Unloading type centrifugal machine with filter bag conducting reciprocating vibration

A centrifuge and filter bag technology, applied to centrifuges, centrifuges with rotating drums, etc., can solve problems such as increased operating costs, power consumption, and next-time filter cake pollution, and achieve low maintenance costs and reduced The effect of unloading power consumption and saving operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

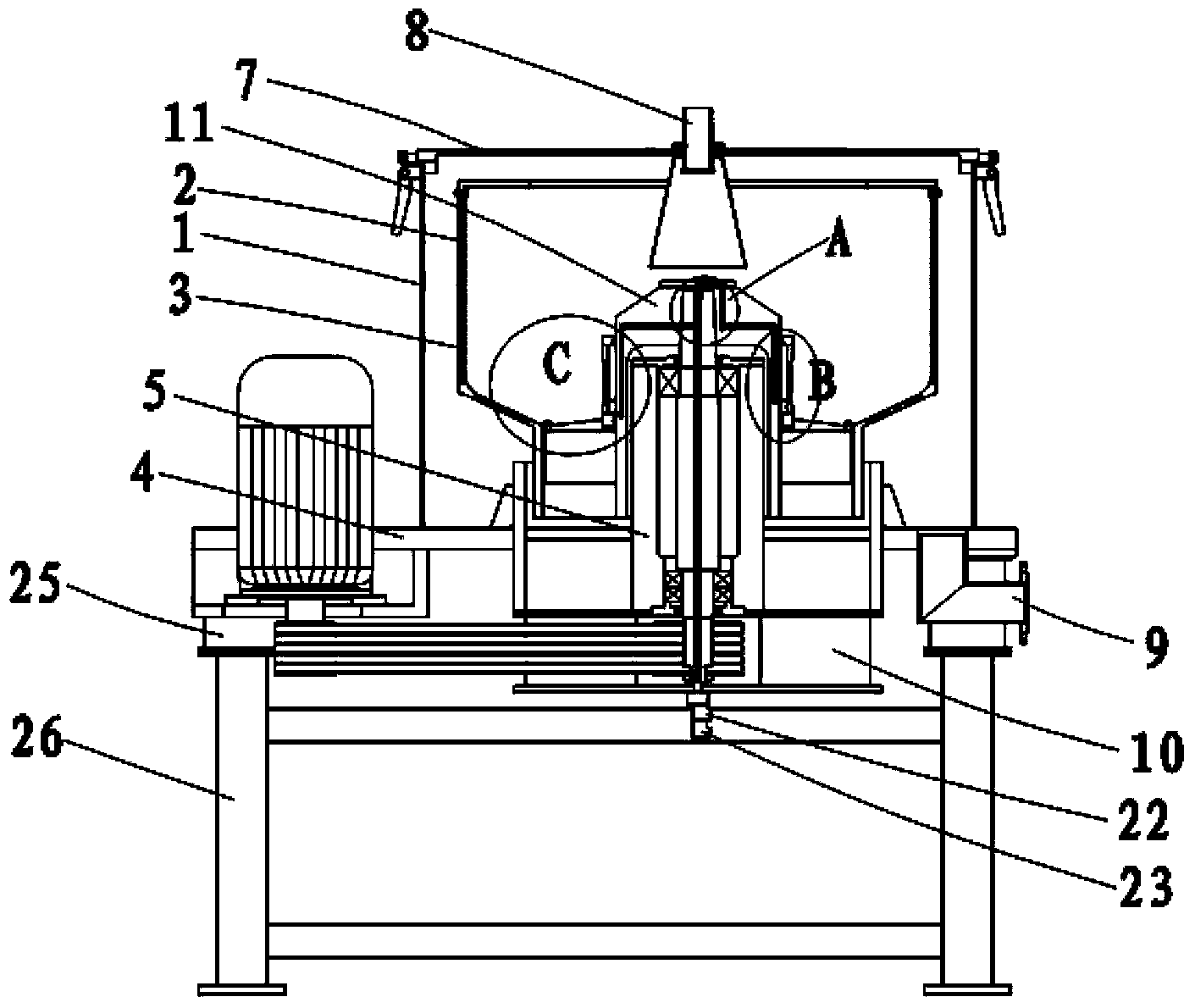

[0022] Embodiment: filter bag reciprocating oscillation discharge type centrifuge of the present invention, it comprises:

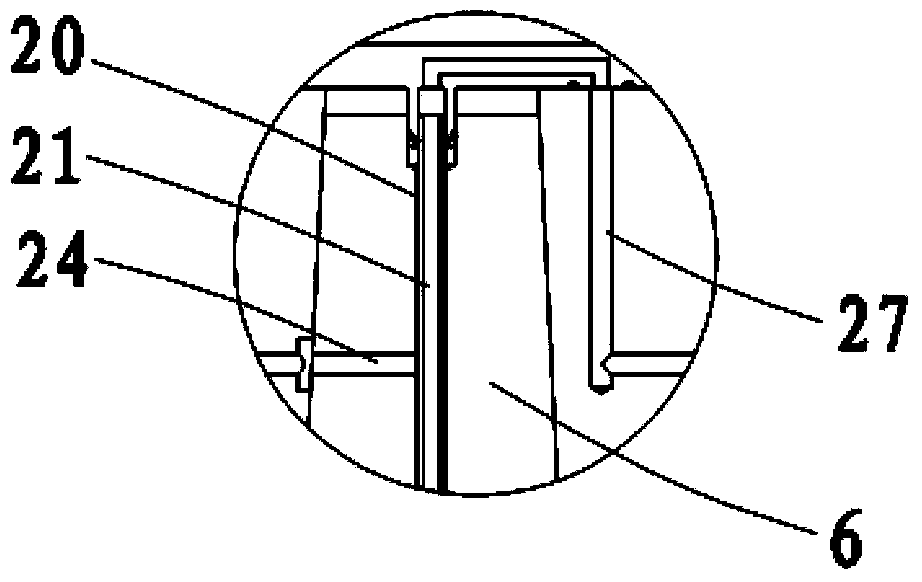

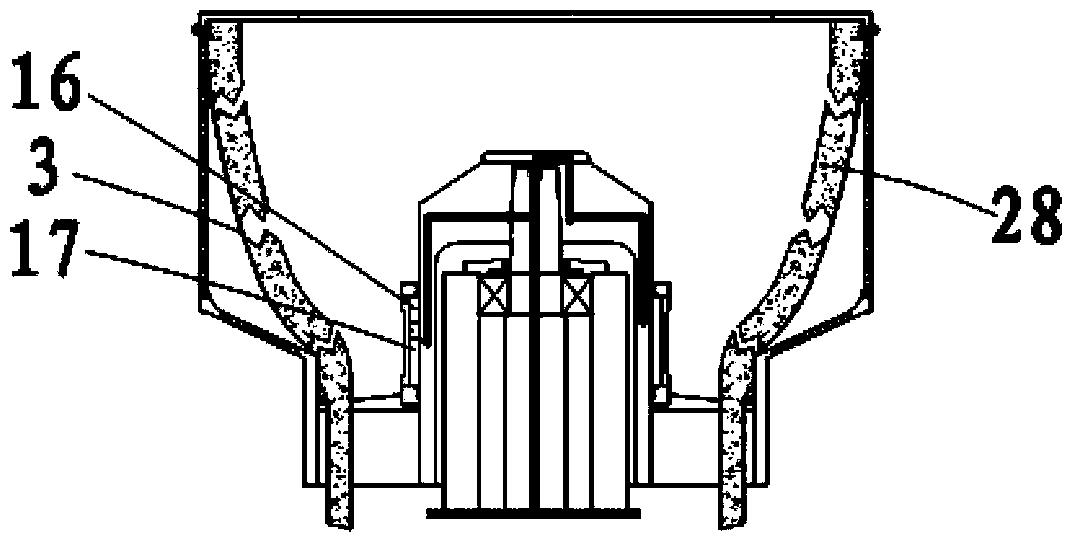

[0023] The drum 2 that can rotate at high speed is a three-section composite structure of column-cone-column with a large upper part and a smaller lower part. The drum wall is not perforated. The drum 2 is equipped with a column-cone-column filter bag 3 in the same shape as its inner wall. The filter bag is attached to the inner wall of the drum. The liquid in the material passes through the filter bag 3 and then passes through the series of The small holes leak out, and the solids in the material are trapped on the inner surface of the filter bag 3 to form a filter cake.

[0024] The upper end of the filter bag 3 is fixed by the pressure ring and the upper end of the drum 2, and the lower part of the filter bag is fixed by the pressure ring and the connecting plate 18. There is a gap between the outer circumference of the connecting disc 18 and the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com