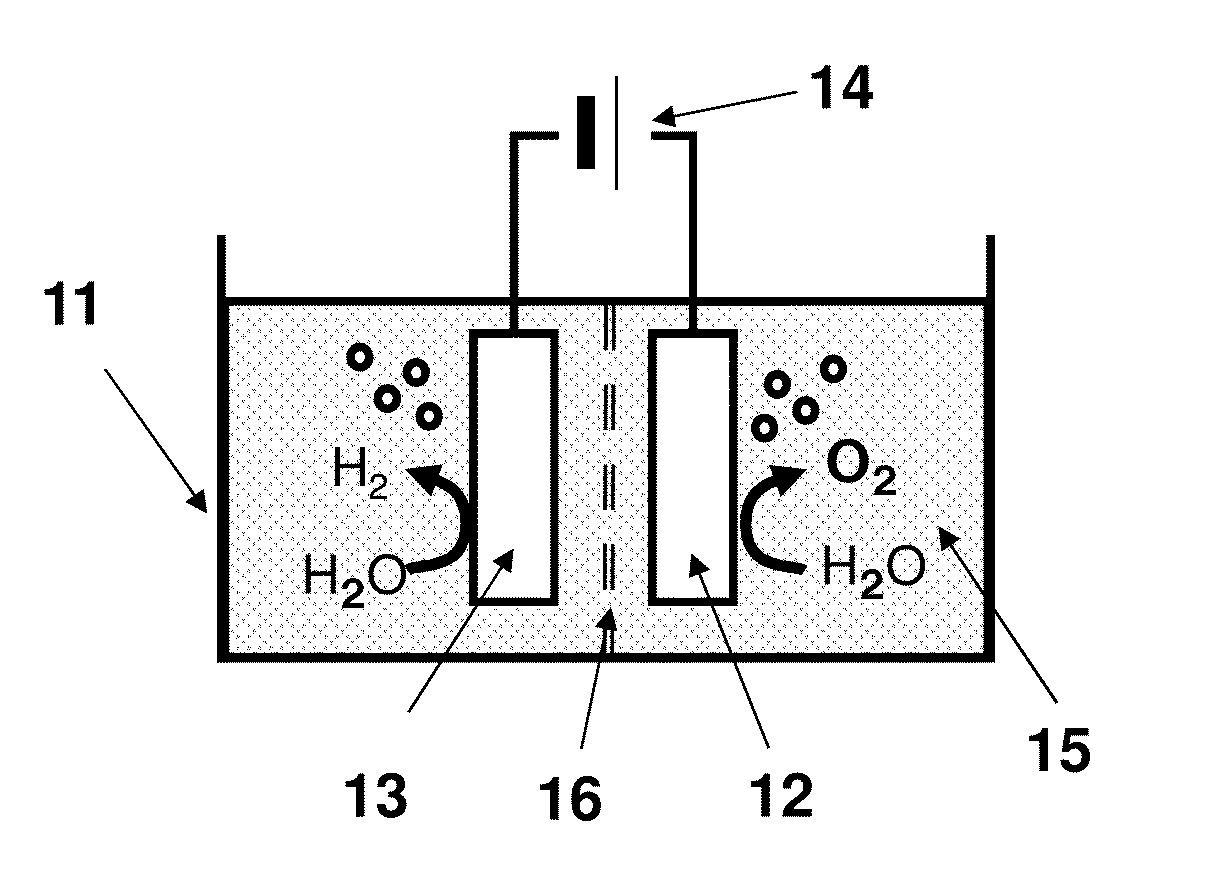

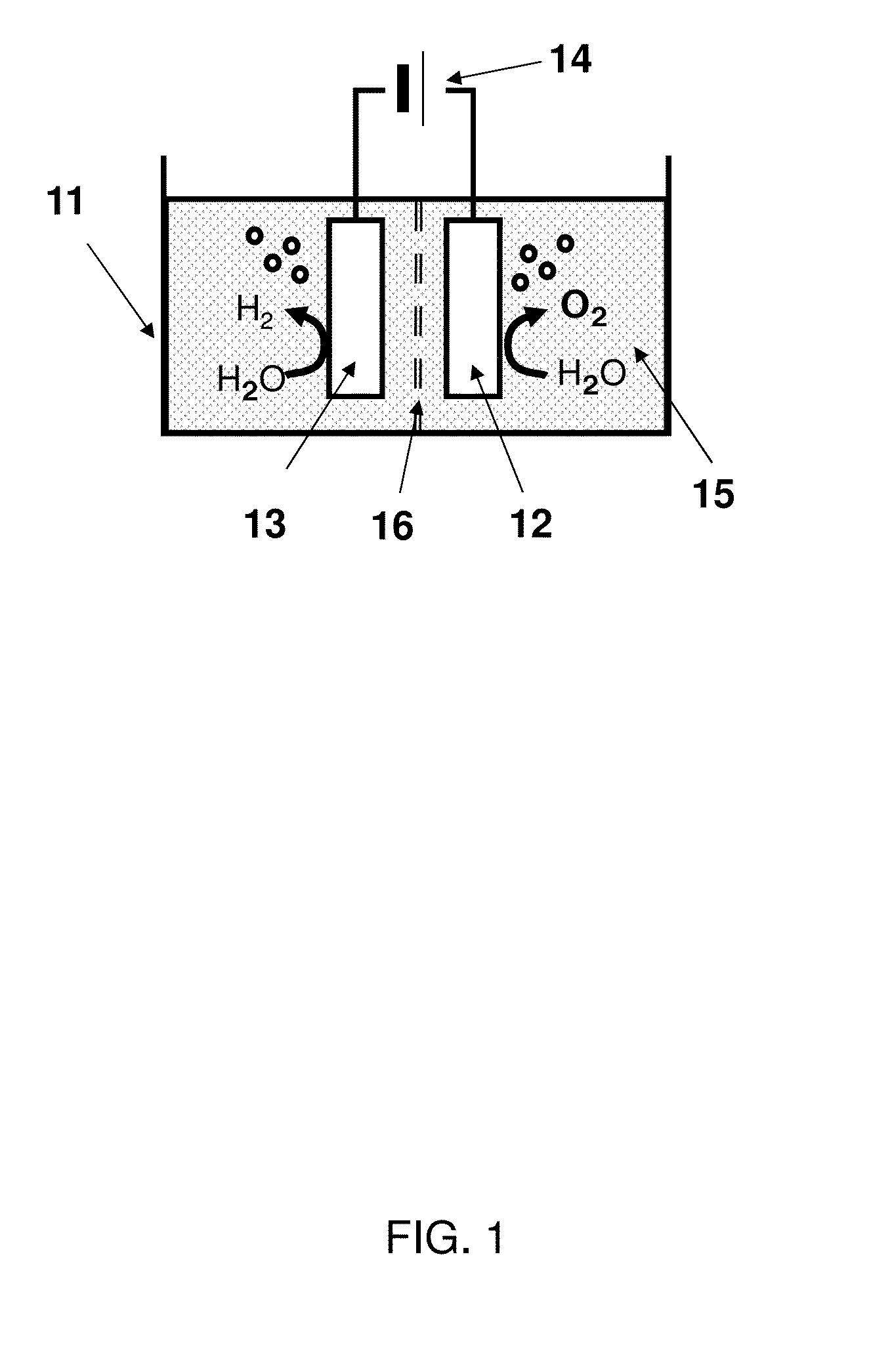

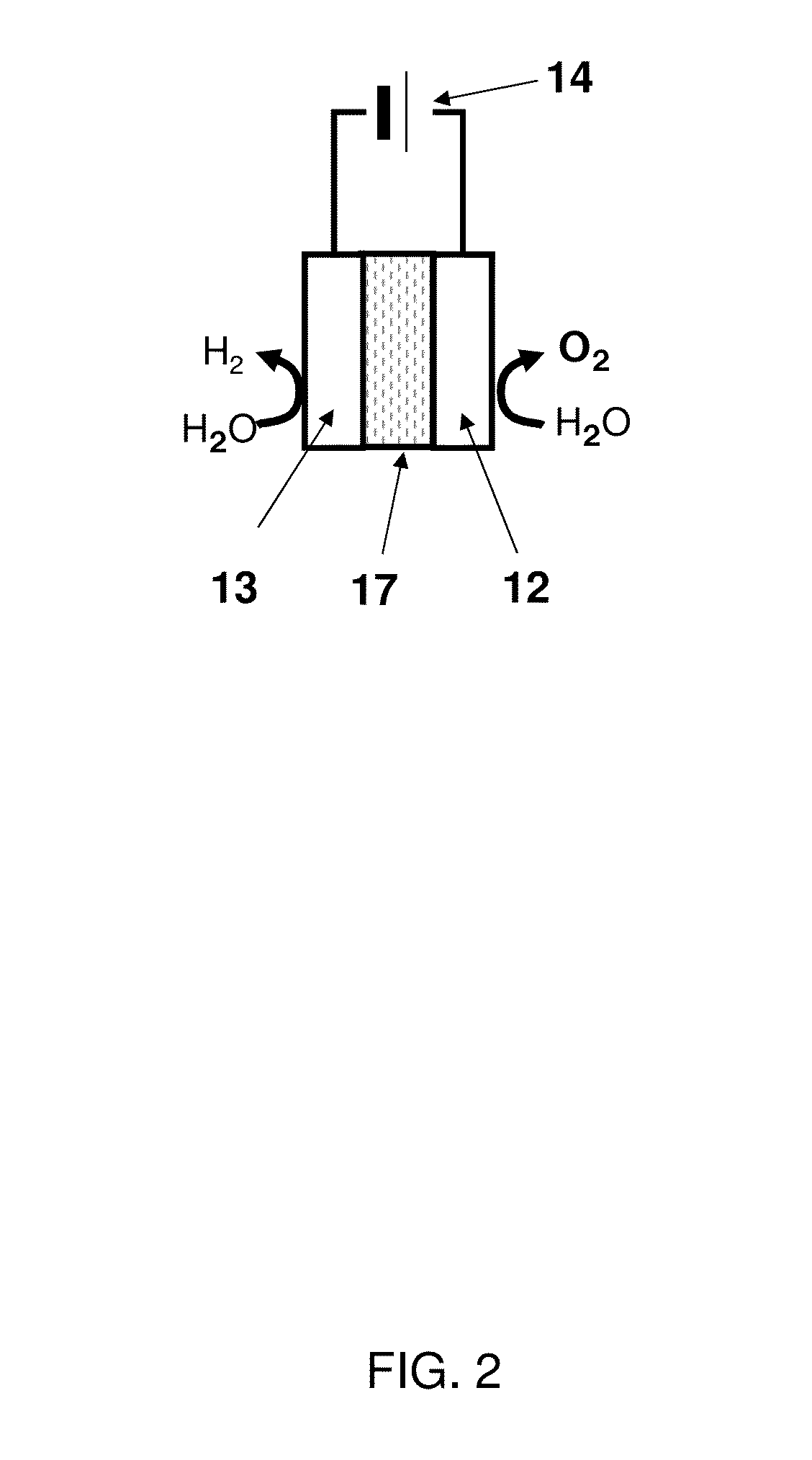

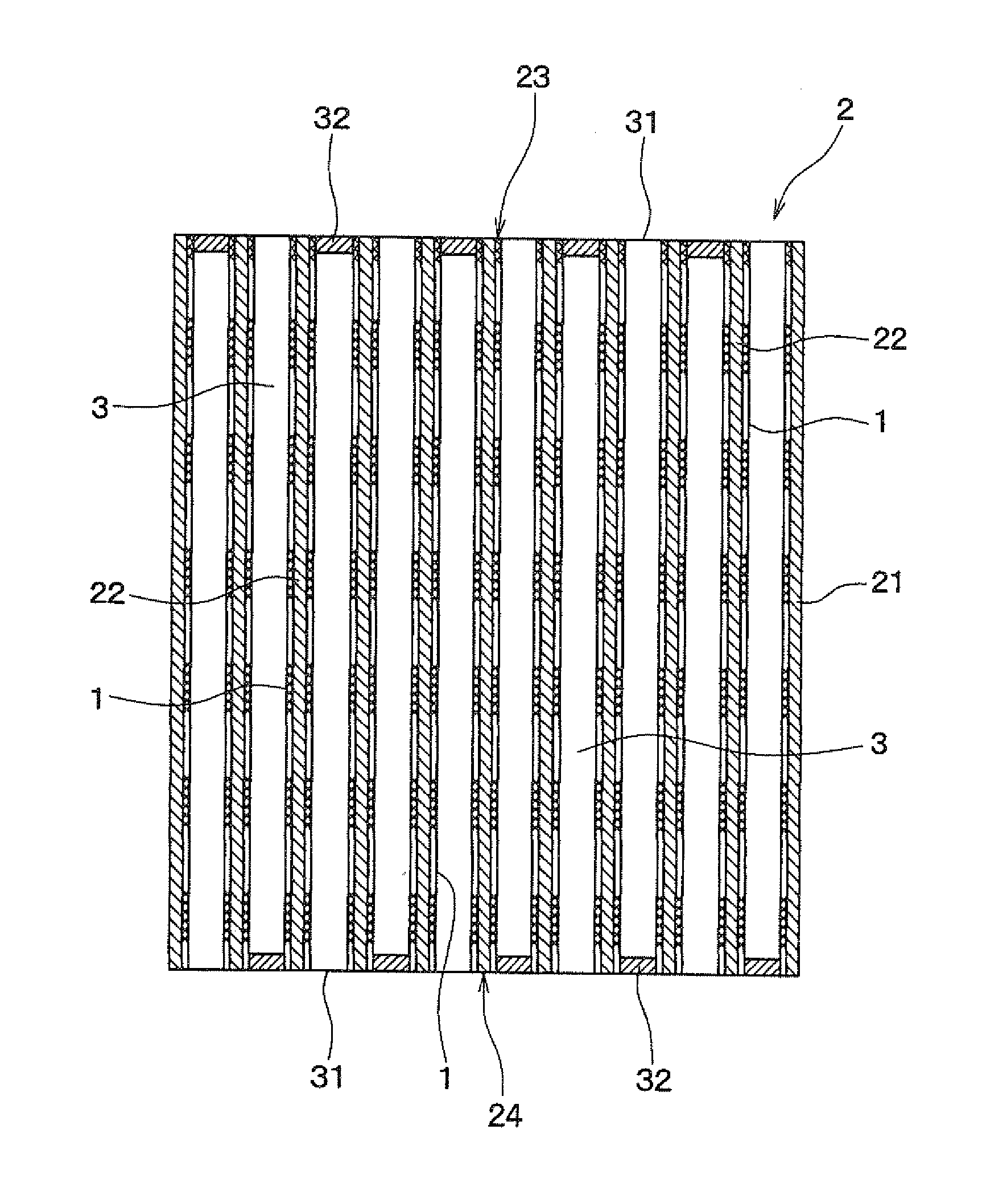

Method for generating oxygen and water electrolysis device

The present invention provides a method for efficiently generating oxygen by electrolyzing water using a copper delafossite compound as an anode. First, in the present invention, a water electrolysis device is prepared. The water electrolysis device comprises a container, a power supply, an anode, a cathode; and an aqueous electrolytic solution. The anode and the cathode are in contact with the aqueous electrolytic solution. The anode has a copper cobalt delafossite compound represented by a chemical formula CuCoO2. The copper cobalt delafossite compound is in contact with the aqueous electrolytic solution. Then, an electric potential difference is applied between the cathode and the anode using the power supply to generate oxygen on the anode due to electrolysis of water which occurs on the copper cobalt delafossite compound.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

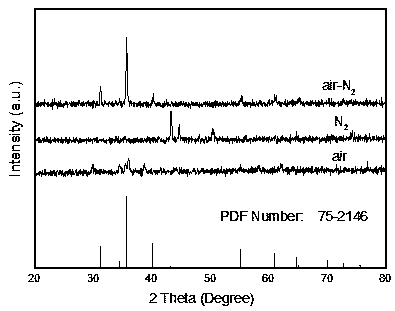

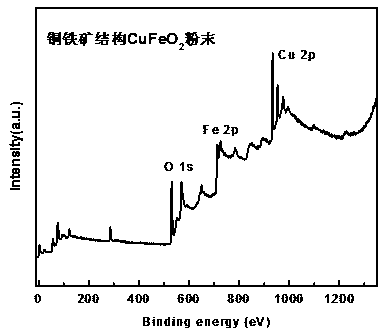

Delafossite structure CuFeO2 powder and preparation method and application thereof

ActiveCN108906051AParticle size controllableGuaranteed normal formationIron compoundsLuminescent compositionsAir atmosphereDelafossite

The invention relates to a delafossite structure CuFeO2 powder and a preparation method and application thereof. The preparation method comprises the following steps: S1: dissolving bivalent copper salt and trivalent iron salt, adding citric acid and PEG, stirring and dissolving, adjusting the PH value to 2 to 3 with NH3.H2O to obtain a reaction precursor; and S2: drying the reaction precursor, grinding the precursor into powder and performing annealing treatment, wherein the process of the annealing treatment is: in an air atmosphere, raising the temperature to 900 DEG C to 1200 DEG C at a heating rate of 5 DEG C to 15 DEG C / min, keeping the temperature for 4 hours and 6 hours, and then cooling in an inert atmosphere. The preparation method provided by the invention has the advantages ofshort cycle, high purity and suitability for mass preparation and industrial production; and the prepared CuFeO2 has high hole mobility, good photochemical stability and high conduction band energy.

Owner:GUANGDONG UNIV OF TECH

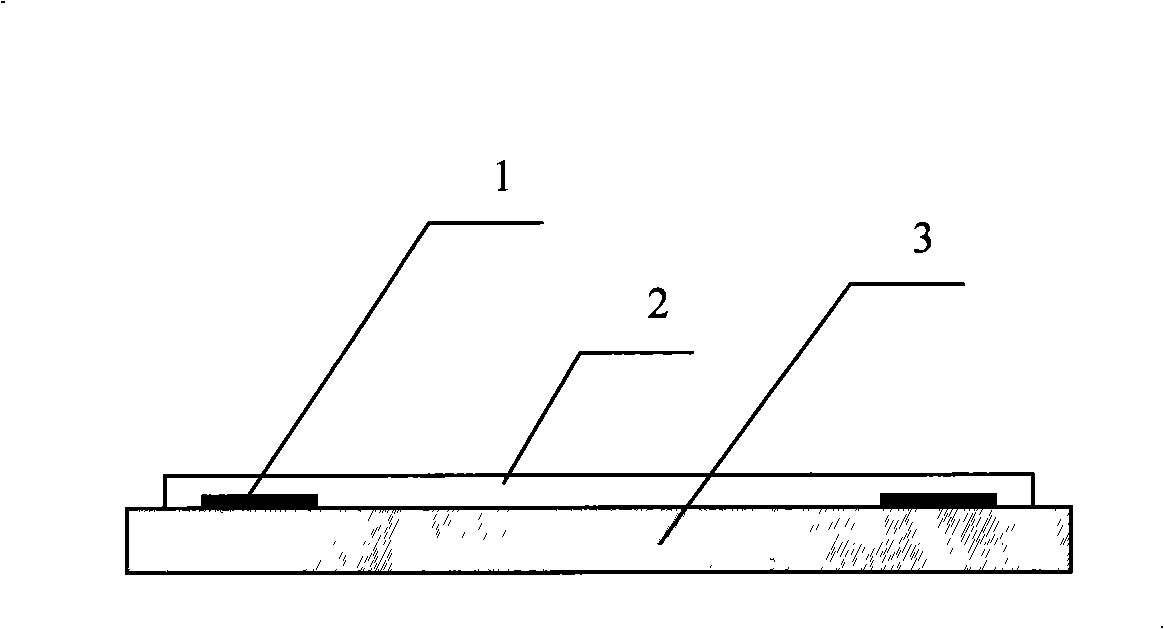

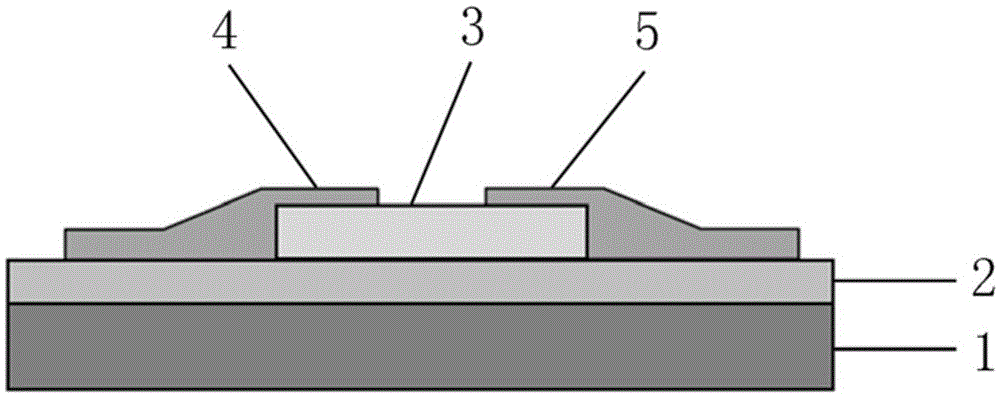

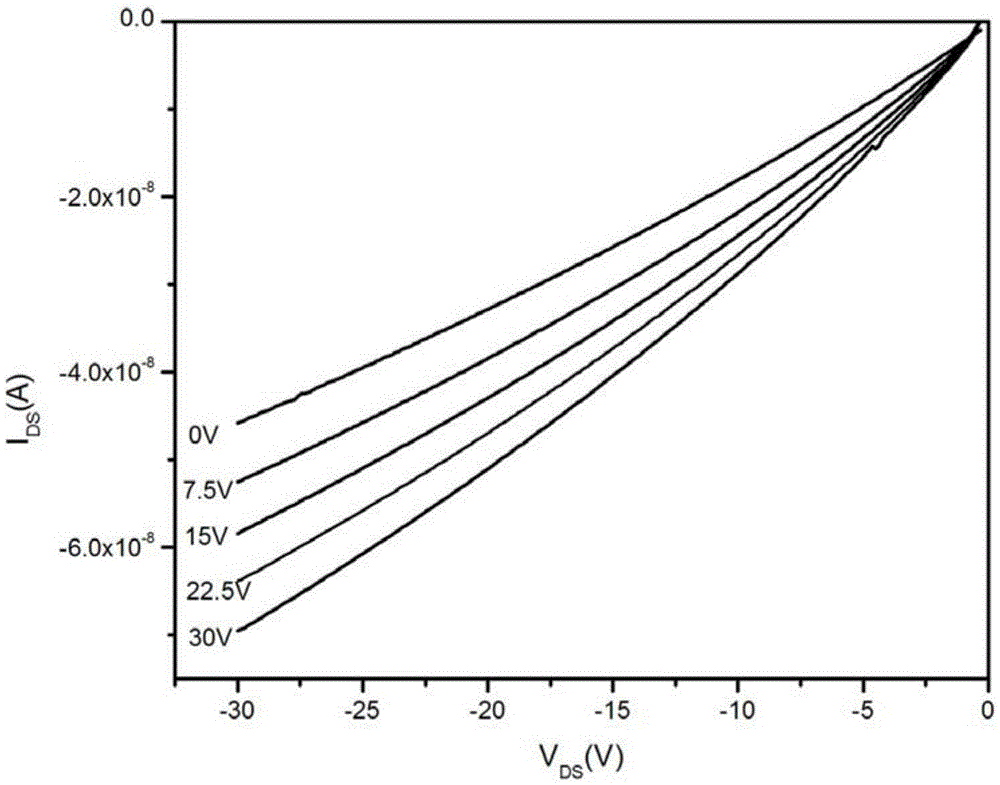

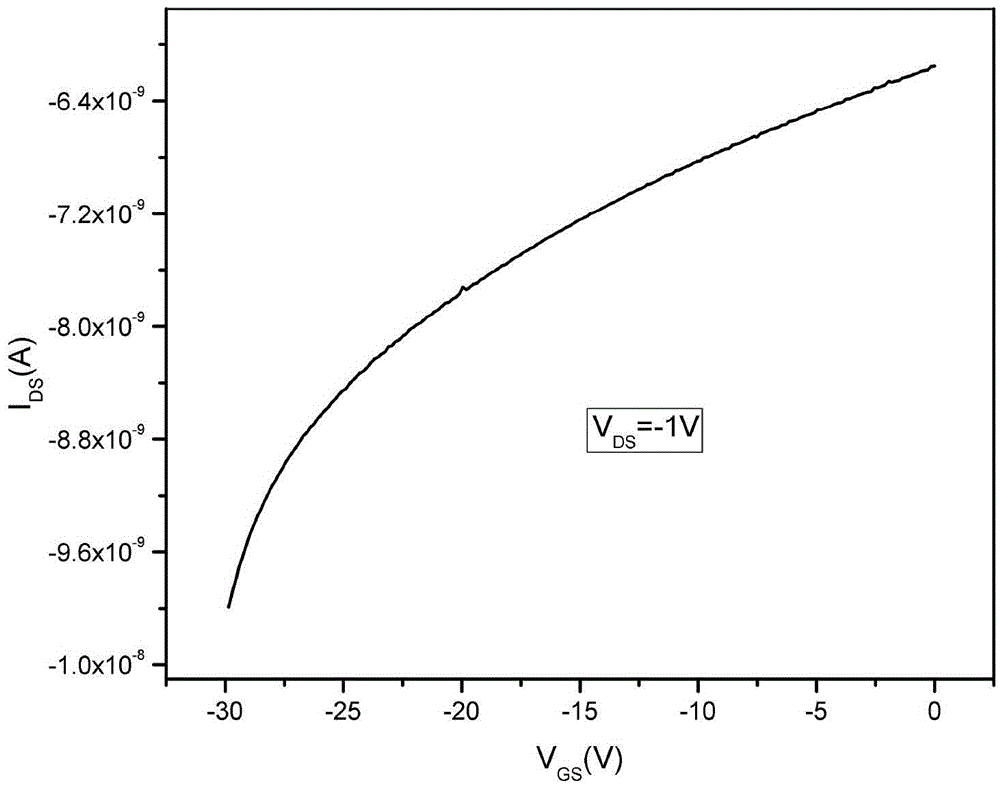

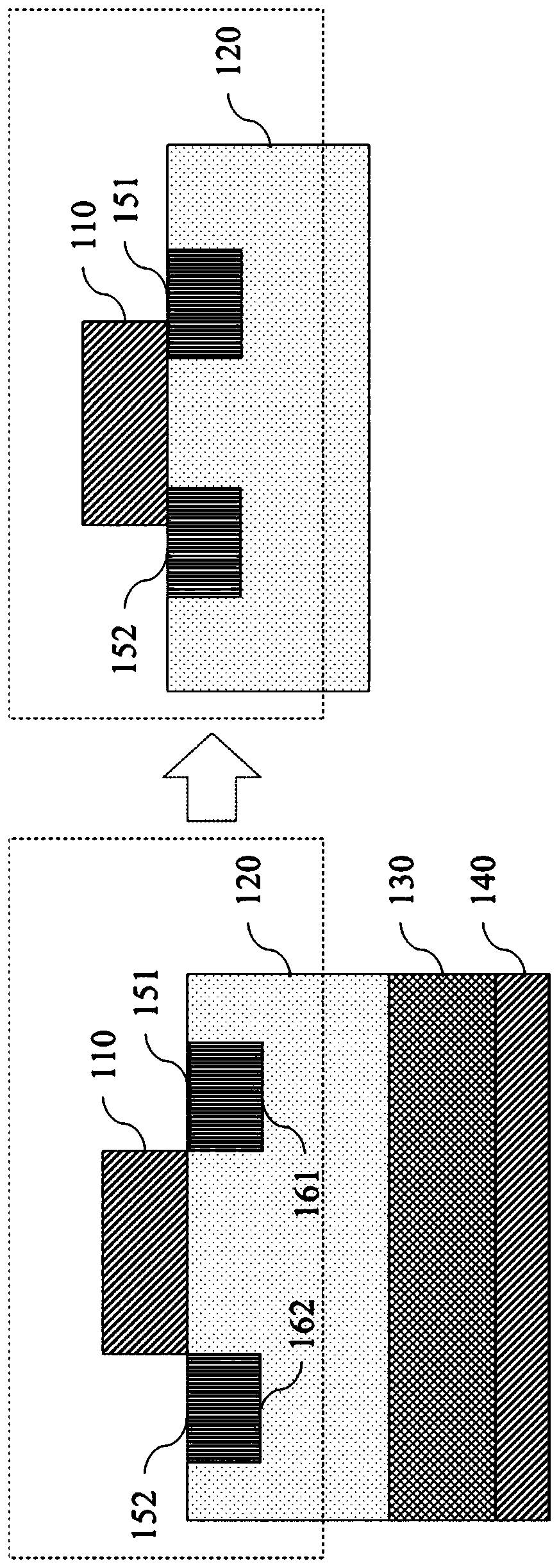

P-type oxide semiconductor thin-film transistor and preparing method thereof

InactiveCN105489656ASimple structureProcess compatibleTransistorSemiconductor/solid-state device manufacturingChemical stabilityLight-emitting diode

The invention discloses a P-type oxide semiconductor thin-film transistor and a preparing method thereof. The thin-film transistor comprises the components of a heavily doped silicon substrate which is used as a gate electrode; an insulating layer which is an insulating oxide film and is arranged on the gate electrode; an active layer which is a P-type delafossite-structured oxide film and is arranged on the insulating layer; a source electrode and a drain electrode which are Cu films and are arranged on the active layer. The P-type delafossite-structured oxide film is made of CuAlO2, CuInO2 or CuGaO2. The P-type delafossite-structured oxide film which is used as the active layer represents a stable P-type semiconductor characteristic, thereby realizing large valence band maximum frequency bandwidth and high hole mobility. The p-type oxide semiconductor thin-film transistor has a simple structure and furthermore the preparing process of the p-type oxide semiconductor thin-film transistor is compatible with microelectronic technology. Furthermore the p-type oxide semiconductor thin-film transistor has advantages of high chemical stability and excellent electrical property. The p-type oxide semiconductor thin-film transistor has a wide application prospect in organic light-emitting diode displaying, complementary oxide semiconductor electronic circuits and transparent electronic circuits.

Owner:HENAN UNIVERSITY

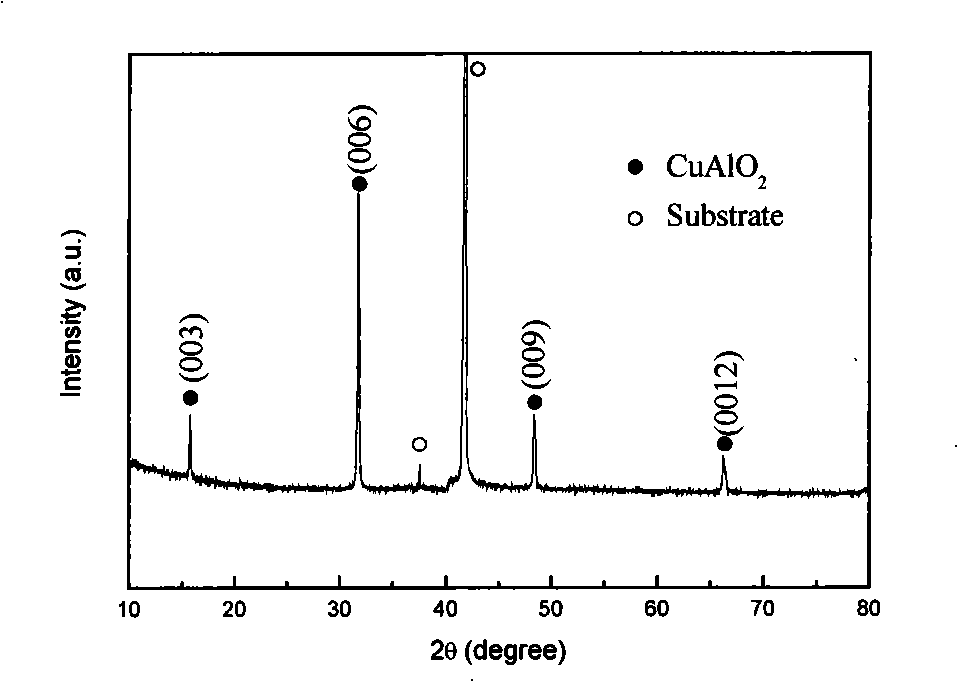

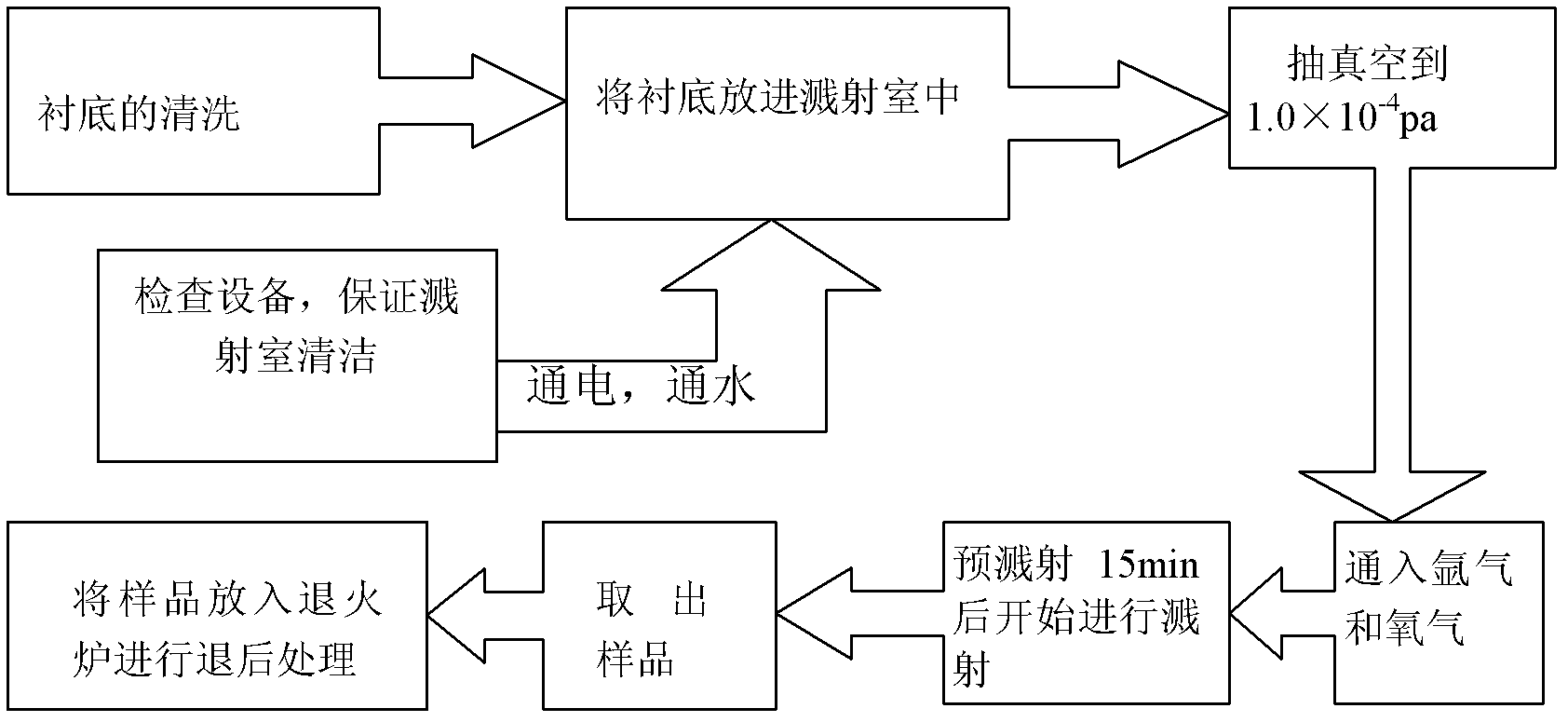

Preparation method of delafossite type copper aluminum oxide infrared transparent conductive film

InactiveCN102586746AQuality improvementAvoid churnVacuum evaporation coatingSputtering coatingChemical reactionCopper oxide

The invention relates to a preparation method of a nanoscale infrared transparent conductive film, in particular to a preparation method of an infrared transparent conductive film which is used in the infrared window and is transparent and conductive. The preparation method selects sapphire or silicon (111) as a substrate material for thin film growth; the preparation method of the thin film mainly adopts a high-vacuum magnetron sputtering technology; a co-target sputtering method is provided, wherein the target materials are respectively a Cu2O target and a Al2O3 target, or a Cu target and an Al target; and the obtained thin film is annealed in nitrogen at 500-600 DEG C for 3-5h to complete a preliminary chemical reaction, and then the thin film is annealed at a high temperature of 1000-1200 DEG C for 3-5h to completely react and crystallize. According to the preparation method, by adjusting the power of the two targets to control the compositions of the thin film, the problem of the one-target sputtering method that the ratio of Cu to Al can not be accurately controlled to be 1:1 so as to generate various oxides is solved; and the two-step annealing mode is adopted to avoid the loss of the related copper oxides caused by direct high-temperature annealing, thus the quality of the thin film can be increased.

Owner:JILIN UNIV

A kind of low-temperature preparation method of delafossite structure cufeo2 crystal material

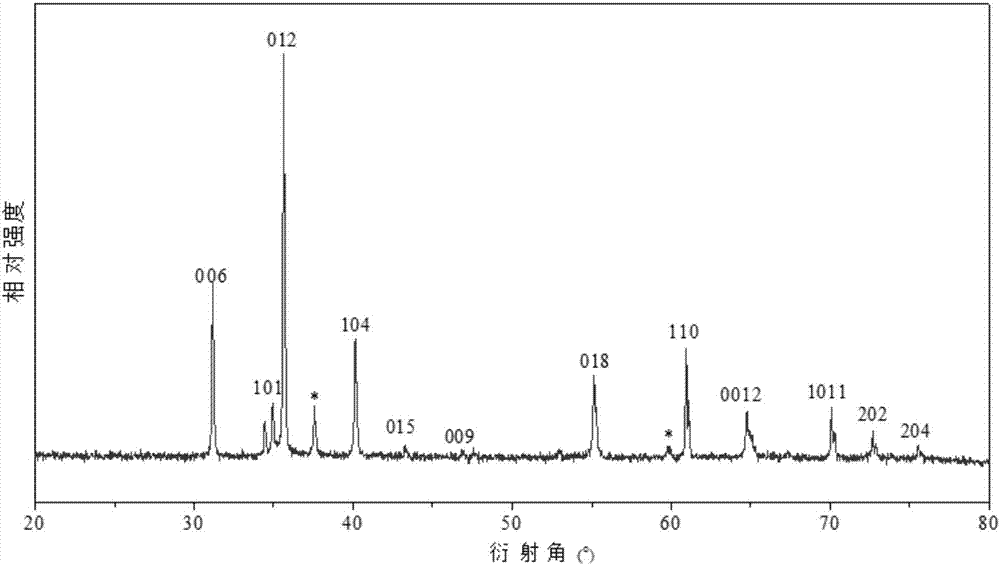

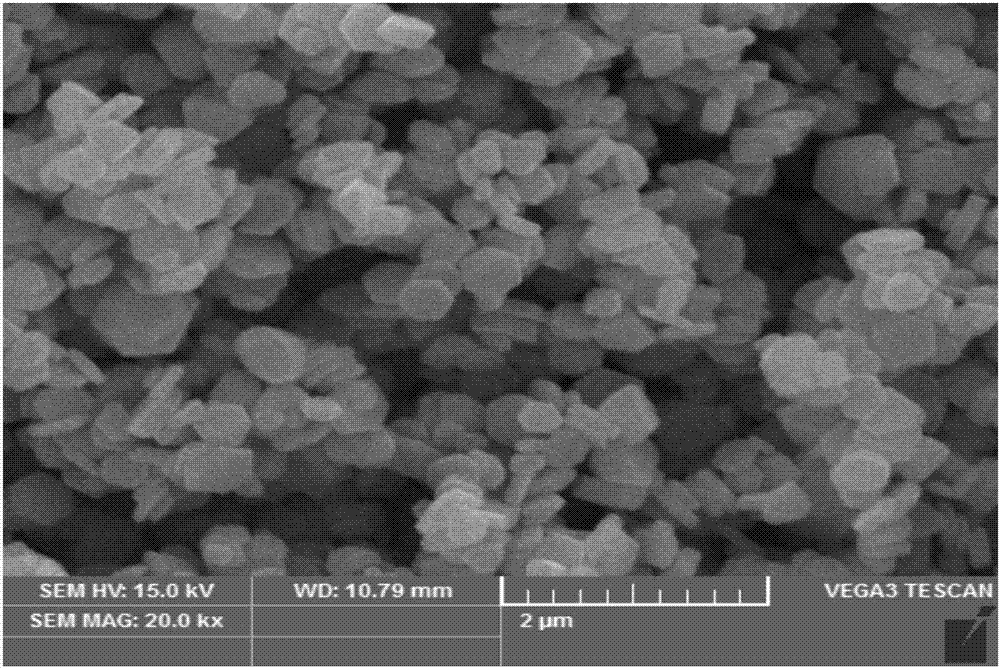

ActiveCN104058461BSimple preparation processProcess parameters are easy to controlMaterial nanotechnologyIron compoundsDelafossiteReaction temperature

The invention discloses a low-temperature preparation method for a CuFeO2 crystal material of a delafossite structure, in particular to a low-temperature hydrothermal synthesis method for rapidly preparing the CuFeO2 nanocrystalline material of the delafossite structure. The method comprises the steps that parameters including reaction precursor components, the reaction temperature and the filling rate of a reaction solution in a hydrothermal reaction kettle are regulated and controlled through a low-temperature hydrothermal reaction, reactants including Cu(NO3)2 and FeCl2 react for 12 hours to 48 hours at the temperature ranging from 100 DEG C to 160 DEG C, and then, after a reaction product is processed through centrifugal cleaning and dried, the nanoscale CuFeO2 crystal material is obtained. The low-temperature preparation method for the CuFeO2 crystal material of the delafossite structure is easy to operate, the technological parameters are easy to control, no pollution is caused, the yield is high, and the method can be widely used for photoelectricity functional devices such as transparent conducting oxide.

Owner:WUHAN UNIV OF TECH

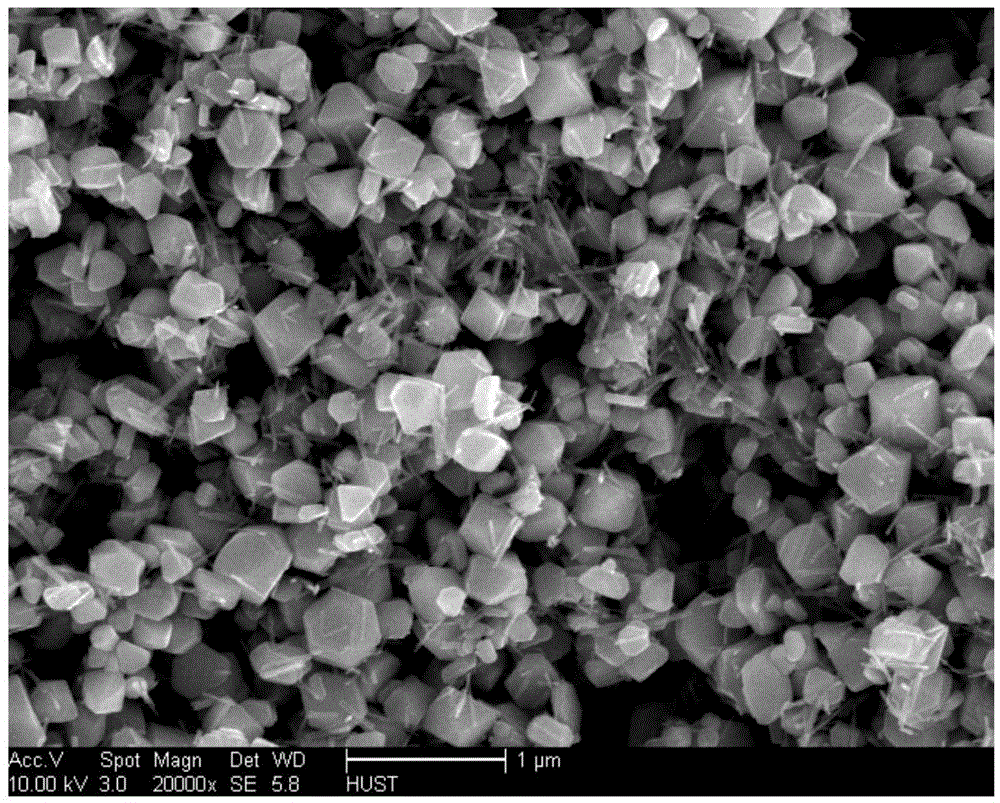

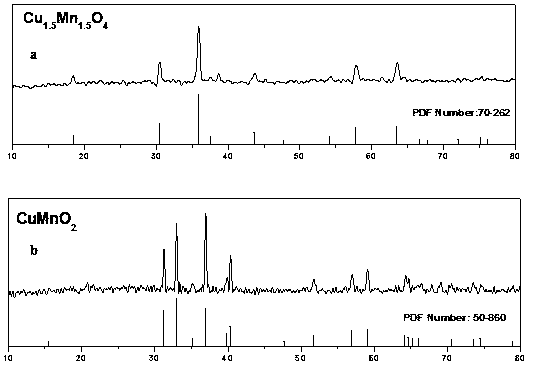

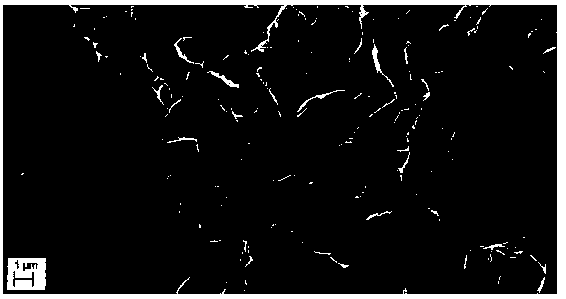

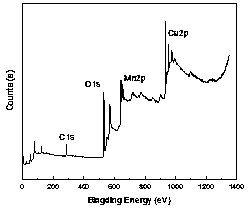

Delafossite structured CuMnO2 powder and preparation method and application thereof

ActiveCN108862395AHigh hole mobilityHigh photochemical stabilityMetal/metal-oxides/metal-hydroxide catalystsManganates/permanganatesAir atmosphereDelafossite

The invention relates to delafossite structured CuMnO2 powder and a preparation method and application thereof. The preparation method comprises the following steps: S1, dissolving divalent copper salt and divalent manganese salt, adding citric acid and PEG, stirring for dissolving, and adjusting the PH value to 2 to 3 with NH3.H2O, so as to obtain a reaction precursor; and S2, drying the reactionprecursor, grinding into powder, and performing annealing treatment in the process of heating to 900 to 1,200 DEG C at a heating rate of 5 to 15 DEG C per minute under an air atmosphere, maintainingthe temperature for 4 to 6 hours, then performing heat preservation at 1,000 to 1,200 DEG C for 2 to 4 hours under an inert atmosphere, and cooling. The preparation method provided by the invention has the advantages of short cycle and high purity, and is suitable for large-scale preparation and favorable to industrial production; and the CuMnO2 powder has high hole mobility, good photochemical stability and high conduction band energy.

Owner:GUANGDONG UNIV OF TECH

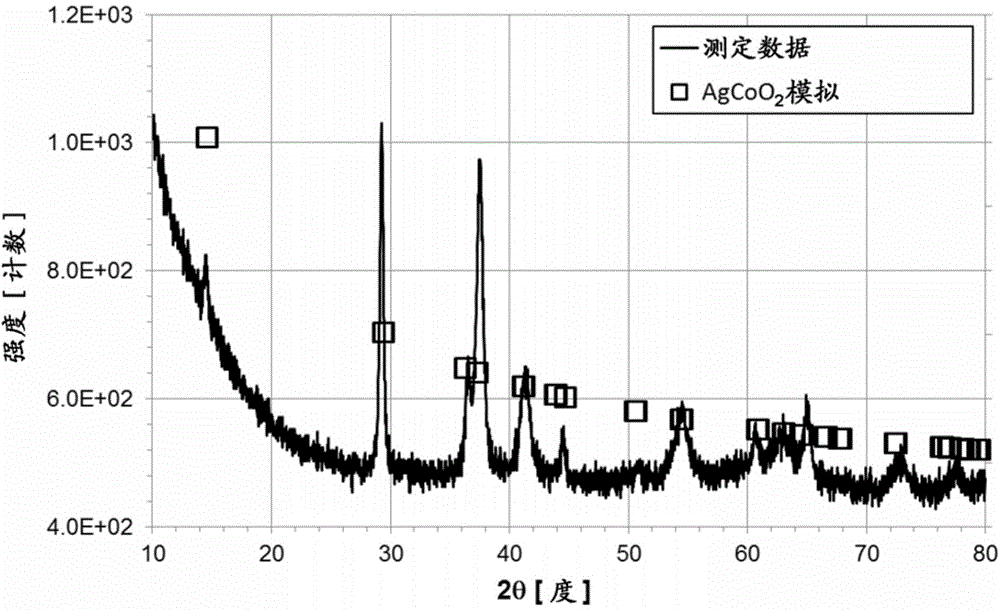

Method for generating oxygen, water electrolysis device and anode

The present invention provides a method for generating oxygen. The method comprises (a) preparing a water electrolysis device comprising a container storing an electrolyte aqueous solution; an anode which is in contact with the electrolyte aqueous solution and includes at least one silver delafossite compound selected from the group consisting of a silver cobalt delafossite compound represented by a chemical formula AgCoO 2 and a silver rhodium delafossite compound represented by a chemical formula AgRhO 2 ; a cathode which is in contact with the electrolyte aqueous solution; and a power supply, wherein the at least one silver delafossite compound is in contact with the electrolyte aqueous solution, and (b) applying an electric potential difference between the cathode and the anode using the power supply to generate oxygen on the anode due to electrolysis of water which occurs on the at least one silver delafossite compound.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

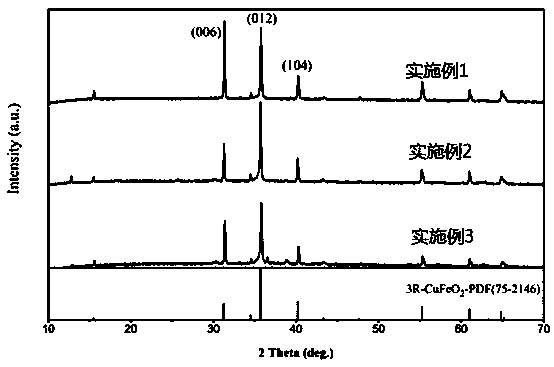

Preparation method of CuFeO2 microcrystalline material of high-purity 3R delafossite structure

InactiveCN110395769ASimple preparation processProcess parameters are easy to controlHydrogen productionIron compoundsDissolutionHydrogen production

The invention discloses a preparation method of a CuFeO2 microcrystalline material of a high-purity 3R delafossite structure. The preparation method comprises the steps: adding Cu(NO3)2.3H2O and Fe(NO3)3.9H2O into deionized water, performing magnetic stirring for dissolution so as to obtain a mixed solution, adding a NaOH solution dropwise to the mixed solution, then performing ultrasonic stirringand magnetic stirring sequentially, then adding n-propionaldehyde dropwise, keeping magnetic stirring until formation of a colloidal suspension, adding the colloidal suspension to a reaction vessel,performing a reaction at 100-180 DEG C for 6-24 h, cooling the kettle body naturally to room temperature after completion of the reaction, opening the kettle body, taking out the reaction product, washing the reaction product, and performing drying so as to obtain the CuFeO2 microcrystalline material of a high-purity 3R delafossite structure. The preparation method has simple operation and easilycontrollable process parameters, no pollution, high yield, completely developed grains and uniformly distributed particle size are achieved, the product can be widely applied to photocatalytic decomposition of water for hydrogen production, degradation of pollutants, photocatalytic reduction of CO2, transparent conductive oxides and ferromagnetic materials and other materials and devices with photoelectric conversion functions.

Owner:KUNMING UNIV OF SCI & TECH

Method for generating oxygen, and water electrolysis device

The present invention provides a method for generating oxygen. The method comprises (a) preparing a water electrolysis device comprising a container storing an electrolyte aqueous solution; an anode which is in contact with the electrolyte aqueous solution and includes at least one silver delafossite compound selected from the group consisting of a silver cobalt delafossite compound represented by a chemical formula AgCoO2 and a silver rhodium delafossite compound represented by a chemical formula AgRhO2; a cathode which is in contact with the electrolyte aqueous solution; and a power supply, wherein the at least one silver delafossite compound is in contact with the electrolyte aqueous solution, and (b) applying an electric potential difference between the cathode and the anode using the power supply to generate oxygen on the anode due to electrolysis of water which occurs on the at least one silver delafossite compound.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Method for generating oxygen and water electrolysis device

The present invention provides a method for efficiently generating oxygen by electrolyzing water using a copper delafossite compound as an anode. First, in the present invention, a water electrolysis device is prepared. The water electrolysis device comprises container, a power supply, an anode, a cathode; and an aqueous electrolytic solution. The anode and the cathode are in contact with the aqueous electrolytic solution. The anode has a copper rhodium delafossite compound represented by a chemical formula CuRhO2. The copper rhodium delafossite compound is in contact with the aqueous electrolytic solution. Then, an electric potential difference is applied between the cathode and the anode using the power supply to generate oxygen on the anode due to electrolysis of water which occurs on the copper rhodium delafossite compound.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

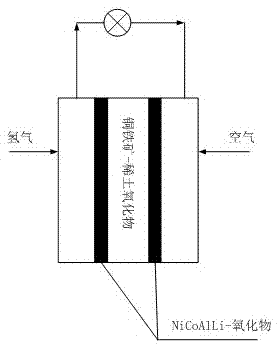

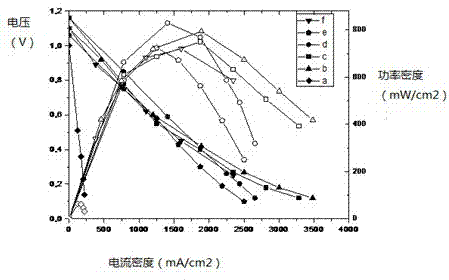

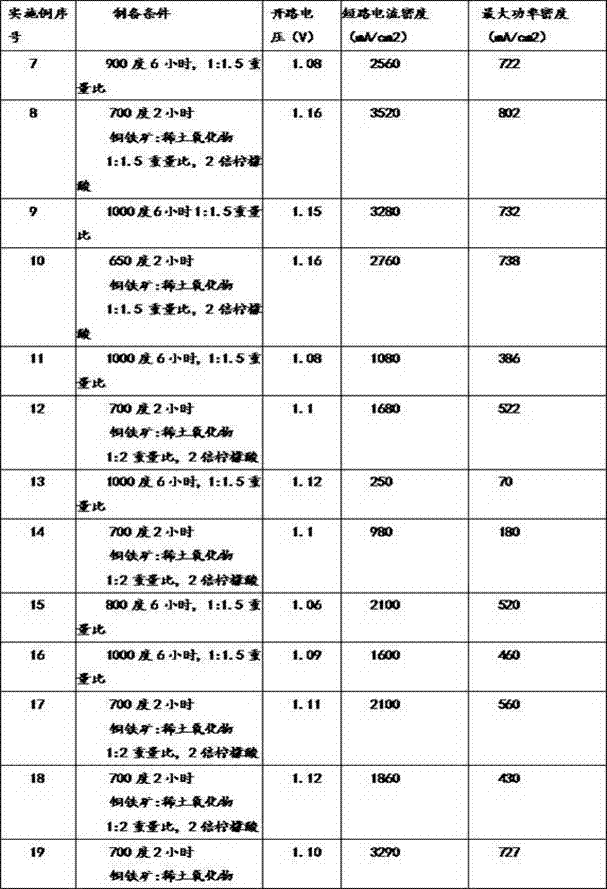

Delafossite oxide, low-temperature fuel cell material and preparation method

PendingCN107204473AAvoid chemistryAvoid featuresOxygen/ozone/oxide/hydroxideFuel cell detailsFuel cellsDelafossite

The invention discloses delafossite oxide, a low-temperature fuel cell material and a preparation method. The delafossite oxide is CuM1-xAxO2, 0x0.3 or is compounded proportionally by one and more than one of the above materials, M is trivalent metal ion of B, Y, Cr, Al, Fe, La or In, and A is plus-divalent metal ion of Mg, Ca, Ni, Sr and Zn. A composite material of the delafossite oxide and rare earth oxide is used for the low-temperature oxide fuel cell for the first time. In a temperature interval from 300 DEG C to 600 DEG C, a cell successfully demonstrates and outputs current density of KmA and power density reaching more than 800mw (550C). A new path is provided for developing new-generation commercial efficient fuel cell products.

Owner:NANJING YUNNA NANO TECH

Room temperature ammonia gas sensor using p-type delafossite structure oxide as sensitive material, and preparation method thereof

ActiveCN108680609ASimple preparation processEasy to operateMaterial resistanceResistive sensorsHigh selectivity

The invention discloses a room temperature ammonia gas sensor using a p-type delafossite structure oxide as a sensitive material, and a preparation method thereof. According to the present invention,the resistive room temperature ammonia gas sensor with excellent performance is constructed by using the p-type delafossite structure AgAlO2 as the sensitive material of the ammonia gas sensor; by completely utilizing the advantages of high sensitivity, low cost, simple device, easy integration and easy on-site continuous detection of the semiconductor resistor type sensing material and the characteristic of high selectivity of AgAlO2 to ammonia gas at a room temperature, the resistive sensor with characteristics of working at a room temperature, sensitive response to ammonia gas (the detection lower limit can reach 1000000-level), good selectivity, good stability, economy and environmental protection can be constructed, the good sensitive material is provided for ammonia sensors, and thenew application field is provided for P-type wide band gap delafossite structure oxides.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Method for quickly preparing single-phase delafossite structure CuFeO2 microcrystalline material

InactiveCN110436526AAvoid accuracyTo avoid deviations from its actual valueIron compoundsFilling rateParticle-size distribution

The invention discloses a method for quickly preparing a single-phase delafossite structure CuFeO2 microcrystalline material. The method comprises the steps that Cu(NO3)<2>.3H2O and Fe(NO3)<3>.9H2O are added into deionized water according to the mole ratio of 1:1, magnetic stirring for dissolving is conducted, and thus a mixed solution is obtained; a NaOH solution is dropwise added into the mixedsolution drop by drop, and then ultrasonic stirring and magnetic stirring are conducted in sequence; n-propanal is added into the solution dropwise, and then magnetic stirring is continued till colloidal suspension is formed; and the colloidal suspension is added into a microwave digestion tank, the filling rate of the colloidal suspension is 10-35%, microwave heating is conducted after sealing, after reaction is completed, a reaction product is naturally cooled to the room temperature, the microwave digestion tank is opened to take the reaction product out, and the reaction product is washedand dried to obtain the single-phase delafossite structure CuFeO2 microcrystalline material. According to the method, the reaction time is extremely short, energy consumption is less, operation is easy, technological parameters are easy to control, pollution is avoided, the yield is high, grains are developed completely, particle size distribution is even, and the single-phase delafossite structure CuFeO2 microcrystalline material can be widely applied to the fields of photocatalysis, photovoltaics, transparent conductive oxide, ferroelectric and the like.

Owner:KUNMING UNIV OF SCI & TECH

Exhaust gas purification catalyst

ActiveUS20190336949A1Improve performanceImprove exhaust gas purification performanceInternal combustion piston enginesExhaust apparatusDelafossiteExhaust fumes

Provided is a novel exhaust gas purification catalyst, which uses a Cu-based delafossite oxide, capable of increasing the exhaust gas purification performance compared to the case of using the Cu-based delafossite oxide alone. Proposed is an exhaust gas purification catalyst comprising a delafossite-type oxide represented by a general formula ABO2 and an inorganic porous material, wherein Cu is contained in the A site of the general formula of the delafossite oxide, one or two or more elements selected from the group consisting of Mn, Al, Cr, Ga, Fe, Co, Ni, In, La, Nd, Sm, Eu, Y, V, and Ti are contained in the B site thereof, and Cu is contained in 3 to 30% relative to the total content (mass) of the delafossite-type oxide and the inorganic porous material.

Owner:MITSUI MINING & SMELTING CO LTD

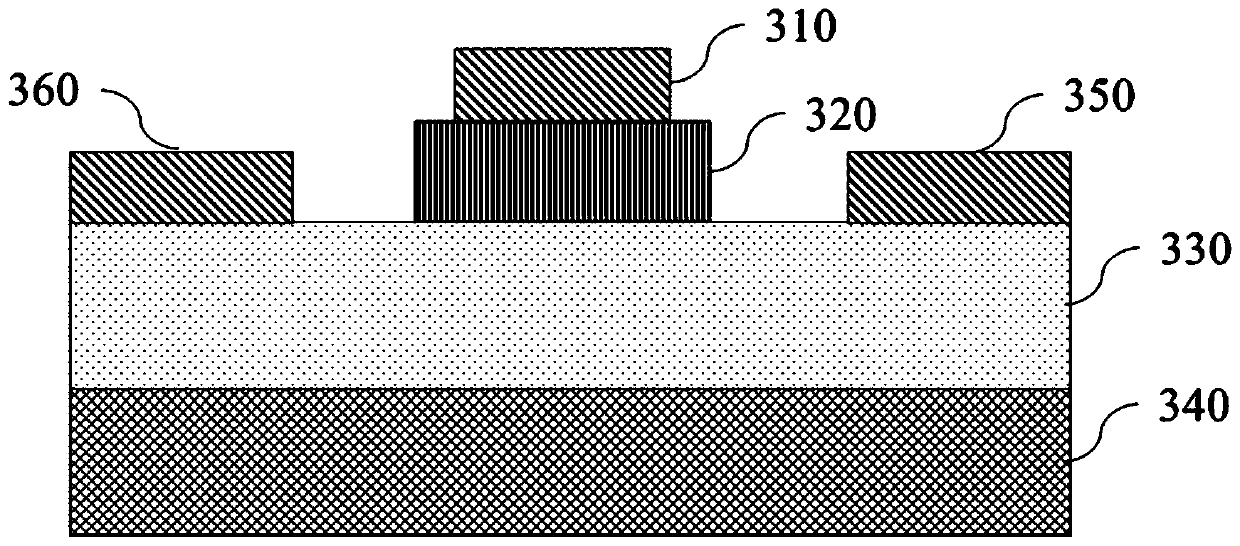

A planar structure perovskite solar cell based on p-type delafossite semiconductor material and its preparation

ActiveCN105679941BGood repeatabilityLow costFinal product manufactureSolid-state devicesSemiconductor materialsPerovskite (structure)

The invention relates to a planar structure perovskite solar cell and a preparation method thereof. The cell includes a hole transport layer and a light-harvesting layer; the light-harvesting layer is formed of an MXZ3 type perovskite material, wherein M is selected from Cs+, CH3NH3+, CH3CH2NH3+, CH(NH2)2+ or a mixture thereof, X is selected from Pb2+, Sn2+, Ge2+ or a mixture thereof, Z is selected from Cl-, Br-, I- or a mixture thereof; the hole transport layer is composed of p-type Doped or undoped ADO2 type semiconductor material of delafossite structure, wherein, A is selected from Cu or Ag, D is selected from one or more of Cr, Ga, Sc, In, Y or Fe, doped The heteroelement is selected from one or two of Mg, Ca, Sr or Ga. The thin film of the hole transport layer of the present invention has good electrical conductivity, suitable energy level position, high light transmittance and low cost, can obtain solar cell devices with excellent performance and stability, and is beneficial to the advancement of the industrialization of perovskite solar cells.

Owner:HANGZHOU ZHONGNENG PHOTOELECTRIC TECH CO LTD

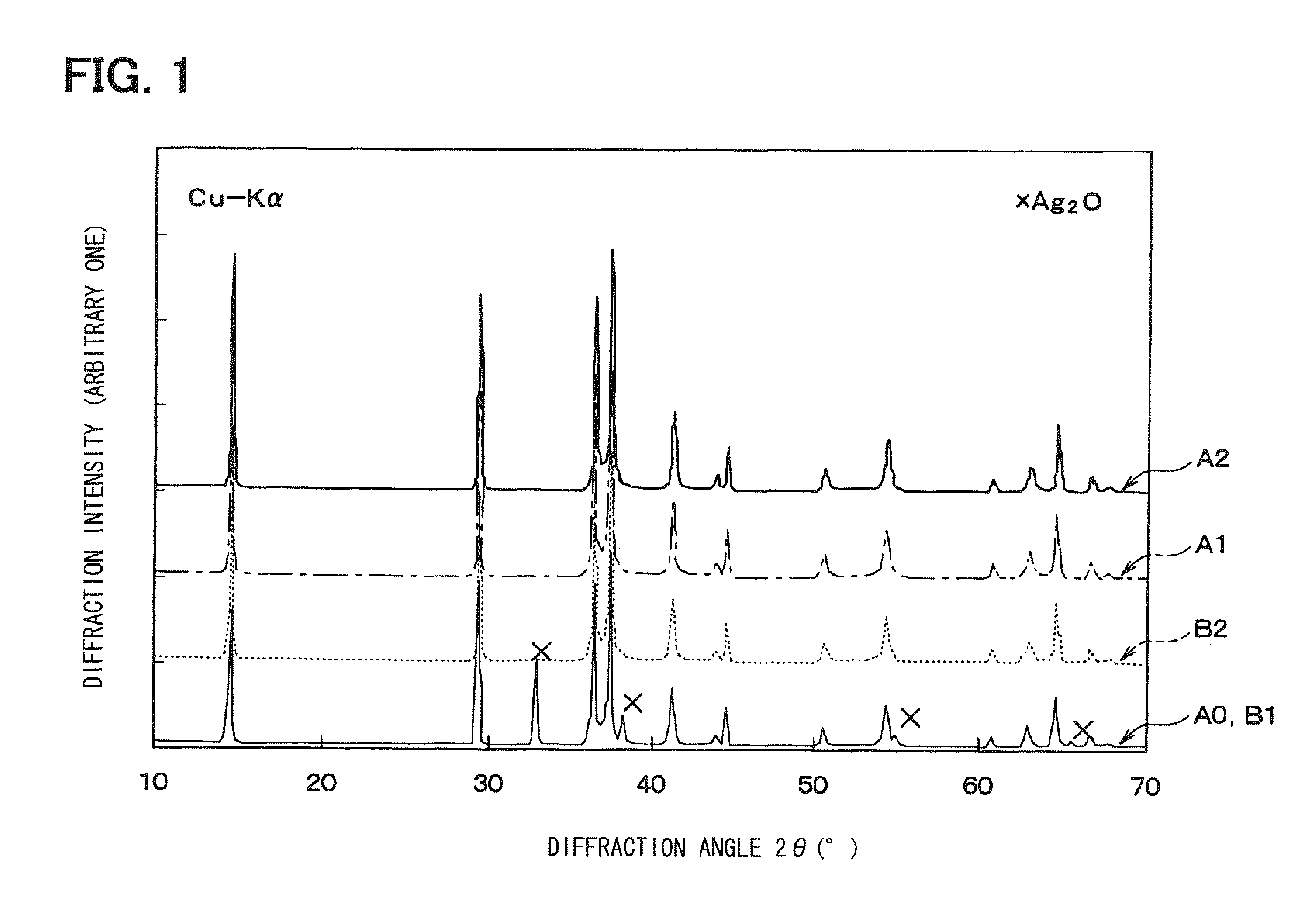

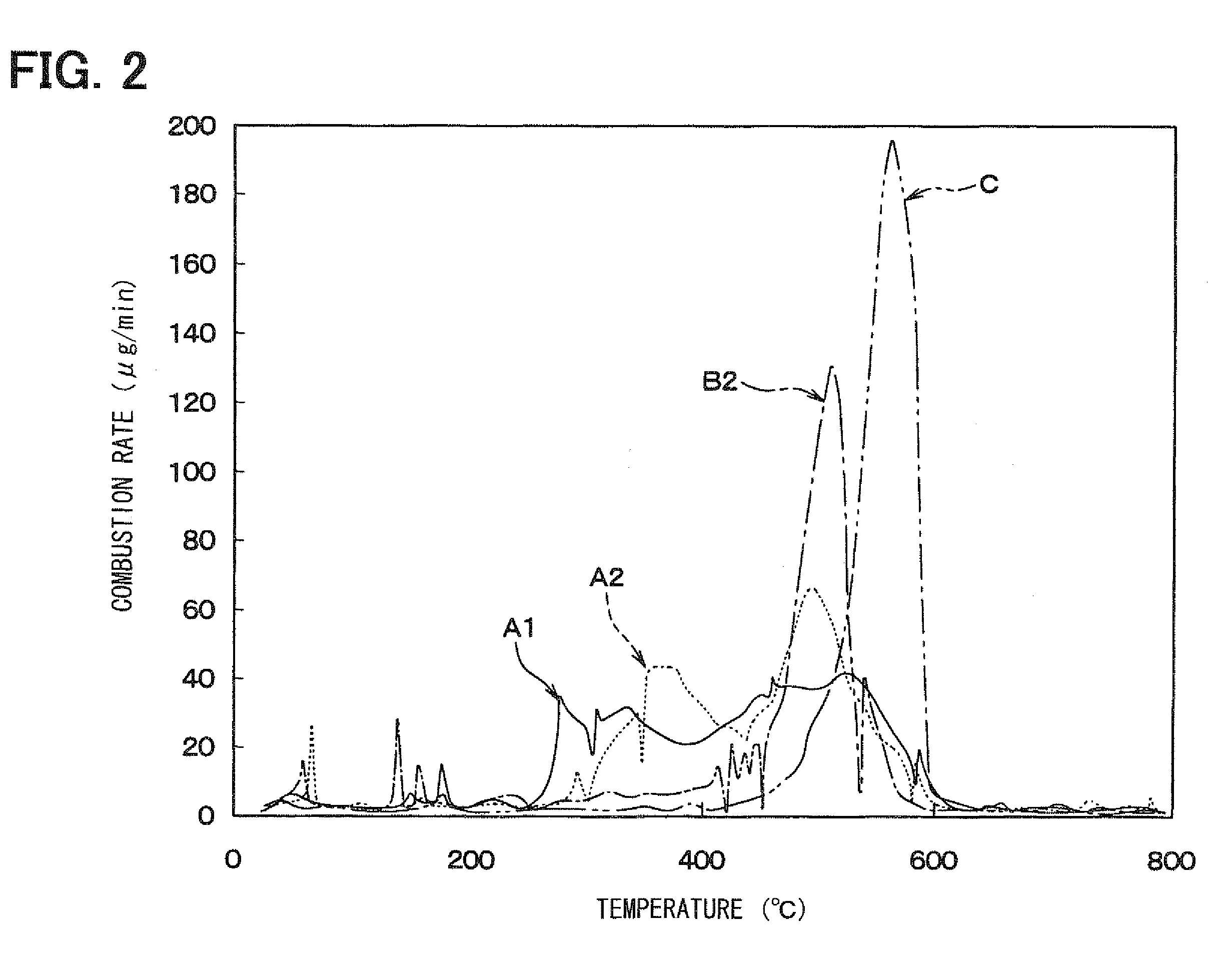

Method of manufacturing catalyst material

In a method of manufacturing a catalyst material to be used for burning carbon, a hydrothermal treatment is applied to NaAlO2 and Ag2O at a temperature of 150° C. or more to obtain delafossite-type AgAlO2 containing an Ag compound, and an excess amount of the Ag compound is removed by washing the delafossite-type AgAlO2 containing the Ag compound. As a result, a manufacturing method of a catalyst material that can burn soot at low temperature can be provided without corroding a honeycomb structure for supporting.

Owner:DENSO CORP

Method for preparing porous structure delafossite crystalline material

The invention discloses a method for preparing a porous structure delafossite crystal material. In the method, PEG is used as a template and mixed with a precursor solution containing Fe2+ and Cu2+, and then CuFeO2 is prepared by a hydrothermal method, and then calcined to remove PEG to form a porous Structure delafossite crystal material CuFeO2. The method of the invention is simple, the process is easy to control and the specific surface area of the product is large.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Delafossite structure material and preparation method thereof, and perovskite solar cell

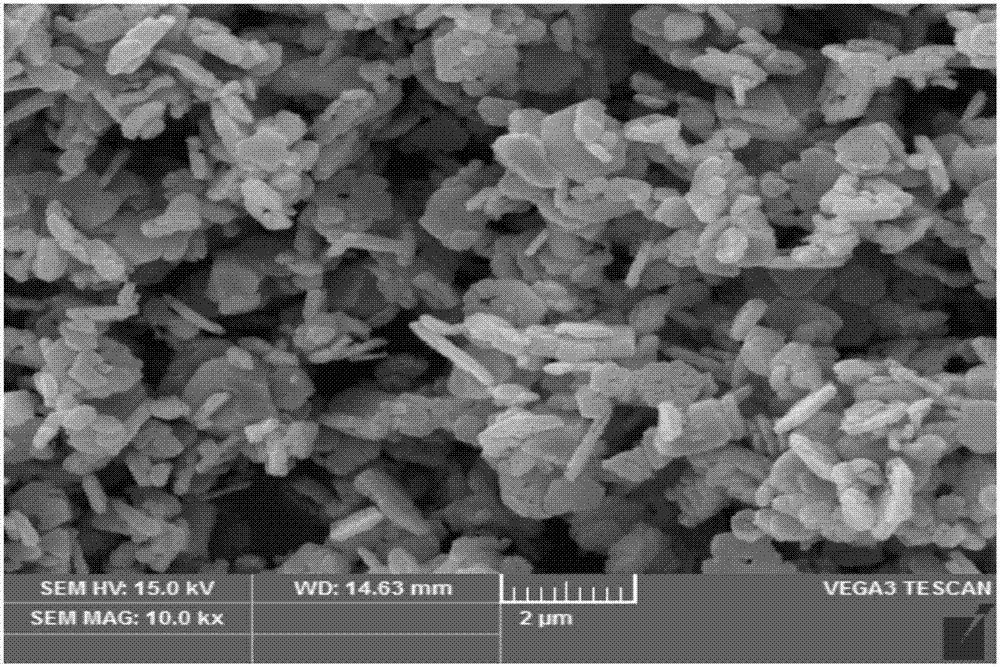

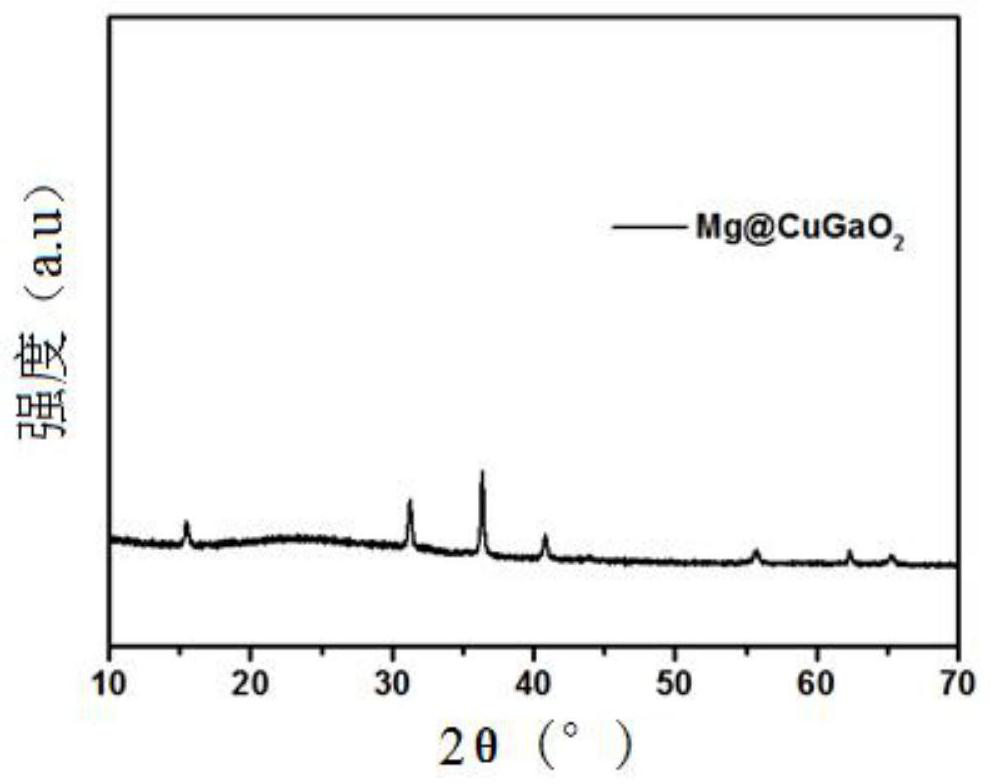

PendingCN111682112AImprove conductivityImprove thermal stabilityGallium/indium/thallium compoundsSolid-state devicesPerovskite solar cellDelafossite

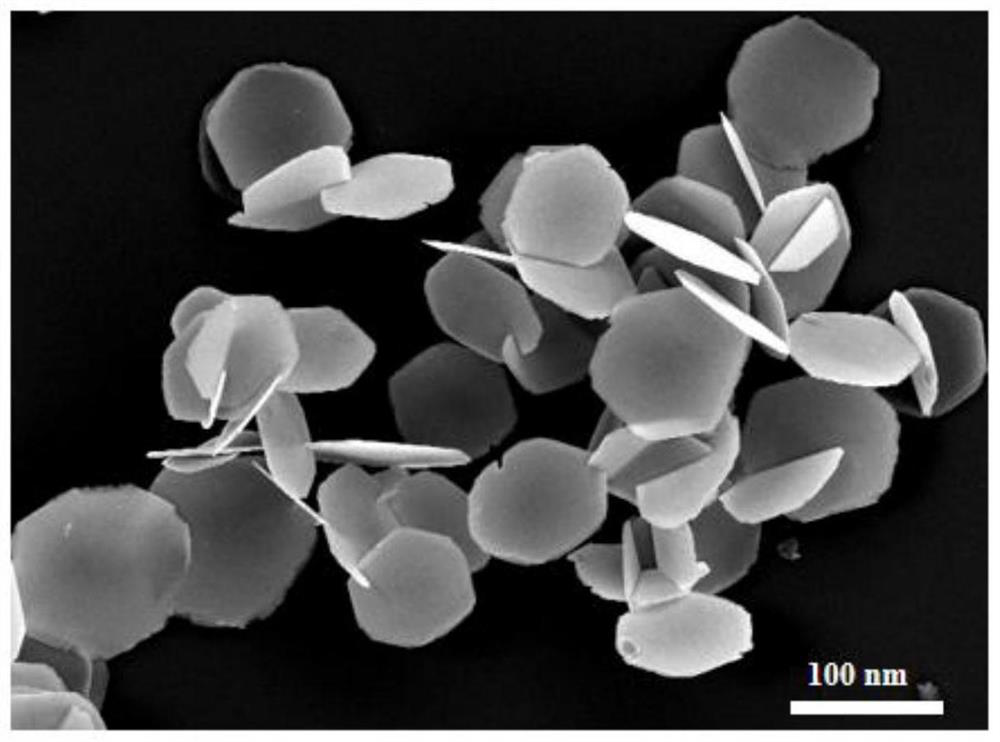

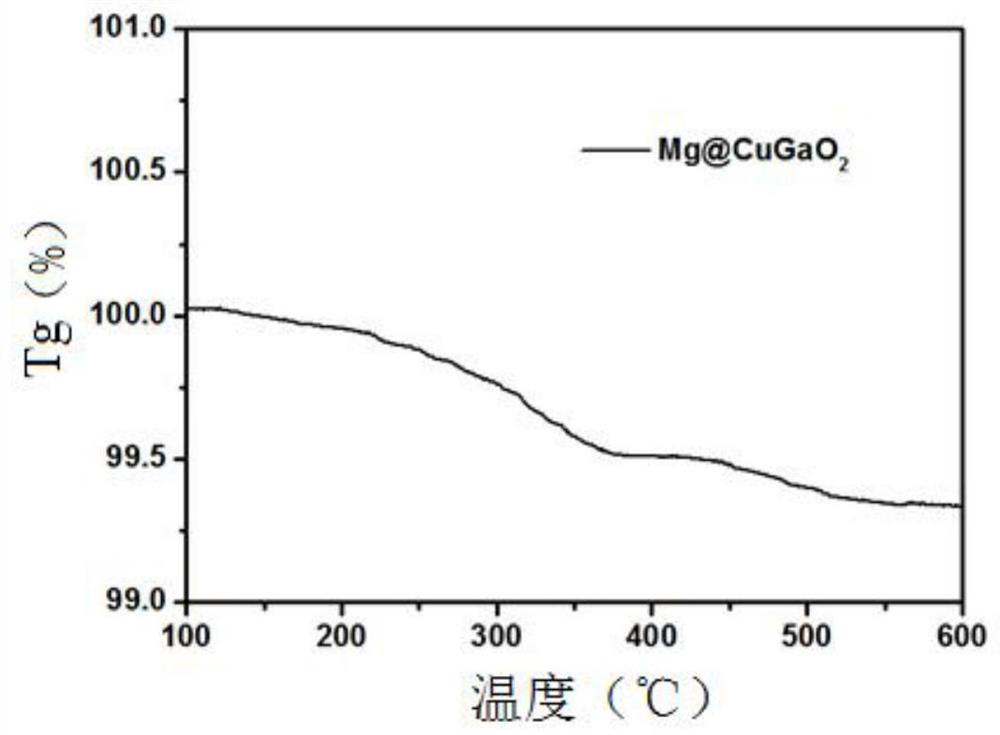

The invention discloses a delafossite structure material, a preparation method thereof and a perovskite solar cell. The delafossite structure material provided by the invention comprises Mg-doped CuGaO2, the delafossite structure material is in the shape of a wafer or a cylinder microscopically, the diameter of the delafossite structure material ranges from 3 nm to 100 nm, and the thickness of thedelafossite structure material ranges from 1 nm to 20 nm. The delafossite structure material can be further used as a hole transport layer to be applied to the perovskite solar cell. The hole transport layer can well solve the problem that the long-term stability of a formal perovskite solar cell is not satisfying. In addition, when the hole transport layer is applied to a trans-perovskite solarcell, the device efficiency of the trans-perovskite solar cell can be further improved.

Owner:SHENZHEN INST OF ADVANCED TECH

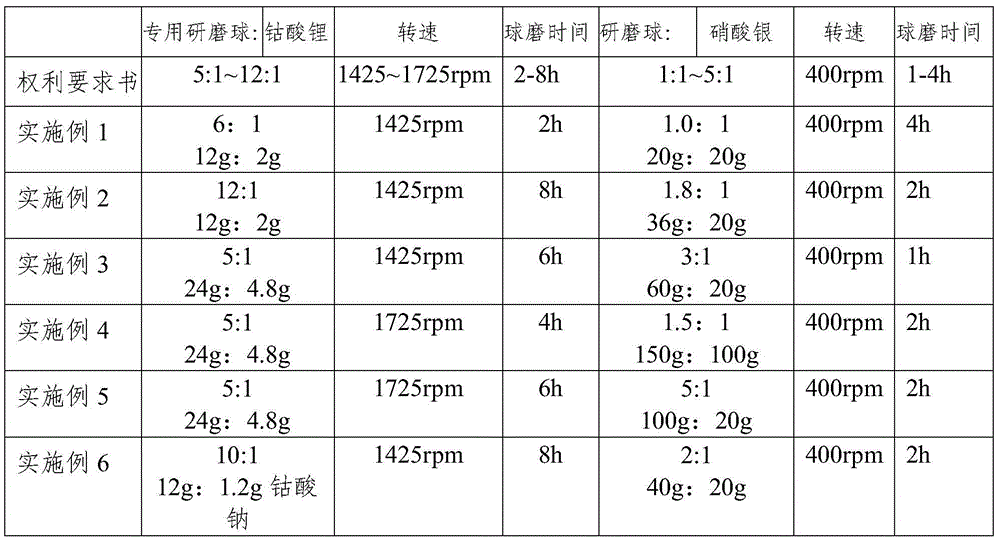

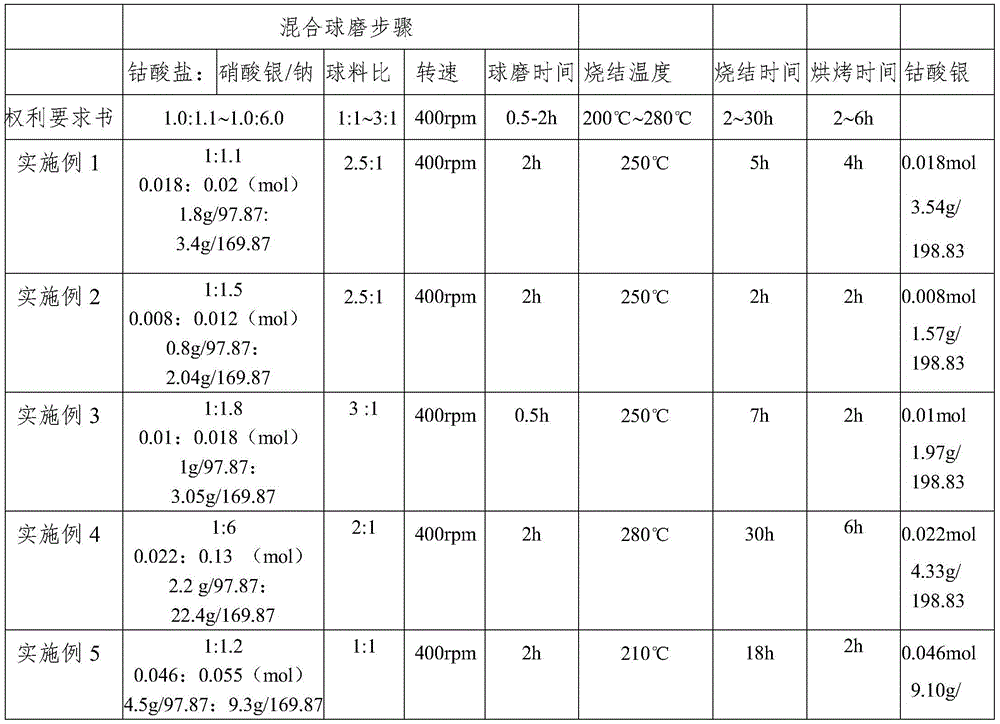

A method for preparing silver cobaltate polycrystalline powder with high single-phase delafossite structure

InactiveCN103601256BMild reaction conditionsReduce energy consumptionCobalt compoundsThermoelectric materialsElectron

The invention discloses a simple, fast and environmental-protection preparation method for preparing a high single-phase delafossite structure silver cobaltate polycrystalline powder. The method comprises the steps: firstly, respectively preprocessing cobaltate and a silver nitrate solid powder, then weighing the processed cobaltate and the processed silver nitrate solid powder according to a certain ratio and mixing, sintering the evenly mixed solid powder at the temperature of 200 DEG C-280 DEG C for 2-30 h, finally cleaning the sintered product with deionized water until the filtrate pH is 7.0, and baking the filter cake in an infrared box for 2-6 h to obtain the high single-phase delafossite structure silver cobaltate powder. The method requires no additives, and has the advantages of mild reaction conditions, low energy consumption, simple process, and convenient and safe operation. The prepared delafossite structure silver cobaltate polycrystalline powder can be widely used in the fields of electron devices, thermoelectric materials and the like, and has good economic benefits and social benefits.

Owner:INST OF ELECTRONICS ENG CHINA ACAD OF ENG PHYSICS

Heterojunction semiconductor structure based on gallium oxide and semiconductor device

ActiveCN111129122AImprove current carrying capacityAchieve matchingSemiconductor devicesHeterojunctionValence band

The invention discloses a heterojunction semiconductor structure based on gallium oxide, which structurally comprises at least one gallium oxide base layer and at least one delafossite layer, whereinthe gallium oxide base layer is provided with a plurality of contact surfaces; and the delafossite layer and the gallium oxide base layer form a heterojunction structure through the contact surfaces.By means of the structure, the matching of the forbidden bandwidth, the matching of the conduction band and the matching of the valence band are achieved, and the current transport capacity of the structure is improved; besides, the heterogeneous PN junction structure also realizes the matching of a crystal structure, avoids the formation of a large number of dislocation defects on the contact surface of the heterogeneous PN junction, and improves the forward transport performance of the PN junction, the on-resistance of a device adopting the structure and the performance stability of the device; and finally, the preparation process of the delafossite material is simple, the delafossite material can be directly formed by adopting a similar sol-gel method or a hydrothermal synthesis method,the preparation cost and process of the structure are greatly reduced, and large-scale industrial production is easy to realize.

Owner:合肥中科微电子创新中心有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com