Method for quickly preparing single-phase delafossite structure CuFeO2 microcrystalline material

A technology of microcrystalline materials and single-phase copper, applied in chemical instruments and methods, iron compounds, inorganic chemistry, etc., can solve the problems of limited material application and further development, inaccurate chemical properties, long reaction time, etc. The parameters are easy to control, the price is low, and the effect of a single output is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

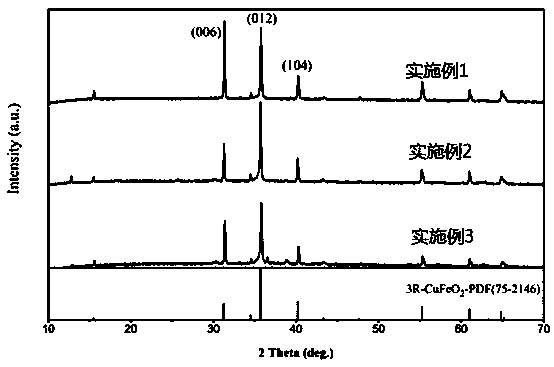

Embodiment 1

[0029] A rapid preparation of single-phase delafossite structure CuFeO 2 The method of microcrystalline material, concrete steps are as follows:

[0030] (1) Adding Cu(NO 3 ) 2 .3H 2 O and Fe(NO 3 ) 3 .9H 2 O is added into deionized water according to a molar ratio of 1:1, fully stirred in a magnetic stirrer for 10 min to dissolve, and the stirring speed of the magnetic stirrer is 450 rpm to obtain a mixed solution, in which Cu(NO 3 ) 2 The concentration is 0.8mol / L;

[0031] (2) Add NaOH solution dropwise to the mixed solution in step (1), the concentration of NaOH solution is 1.5mol / L, the dropping speed is 1.5mL / min, the amount of NaOH is according to Cu(NO 3 ) 2 .3H 2 O and Fe(NO 3 ) 3 .9H 2 10 times the amount of the total substance of O was added, followed by ultrasonication for 10min and magnetic stirring for 15min, the ultrasonic power was 400W, and the stirring speed of the magnetic stirrer was 400 rpm;

[0032] (3) Add n-propionaldehyde dropwise to the ...

Embodiment 2

[0035] A rapid preparation of single-phase delafossite structure CuFeO 2 The method of microcrystalline material, concrete steps are as follows:

[0036] (1) Adding Cu(NO 3 ) 2 .3H 2 O and Fe(NO 3 ) 3 .9H 2O is added into deionized water according to a molar ratio of 1:1, fully stirred in a magnetic stirrer for 15min to dissolve, and the stirring speed of the magnetic stirrer is 300 rpm to obtain a mixed solution, in which Cu(NO 3 ) 2 The concentration is 0.5mol / L;

[0037] (2) Add NaOH solution dropwise to the mixed solution in step (1), the concentration of NaOH solution is 4mol / L, the dropping rate is 2.5mL / min, the amount of NaOH is according to Cu(NO 3 ) 2 .3H 2 O and Fe(NO 3 ) 3 .9H 2 4 times the amount of the total substance of O was added, followed by ultrasonication for 15min and magnetic stirring for 10min, the ultrasonic power was 300W, and the stirring speed of the magnetic stirrer was 450 rpm;

[0038] (3) Add n-propionaldehyde dropwise to the soluti...

Embodiment 3

[0041] A rapid preparation of single-phase delafossite structure CuFeO 2 The method of microcrystalline material, concrete steps are as follows:

[0042] (1) Adding Cu(NO 3 ) 2 .3H 2 O and Fe(NO 3 ) 3 .9H 2 O is added into deionized water according to a molar ratio of 1:1, fully stirred in a magnetic stirrer for 12min to dissolve, and the stirring speed of the magnetic stirrer is 350 rpm to obtain a mixed solution, in which Cu(NO 3 ) 2 The concentration is 0.6mol / L;

[0043] (2) Add NaOH solution dropwise to the mixed solution in step (1), the concentration of NaOH solution is 2mol / L, the dropping rate is 2mL / min, the amount of NaOH is according to Cu(NO 3 ) 2 .3H 2 O and Fe(NO 3 ) 3 .9H 2 5 times of the amount of the total substance of O was added, followed by ultrasonication for 12min and magnetic stirring for 12min, the ultrasonic power was 350W, and the stirring speed of the magnetic stirrer was 350 rpm;

[0044] (3) After adding n-propionaldehyde dropwise to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com