Vibration cake unloading filter press capable of pulling filter plates in one time

A technology of filter press and filter plate, which is applied in the field of one-time filter plate vibration cake unloading filter press, which can solve the problems of economic benefit loss, increased production cost, low filtration efficiency, etc., and achieve economic benefit and cake unloading speed Fast, high filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

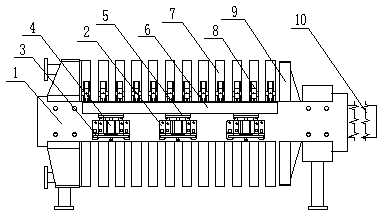

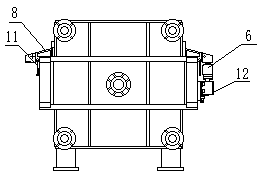

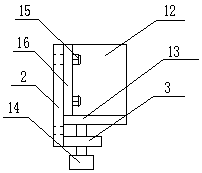

[0014] see figure 1 , figure 2 and image 3 As shown, the present invention provides a filter press that pulls the filter plate once and vibrates to unload the cake. A bottom plate 2 is provided. A baffle plate 3 is welded below the bottom plate 2. Adjusting bolts 14 are installed on the baffle plate 3 to make the bottom plate 2. The material used with the baffle plate 3 is a carbon structural steel middle plate, and an adjustment plate 16 is set. The adjustment plate 16 is connected to the bottom plate 2, and the adjustment plate 16 is provided with a slot hole, and the hexagonal bolt 15 is used to connect the bottom plate 2. Weld the reinforcing ribs 12 on the plane, and weld the base 13 under the adjustment plate 16. This structure forms the cylinder support body. At least two or more than two sets of cylinder assemblies 4 are installed on each filter press to make the cylinder support body. The material is a carbon structural steel middle plate, the cylinder support bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com