Maintenance equipment for prefabricated parts after pouring

A technology of prefabricated parts and equipment, which is applied in the fields of manufacturing tools, filtration separation, ceramic molding machines, etc., can solve the problems such as the clogging of the filter screen and affect the filtering effect, and achieve the effect of convenient disassembly and convenient replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

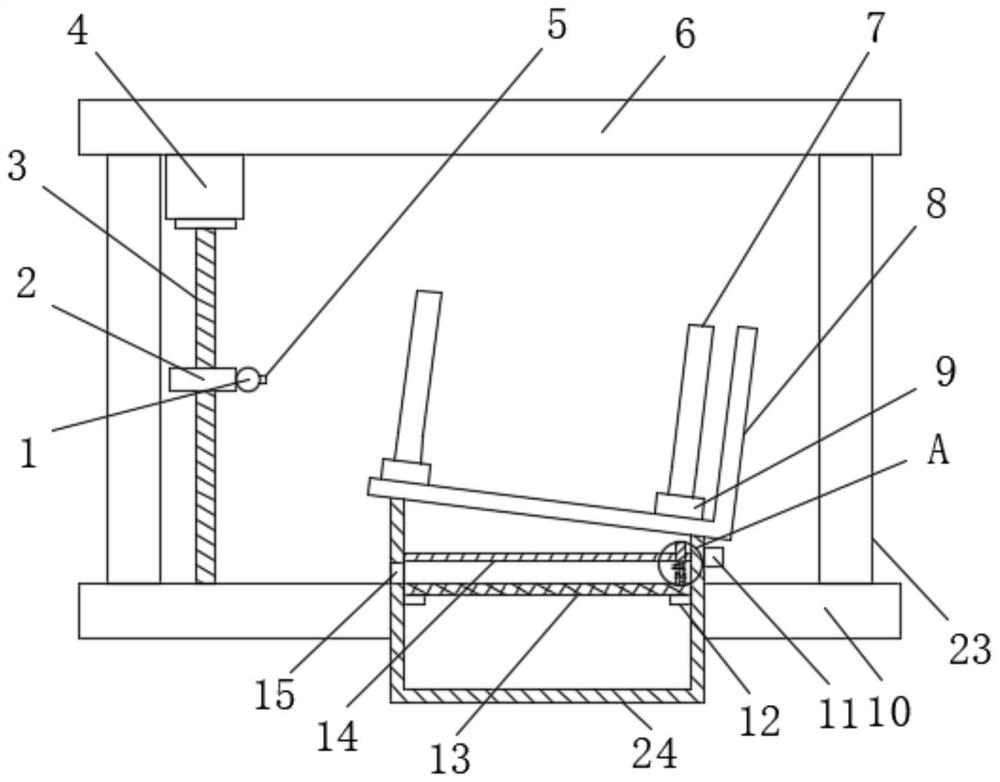

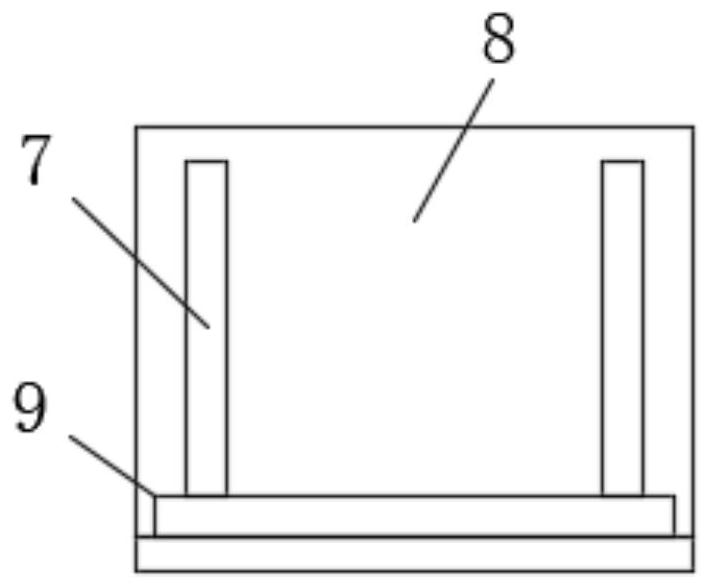

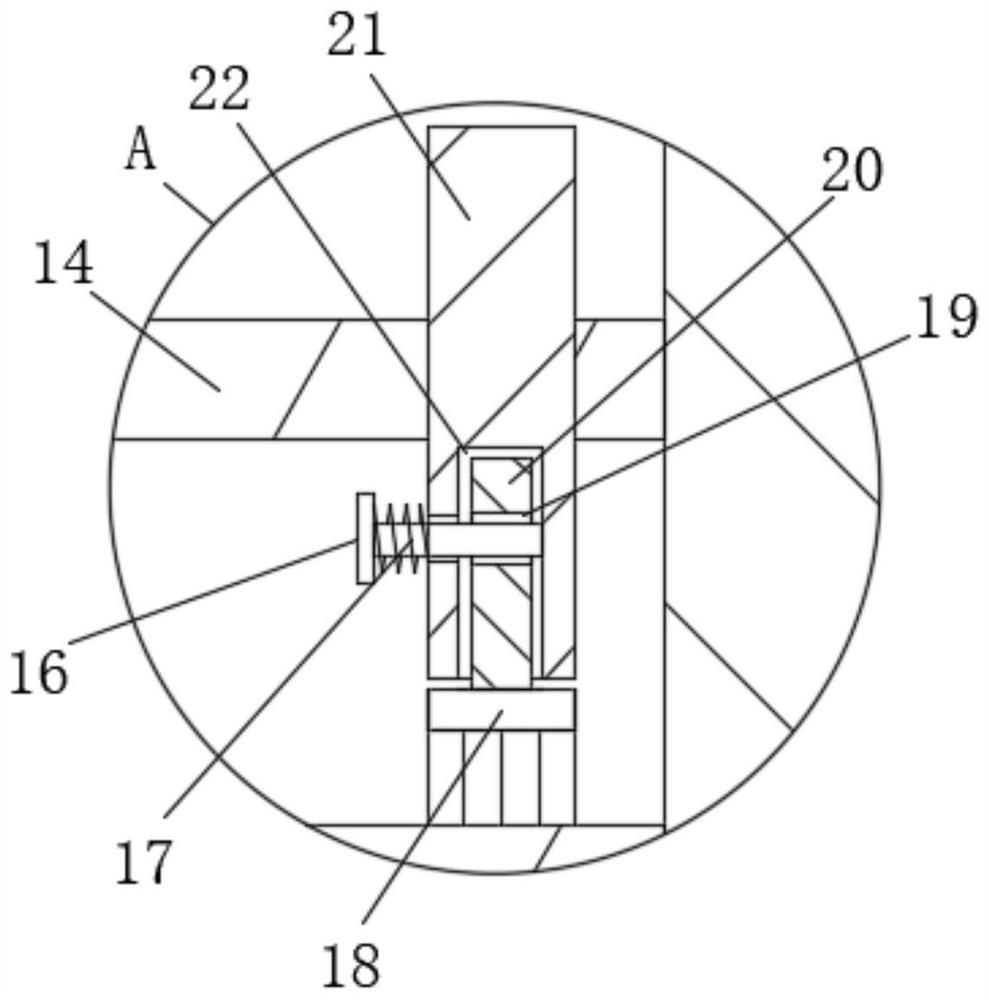

[0020] see Figure 1-3 , a maintenance equipment for prefabricated parts after pouring, comprising a bottom plate 10, four uprights 23 are evenly fixedly installed on the upper surface of the bottom plate 10, the upper ends of the four uprights 23 are jointly fixedly connected with a top plate 6, and the lower surface of the top plate 6 is symmetrically fixed and installed with Drive motor 4, the output shaft of each drive motor 4 is fixedly connected with threaded column 3, and the outside of two threaded columns 3 is jointly screwed with movable plate 2, and one side of movable plate 2 is fixedly installed with spray pipe 1, spraying A plurality of nozzles 5 are fixedly connected to the outside of the pipe 1, a water reservoir 24 is fixedly installed inside the bottom plate 10, a support plate 8 is fixedly installed on the top of the water reservoir 24, and a sewage discharge channel 15 is opened on one side of the water reservoir 24 , the inside of the reservoir 24 is symme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com