Delafossite oxide, low-temperature fuel cell material and preparation method

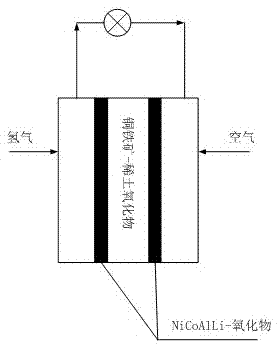

A fuel cell and oxide technology, applied in fuel cells, chemical instruments and methods, fuel cell components, etc., can solve the problem of not seeing single-component fuel cells, achieve broad development space and degrees of freedom, reduce manufacturing cost, effect of avoiding matching problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

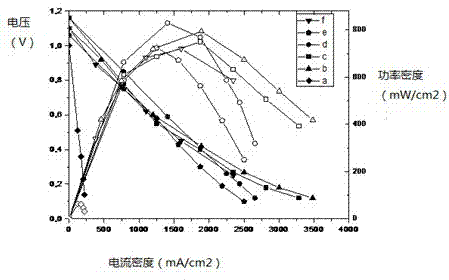

Examples

Embodiment 3

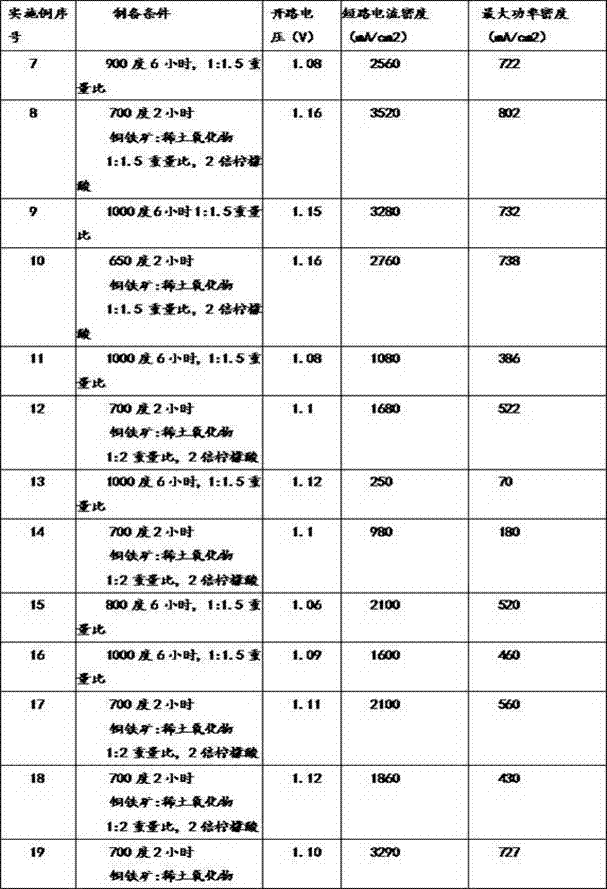

[0034] Example 3 Mix the oxides of Cu, Cr and Mg according to the molar ratio of Cu: Cr: Mg=1:0.97:0.03, and grind them evenly, and then grind them at 800-1300 o C calcined for 5-20 hours to obtain Cuacr 0.97 Mg 0.03 o 2 copper oxide.

[0035] Example 4 Mix the oxides of Cu, Y and Ca according to the molar ratio of Cu:Y:Ca=1:0.96:0.04, grind them evenly, and then grind them at 800-1300 o C calcined for 5-20 hours to obtain CuY 0.96 Ca 0.04 o 2 copper oxide.

[0036] implement 5 Mix the oxides of Cu, La and Y according to the molar ratio of Cu:La:Y=1:0.9:0.1, grind them evenly, and then grind them at 800-1300 o C calcined for 5-20 hours to obtain CuLa 0.9 Y 0.1 o 2 copper oxide.

[0037] implement 6Mix the oxides of Cu, Fe and Y according to the molar ratio of Cu:Fe:Y=1:0.9:0.1, grind them evenly, and then grind them at 800-1300 o C calcined for 5-20 hours to obtain CuLa 0.9 Y 0.1 o 2 copper oxide.

[0038] Further preparation of rare earth - Co...

Embodiment 8

[0040] Example 8 CuY 0.96 Ca 0.04 o 2 Mix with rare earth LCP-oxide in a weight ratio of 1-4, then add citric acid 1-4 times the weight of the two materials to make a slurry, and then mix it at 600-800 o C calcined for 1-6 hours. Prepared for use as a composite material.

Embodiment 9

[0041] Example 9 CuCr 0.97 Mg 0.03 o 2 Weigh and mix with rare earth LCP-oxide according to the weight ratio of 1-4, and grind evenly, then in 600-800 o C calcined for 1-6 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com