Method for improving wheat flour color

A wheat flour and pink technology, applied in grain processing, etc., can solve the problems of increasing the use of additives, using banned products, and harming the interests of consumers, so as to achieve the effects of reducing dietary hazards, low cost, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] In one embodiment of the present invention, 20 g of wheat flour is weighed and added to a 500 ml ball mill jar, 200 ball milling beads with a diameter of 6 mm, 100 balls with a diameter of 10 mm, and 5 balls with a diameter of 20 mm are selected and mixed evenly with the sample.

[0047] The ball mill adopts a planetary ball mill, which can accommodate 4 sets of ball mill tanks;

[0048] Put the ball mill jar with the sample into the planetary ball mill symmetrically and correctly, and set the machine operating parameters: the speed is 400r / min, the forward rotation is 5min, the reverse rotation is 5min, and the cycle is once.

[0049] After processing, the samples were taken out, sieved and sealed for storage.

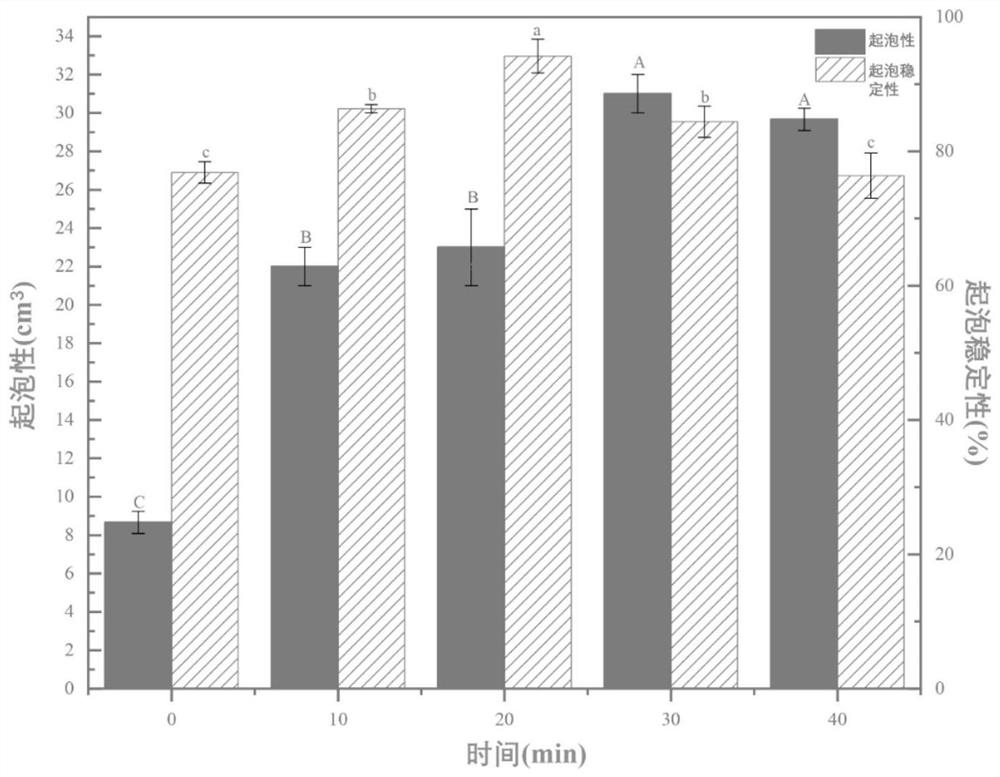

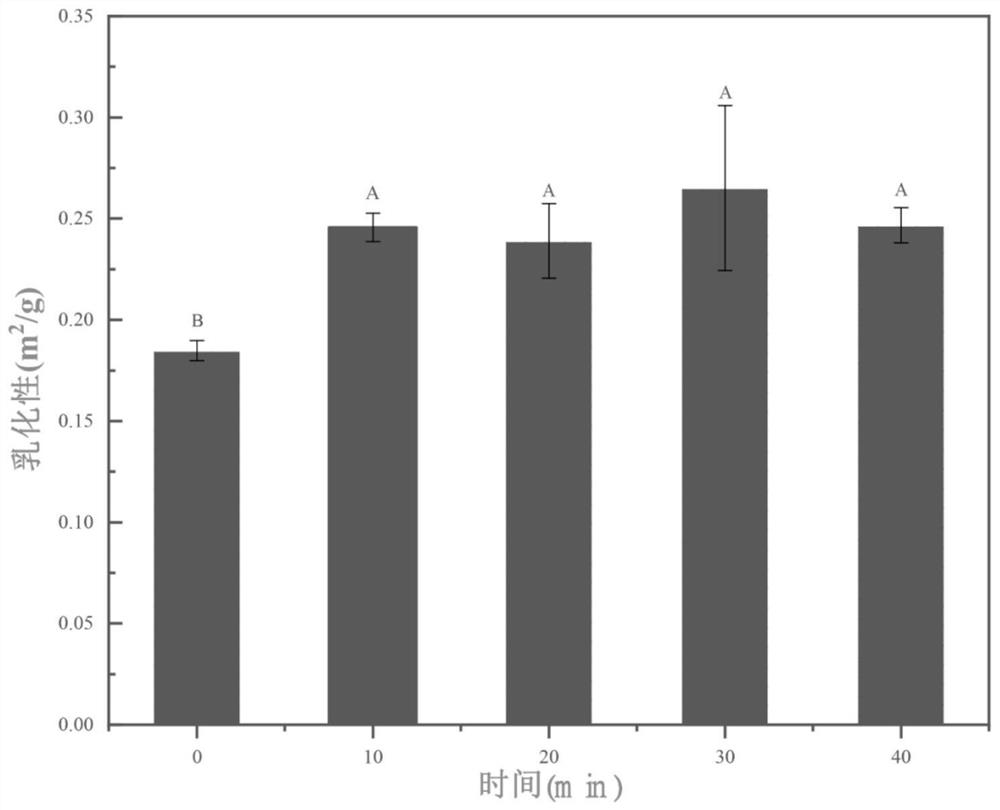

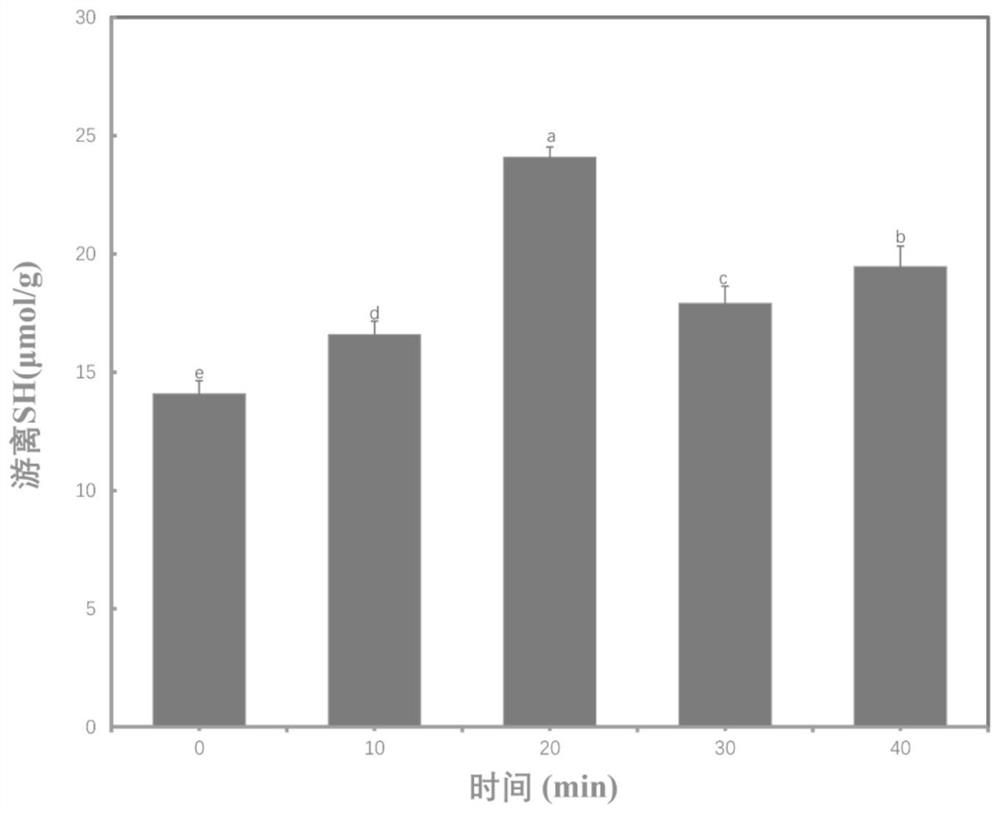

[0050]Some samples were taken to determine their structure and function. After one cycle, compared with the untreated sample, the free sulfhydryl groups in the sample treated for one cycle increased, and the corresponding emulsifying, foaming, and oil-absorbin...

Embodiment 2

[0052] In another embodiment of the present invention, 500 g of wheat flour is weighed and added to a 5 L ball milling jar, 1000 ball milling beads with a diameter of 6 mm, 500 balls with a diameter of 10 mm, and 25 balls with a diameter of 20 mm are selected and mixed with the sample evenly.

[0053] Put the ball mill jar with the sample into the planetary ball mill symmetrically and correctly, and set the machine operating parameters: the speed is 400r / min, the forward rotation is 5min, the reverse rotation is 5min, and the rotation time is two time units.

[0054] After processing, the samples were taken out, sieved and sealed for storage.

[0055] Some samples were taken to determine their structure and function. After the second cycle, compared with the untreated sample, the free mercapto groups in the sample treated for the second cycle increased significantly, and the corresponding foaming and oil absorption properties were also greatly improved, while the emulsificatio...

Embodiment 3

[0057] In yet another embodiment of the present invention, 20 g of wheat flour is weighed and added to a 500 ml ball mill jar, 200 ball milling beads with a diameter of 6 mm, 100 balls with a diameter of 10 mm, and 5 balls with a diameter of 20 mm are selected and mixed with the sample evenly.

[0058] Put the ball mill jar with the sample into the planetary ball mill symmetrically and correctly, and set the machine operating parameters: the speed is 400r / min, the forward rotation is 5min, the reverse rotation is 5min, and the rotation time is three time units.

[0059] After processing, the samples were taken out, sieved and sealed for storage.

[0060] Some samples were taken to determine their structure and function. After three cycles, compared with the untreated sample, the free sulfhydryl group in the sample treated for three cycles decreased, and the corresponding foaming property and oil absorption also tended to decrease, while the emulsifying property had a small ran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com