Energy-saving and environment-friendly dust removing system for asphalt concrete stirring station

A dust removal system, energy saving and environmental protection technology, applied in the direction of dispersion particle separation, chemical instruments and methods, combined devices, etc., can solve the problems of affecting the filtering effect, burning holes in the filter bag, large equipment, etc., and achieve good filtering and regulating effect, Increase the reaction time, good temperature control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

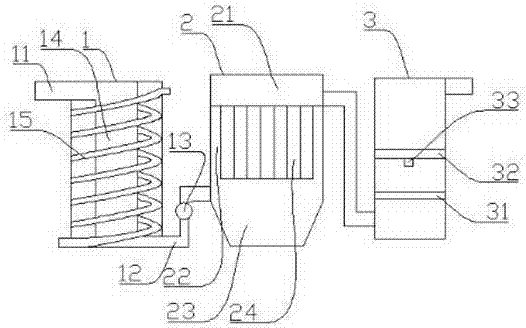

[0015] Reference attached figure 1 , the present invention provides an energy-saving and environment-friendly dedusting system for asphalt concrete mixing plants. The outlet is connected, and the temperature control device 1 includes a hollow inner tank 14 and an outer shell, and a circulation pipeline 15 is arranged between the outer shell and the inner tank 14; The temperature sensor 13; the spray dust removal device 3 includes a housing, a filter screen 31 and a nozzle 33 arranged inside the housing, the nozzle 33 is connected with a water pipe 32, and the nozzle 33 is arranged above the filter screen 31.

[0016] The temperature control device 1 includes a first air inlet 11 and a first air outlet 12, and the temperature sensor 13 is arranged on the connecting pipeline between the first air outlet 12 and the air inlet of the bag dust removal device 2. On the temperature sensor 13 Electrically connected with a display screen, the temperature control device 1 also includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com