All crank unloading device for press filter

A technology of unloading device and filter press, which is applied in the direction of filtration and separation, separation methods, chemical instruments and methods, etc., to achieve good effects, save materials, and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

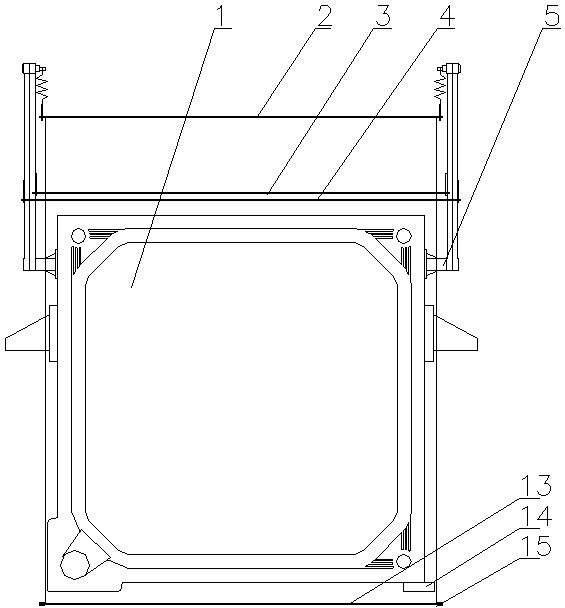

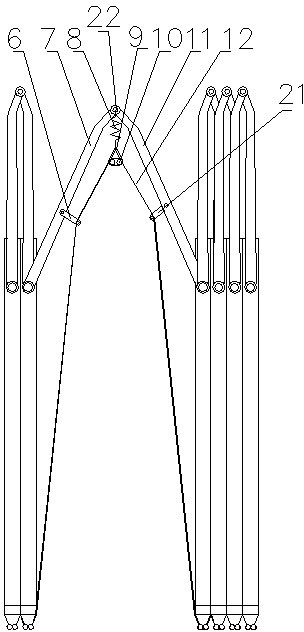

[0027] see Figure 1 to Figure 2 , the filter press full varicose unloading device in this embodiment includes several full varicose unloading mechanisms, each full varicose unloading mechanism includes two adjacent lower corner feeding filter plates 1, and the lower ends are respectively connected to one piece by rotation. The lower ends of the two outer varicose arms 7 on both sides of the lower corner feeding filter plate 1 are respectively rotatably connected to the two inner varicose arms 11 on both sides of the other lower corner feeding filter plate 1 , and are respectively rotatably connected to the two outer varicose arms 7 The two long cloth swing plates 6 are respectively rotated to the two short cloth swing plates 21 connected to the two inner varicose arms 11, and the two ends are connected to the long cloth rollers on the two long cloth swing plates 6 respectively. 4. The short support rollers 3 connected to two short support cloth swing plates 21 at both ends, t...

Embodiment 2

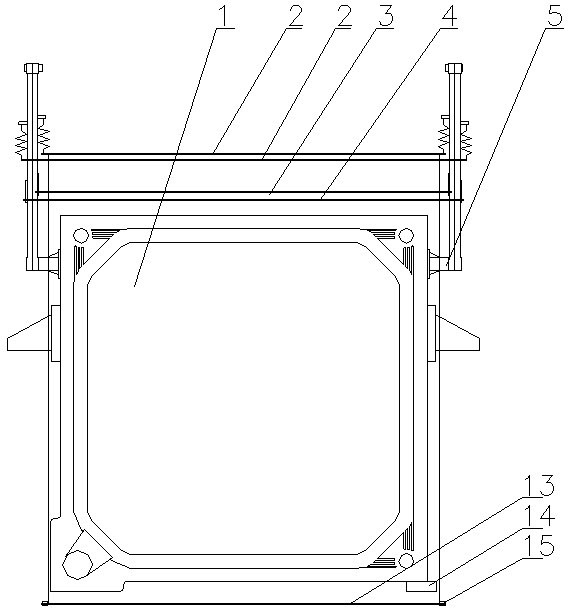

[0035] see Figure 3 to Figure 4 , the filter press full varicose unloading device in this embodiment includes several full varicose unloading mechanisms, each full varicose unloading mechanism includes two adjacent lower corner feeding filter plates 1, and the lower ends are respectively connected to one piece by rotation. The lower ends of the two outer varicose arms 7 on both sides of the lower corner feeding filter plate 1 are respectively rotatably connected to the two inner varicose arms 11 on both sides of the other lower corner feeding filter plate 1 , and are respectively rotatably connected to the two outer varicose arms 7 The two long cloth swing plates 6 are respectively rotated to the two short cloth swing plates 21 connected to the two inner varicose arms 11, and the two ends are connected to the long cloth rollers on the two long cloth swing plates 6 respectively. 4. The short support rollers 3 connected to two short support cloth swing plates 21 at both ends, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com