Patents

Literature

69results about How to "Does not affect filtering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

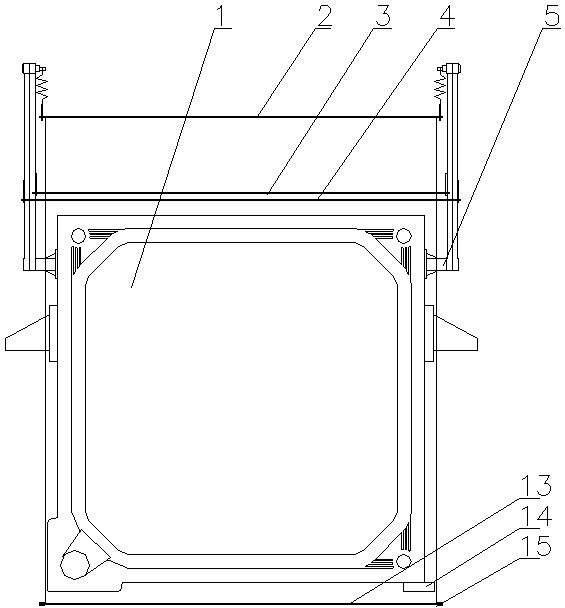

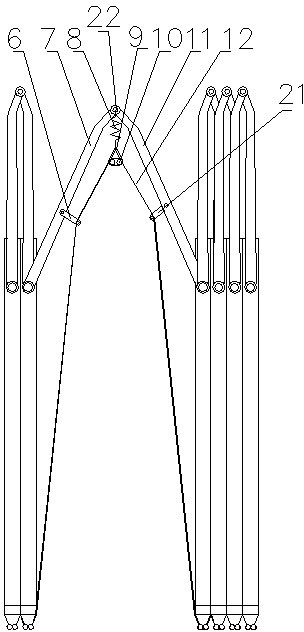

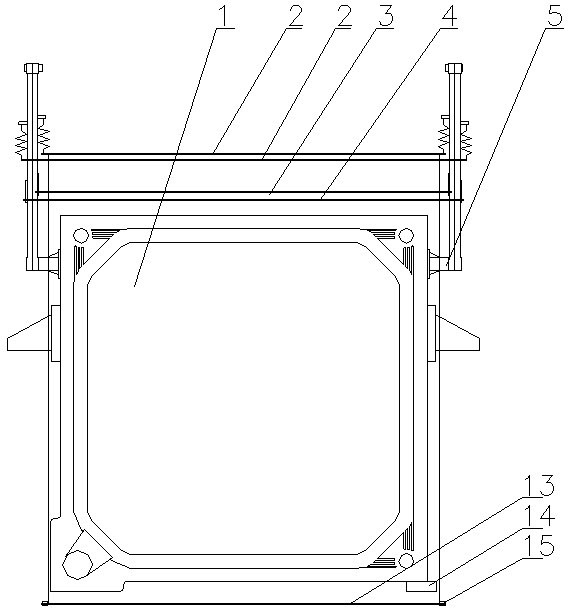

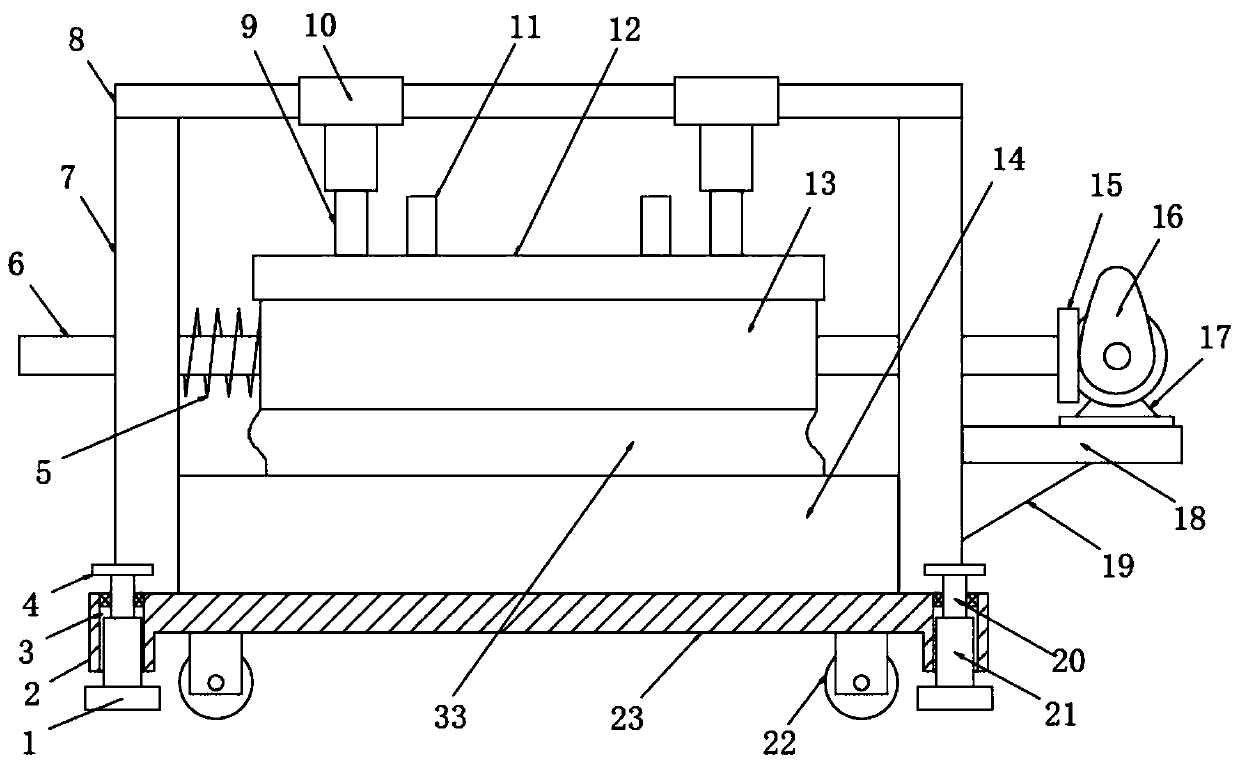

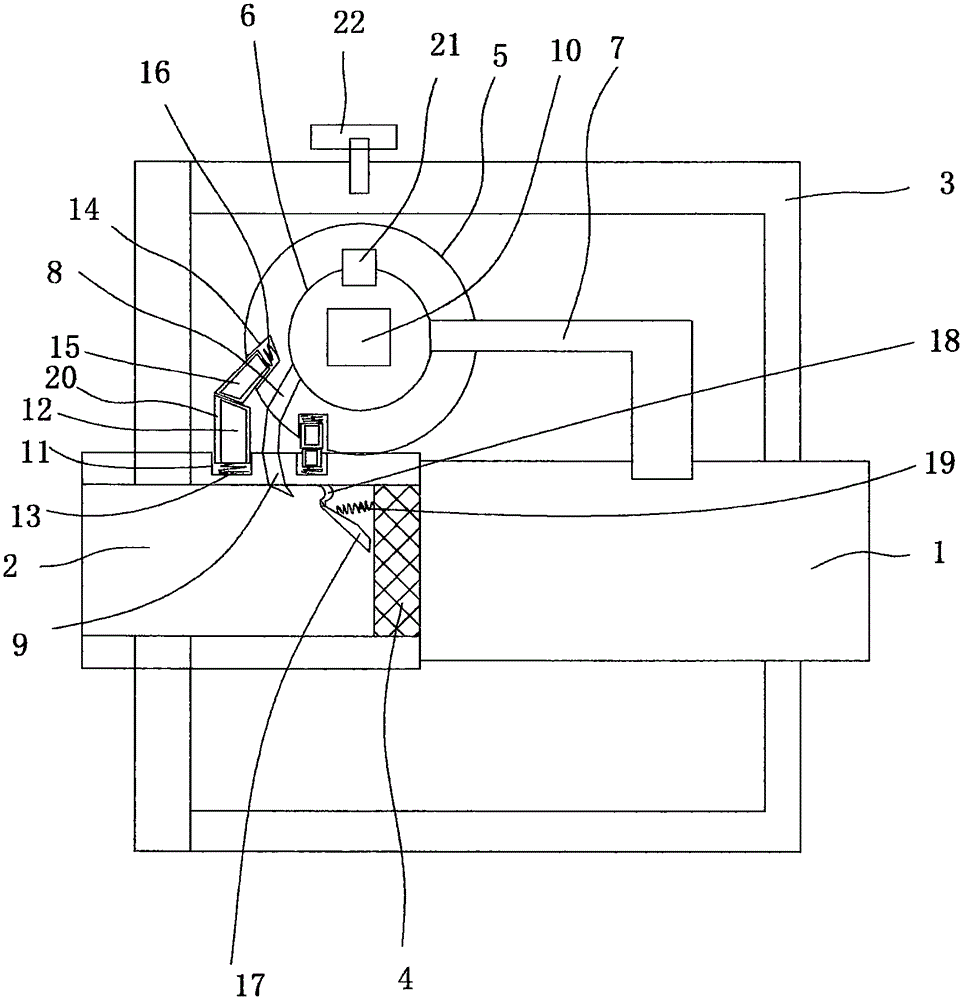

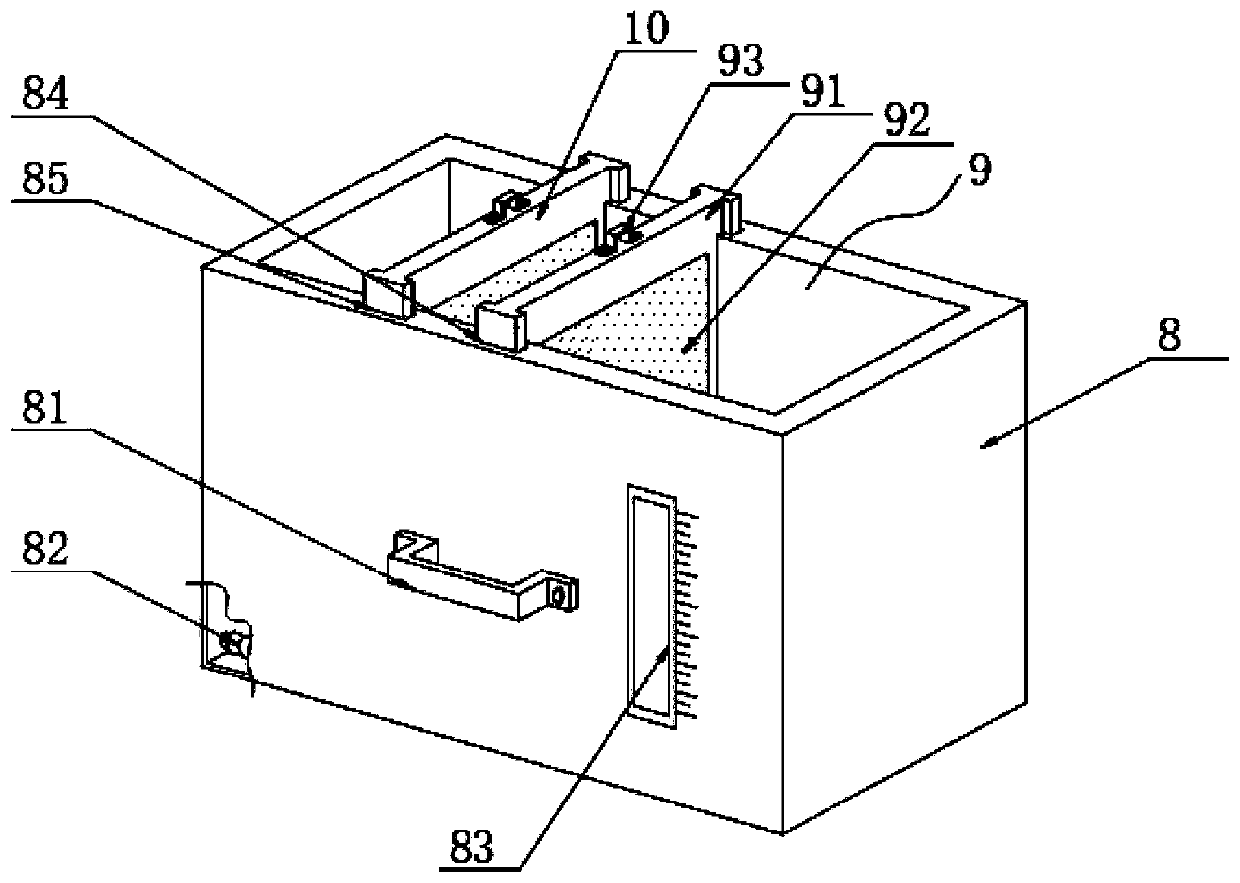

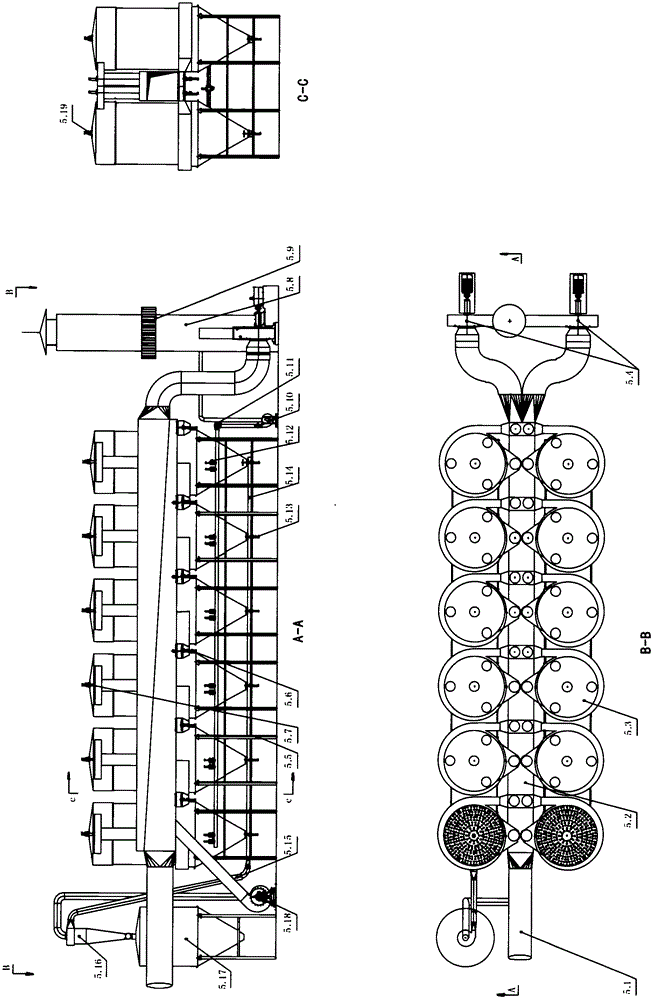

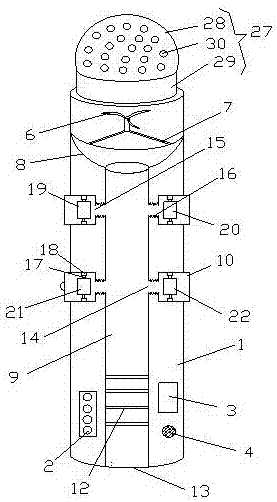

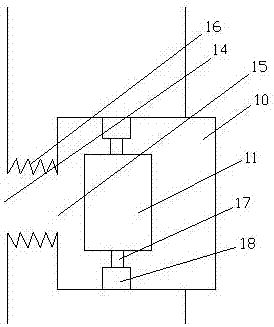

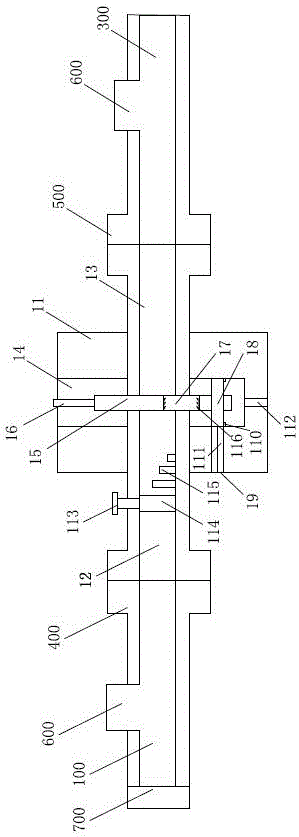

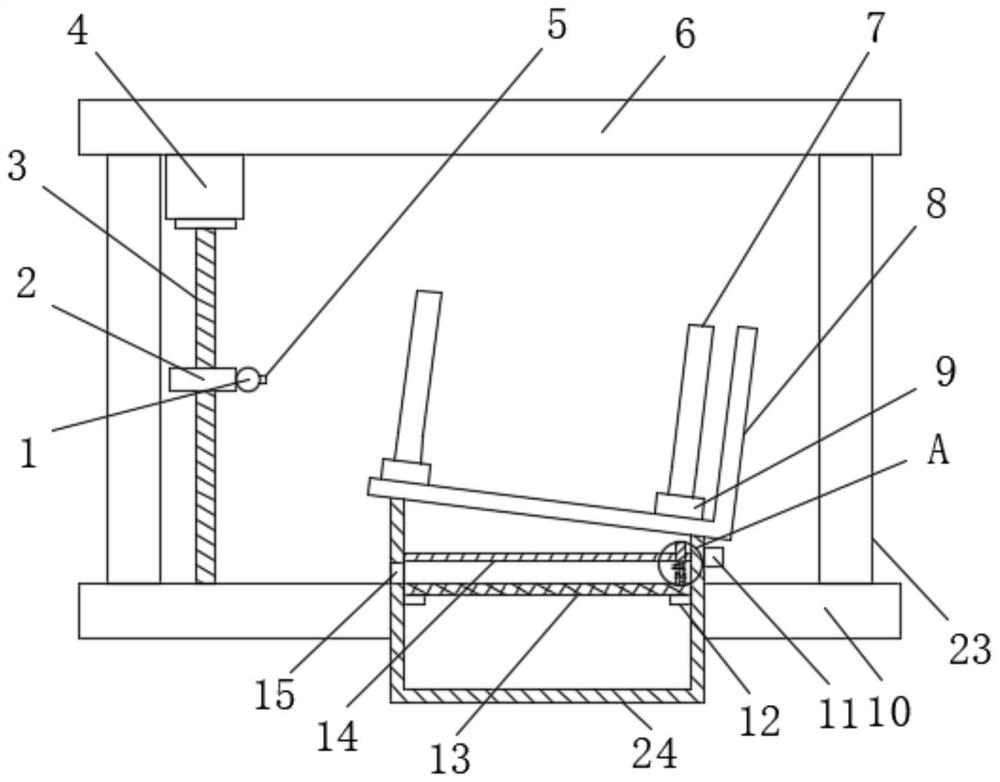

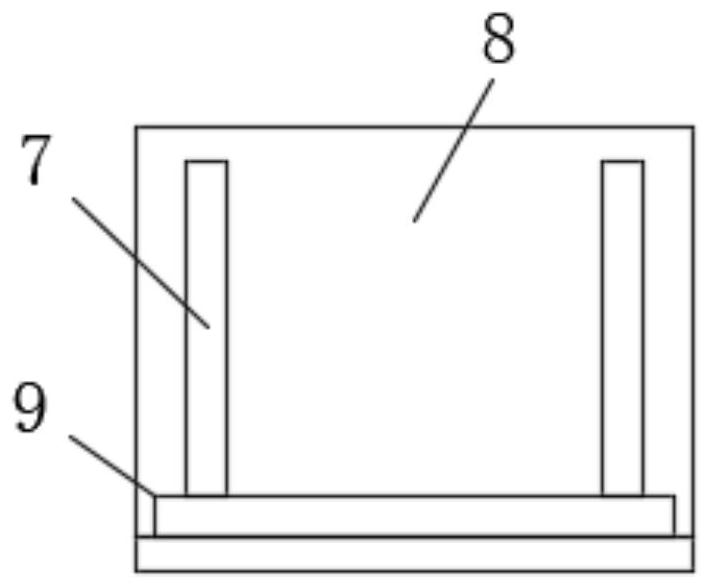

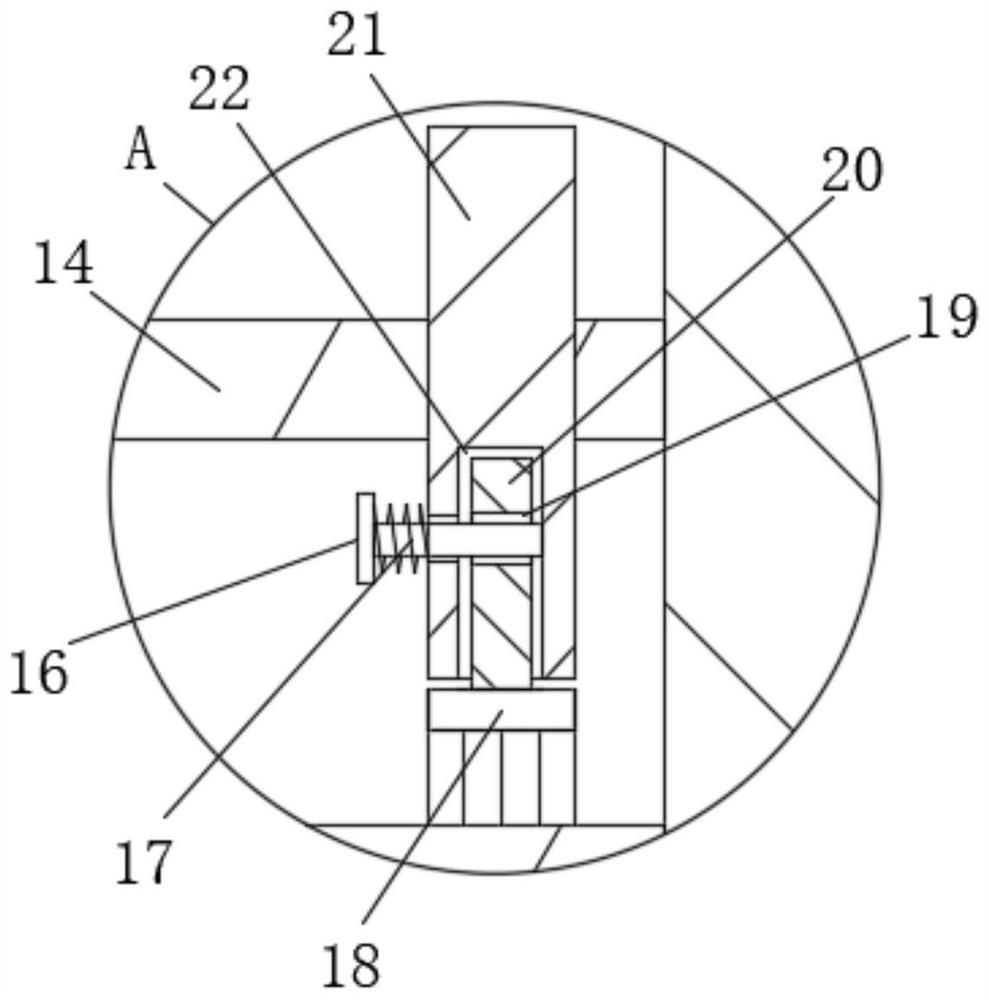

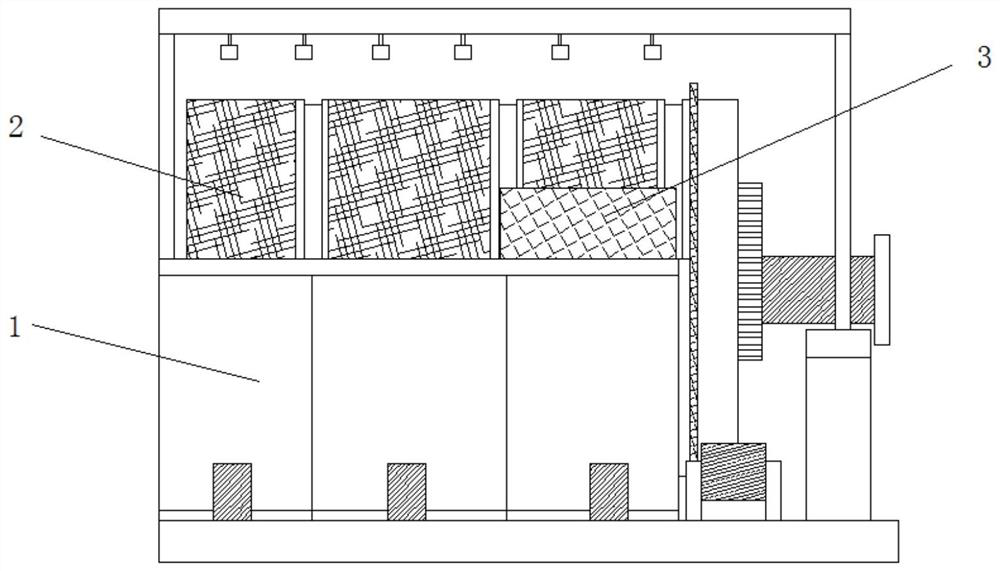

All crank unloading device for press filter

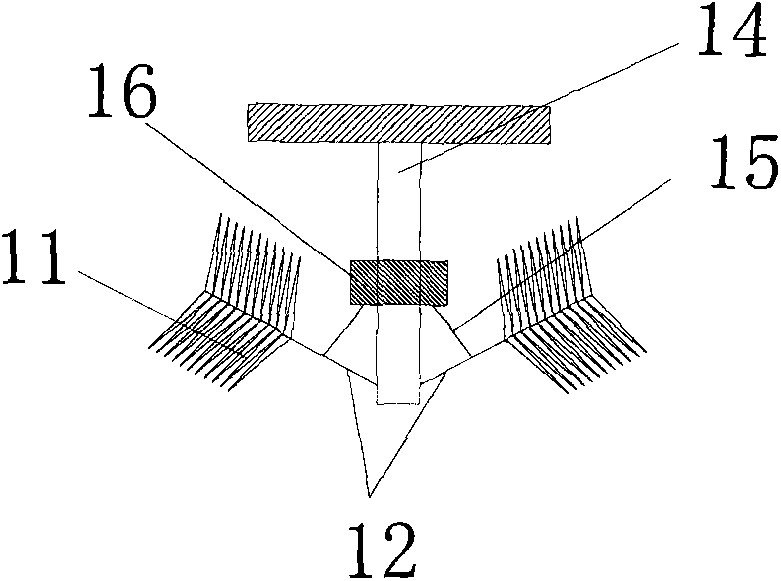

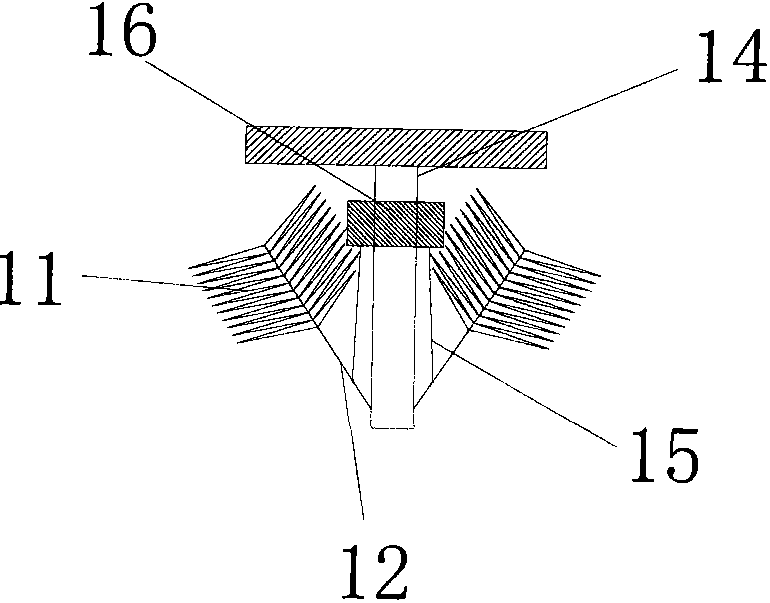

The invention relates to an all crank unloading device for press filter. At present, there is no all crank unloading device for press filter with reasonable structural design and reliable performance. The device comprises plural all crank unloading mechanisms. The all crank unloading mechanism includes two lower-corner feeding filter plates, two outer crank arms, two inner crank arms, two long cloth supporting swing plates, two short cloth supporting swing plates, a long cloth supporting roll, a short cloth supporting roll, two crank arm connection shafts, two pieces of lower-corner feeding filter cloth, two filter cloth sinker rods, two balance blocks, a sinker rod locking unit, and a suspension vibrating mechanism. One outer crank arm and one inner crank arm on the same side of the lower-corner feeding filter plate are connected via one crank arm connection shaft, the two filter cloth sinker rods are connected at the lower parts of the two pieces of lower-corner feeding filter cloth in a penetrating manner, and adjacent two filter cloth sinker rods in adjacent two all crank unloading mechanisms are fixed through the sinker rod locking unit. The device provided by the invention has unloading assisting effects on both upper and lower half parts of a filter cake during crank unloading.

Owner:ZHEJIANG HUAZHANG TECH

Process for preparing high temperature ceramic pigment

The invention discloses a high-temperature ceramic color preparing method of zirconium silicate encapsulated cadmium sulfoselenide series, which comprises the following steps: (1) the method doesn't need high-temperature and high-pressure equipment, which possesses mild reacting condition; (2) there is no gel in the preparing course to influence filter; (3) the method can generate yellow to orange yellow, orange red, red color; (4) the method displays high recovering rate and low cost.

Owner:XIANGTAN UNIV

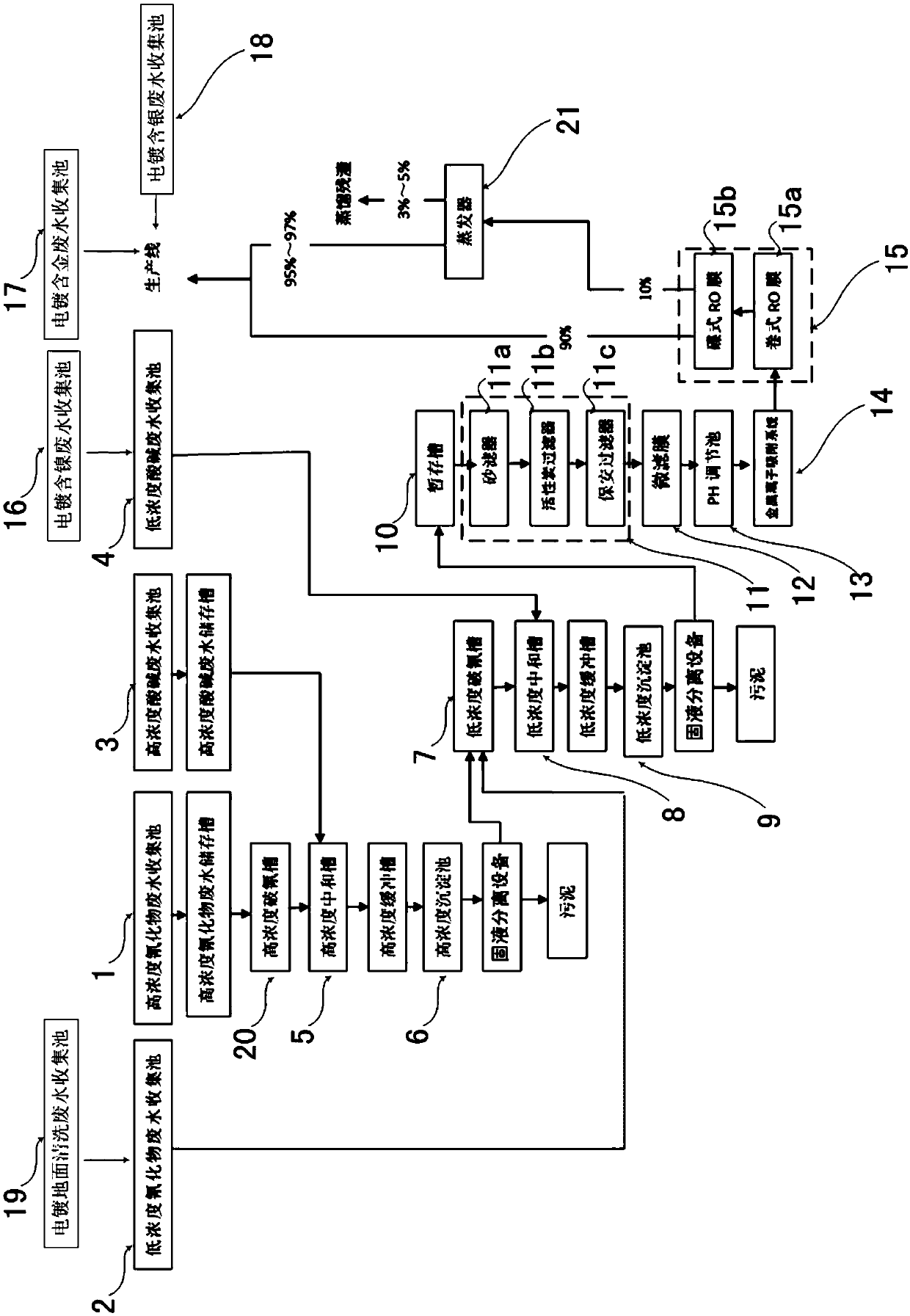

Zero-release treatment process of electroplating wastewater

ActiveCN109516629ALow costReduce operating loadWater contaminantsTreatment involving filtrationHigh concentrationHydrogen

The invention provides a zero-release treatment process of electroplating wastewater. The zero-release treatment process comprises the following steps of S1, collecting the wastewater in a classification manner; S2, enabling the wastewater, which is subjected to cyanide breakage, in a high-concentration cyanide wastewater collecting pool to flow into a high-concentration neutralizing tank togetherwith the wastewater in a high-concentration acid-alkali wastewater collecting pool, and generating a deposit; S3, discharging sludge from the wastewater in the high-concentration neutralizing tank through deposition, and flowing into a low-concentration cyanide breaking tank together with the wastewater in a low-concentration cyanide wastewater collecting pool; S4, enabling the wastewater in thelow-concentration cyanide breaking tank and the wastewater in a low-concentration acid-alkali wastewater collecting pool to flow into a low-concentration neutralizing tank, and generating a deposit; S5, discharging sludge from the low-concentration neutralizing tank through the deposition; S6, filtering the wastewater in a temporary storage tank and then flowing into a PH (Potential of Hydrogen) regulating pool; and S7, enabling wastewater in the PH regulating pool to pass through a metal ion adsorption system and a reverse osmosis membrane system in sequence to form reverse osmosis water andconcentrated water. The wastewater reuse rate of the zero-release treatment process can be up to 95% or above; and moreover, the zero-release treatment process can be used for saving water, conservingenergy and protecting an environment.

Owner:SHANGHAI RADIALL ELECTRONICS

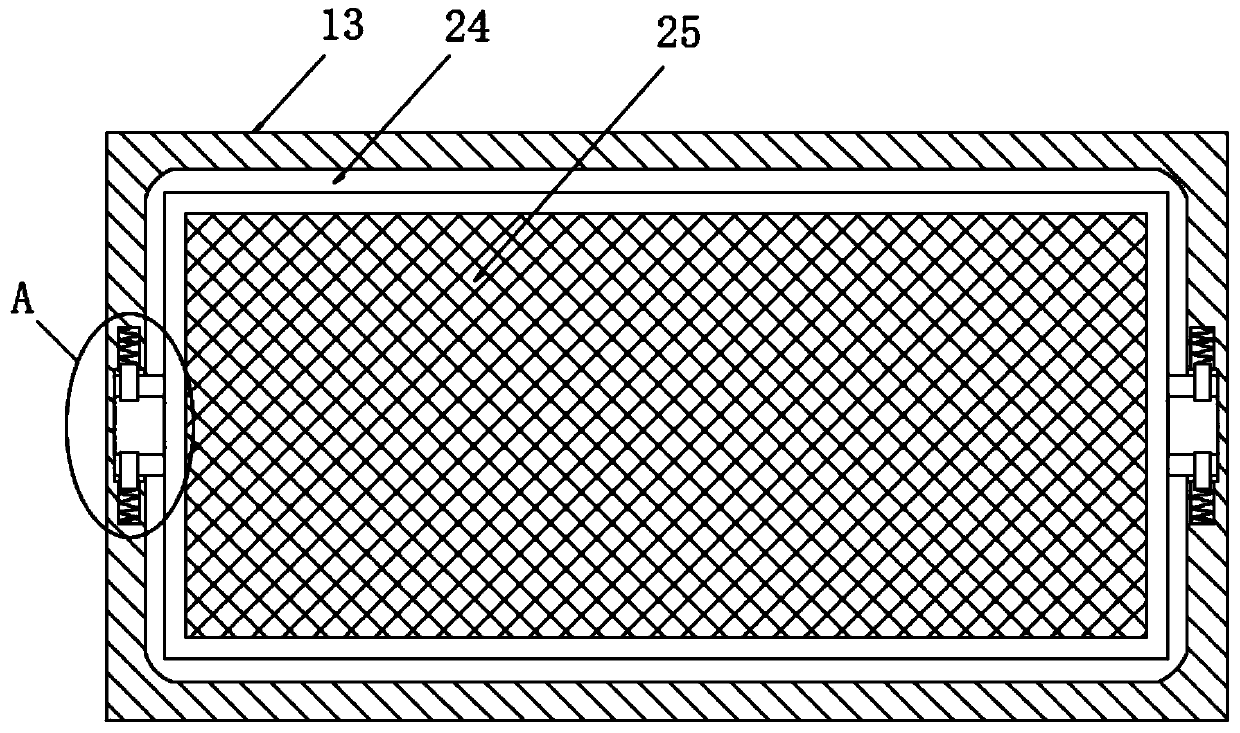

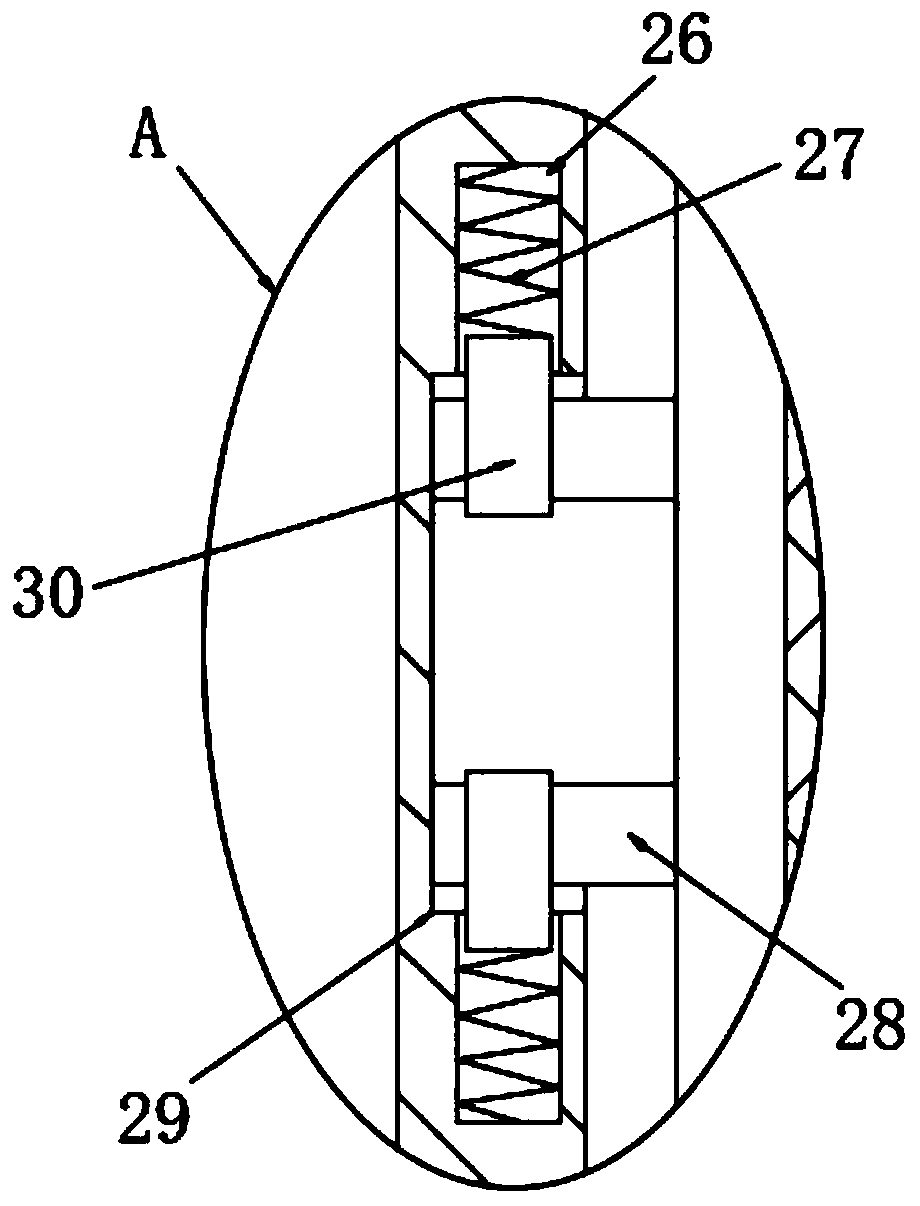

Particle sieving device for production of complex fertilizer anti-caking agents

InactiveCN111014013AEasy to disassembleEasy to cleanSievingScreeningAnticaking agentStructural engineering

The invention discloses a particle sieving device for the production of complex fertilizer anti-caking agents. The particle sieving device comprises a mounting base, wherein a position-limiting platecorresponding to a cam is fixedly connected to the ends of two movable rods which are arranged on the right side; a sieving box is fixedly connected to the ends of four movable rods; first return springs are symmetrically and fixedly mounted between the sieving box and vertical plates; the bottom of the sieving box is fixedly equipped with a bottom carrying cloth bag corresponding to an accommodation box; a groove and two clamping grooves are formed in the upper surface of the sieving box; the inside of each of the clamping grooves is symmetrically provided with mounting grooves; the inside ofeach of the mounting grooves is fixedly equipped with a second return spring; one end of each of the second return springs is fixedly connected with a position-limiting rod; a sieving mesh is arranged inside the groove; and clamping blocks matched with the clamping grooves are symmetrically and fixedly mounted at the outside of the sieving mesh. In the particle sieving device for the production of the complex fertilizer anti-caking agents, the sieving mesh is clamped to the sieving box through the clamping blocks and the clamping grooves, and the positions of the clamping blocks can be limited by virtue of the second return springs and the position-limiting rods, so that the sieving mesh can be easily dismounted and easily cleaned.

Owner:安徽海豚生物科技有限公司

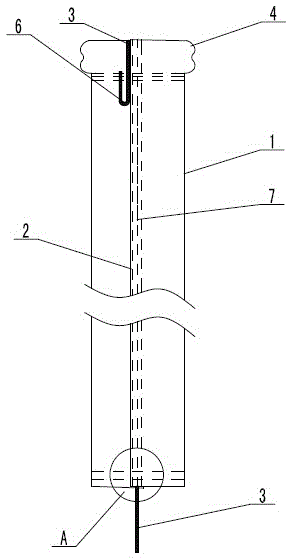

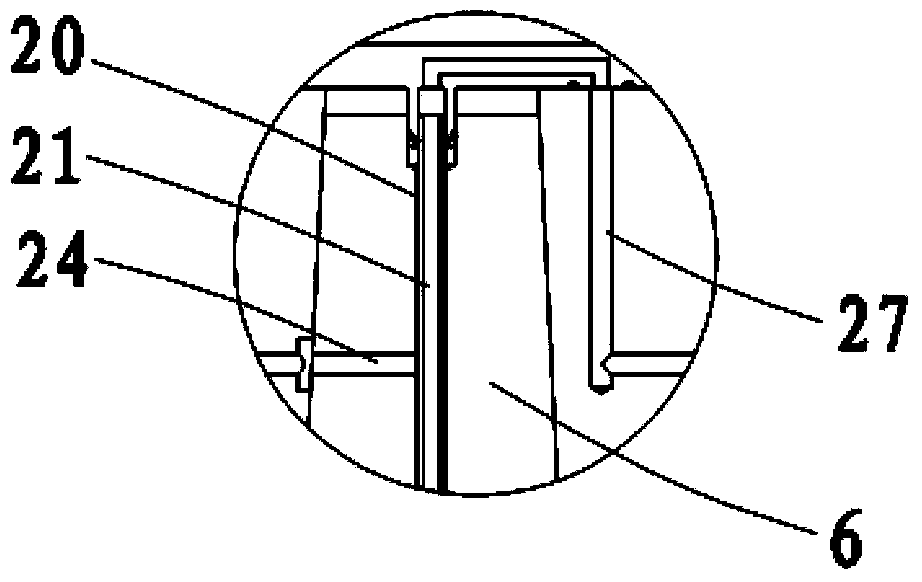

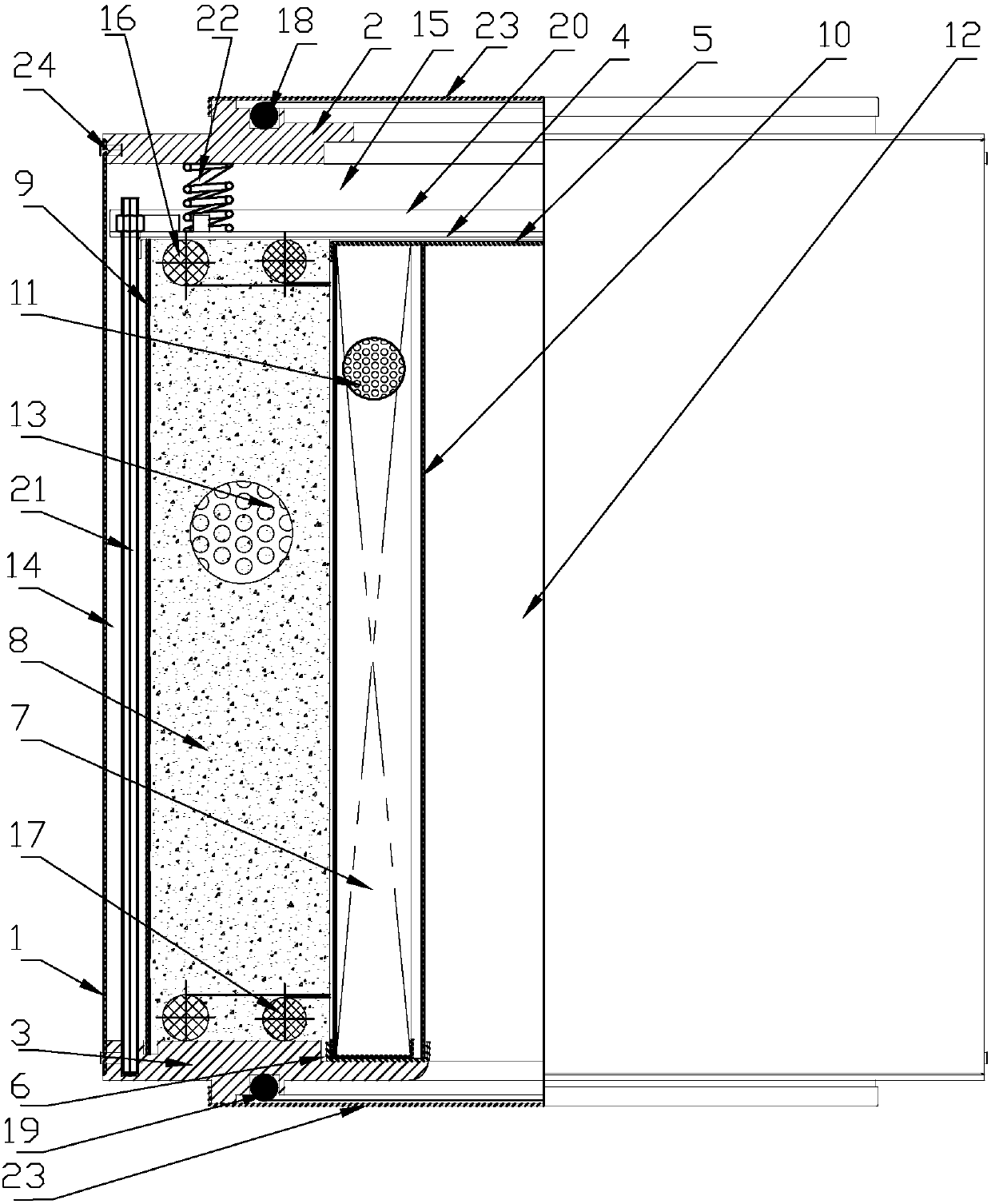

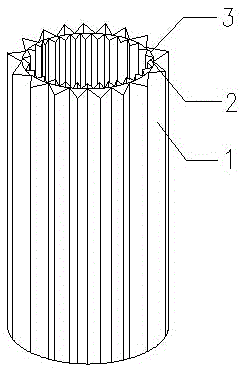

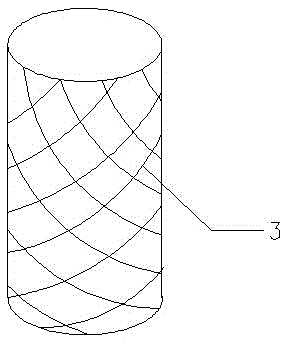

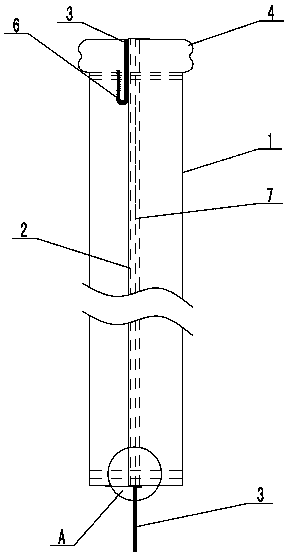

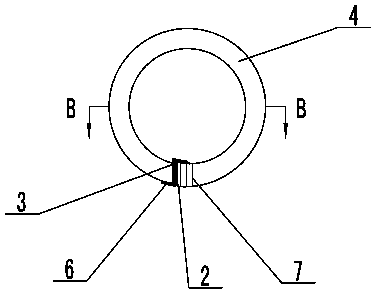

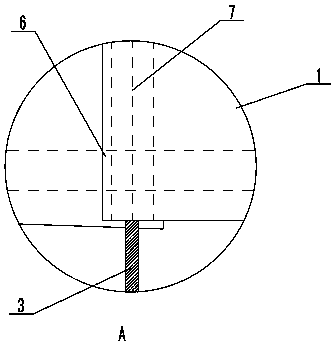

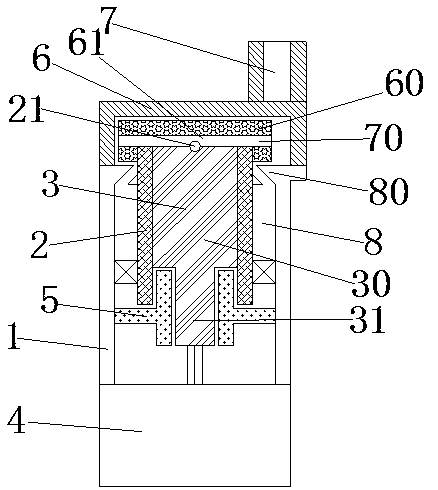

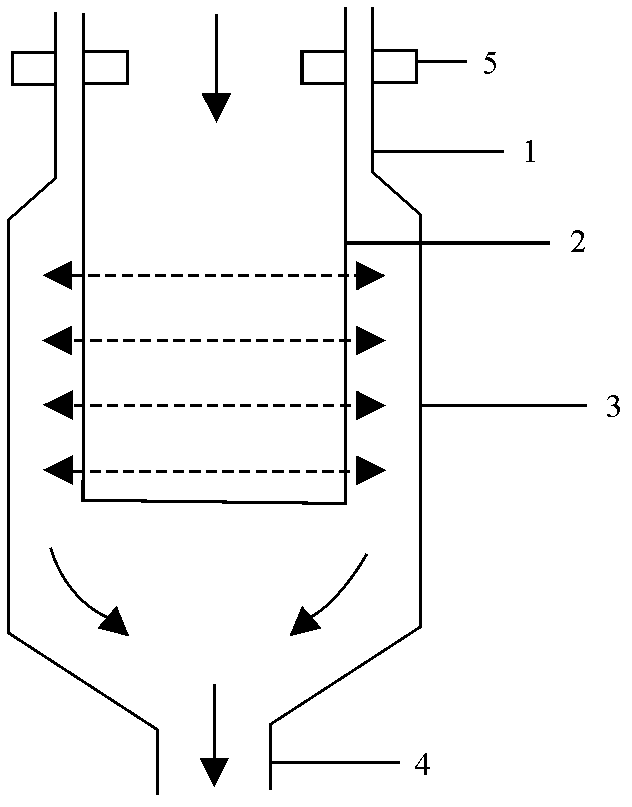

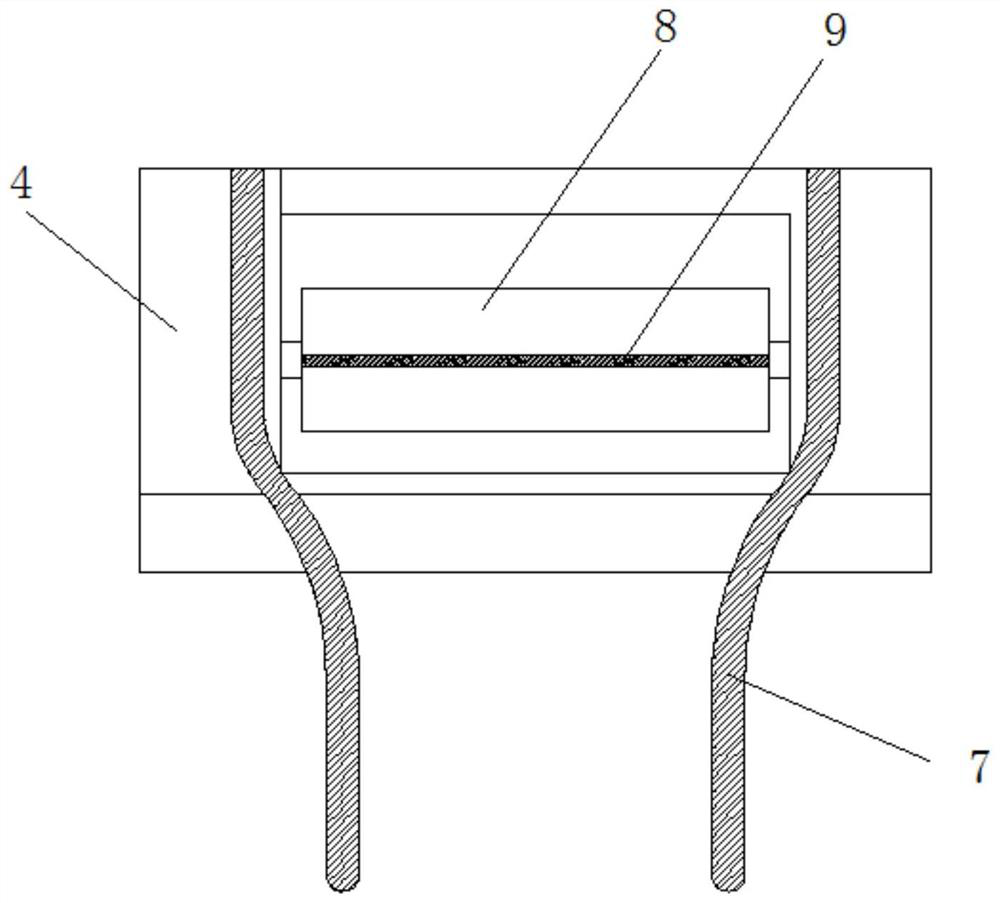

Electrically conductive filter bag and production method thereof

ActiveCN105854442AEasy to installDoes not affect filteringDispersed particle filtrationMechanical engineeringElectrical and Electronics engineering

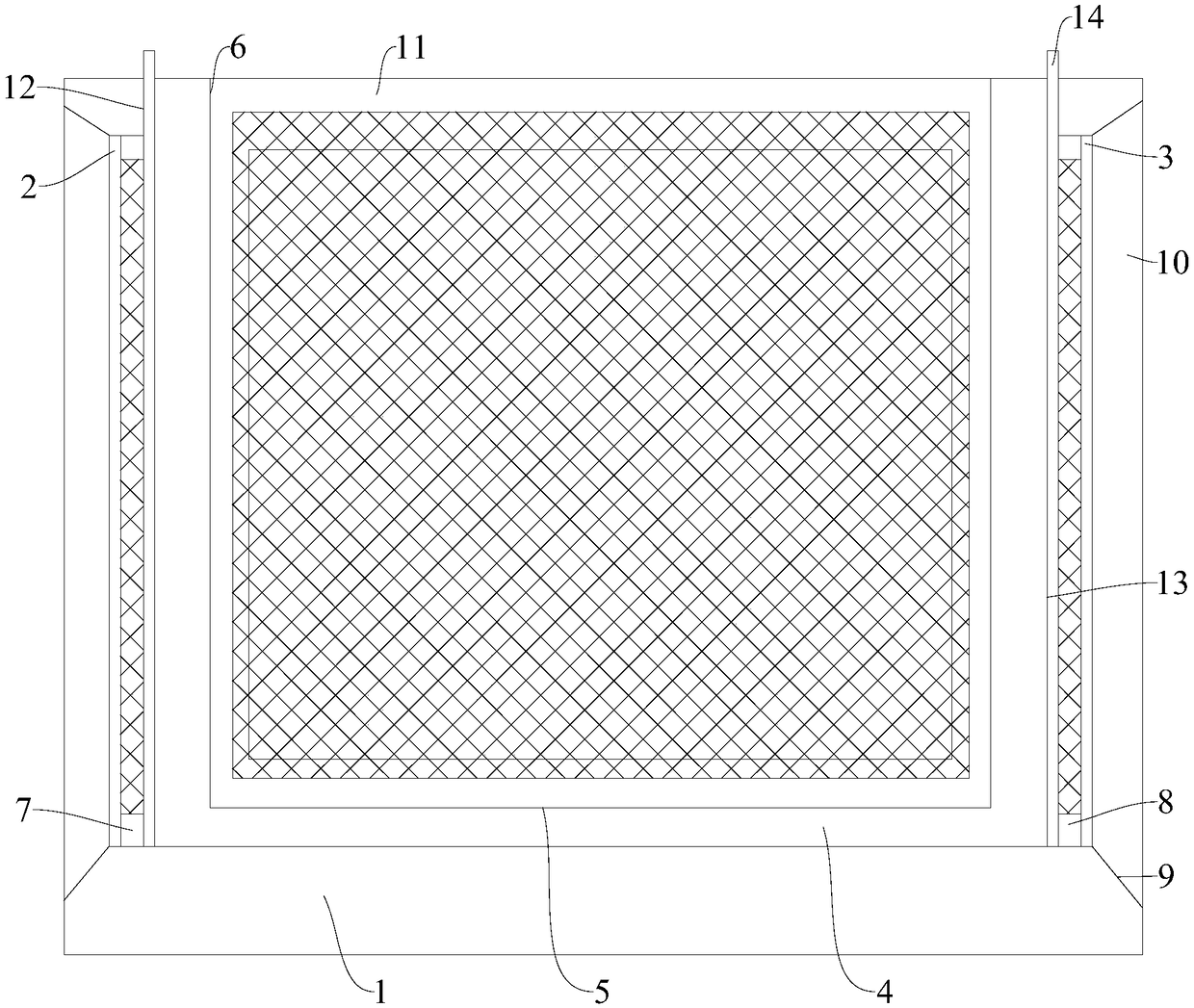

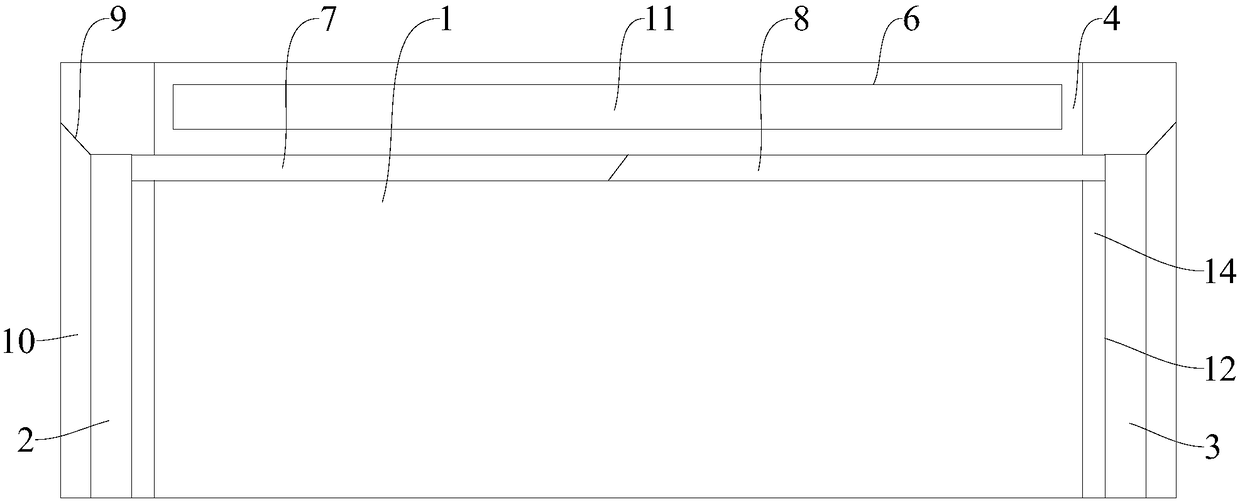

An electrically conductive filter bag and a production method thereof belong to the technical field of electrically conductive bag. The electrically conductive filter bag includes a bag body (1) and q bag bottom sewn at the bottom of the bag body (1); the bag body (1) is provided with a double-layer edge for sewing (2); the double-layer edge (2) is internally provided with a conductive strip (3); the conductive strip (3) is fixed by suture (7) sewn on the double-layer edge; the upper end of the bag body (1) is provided with an annular skeleton; the top of the conductive strip (3) exposes from the top of the double-layer edge (2), and winds from the inside of the bag body (1) to the outside of the bag body (1), and is then fixed below the annular skeleton onto the bag body (1); and the bottom end of the conductive strip (3) exposes from the bottom of the double-layer edge and is placed outside the bag body (1). The electrically conductive filter bag has good conductive effect, prevents conductive failure caused by collision of the keel and the conductive strip in the bag body. The production method completes sewing of the bag body and the conductive strip in one step, and improves the production efficiency of the electrically conductive filter bag.

Owner:山东兴国新力环保科技股份有限公司

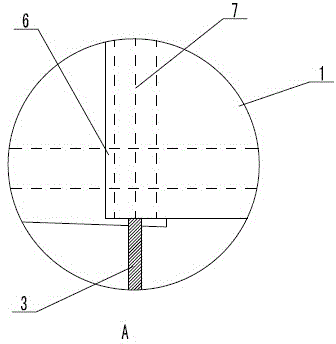

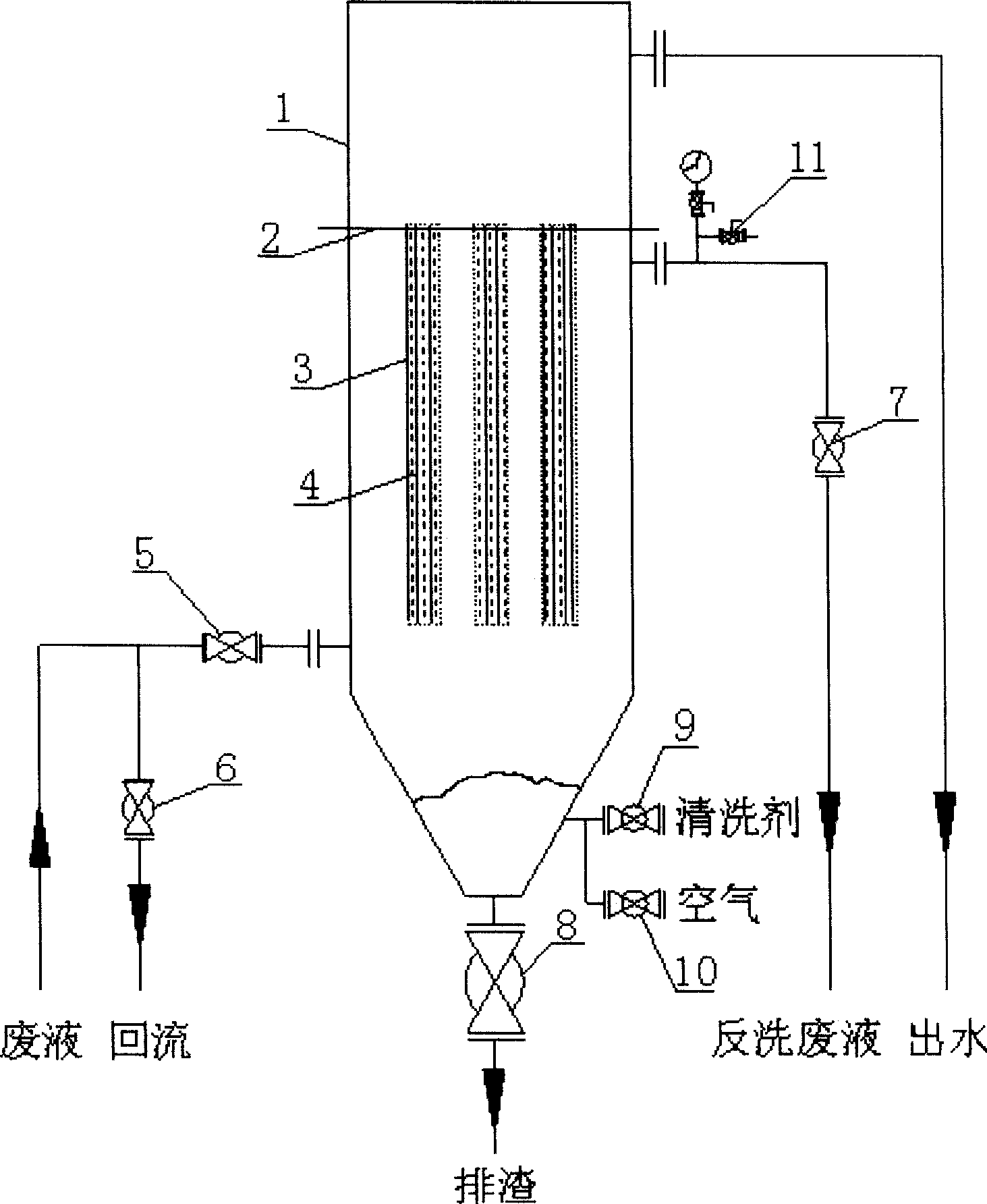

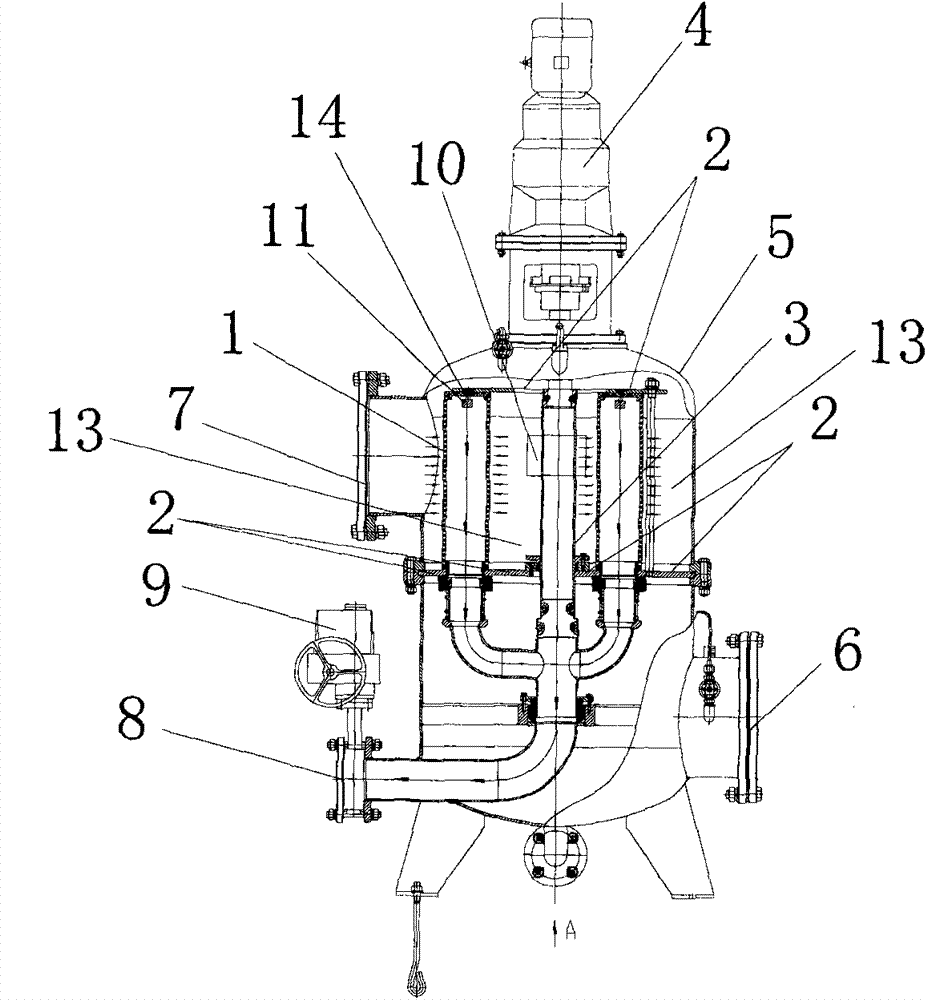

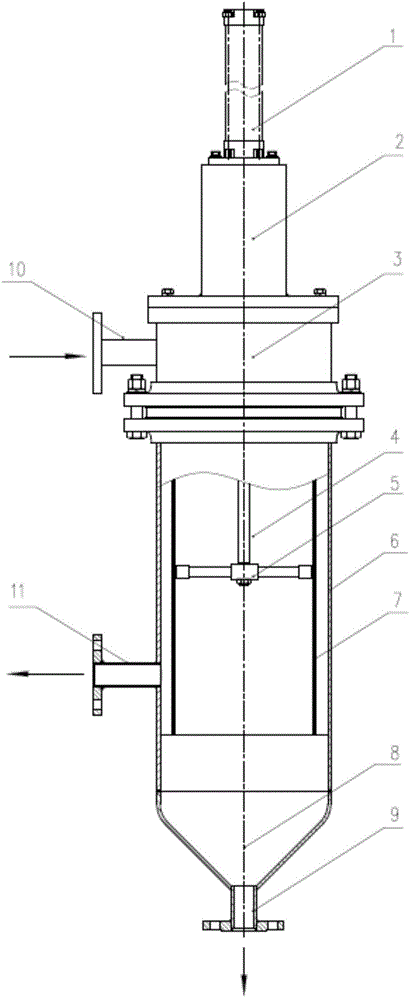

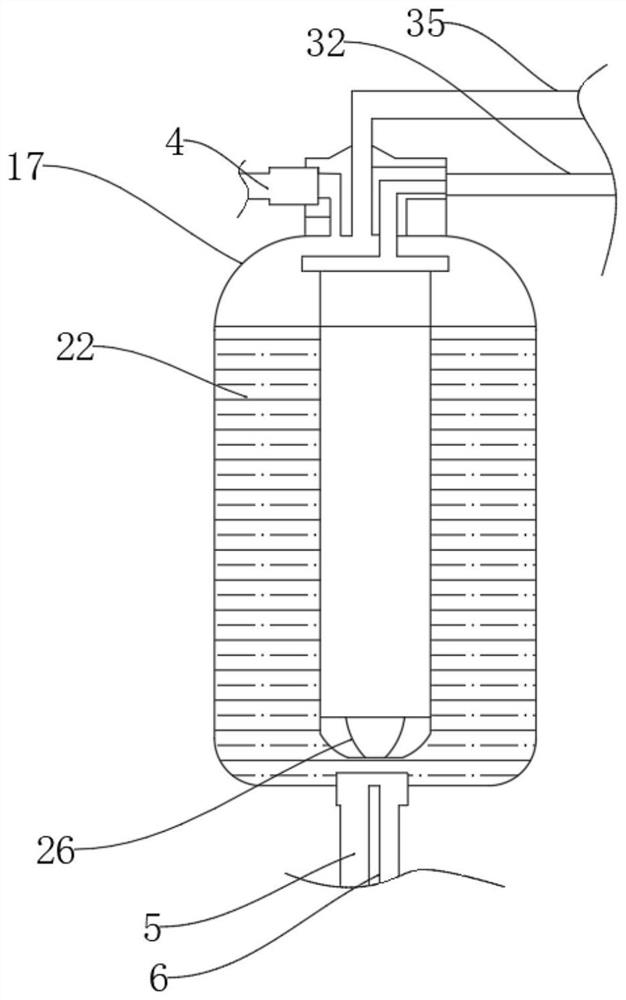

Microporous film filter for processing heavy metal wastewater

ActiveCN101468264ANew appearanceSimple structureStationary filtering element filtersSteel tubeHeavy water

The invention relates to a millipore membrane filter for treating heavy water waste water, which belongs to the technical field of wastewater treatment. The filter comprises a tank body, a stainless steel tube sheet, a bulky polyfluortetraethylene membrane filter bag, filter bag support cage frameworks, an acid feeding flexible valve, a reflux flexible valve, a backsurge flexible valve, a mud discharge flexible, a cleaning agent liquid feeding valve, an air electromagnetic valve and an exhaust electromagnetic valve, wherein the bulky polyfluortetraethylene membrane bag is sleeved on the filter bag support cage framework, and all filter bag support cage frameworks are fixed on the stainless steel tube sheet through screws. The stainless steel tube sheet divides the tank body into two parts, wherein the upper part is a clean water area, and the lower part is a waste liquid area (a filter area). The filter has a simple structure, and takes a membrane made of a bulky polyfluortetraethylene material as a filter material, so as to achieve the real surface filter effect, and completely retain impurities in an acid liquid on the surface of the membrane. Because the selected membrane has excellent acid resistance, hydrophobias and smaller friction coefficient, the block phenomenon of the filter material can not occur.

Owner:SHANGHAI TONGJI CLEARON ENVIRONMENTAL PROTECTION EQUIP ENG CO LTD

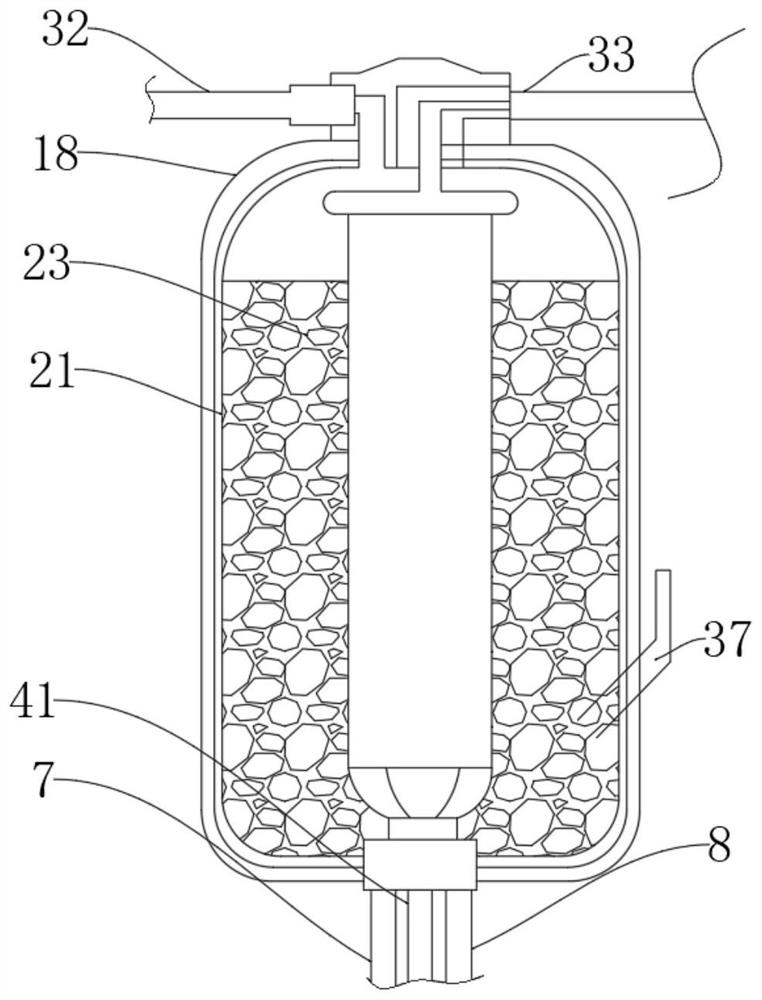

Filter cleaning apparatus

InactiveCN104722115ADoes not affect filteringImprove work efficiencyStationary filtering element filtersSolenoid valvePressure difference

A filter cleaning apparatus comprises a filter core, a gap is arranged between the filter core and each of the sidewall of a shell and an intermediate disk, gaps are connected to form a filtrate cavity, the upper portion of the shell is provided with a filtrate outlet, the filtrate outlet is connected with the filtrate cavity, the filter core is fixed on the intermediate disk of a filter, the intermediate disk is sleeved on a main shaft, the main shaft is connected with a drive device, the drive device is arranged at the top of the shell of the filter, the lower portion of the shell is provided with a filtrate inlet, the filtrate inlet is connected with the filter core, a dirt outlet is arranged at the bottom of the shell and is connected with a solenoid valve, a pressure difference controller is arranged in the shell, cleaning brushes connected with supporting skeletons are arranged in the filter core, the supporting skeletons are connected with a telescoping rod, a sliding sleeve is sleeved on the telescoping rod in a sliding manner, and the telescoping rod is connected with the drive device through the main shaft. The telescoping rod is elongated to push the sliding sleeve close to the supporting skeletons, and the supporting skeletons are pushed by the supporting rods and are opened, so the cleaning brushes contact with the inner wall of the filter core of the filter to clean dirt attached to the inside of the filter core, thereby the apparatus has the advantages of time saving, labor saving and high working efficiency.

Owner:SICHUAN FINE PURIFICATION EQUIP

Lateral overturning type easy-to-wash wastewater filtering mechanism

PendingCN108392875AImprove cleaning efficiencyDoes not affect filteringStationary filtering element filtersSolid-stateEngineering

The invention relates to the technical field of wastewater treatment and in particular relates to a lateral overturning type easy-to-wash wastewater filtering mechanism. The lateral overturning type easy-to-wash wastewater filtering mechanism comprises a main flow channel for conveying wastewater; a left-side inner wall of the main flow channel is provided with a left-side containing groove. According to the lateral overturning type easy-to-wash wastewater filtering mechanism provided by the invention, a lateral containing groove, which is internally provided with an overturning filtering frame, is formed in the upper side of the inner side face of the main flow channel, and an outer-side cleaning opening of an outer-side sealing cover plate is formed in the outer side face of the main flow channel; the overturning filtering frame is turned outward to enter the lateral containing groove; then solid-state impurities on the surface of the overturning filtering frame are cleaned by opening the outer-side sealing cover plate and closing an inner-side sealing plate; in a cleaning process, auxiliary filtering can be carried out through a detachable type auxiliary filtering screen frame and filtering work is not influenced; the outer-side cleaning opening with an inclined plane is used for cleaning solid-state filtering matters on the overturning filtering frame, so that the whole cleaning efficiency is greatly improved.

Owner:苏州凯新分离科技有限公司

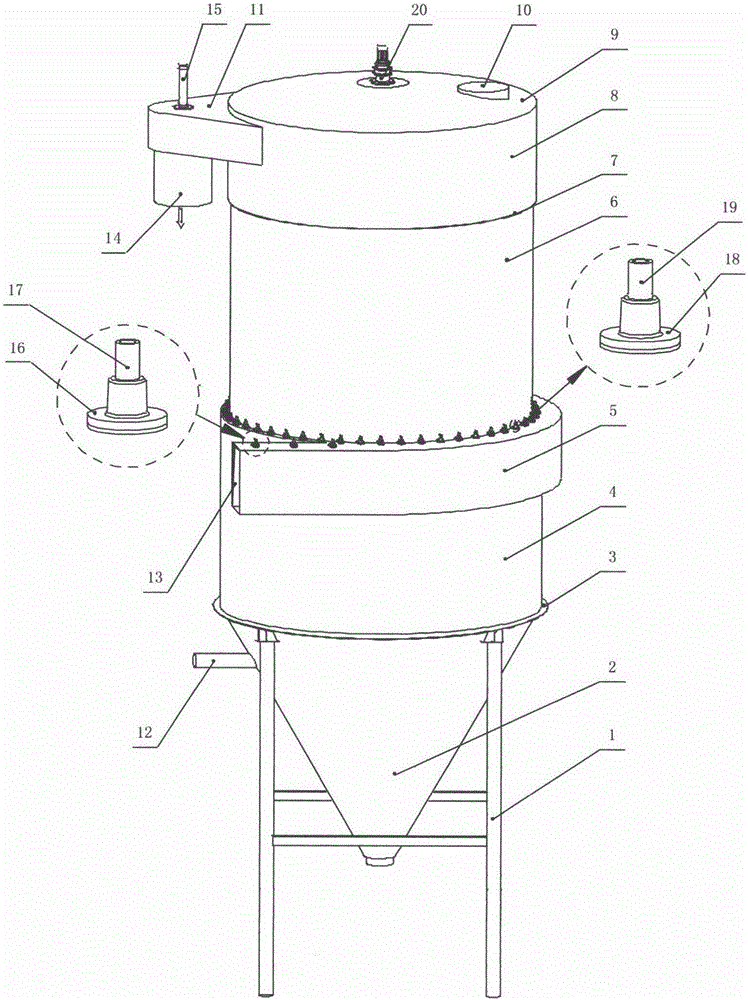

Rotary table type dust removal apparatus for cleaning filter screen

InactiveCN105413339ASimple structureEasy to useDispersed particle filtrationTransportation and packagingAirflowEngineering

The present invention discloses a rotary table type dust removal apparatus for cleaning a filter screen. The apparatus comprises a housing provided with an air inlet channel and an air outlet channel, the filter screen is arranged at a joint point of the air outlet channel and the air inlet channel, a rotary table is arranged in the housing, a cavity is formed in the rotary table, a cleaning air channel is formed between the cavity and the air inlet channel, a cleaning tuyere is further arranged on the rotary table and is arranged on a disk edge of the rotary table, an inclined cleaning air hole is formed in the air outlet channel, an air outlet of the inclined cleaning air hole is matched with the filter screen, the cleaning tuyere is matched with the inclined cleaning air hole, and a turbocharger is arranged in the cavity. The rotary table type dust removal apparatus for cleaning the filter screen is simple in structure and speedy and convenient to use; a knocking bar is blown by pressurized airflow in the rotary table, so that the knocking bar knocks the filter screen under the effect of a spring plate, dust separated from the filter screen is blown out of the housing under the effect of the airflow of the air inlet channel, and cleaning of the filter screen is completed. The apparatus is good in stability, cannot affect normal filtering effect, and is high in applicability and good in practicality.

Owner:ENVIRONMENTAL ENG SCI & TECH CO LTD HUAIAN AMPANG

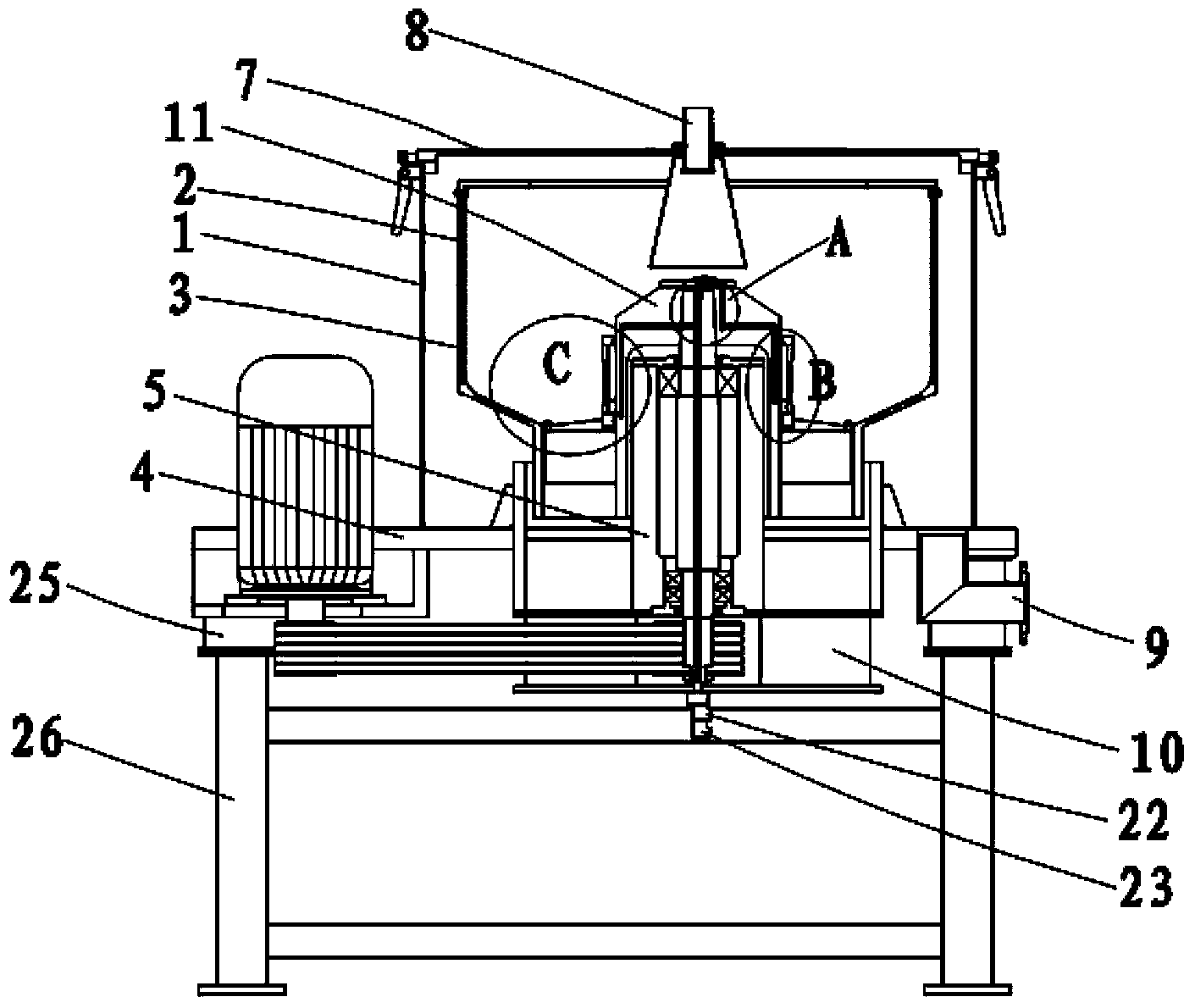

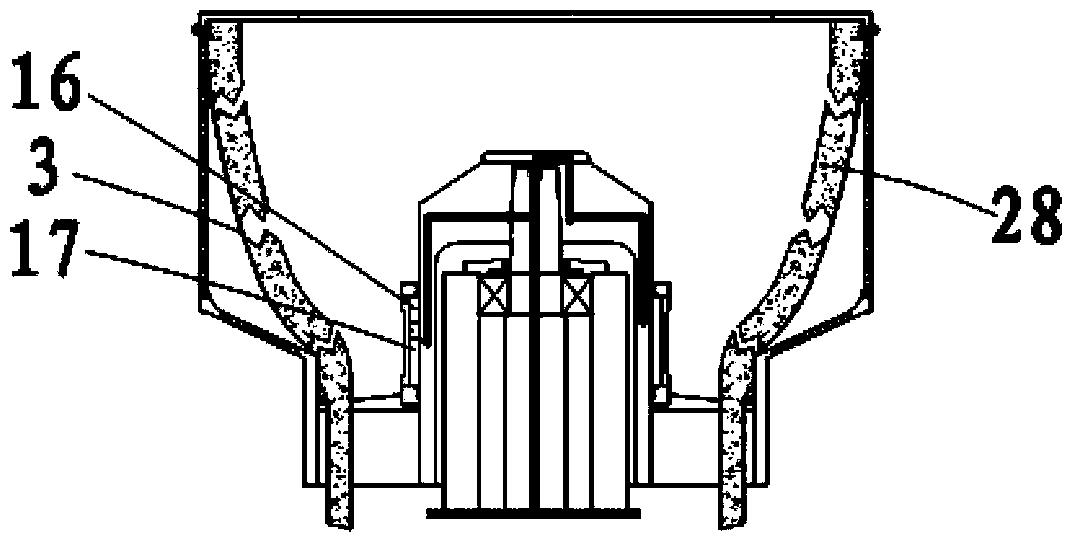

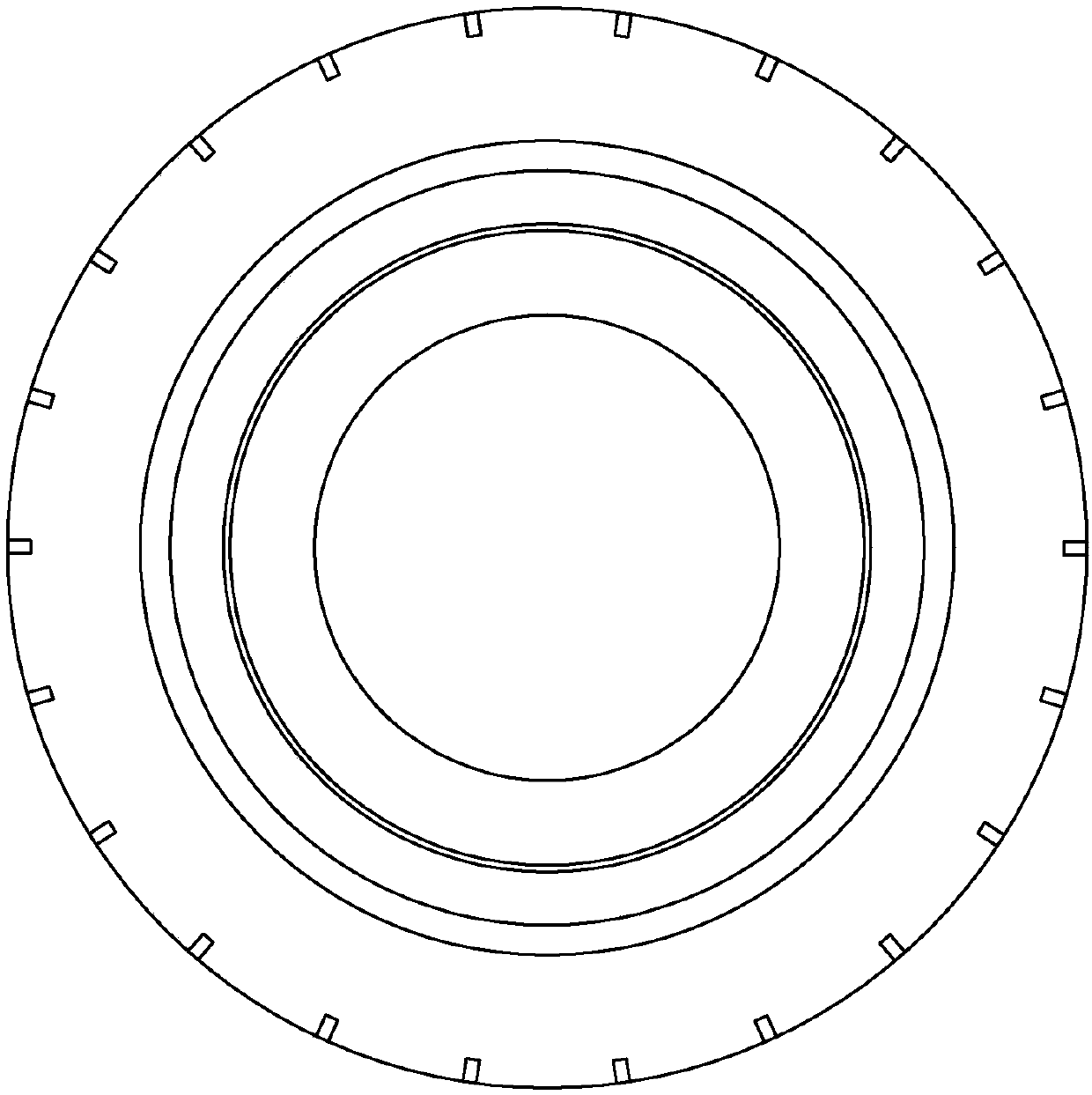

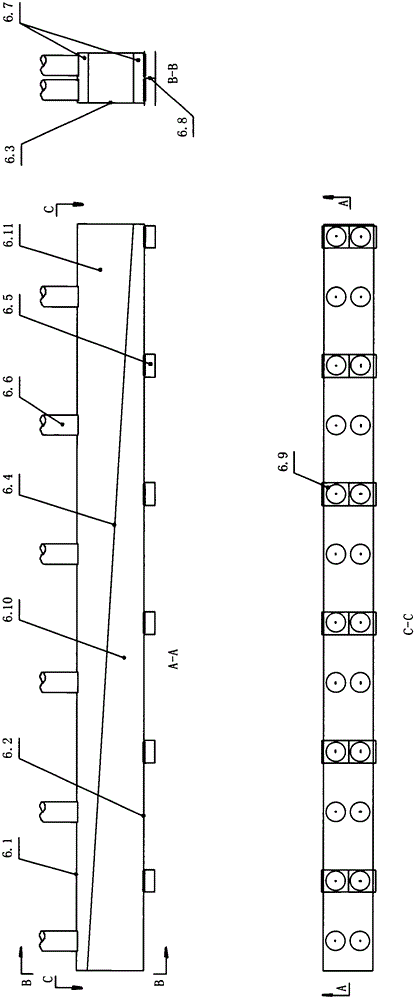

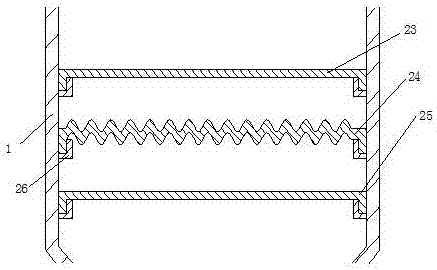

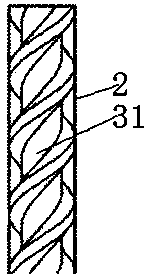

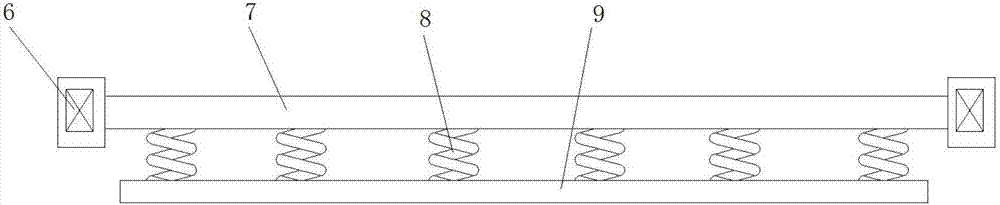

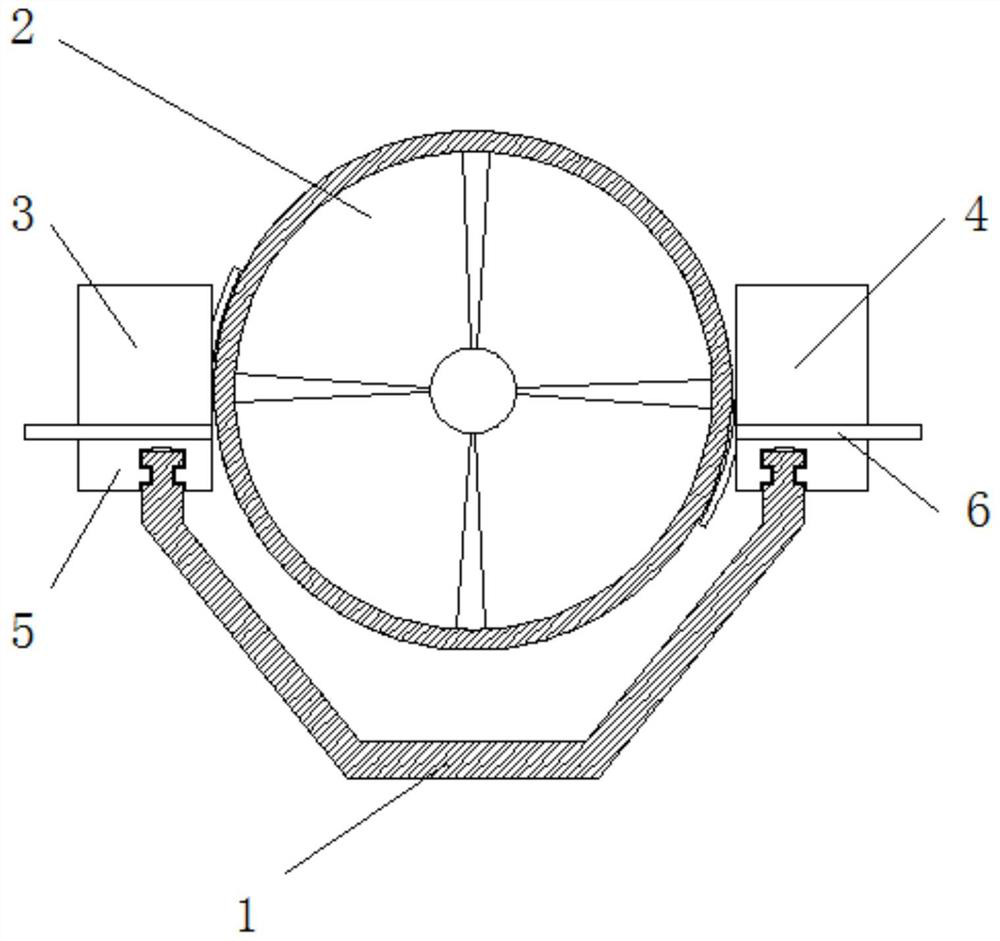

Unloading type centrifugal machine with filter bag conducting reciprocating vibration

The invention discloses an unloading type centrifugal machine with a filter bag conducting reciprocating vibration. A drum of the unloading type centrifugal machine is of a column-taper-column three-sectional combined type structure, a filter cake is extruded due to the contraction action of the taper section of the drum, and unloading of the filter cake is facilitated. The column section at the tail end of the drum has the guide function for the reciprocating filter bag, has the guide function on the filter cake at the same time, and guides the filer cake to a filter cake unloading port of a chassis of the drum. The unloading type centrifugal machine achieves unloading through the reciprocating vibration of the filter bag, traditional unloading structures such as a scraper and a spiral are completely removed, no mechanical scraping action can play on the filter cake, the shape of crystal particles in the filter cake cannot be damaged, the structure of the crystal particles of the filter cake can be completely kept, and the unloading type centrifugal machine is particularly suitable for being used on occasions where the crystal perfection of the filter cake needs to be kept. In addition, by means of the reciprocating vibration of the filter bag, complete unloading can be achieved, and no filter cake will be left on the filter bag.

Owner:HEFEI GENERAL MACHINERY RES INST

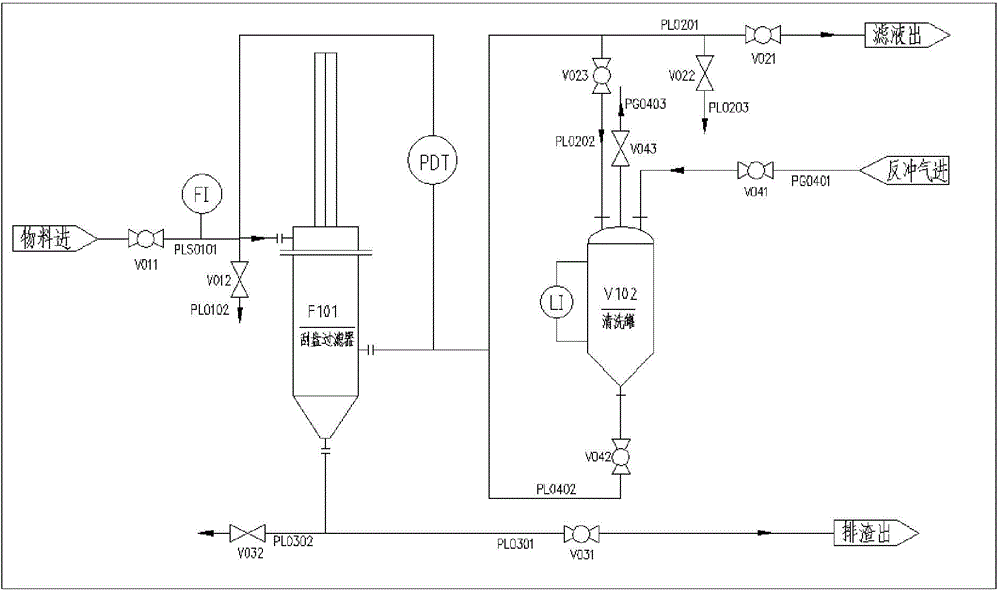

Scraping plate filtering device applied to high-temperature coal tar purification system, purification system and purification process

InactiveCN105435509AThe device and process are easy to operateImprove work efficiencyWorking-up tarStationary filtering element filtersSlagCorrosion

The invention discloses a scraping plate filtering device applied to a high-temperature coal tar purification system, a purification system and a purification process. According to the scheme, the process comprises the steps that high-temperature coal tar is firstly fed into a filtering cylinder through an inlet of a scraping plate filter, wherein solid impurities in the coal tar are intercepted on the inner surface of a filter element, and the filtered coal tar partially enters into a cleaning tank and is discharged from a coal tar discharge pipe partially; when a filter medium needs to be cleaned, a scraping plate moves constantly up and down to scrape the solid impurities deposited on the surface of a medium; when the impurities are separated from a filter screen, a cleaning disc feeds dirt into a slag collecting chamber in the bottom of a housing, and the dirt is finally discharged from a slag out so as to clean the filter element; and after a long period of time of operation, the filter element is reversely cleaned, so that the impurities which cannot be scraped on the inner surface of the filter element are conveniently cleaned. The scraping plate technology has a closed process for filtration and directly performs filtration without adding filter aids, and the scraping plate filtering device is high in corrosion resistance and high in filtering precision and has the remarkable advantages of being suitable for high-high viscosity fluids, low in energy consumption and the like.

Owner:SHANGHAI ANHORN ENVIRONMENTAL TECH CO LTD

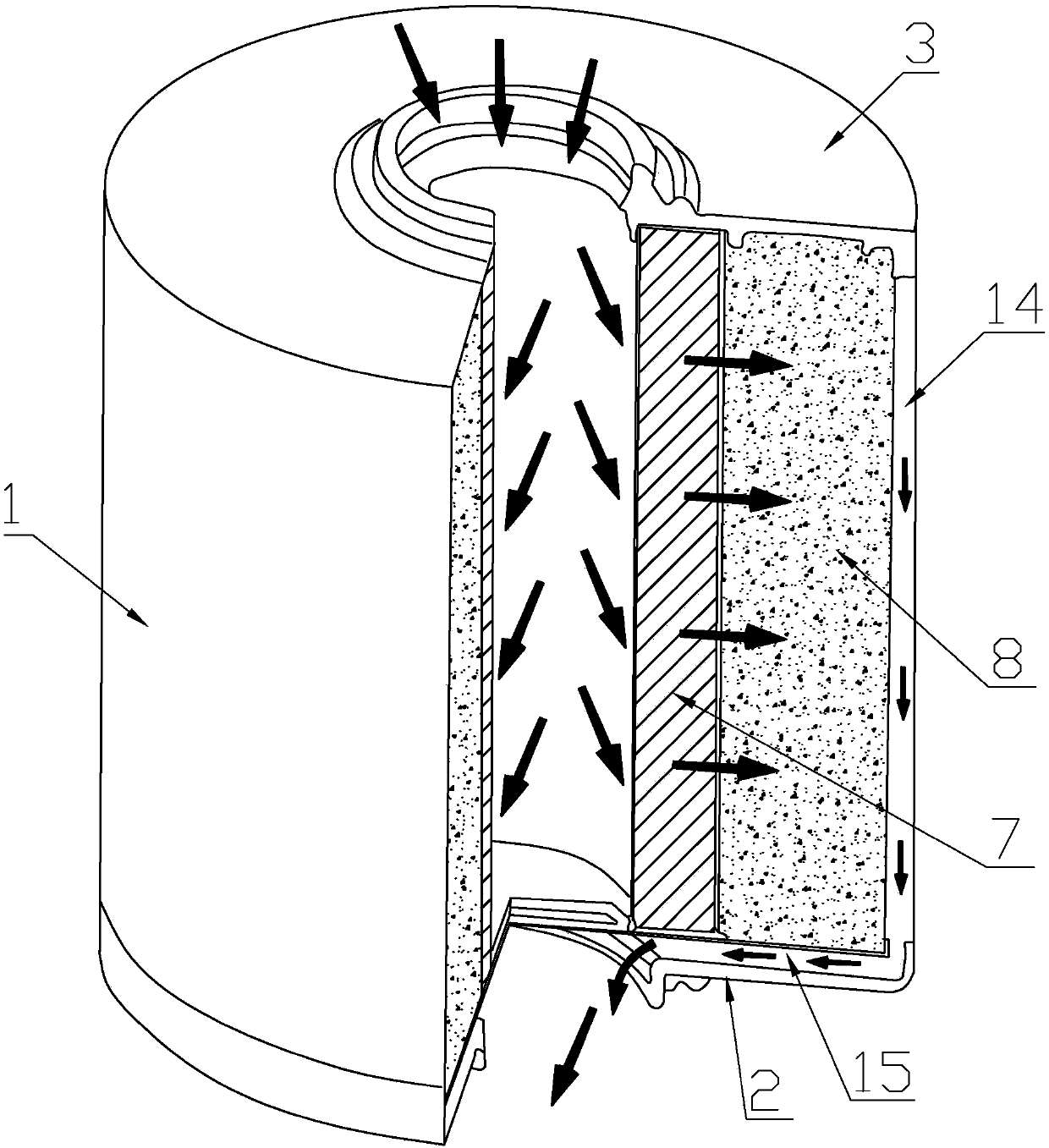

Three-proofing filtering element

InactiveCN107051003AImprove adsorption capacityAvoid affecting the filtering effectGas treatmentDispersed particle filtrationParticulatesPollen

The invention discloses a three-proofing filtering element, which comprises a metal external barrel, an upper cover plate, a lower cover plate, a metal inner cover, a paper core upper end cover, a paper core lower end cover, a paper core and an activated carbon granule layer. The three-proofing filtering element has a scientific and reasonable overall structure, can efficiently filter particulates and gas smoke through two-stage filtering, is suitable for military installation, refuge places, fire sites and other specific environments, and has excellent resistance to impact, firing pulse and harsh environment. In the first-stage filtering, the paper core, especially fiberglass paper core, is adopted for filtering, thus having the advantages of high filtering precision, low original resistance, high filtering efficiency, high temperature resistance and high pressure resistance, strong chemical resistance, and resistance to mold and moisture. In the second-stage filtering, activated carbon is adopted for filtering, adsorption and conversion, thus having a distinct effect of removing toxic chemicals, fine dust, pollen, pathogenic bacteria, smoke, water molecules, off odor, formaldehyde, VOC organic volatiles and other gases, and the effective rate is up to 99.99995%.

Owner:江苏富滤盛滤清器有限公司

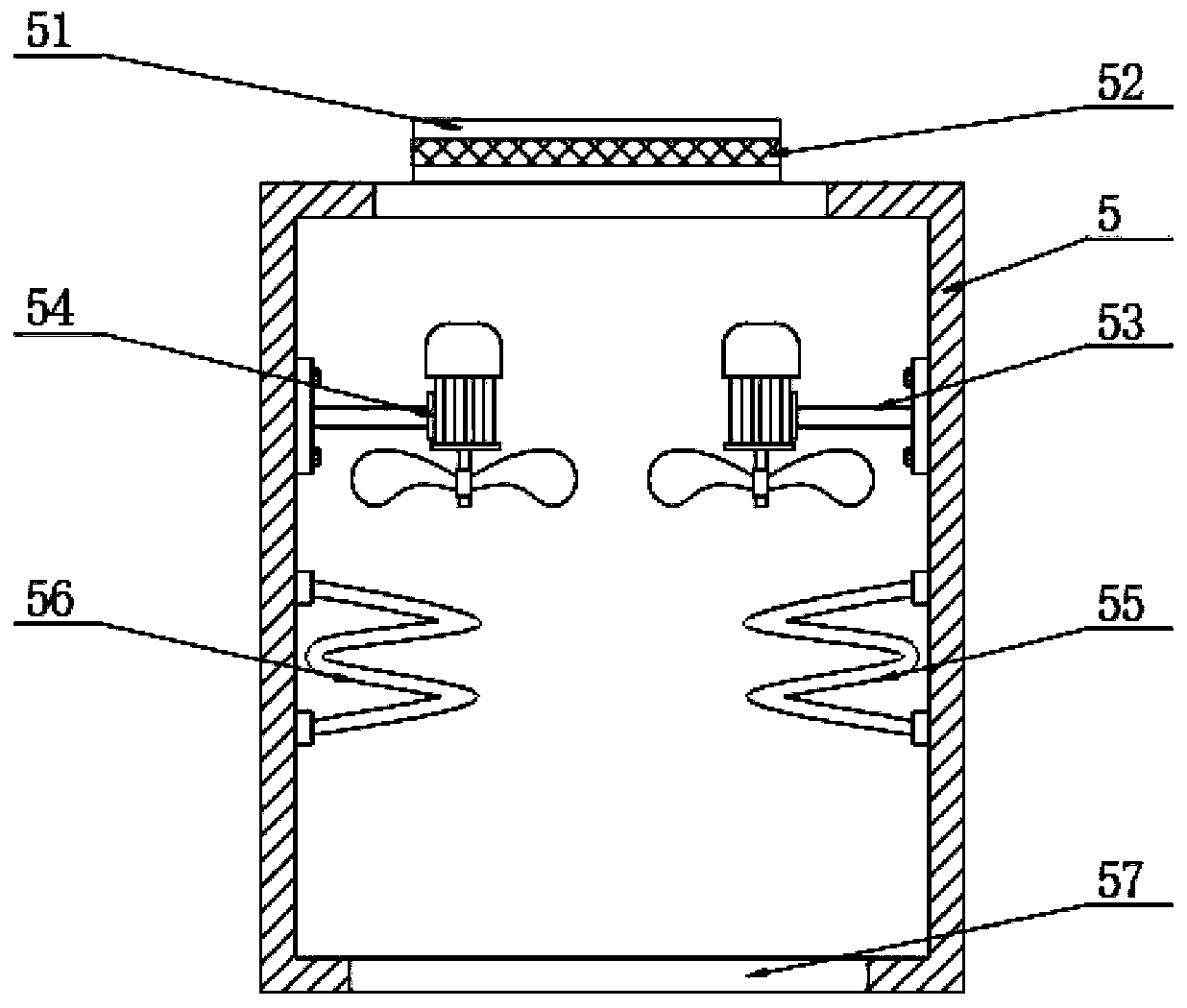

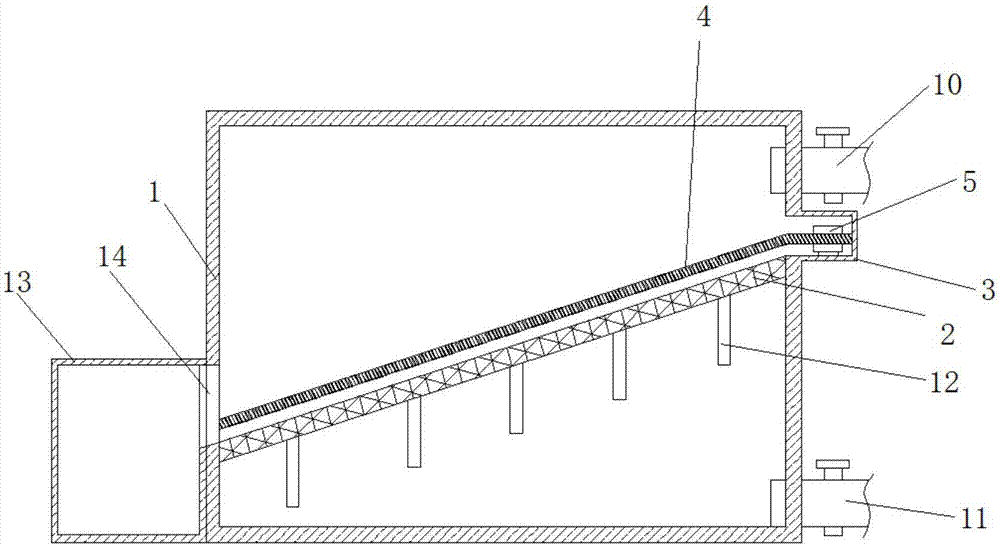

Modular cleaning and drying integrated equipment based on nut processing

ActiveCN109938373AThere will be no problem of anti-tideAvoid the problem of blister washingFood treatmentSurface cleaningWater vapor

The invention discloses modular cleaning and drying integrated equipment based on nut processing. The equipment adopts the method of spraying water vapor for cleaning, avoids the problem of water soaking for washing, cleaning with the water vapor only cleans the outer surfaces of nuts and cannot cause internal wetness, and after surface cleaning with the water vapor is completed, rapid drying is performed by using a drying assembly, so that rapid drying can be achieved before permeation of the water vapor, and the problem of getting damp of the nuts cannot occur during storage. The modular cleaning and drying integrated equipment based on nut processing has the advantages that the spraying mode is adopted, and spraying is performed at the upper and lower portions simultaneously, so that cleaning can be performed from each angle, cleaning is thorough, the cleaning efficiency is high, nut products do not need manual cleaning, and the labor intensity of users is reduced; when the equipment performs cleaning, an overturning plate obliquely arranged on a conveyor belt can turn over the nuts, so that the sprayed water vapor clean the nuts from all directions and all angles, and the nutscan collide and impact with each other during rising and falling, thereby ensuring the oblique performance.

Owner:GUIZHOU UNIV OF ENG SCI

Atmospheric pollution purification complete equipment capable of achieving dust removal, haze control, desulfuration, denitration, deodorization and formaldehyde removal

InactiveCN106390700ASolve the problem of uneven loadReduce the impactHuman health protectionCombination devicesPlasma technologyThree stage

The invention provides atmospheric pollution purification complete equipment capable of achieving dust removal, haze control, desulfuration, denitration, deodorization and formaldehyde removal, and belongs to separating type (B01D) and plasma technology type (H05H) physical or chemical methods. According to the atmospheric pollution purification complete equipment capable of achieving dust removal, haze control, desulfuration, denitration, deodorization and formaldehyde removal, unit modules are combined to be used, dust removal, haze control, desulfuration, denitration, deodorization and formaldehyde removal are simultaneously conducted on multiple atmospheric pollution factors through multiple three-stage purification treatment including charge coagulation, electron bombardment and bag dust removal, and then comprehensive treatment of atmospheric pollution is effectively achieved; the modularization, standardization and combination design is adopted, and industrialized mass production, scattered transportation, modularized installation, generalized interchange and cross-regional popularization can be conducted according to the purification requirements such as the property and the scale of the pollution factors.

Owner:黄启瑞

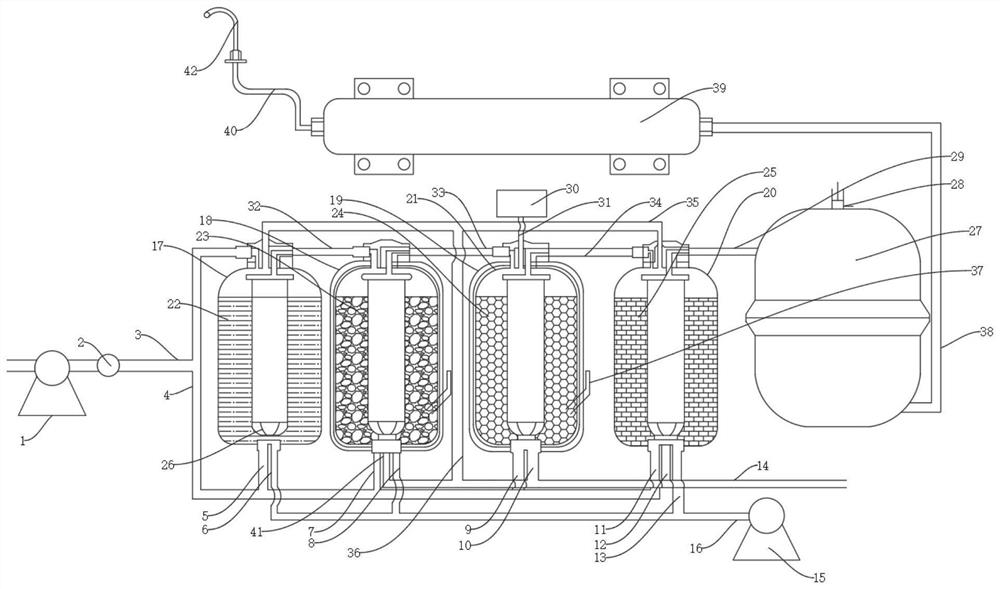

Self-cleaning long-service-life household water purifier

PendingCN113173659ADoes not affect filteringExtended service lifeSpecific water treatment objectivesTreatment involving filtrationAir pumpWater flow

A disclosed self-cleaning long-service-life household water purifier comprises a water pump and an air pump, a main water pipe is arranged in the outer side of the water pump, a first auxiliary water pipe is arranged on the outer side of the main water pipe, and a flow meter is arranged on the outer side of the main water pipe; and a filtering tank I, a filtering tank II, a filtering tank III and a filtering tank IV are arranged between the water pump and the air pump. According to the self-cleaning long-service-life household water purifier, through mutual cooperation of first to fourth filtering barrels, four-stage filtering can be achieved, it is guaranteed that the water purifying effect of safer drinking is achieved, backwashing of the first filtering barrel and the fourth filtering barrel is achieved through reverse flushing of water flow and air flow, desorption of the second filtering barrel and the third filtering barrel is realized through thermal desorption and salt desorption, so that impurity molecules adsorbed on the surface of a filter element material fall off, the self-cleaning effect is realized, the service life of the filter element is prolonged, the filter element material is recycled, and the filter element replacement frequency is reduced while the filtered water is safer and healthier.

Owner:CHONGQING UNIV OF ARTS & SCI

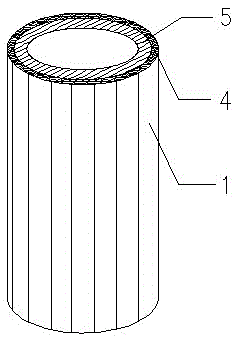

Filter element of gas filter

InactiveCN105545554AIncreased deformation resistanceDoes not affect filteringMachines/enginesLiquid fuel feedersFuel filterPulp and paper industry

The invention discloses a filter element of a gas filter. The filter element comprises outer-layer filter paper, a plastic supporting net and inner-layer filter paper. The outer-layer filter paper and the inner-layer filter paper are hollow cylindrical bodies formed through longitudinal folding. The plastic supporting net is clamped between the outer-layer filter paper and the inner-layer filter paper. The upper portion and the lower portion of the filter element are fixed in a fused mode through resin adhesive tape and a non-woven fabric gasket. Compared with the prior art, the filter element has the following advantages that a double-layer filter paper structure is adopted, the plastic supporting net is additionally arranged between the outer-layer filter paper and the inner-layer filter paper, the deformation-resistant strength of the filter element is enhanced, and meanwhile the connection problem between the outer-layer filter paper and the inner-layer filter paper is solved; due to the fact that meshes of the plastic supporting net are large, filtering of gas dirt cannot be affected, the two ends of the filter element are fixed in the fused mode through the resin adhesive tape and the non-woven fabric gasket, the structure is simple, machining is convenient, the step of welding the filter element with an outer end cover is avoided, and efficient filtering, simple manufacturing, environment friendliness and reduction of manufacturing cost are achieved.

Owner:BENGBU CITY MINGWEI FILTER CO LTD

LED display packaging method

ActiveCN101404260AImprove uniformityImprove work efficiencySemiconductor/solid-state device manufacturingIdentification meansEpoxyLED display

The invention disclosures a packaging method of an LED display. The packaging method comprises the following steps: a. providing a packaging support or a base plate; b. die bonding; c. wire bonding; and d. sealing. The sealing comprises steps as follows: d1. a forming die chamber which is matched with the packaging support or the base plate is selected; d2. liquid epoxy resin is potted in the forming die chamber; d3. the packaging support or the base plate is filtered in industrial acetone; d4. the packaging support or the base plate is taken out and dried; d5. the packaging support or the base plate is slantwise put in the forming die chamber and is compressed; and d6. the packaging support or the base plate is baked to solidify the epoxy resin. The packaging method can effectively control the generation of gas bubble, and has the advantages of high operation efficiency and simple operation. LED displays packaged by the method provide uniform light.

Owner:JIANGSU WENRUN OPTOELECTRONICS

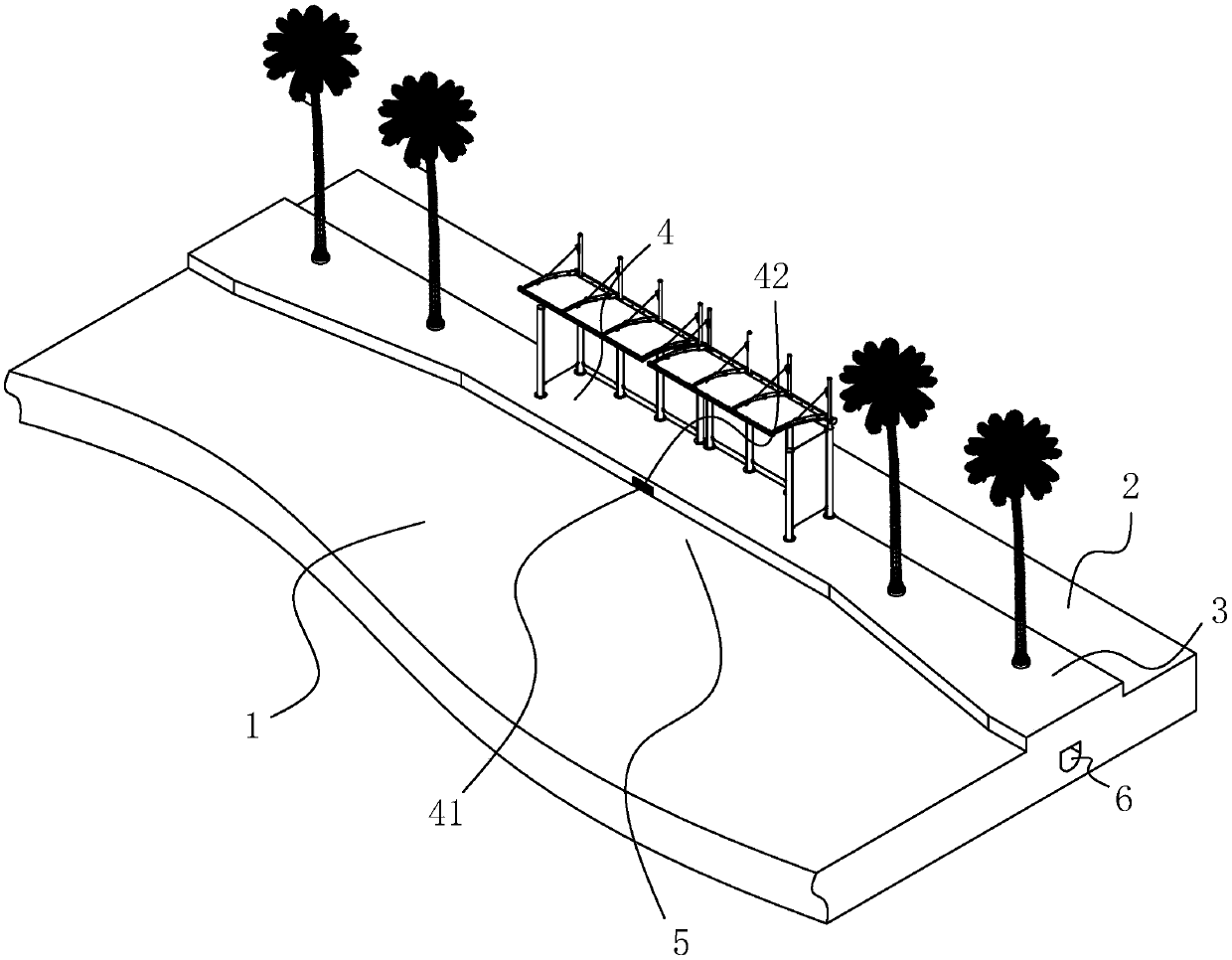

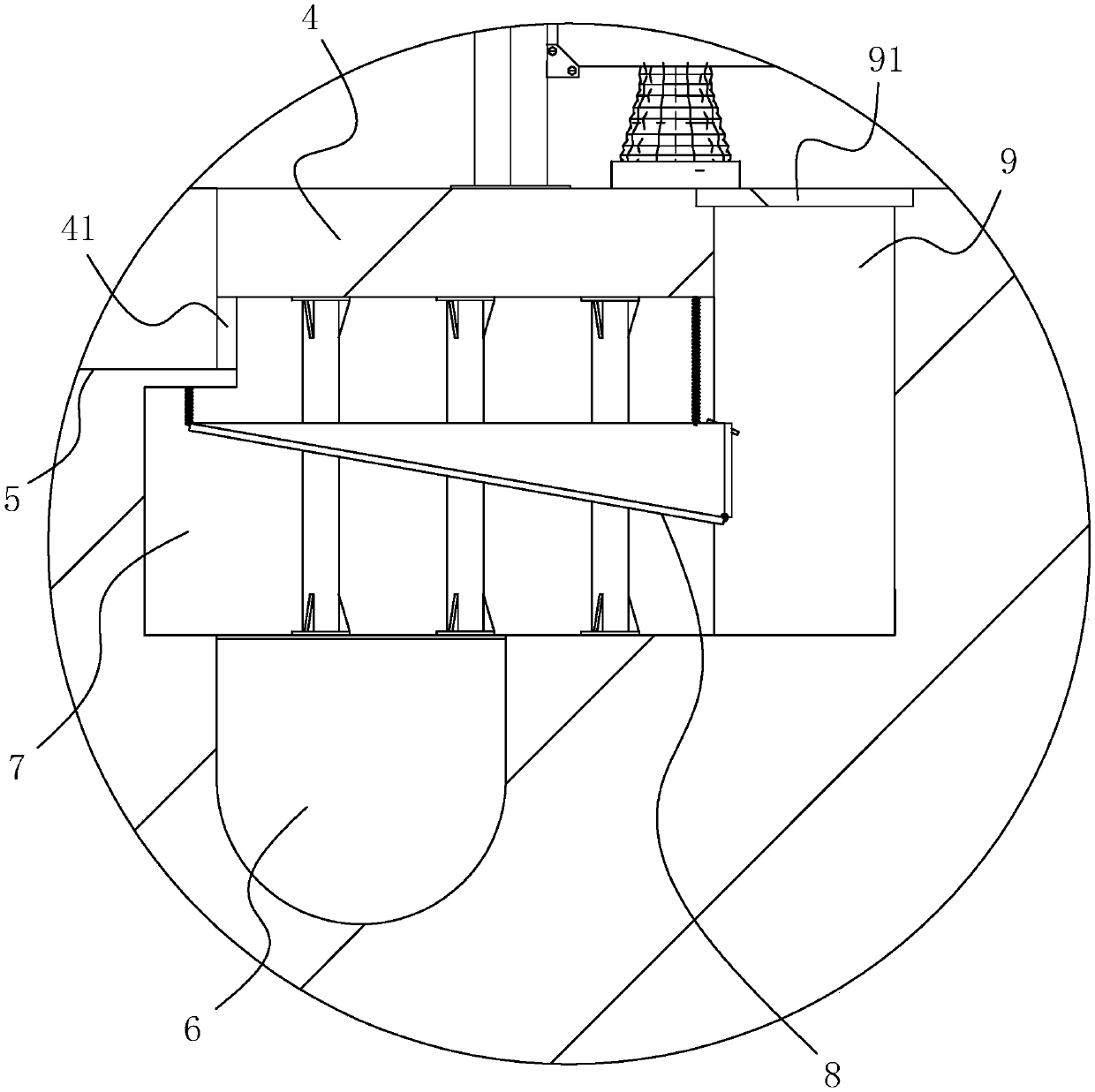

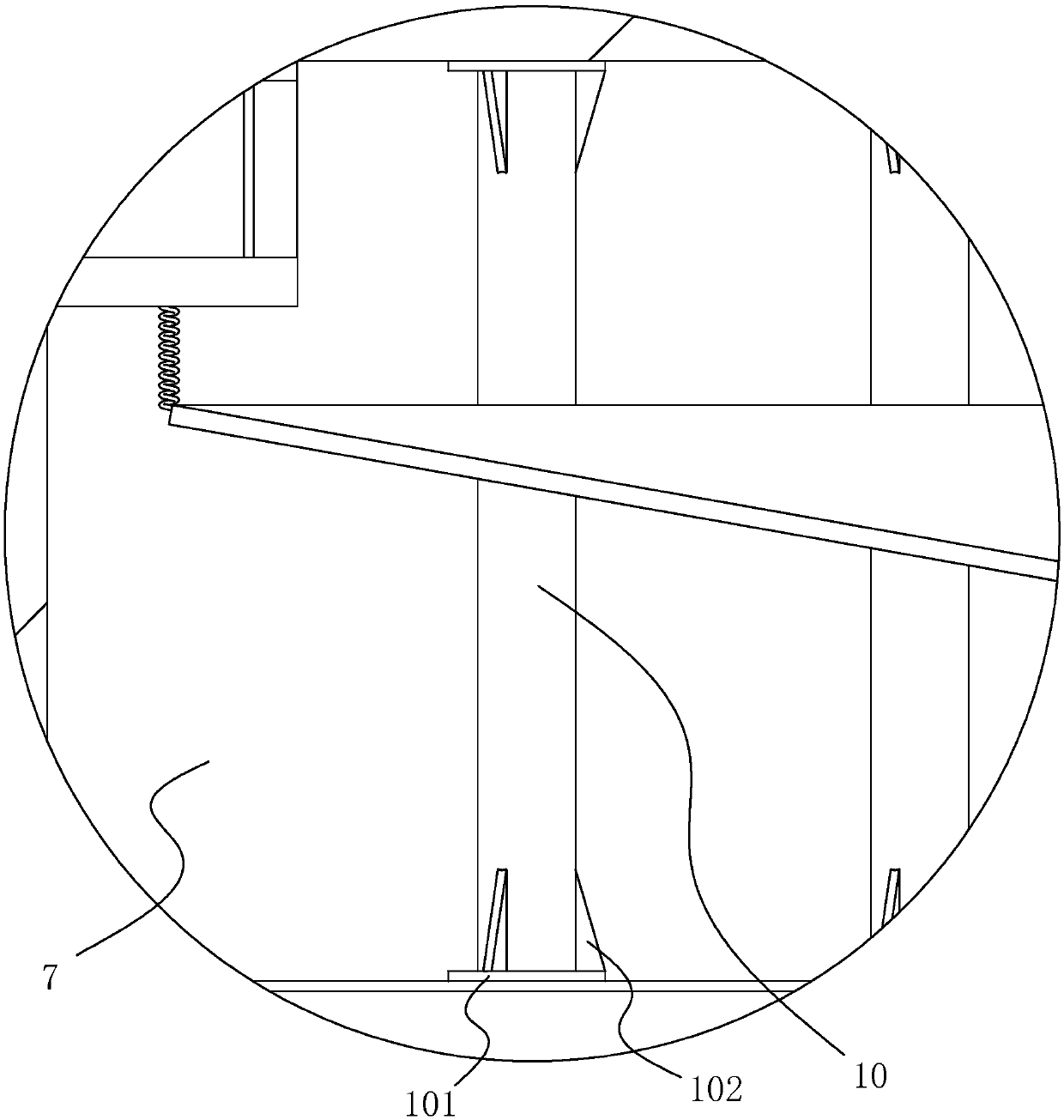

Municipal road rainwater flow-guiding structure

InactiveCN109610614ADoes not affect filteringNo cloggingSewerage structuresVertical projectionParking area

The invention discloses a municipal road rainwater flow-guiding structure and relates to the technical field of municipal road drainage structures. The technical field that water is prone to being accumulated in a parking area is solved. According to the technical key points, the municipal road rainwater flow-guiding structure comprises a drainage opening formed in the side, close to the parking area, of a platform and communicating with a municipal drainage pipeline, the municipal road rainwater flow-guiding structure further comprises a cavity formed below the platform and the parking area and located between the drainage opening and the municipal drainage pipeline, a filter piece arranged in the cavity, a treatment chamber formed in the platform, and a sealing cover arranged at the upper end of the treatment chamber in a covering mode, wherein the upper end and the lower end of the treatment chamber communicate with the cavity and the upper surface of the platform correspondingly, the upper end and the lower end of the cavity communicate with the drainage opening and the upper end of the municipal drainage pipeline, and the vertical projection face of the drainage opening is located in the filter piece. The municipal road rainwater flow-guiding structure has the advantage of preventing water accumulation in the parking area.

Owner:WENZHOU FENGCHENG CONSTR CO LTD

Self-purifying environment detecting device

InactiveCN107339787ASolve the problem of prone to blockageEasy maintenanceSpace heating and ventilation safety systemsLighting and heating apparatusLiquid-crystal displayEngineering

The invention discloses a self-purifying environment detecting device. The self-purifying environment detecting device comprises a shell, a microprocessor, a liquid crystal display and an alarm; the self-purifying environment detecting device is provided with an air inlet, an induced draft fan, a supporting frame, an arc-shaped air channel, a detecting air channel, drawer boxes, detecting sensors, a filtering device and an air outlet in sequence from top to bottom; the induced draft fan is fixed to the interior of the shell through the supporting frame; the lower part of the arc-shaped air channel is connected with the detecting air channel; a plurality of air openings are formed in the detecting air channel; detecting inlets which are matched with the air openings are formed in the drawer boxes; the air openings are connected with the detecting inlets through telescopic hoses; and the sensors which are used for detecting are arranged in the drawer boxes. According to the self-purifying environment detecting device, the problem that the current air detecting equipment can detect air, but the detected air is exhausted into the air directly, so air detecting equipment is blocked easily after long-time use because a corresponding filtering net is not provided is solved.

Owner:HEFEI KANGZHIHENG MACHINERY TECH CO LTD

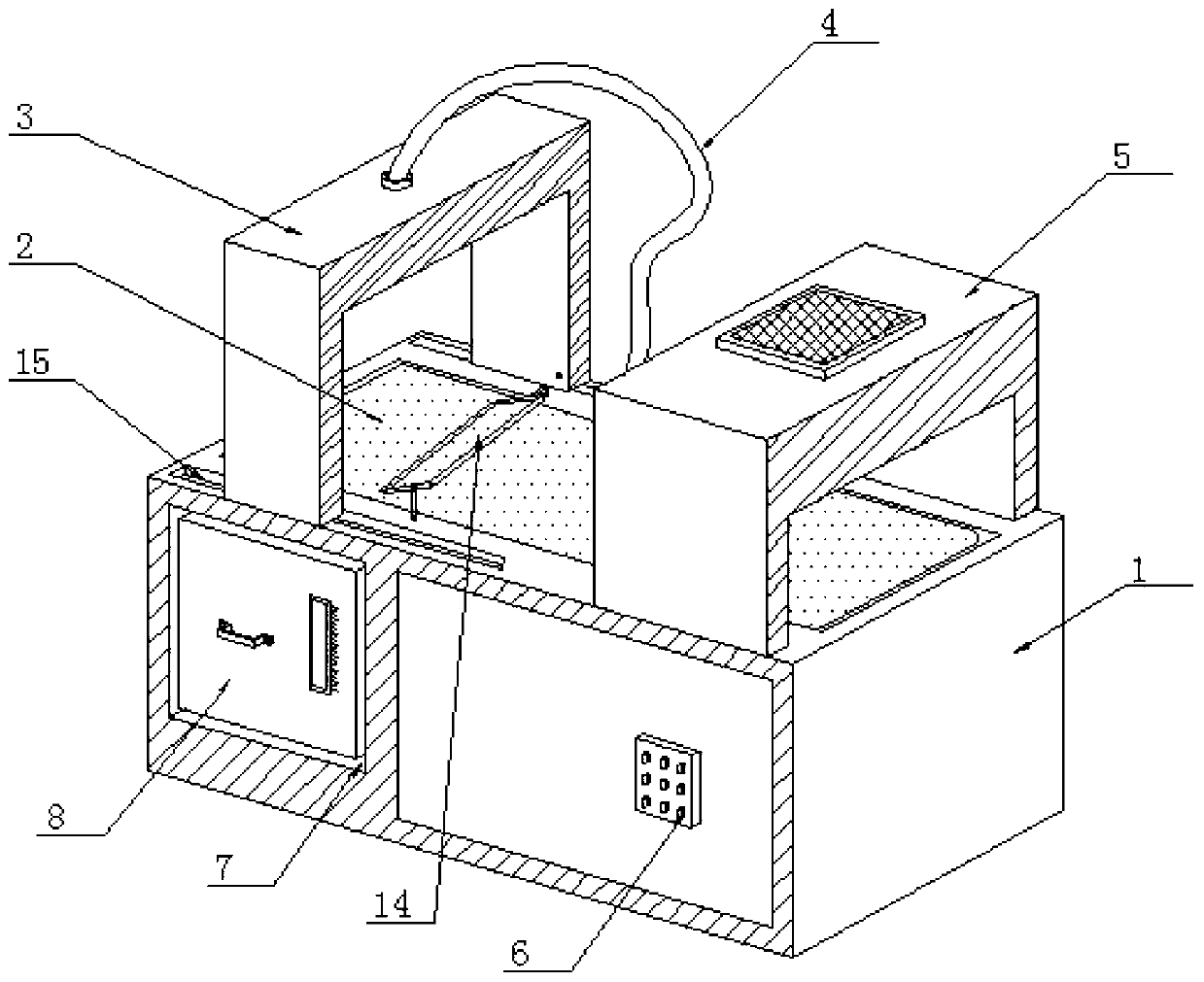

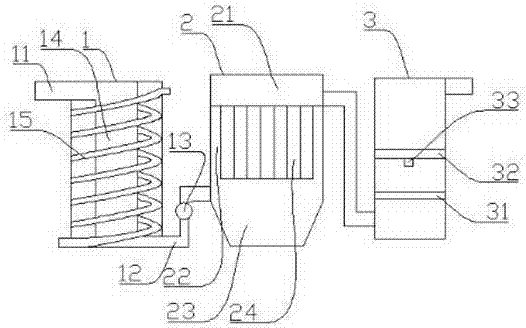

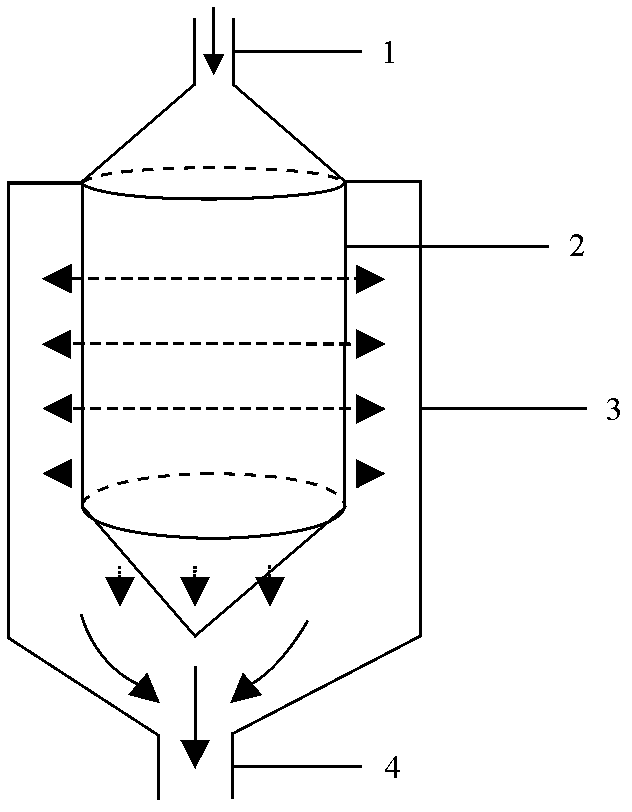

Energy-saving and environment-friendly dust removing system for asphalt concrete stirring station

InactiveCN107321110AReduce the temperatureRealize self-regulationCombination devicesTemperature controlSpray nozzle

The invention discloses an energy-saving and environment-friendly dust removing system for an asphalt concrete stirring station. The energy-saving and environment-friendly dust removing system comprises a temperature control device (1), a cloth-bag dust removing device (2) and a spraying and dust-removing device (3) which are connected in sequence, wherein the temperature control device (1) is connected with a waste-gas outlet and comprises a hollow liner (14) and a shell, and a circulating pipeline (15) is arranged between the shell and the liner (14); a temperature sensor (13) is arranged between the temperature control device (1) and the cloth-bag dust removing device (2); the spraying and dust-removing device (3) comprises a shell, a filtering net (31) and a spraying nozzle (33); the filtering net (31) and the spraying nozzle (33) are arranged in the shell; and the spraying nozzle (33) is connected with a water pipe (32) and is arranged above the filtering net (31). The energy-saving and environment-friendly dust removing system disclosed by the invention has the advantages that the dust-removing effect for waste gas is good, the temperature of the waste gas can be effectively controlled and the service life of the dust removing equipment is prolonged.

Owner:山东中玻节能环保发展有限公司

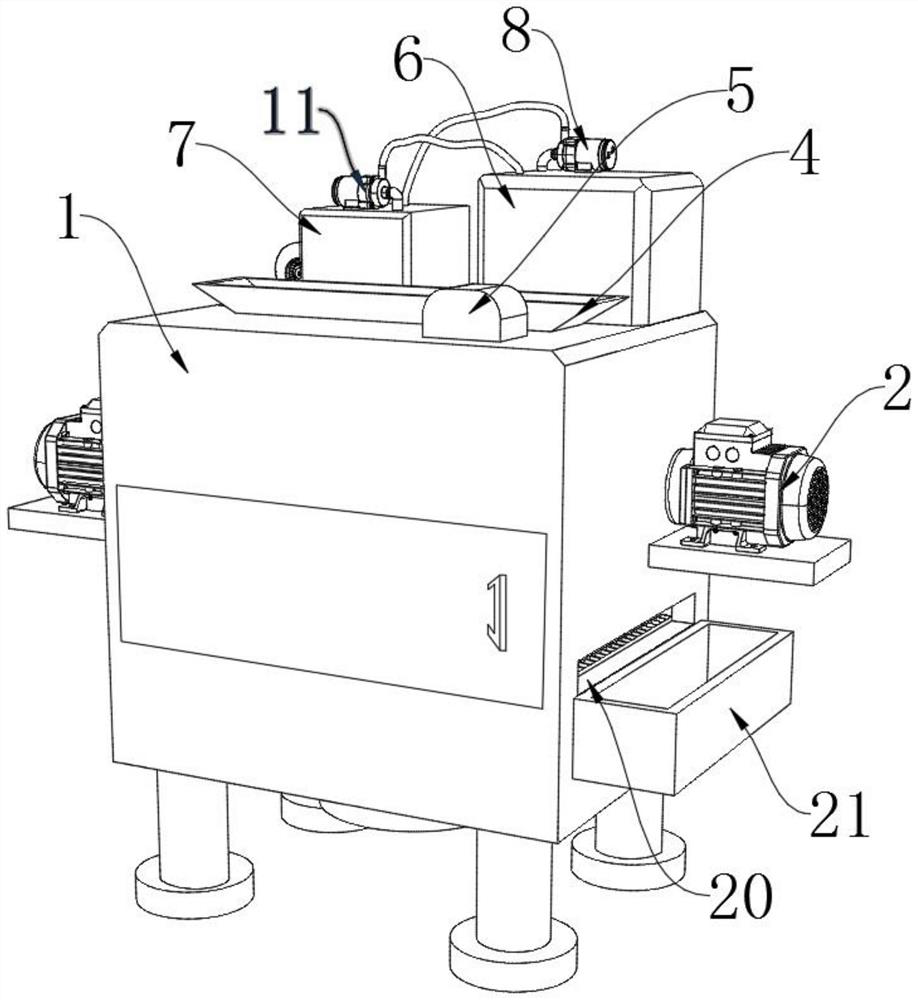

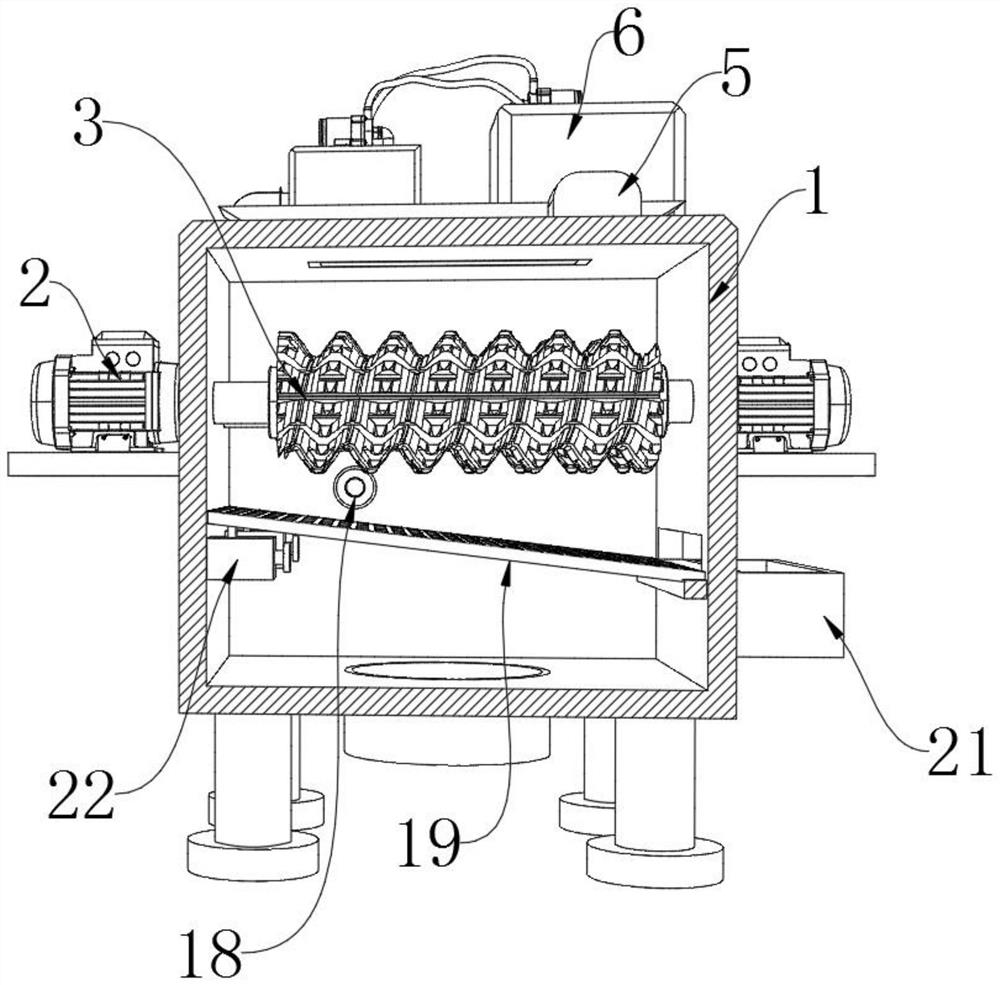

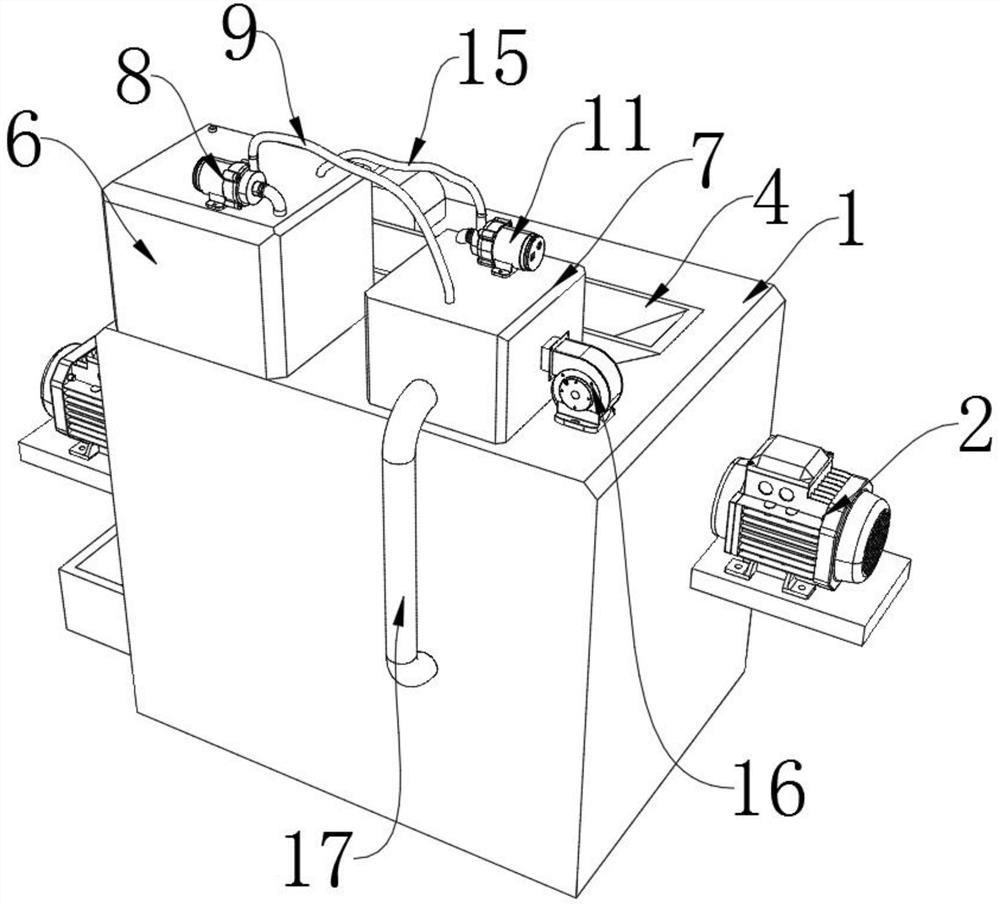

Dust-removal-based water conservancy project stone crushing device

InactiveCN111940082ANot easy to breatheEasy to remove dustUsing liquid separation agentGrain treatmentsElectric machineDust control

The invention discloses a dust-removal-based water conservancy project stone crushing device, and relates to the technical field of stone crushing. The device comprises a device body, wherein two motors are fixed to the two sides of the device body, hobbing cutters are welded to the output ends of the two motors, a feeding port is provided in the top of the device body, a battery box is welded tothe top of the device body and located at one end of the feeding port, a water tank is welded to the top of the device body and located at the other end of the feeding port, a dust box is welded to the top of the device body and located on one side of the water tank, a first water pump is fixed to the top of the water tank through screws, and a first conveying water pipe is clamped to the output end of the first water pump. According to the device, through mutual cooperation of the water tank, the dust box, a fan and a dust suction pipe, dust inside the device can be removed more conveniently,and through mutual cooperation of a fixing frame, a fixing block and a limiting rod, the device can replace a filter screen more conveniently.

Owner:芜湖青悠静谧环保科技有限公司

Novel composite gate valve assembly

InactiveCN106122577AAffect switch actionReduce flow rateOperating means/releasing devices for valvesSlide valveInlet channelEngineering

The invention relates to a valve, in particular to a novel composite gate valve assembly. The novel composite gate valve assembly comprises a water inlet pipeline, a gate valve and a water outlet pipeline. The water inlet pipeline and the gate valve are fixedly connected through a high-pressure threaded flange. The gate valve and the water outlet pipeline are fixedly connected through a welding neck flange. Each of the water outlet pipeline and the water inlet pipeline is provided with a pipeline sight glass. A water inlet channel and a water outlet channel are arranged at the two ends of a valve body. A cavity is formed between the water inlet channel and the water outlet channel. A gate plate is arranged in the cavity. A switch hand wheel is arranged on the top of the gate plate. A passing hole is formed in the gate plate. A transverse filter net is arranged at the bottom of the cavity. A through hole is formed in the middle portion of the transverse filter net and is the same as the cross section of the gate plate in shape. The gate plate penetrates the filter net, and a replacing opening used for drawing the filter net is formed in the side face of the valve body. According to the novel composite gate valve assembly, dirt accumulated in the valve body can be discharged, and the instantaneous pressure intensity in the valve can be relieved.

Owner:DEYANG DIXINJIA VALVE MFR

Maintenance equipment for prefabricated parts after pouring

InactiveCN112659342AImprove cleanlinessDoes not affect filteringCeramic shaping apparatusFiltration separationWater storageStructural engineering

The invention belongs to the technical field of construction machinery, and particularly relates to maintenance equipment for prefabricated parts after pouring. The maintenance equipment comprises a bottom plate, wherein a support plate is fixedly mounted at the top of a water storage pool, a sewage discharging channel is formed in one side of the water storage pool, fixing plates are symmetrically and fixedly mounted on the inner side of the water storage pool, and a filter screen is jointly placed on the upper surfaces of the two fixing plates; and servo motors are symmetrically and fixedly mounted on the other side of the water storage pool, a lead screw is fixedly connected to an output shaft penetrating through the water storage pool, of each servo motor, a scraper is jointly connected to the outer sides of the two lead screws in a threaded mode, a connecting groove is formed in the lower surface of the scraper, a connecting block is clamped in the connecting groove, and a sweeping brush is fixedly mounted on the lower surface of the connecting block. The servo motors are started to drive the lead screws connected with the output shafts of the servo motors to rotate, and the scraper on the outer side drives the sweeping brush clamped through the connecting block and the connecting groove to move horizontally, so that dirt on the surface of the filter screen can be swept out conveniently, and the filtering effect cannot be affected.

Owner:颍上晶宫绿建节能建筑有限责任公司

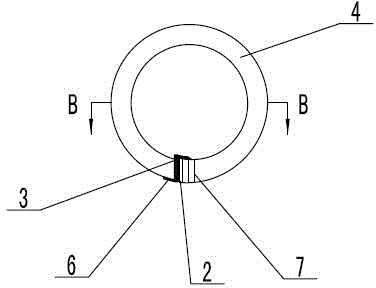

A method of making a conductive filter bag

ActiveCN105854442BEasy to installDoes not affect filteringDispersed particle filtrationKeelEngineering

A method for making a conductive filter bag belongs to the technical field of conductive filter bags. Including the bag body (1) and the bag bottom sewn on the bottom of the bag body (1), a double-layer lap (2) for sewing is distributed on the bag body (1), and the inside of the double-layer lap (2) A conductive strip (3) is provided, and the conductive strip (3) is fixed by a suture (7) sewn on the double-layer lap; The top of the layer lap edge (2) is exposed, and is wound from the inside of the bag body (1) to the outside of the bag body (1), and then fixed on the bag body (1) below the ring frame; The bottom end of the lap is exposed and placed outside the bag body (1). The conductive filter bag has good conductive effect, and can prevent the conduction failure caused by the collision and wear of the keel and the conductive belt in the bag body. production efficiency.

Owner:山东兴国新力环保科技股份有限公司

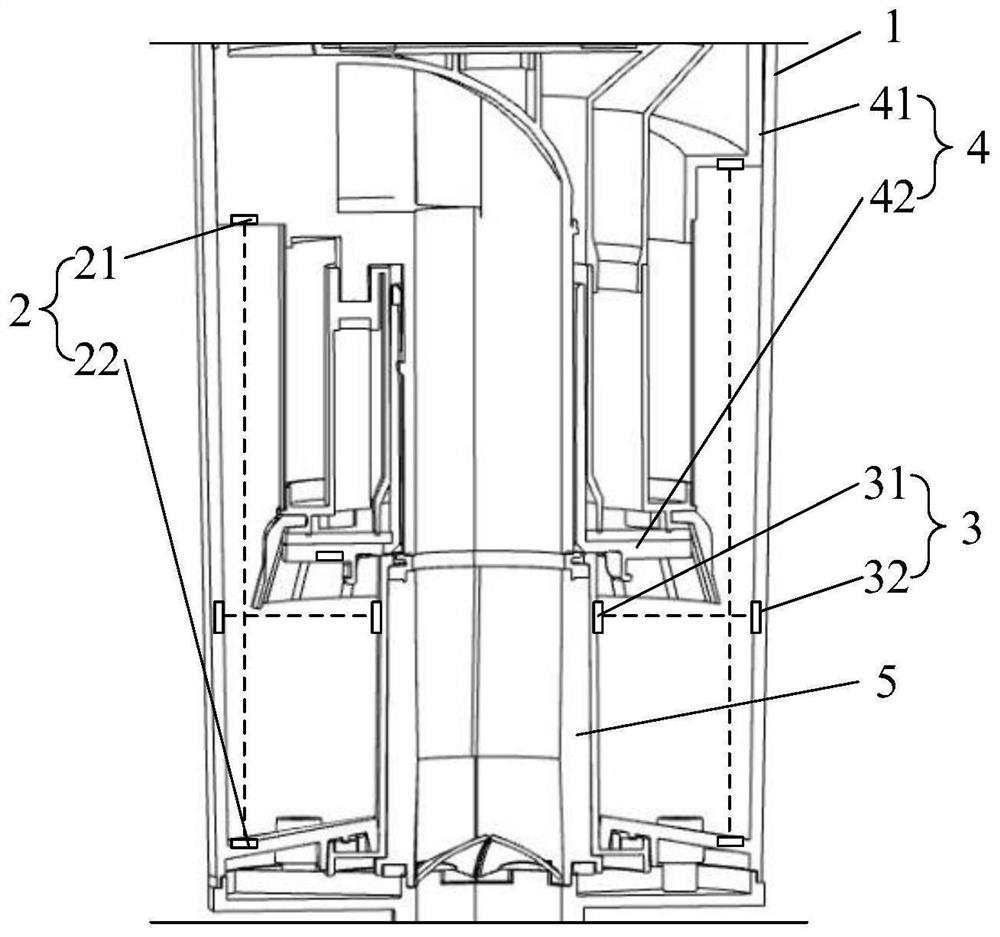

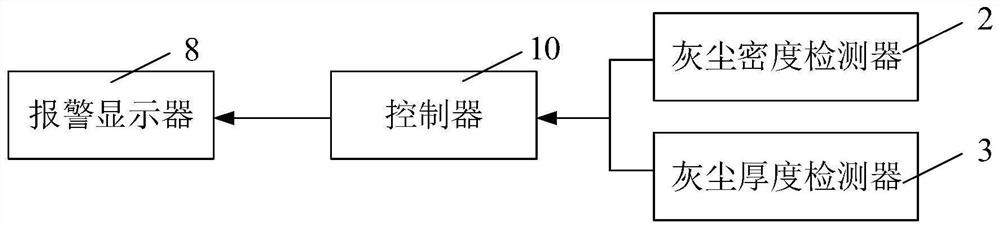

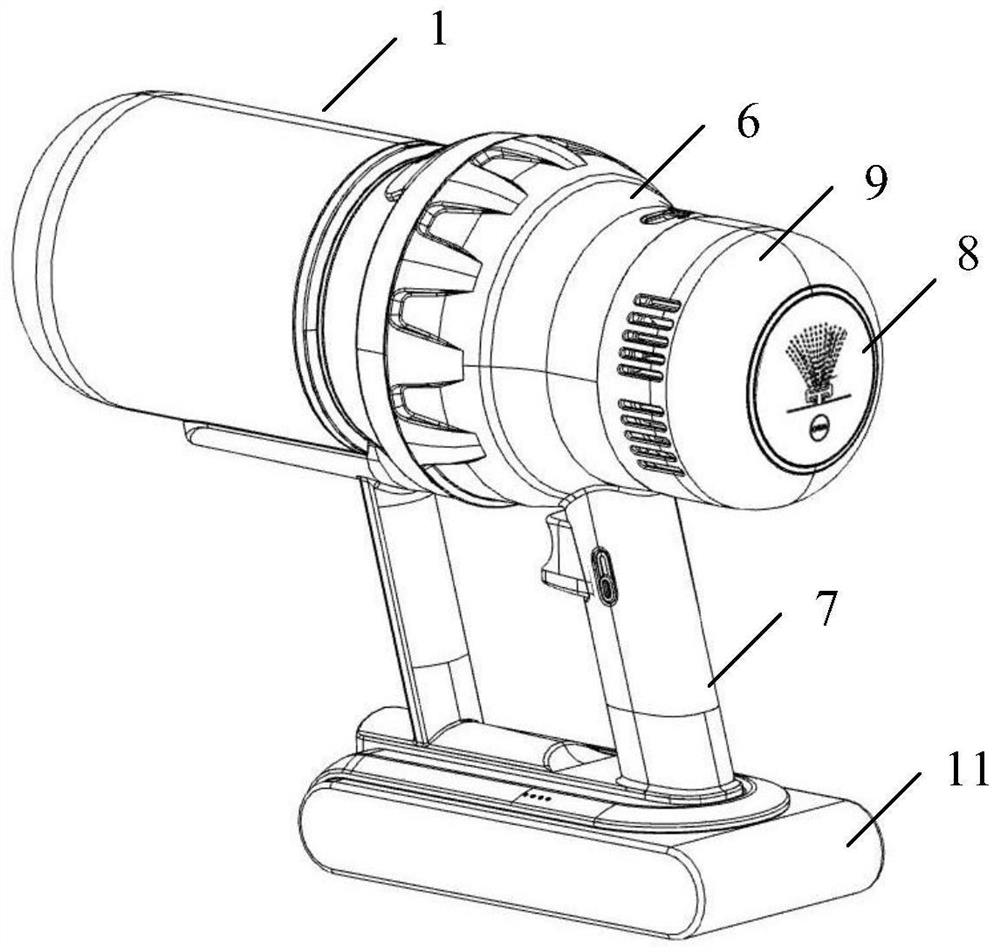

Dust cup, dust collection amount detection method and cleaning equipment

InactiveCN113017477AImprove accuracyDoes not affect filteringSuction filtersElectric equipment installationEnvironmental engineeringMechanical engineering

The invention discloses a dust cup, a dust collection amount detection method and cleaning equipment, belongs to the technical field of ground cleaning, and solves the problems of poor cleaning efficiency and poor use experience of cleaning equipment in the prior art. In the dust cup and the cleaning equipment, a cup body, a dust density detector, a dust thickness detector and a controller are included, and the dust density detector and the dust thickness detector are both arranged in a dust collection area of the cup body and connected with the controller; the controller receives a dust thickness and the dust density; and if the dust thickness reaches a thickness threshold value and the dust density reaches a density threshold value, the dust cup is determined to be in a dust-full state, and otherwise, the dust cup is determined not to be in a dust-full state. The dust cup, the dust collection amount detection method and the cleaning equipment can be used for ground cleaning.

Owner:PUPPY ELECTRONICS APPLIANCES INTERNET TECH (BEIJING) CO LTD

Anti-reflux pressurization type filtering device

PendingCN108993009AAvoid the work of replacing the screwReduce use costMoving filtering element filtersDrive motorStator

The invention relates to an anti-reflux pressurization type filtering device. The filtering device comprises a grid cylinder, a filter element, screw rods and a driving motor, wherein the screw rods comprise a small screw rod and a big screw rod, the screw diameter of the small screw rod is smaller than that of the big screw rod, the small screw rod and the big screw rod are both arranged inside the filter element, and the thread surface of the big screw rod is in sealing contact with the inner wall surface of the filter element. According to the anti-reflux pressurization type filtering device provided by the invention, as the screw rods comprise the big screw rod and the small screw rod, and the filter element can rotate synchronously with the big screw rod, the small screw rod can rotate relatively to a stator barrel, so that abrasion of the big screw rod can be avoided, the small screw rod is arranged inside the stator barrel, and the filtering effect of the filter element cannot be affected. Compared with the prior art, the anti-reflux pressurization type filtering device provided by the invention overcomes the problem caused by the increasing of the distances between the screw rods and the filter element due to the abrasion of the screw rods, can avoid the operation of regularly replacing the screw rods, and greatly reduces the use cost.

Owner:黄得锋

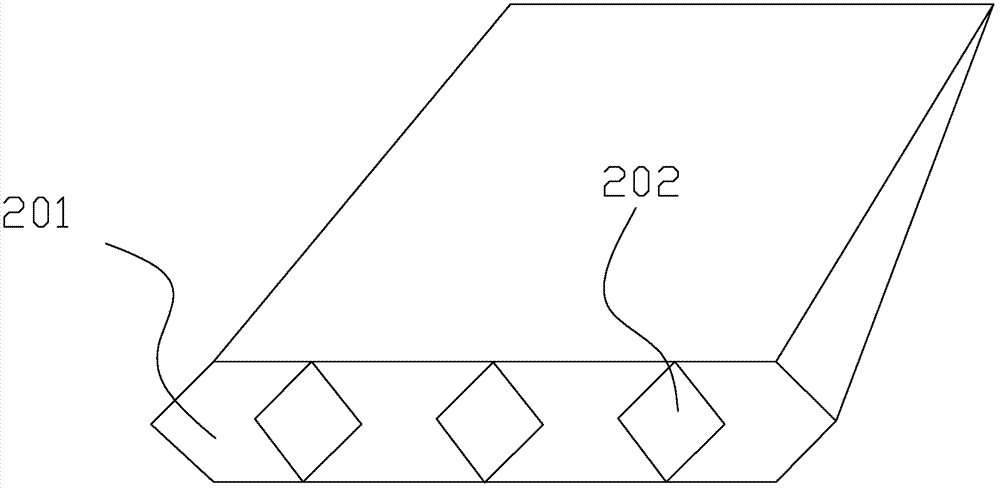

Filtering device for medicine preparation

InactiveCN107335258AAvoid accumulationDoes not affect filteringStationary filtering element filtersDrugs solutionFiltration

The invention discloses a filter device for medical preparation, which comprises a filter tank main body, an inclined filter screen is installed inside the filter tank main body, and a storage compartment is arranged on the side wall of the filter tank main body at the higher end of the filter screen, so that The inner walls on both sides of the main body of the filter pool are provided with moving tracks along the inclination direction of the filter net, and the moving tracks extend to the inside of the storage cabin. The two sets of moving tracks are located in the storage cabin and are movable and equipped with cleaning devices. The cleaning device includes a moving base, and the moving bases are installed on two groups of moving rails, and the moving base devices of the two groups are connected by supporting beams, and supporting springs are equidistantly arranged on the lower side of the supporting beams along the length direction. The invention is novel in design, convenient to use, and can efficiently separate medicinal liquid and medicinal residues, and the medicinal residues can be disposed of in time without affecting the filtering effect of the filter net, thereby improving the filtering efficiency.

Owner:四川省隆昌诚信印务有限公司

Liquid filter

InactiveCN103083958AReduce cloggingExtend your lifeSemi-permeable membranesGravity filtersFluidicsEngineering

The invention discloses a liquid filter manufactured by using liquid column fluidics technology. The liquid filter comprises a filtrate collector, and a nuclear track membrane filter core; a liquid inlet pipe is disposed at the top of the filtrate collector, and a liquid outlet pipe is disposed at the bottom; the nuclear track membrane filter core is disposed in the filtrate collector. The nuclear track membrane is in a bag form, is connected with the liquid inlet pipe at the upper part, and has a flat, conical, semispherical or wedge-shaped bottom. The liquid filter is simple in structure and easy to machine; the filtration efficiency is high; the filter core is not easy to obstruct; and the service life is long.

Owner:刘子渊

Novel air filter bag

InactiveCN103357223AImprove breathabilityDoes not affect filteringDispersed particle filtrationAir volumeAir filter

The invention discloses a novel air filter bag which mainly comprises a large filter bag and small filter bags, wherein the small filter bags are positioned in the large filter bag; the filter area of each small filter bag is 50 percent of that of the large filter bag; the small filter bags are adhered to the large filter bag through thermal melting; the small filter bags are also adhered to one another through the thermal melting. Under the conditions that an air conditioning box is small and the air volume is large, a filter frame is not required to be replaced; a small filter bag page technology is additionally adopted in a conventional filter bag page, so that 50 percent of the filter area is increased in the original filter area; furthermore, bag pages are adhered to one another through the thermal melting by using a high-frequency technology; the ventilating intensity of the bag pages is improved; at high air speed, the filter effect can not be affected by the adhesion of the bag pages; the aims of saving energy and reducing the cost are fulfilled.

Owner:上海菲尔特空气净化技术有限公司

Automatic replacement device for filter screen of sewage microfilter

ActiveCN110772870BAchieve replacementDoes not affect filteringMoving filtering element filtersEngineeringSewage

The invention discloses an automatic replacement device for a filter screen of a sewage microfilter, which comprises a machine body, a rotating cylinder is arranged at the center of the top of the body, a first iron box is arranged on one side of the rotating cylinder, and the rotating cylinder is far away from One side of the first iron box is provided with a second iron box, the bottoms of the first iron box and the second iron box are slidably connected with the top of the body through sliding blocks, and the tops of the sliding blocks are all provided with sliding grooves . The top of the rotating block of the present invention is moved outwards, so that the rotating block rotates, the two sides of the filter screen are released from the fixed state of the groove, and then the locking block and the locking groove are connected to each other, and the telescopic blocks on both sides are fixed by the spring, and the new The filter screen is wound on the rotating cylinder, and the rotating block is separated from the fixing of the toggle bar, so that the rotating bar fixes the edge of the filter screen again, thereby realizing the replacement of the filter screen. It has the advantages of convenient installation, fast disassembly speed, and no need to stop the operation The advantages of ensuring the normal operation of the equipment.

Owner:广东景天环境科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com