Rotary table type dust removal apparatus for cleaning filter screen

A technology of dust removal device and turntable, which is applied in the direction of filtration and separation, membrane filter, transportation and packaging, etc. It can solve the problems of affecting the health of users, increasing the amount of dust accumulated, and increasing cleaning costs, etc., and achieves convenient and fast use and stable use Good, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

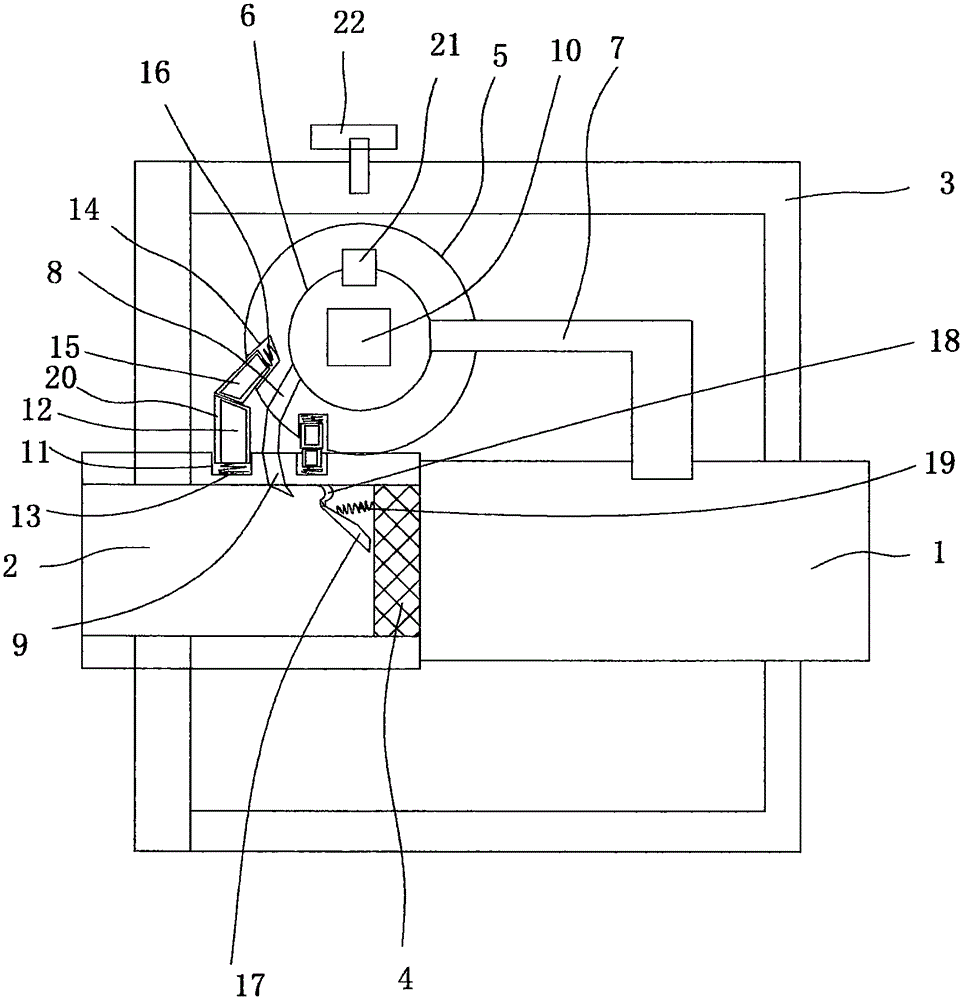

[0014] figure 1 A specific embodiment of the invention is shown in which figure 1 It is a structural schematic diagram of the present invention.

[0015] See figure 1 , a turntable cleaning filter screen type dust removal device, including a housing 3 with an air inlet channel 1 and an air outlet channel 2, a filter screen 4 is provided at the connection between the air outlet channel 2 and the air inlet channel 1 , a turntable 5 is also provided in the housing 3, a cavity 6 is provided in the turntable 5, a cleaning air duct 7 is provided between the cavity 6 and the air inlet channel 1, and the The turntable 5 is also provided with a cleaning air nozzle 8, and the cleaning air nozzle 8 is arranged on the edge of the turntable 5, and an inclined cleaning air hole 9 is arranged on the air outlet passage 2, and the inclined cleaning air hole 9 is arranged on the air outlet channel 2. The air outlet of the hole 9 cooperates with the filter screen 4 , the cleaning air nozzle 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com