Patents

Literature

45results about How to "Guaranteed to completely remove" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

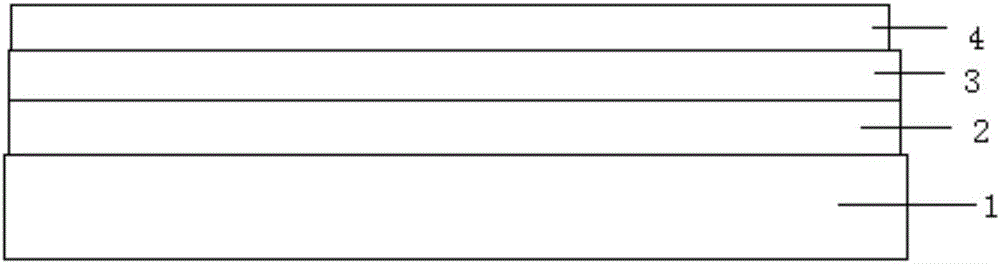

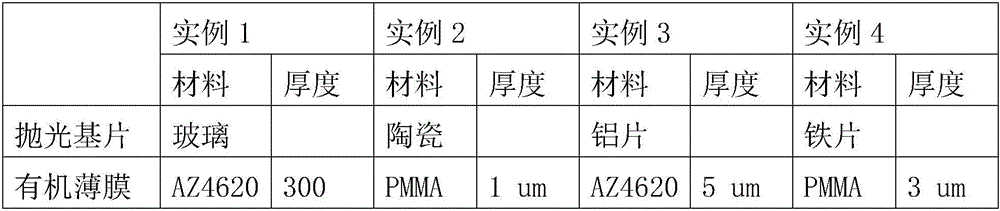

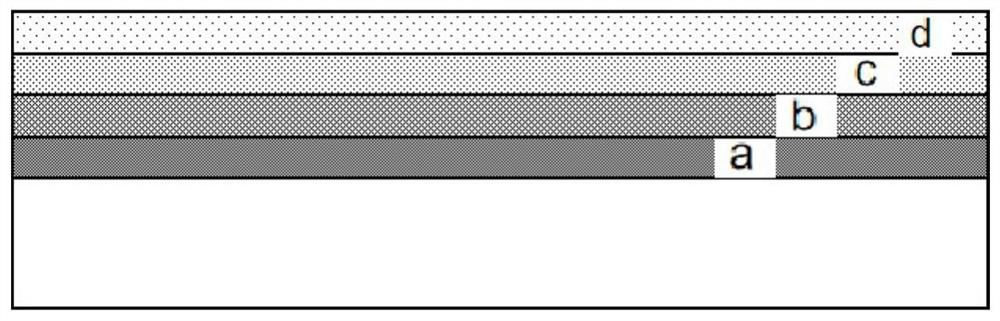

Mask for laser direct writing and etching method of mask

InactiveCN105789031AImprove thermal conductivityTransmit and disperse in timeNanostructure manufactureSemiconductor/solid-state device manufacturingOrganic filmOptoelectronics

The invention relates to a mask for laser direct writing and an etching method of the mask. The mask comprises a polishing substrate, an organic thin film, an oxide thin film and a metal thin film, wherein the organic thin film is attached onto the surface of the polishing substrate, the oxide thin film is deposited on the surface of the organic thin film, the metal thin film is deposited on the surface of the oxide thin film. The metal film in the mask for laser direct writing has high heat conduction performance, heat generated by laser abalation can be timely conducted and dissipated, and the influence of laser abalation on a film layer is reduced; the oxide thin film is relatively high in laser abalation capability, and the line accuracy of laser direct writing can be ensured; and an organic film layer can react with a solvent, so that the mask can be enabled to be completely removed.

Owner:CHINA BUILDING MATERIALS ACAD

Domestic health-care washing-up liquid and preparation method thereof

InactiveCN104893851AReasonable ratioFresh tasteOrganic detergent compounding agentsAnionic-cationic-non-ionic surface-active compoundsLinear alkylbenzeneCleansing Agents

The invention discloses domestic health-care washing-up liquid and relates to the technical field of chemical cleaning agents. The domestic health-care washing-up liquid is prepared from the following raw materials in parts by weight: 10 to 11 parts of linear alkyl benzene sulfonic acid, 11 to 13 parts of alkylolamides, 0.07 to 0.09 part of preservative, 1.2 to 1.4 parts of sodium hydroxide, 6 to 10 parts of fatty alcohol-polyoxyethylene ether, 0.05 to 0.15 part of ethylene diamine tetraacetic acid, 0.5 to 1.5 parts of a thickening agent, 50 to 60 parts of deionized water and 20 to 30 parts of a health-care traditional Chinese medicine preparation. The domestic health-care washing-up liquid has the beneficial effects that the process flow is concise; the raw materials are proportioned reasonably; the washing-up liquid is prepared from innocuous and unpoisonous chemical products and traditional Chinese medicines, so the prepared washing-up liquid is gentle to hands and has fresh taste and innocuous and unpoisonous effect; and during daily use, the washing-up liquid can remove blots normally and has health-care effect, so the washing-up liquid achieves two things at one stroke, has high market value and is convenient to popularize and use.

Owner:安徽省华凯轻工科技有限公司

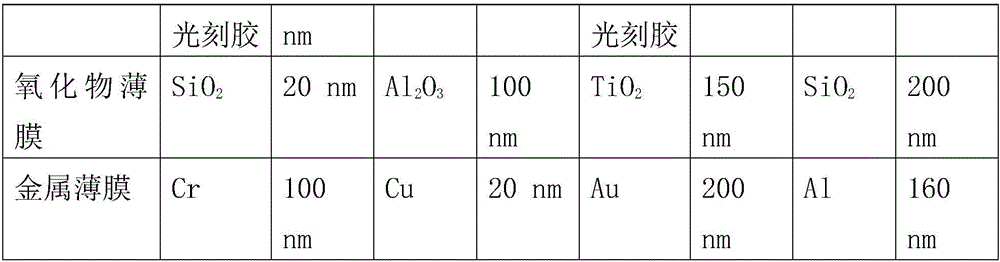

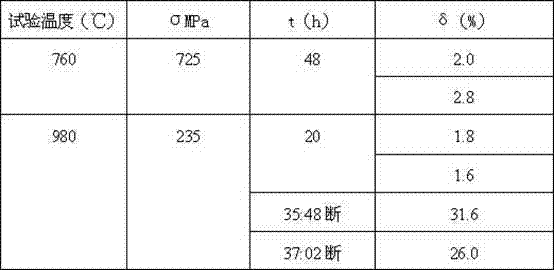

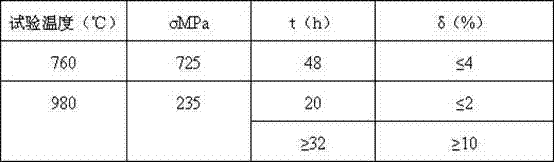

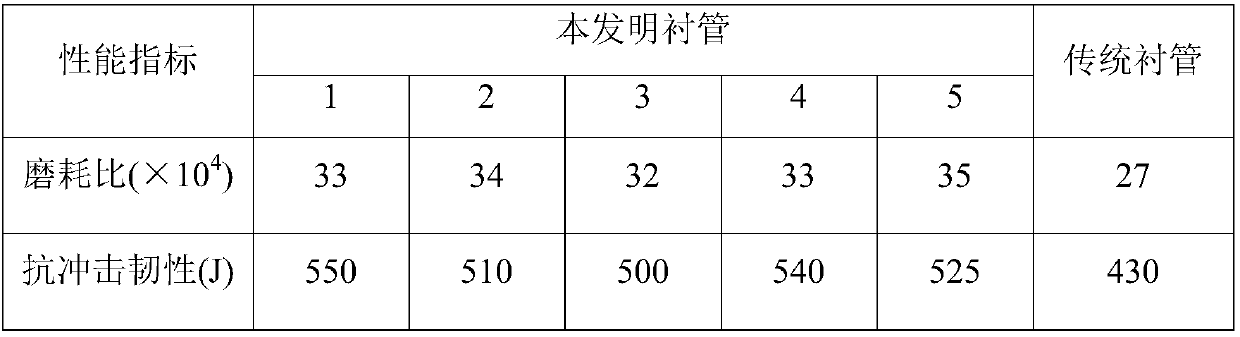

Method for repairing NiCrAlYSi coating on DZ125 blade surface

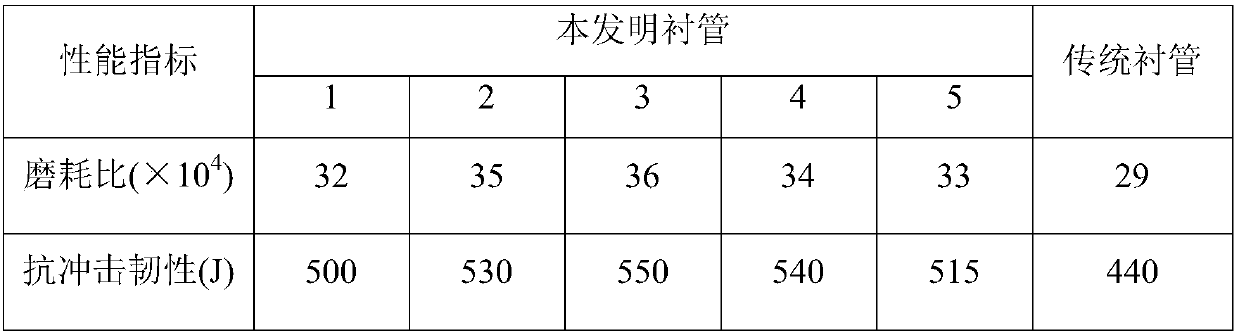

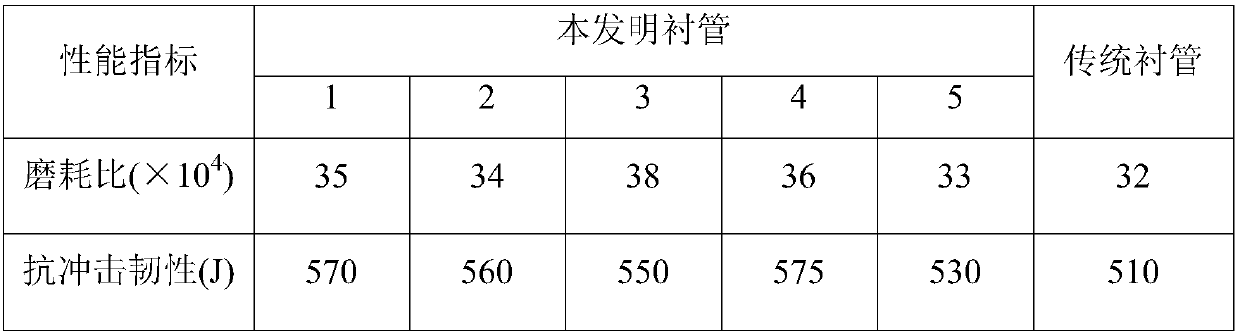

ActiveCN102965623AGuaranteed to completely removeAvoid over corrosionVacuum evaporation coatingSputtering coatingEtchingPerformance index

The invention belongs to the field of surface treatment, and particularly a method for repairing an NiCrAlYSi coating on a DZ125 blade surface. The method comprises the following steps: removing the original NiCrAlYSi coating on the blade in a coating removal tank solution, treating the blade with a wool felt wheel bonded with 180-mesh corundum until no megascopic coating residue is left on the blade surface, plating a new NiCrAlYSi coating with a vacuum arc plating device for 110-130 minutes, and finally, carrying out heat treatment on the blade in a vacuum heat treatment furnace. The blade subjected to coating repair has the advantages of good use effect and stable property and state; surface over etching, fluoroscopy, mechanical properties and other performance indexes can achieve the design requirements; and the blade repaired through the coating by utilizing the method provided by the invention has the advantages of low production cost, operation convenience and wide application prospects.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

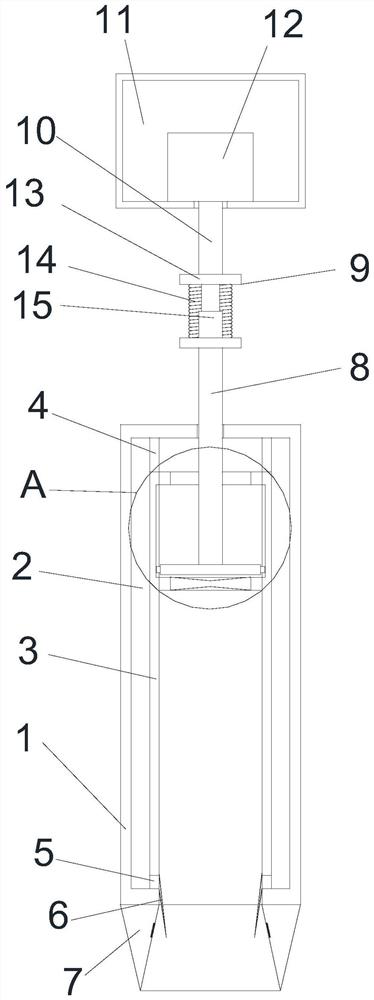

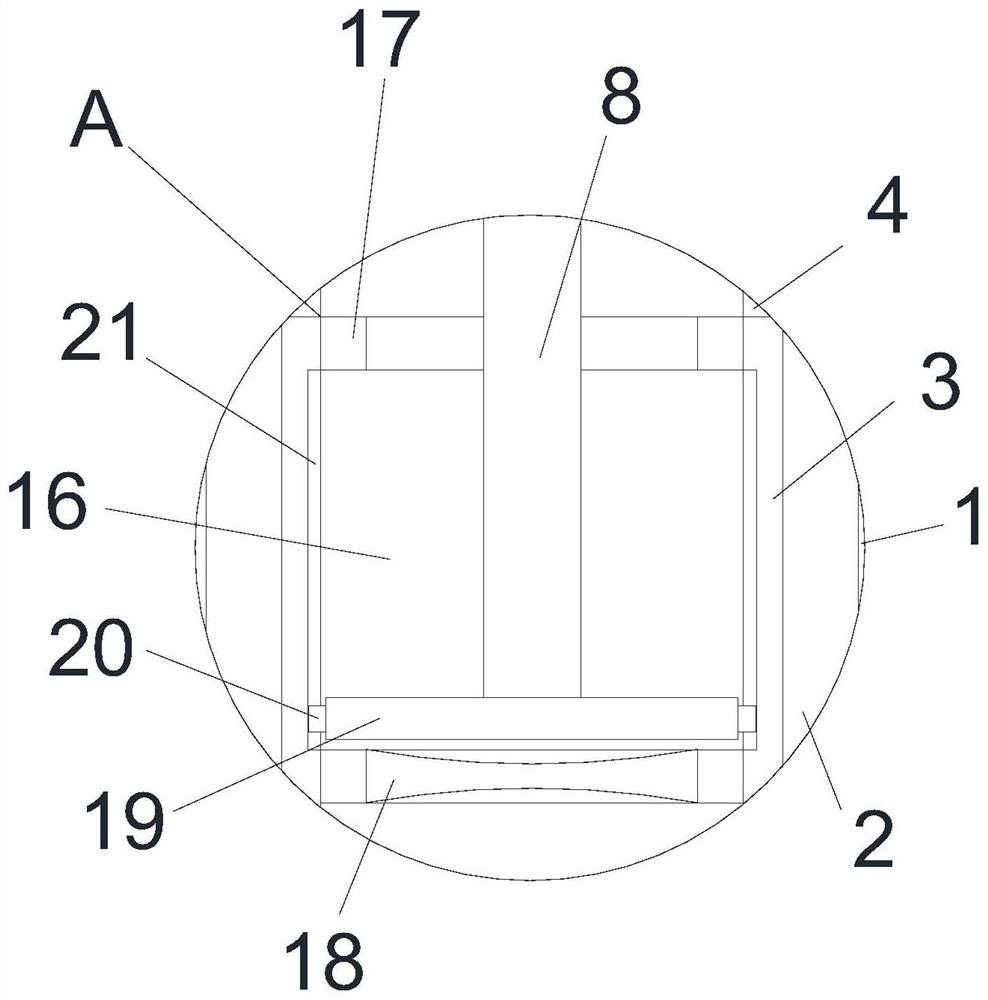

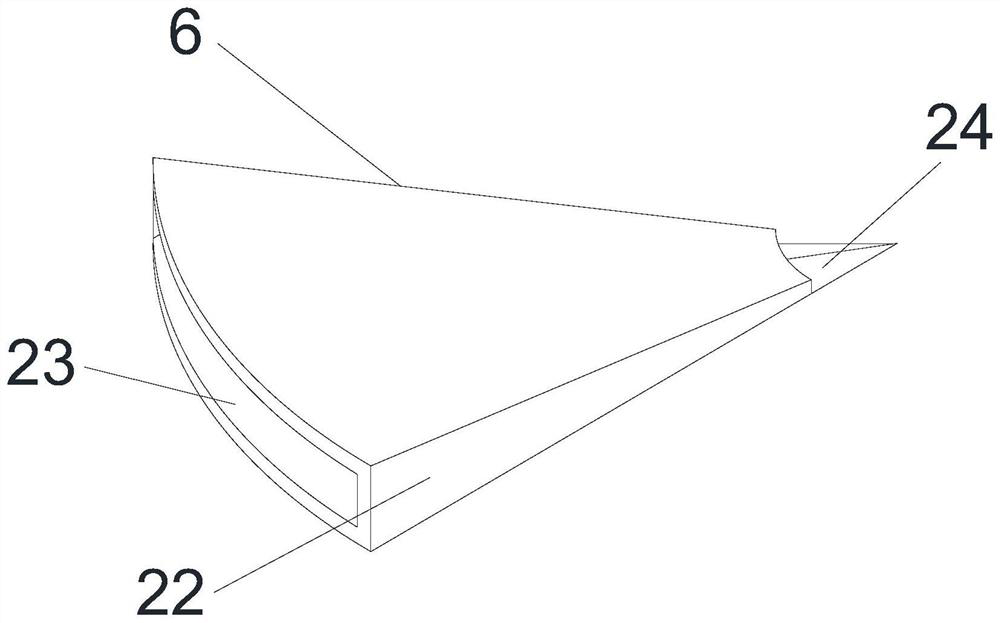

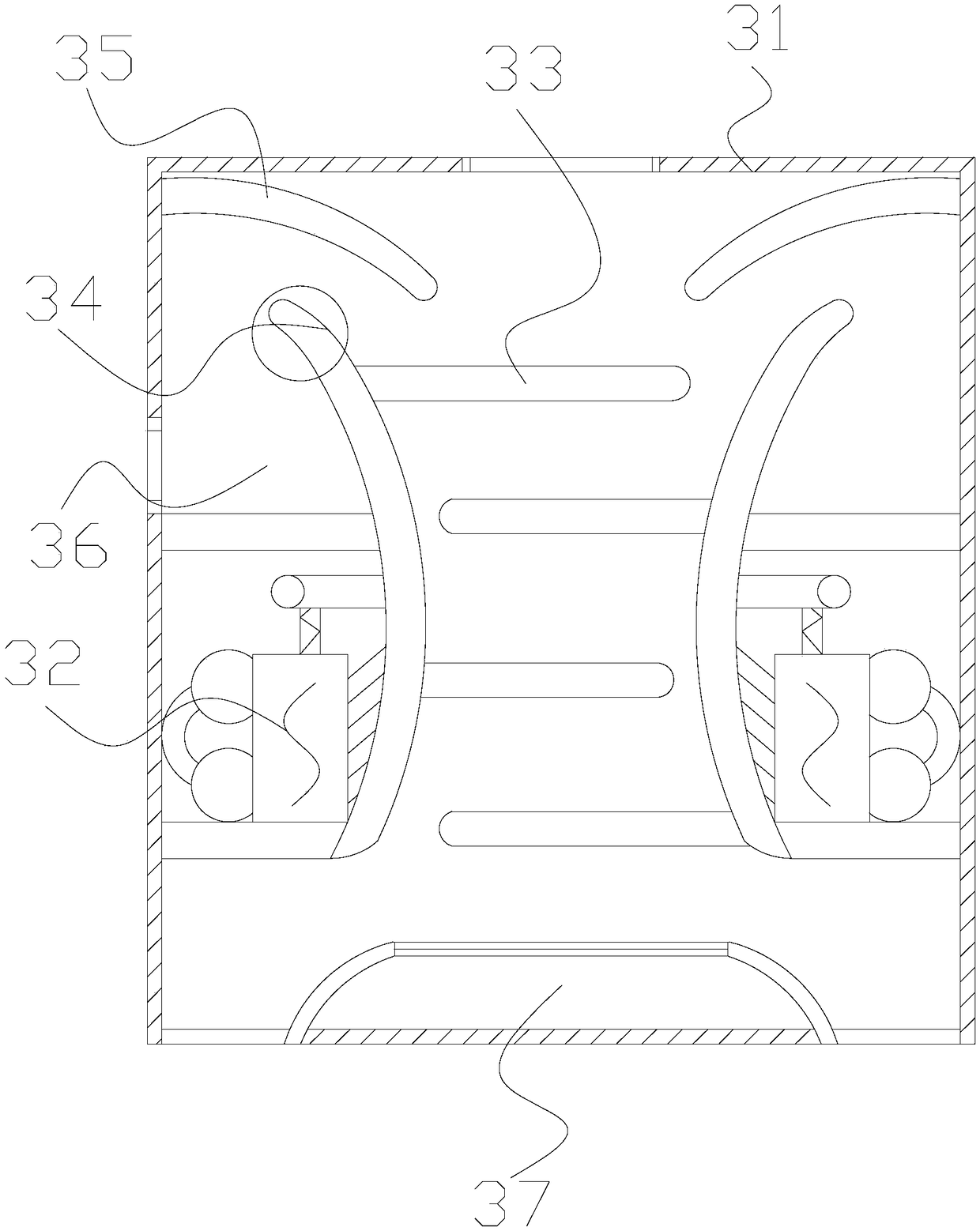

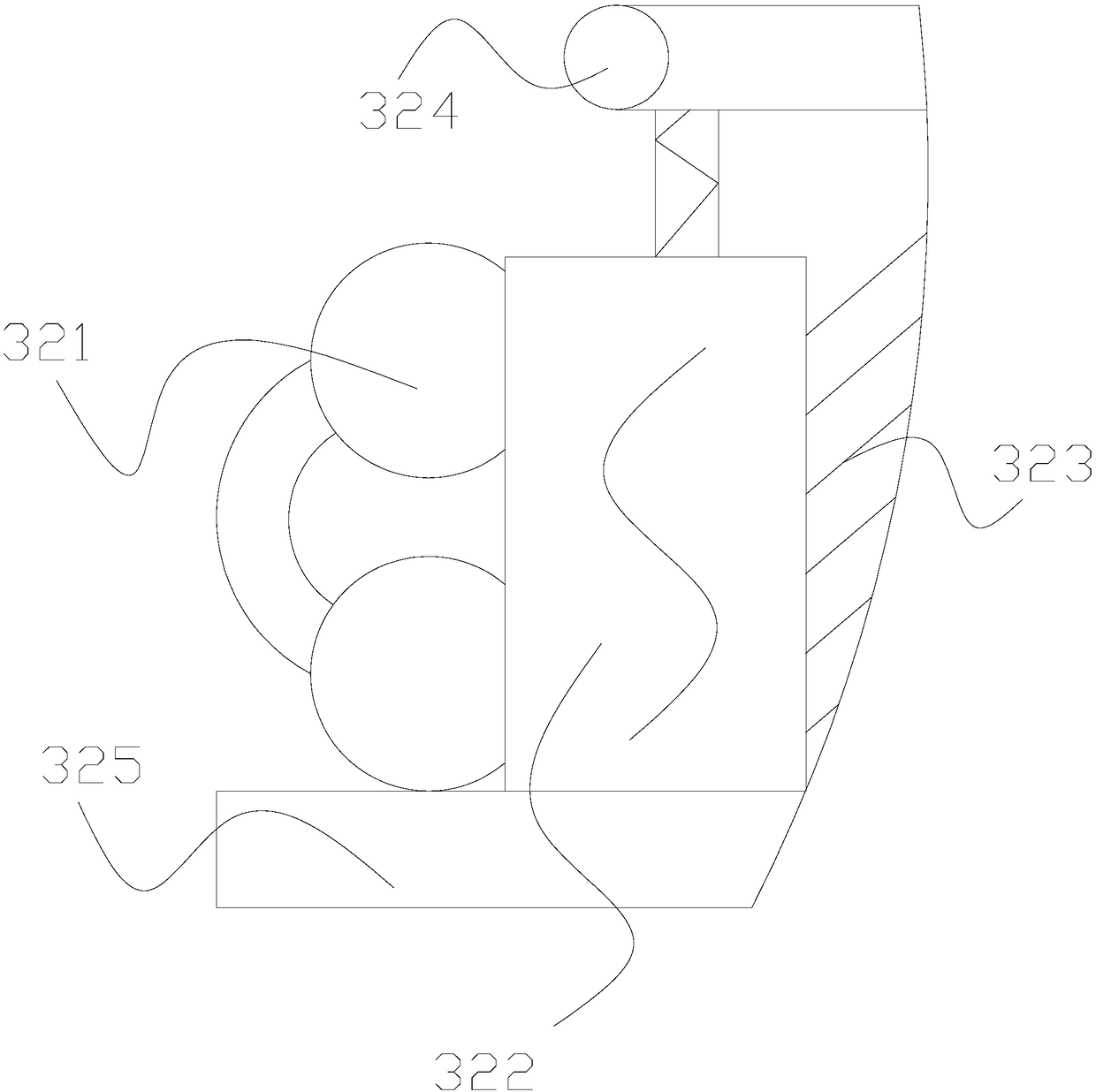

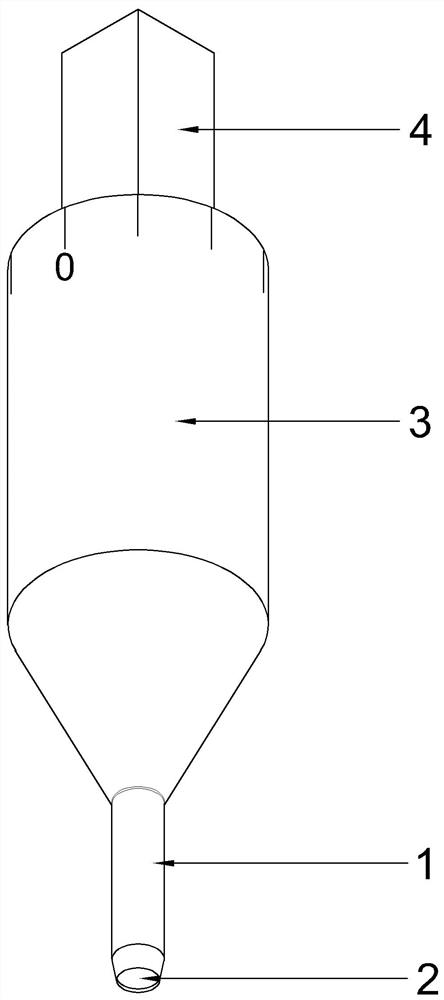

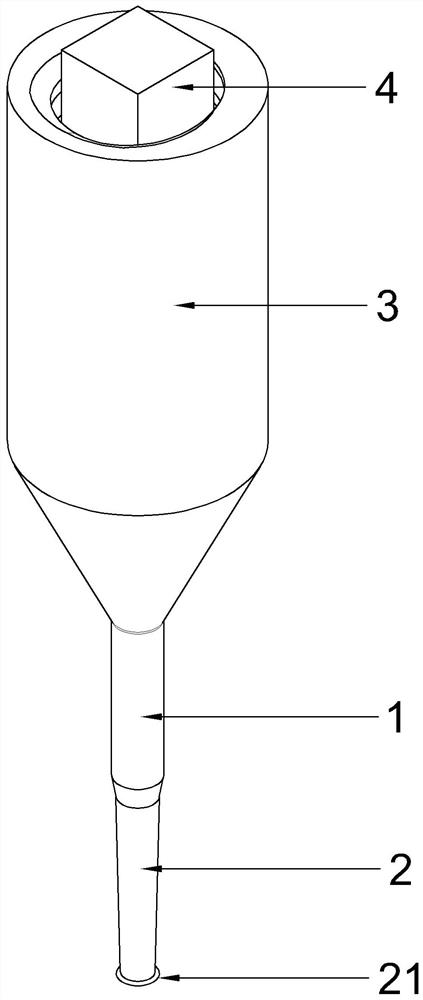

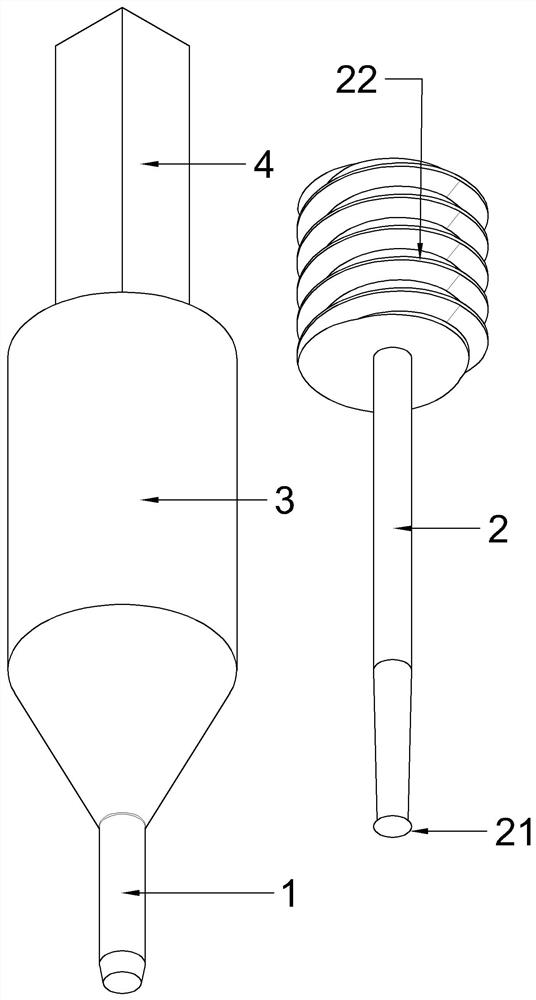

Soil remediation sampler for stratified sampling of soil

ActiveCN111929099AGuaranteed complete removalIncrease pressureWithdrawing sample devicesSoil scienceSoil remediation

The invention discloses a soil remediation sampler for stratified sampling of soil. The invention relates to the technical field of soil remediation. The soil remediation sampler for stratified sampling of soil comprises a sampling main cylinder, an air groove is annularly formed in the inner side wall surface of the sampling main cylinder, an inner cylinder is arranged on the inner side of theair groove; an extrusion transmission groove is annularly formed in the side wall of the top of the inner side of the inner cylinder; according to the soil remediation sampler for stratified samplingof soil, after Sampling is finished, a lower rod is controlled by control equipment to be lifted up; therefore, an extrusion block on the gas control equipment ascends and extrudes the interior of the inner cylinder to extrude gas above the extrusion block; the air groove, the extrusion transmission groove and an inflation groove are used for conducting, so that the air above the extrusion blockis impacted and extruded into a closed air bag on a closed device, the closed air bag is inflated and expanded to be reset and closed, and the effect of completely taking out sandy soil is achieved.

Owner:时科环境技术(上海)有限公司

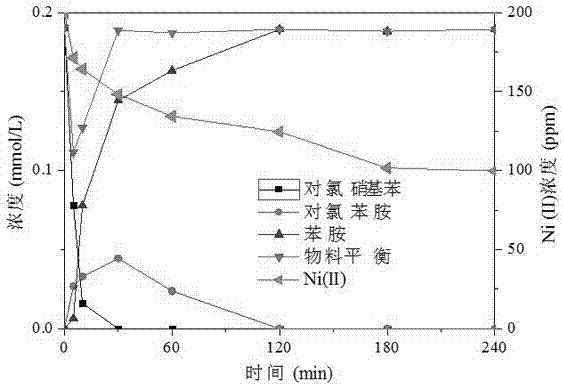

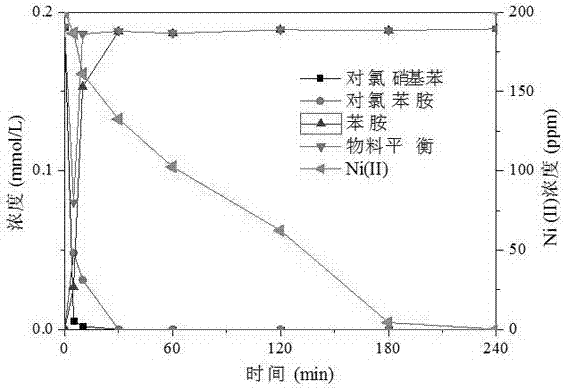

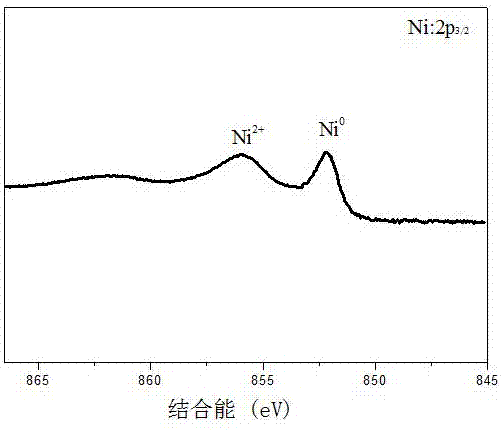

Method for remediating nickel and chlorinated organic compound combined polluted environmental water

InactiveCN107486136AHigh reactivityEfficient conversionOther chemical processesWater contaminantsSodium BentoniteEthyl Chloride

The invention relates to a method for remediating nickel and chlorinated organic compound combined polluted environmental water. The method comprises the following steps: (1) preparing bentonite-loaded zero-valent iron, namely, mixing bentonite, FeSO4.7H2O and NaBH4; stirring and reacting; washing with deoxidized water and ethyl alcohol; then freezing and drying in vacuum to obtain the bentonite-loaded zero-valent iron; (2) adjusting pH of Ni(II) and chlorinated organic compound combined polluted water to be 3-7; (3) adding the bentonite-loaded zero-valent iron prepared in step (1) to the combined polluted water in step (2) under inert gas protection. The method is simple in processes, low in cost, and free from secondary pollution to the environment, and is a simple, effective and low-cost method for remediating Ni(II) and chlorinated organic compound combined polluted water.

Owner:SHAOXING UNIVERSITY

Preparation method for alumina/quartz glass composite fiber

The invention discloses a preparation method for alumina / quartz glass composite fiber and belongs to the field of inorganic fiber. The preparation method comprises the steps as follows: 1, pretreating quartz fiber with a dilute sulfuric acid solution; 2, preparing boehmite sol through a sol-gel method by taking AlCl3.6H2O, metal Al powder, lactic acid and H2O as raw materials; and 3, impregnating the pretreated quartz fiber in the boehmite sol, drying and conducting heat treatment to obtain the alumina / quartz glass composite fiber. The preparation method has the advantages of simple process, convenience in operation and low energy consumption, and the tensile strength and the alkaline resistance of the prepared composition fiber are greatly improved in comparison with those of the quartz fiber.

Owner:TIANJIN POLYTECHNIC UNIV

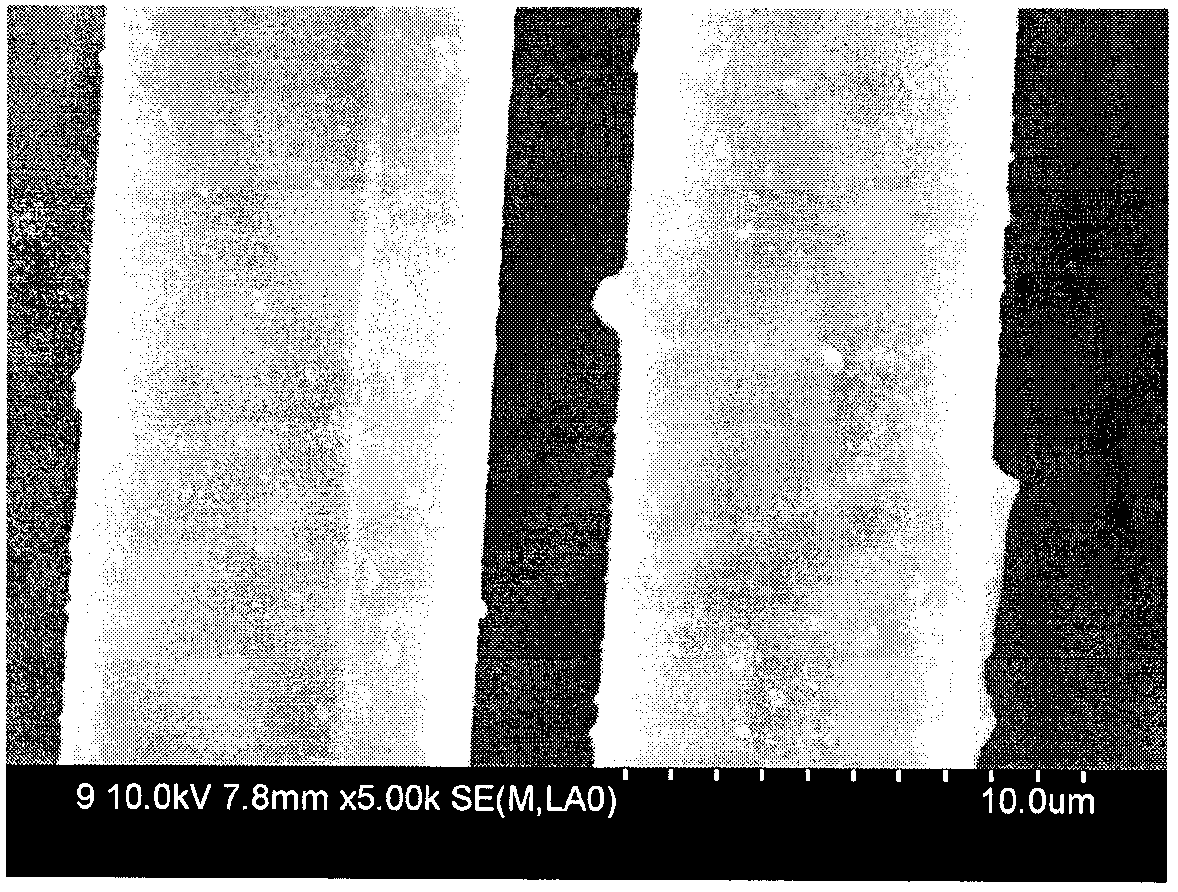

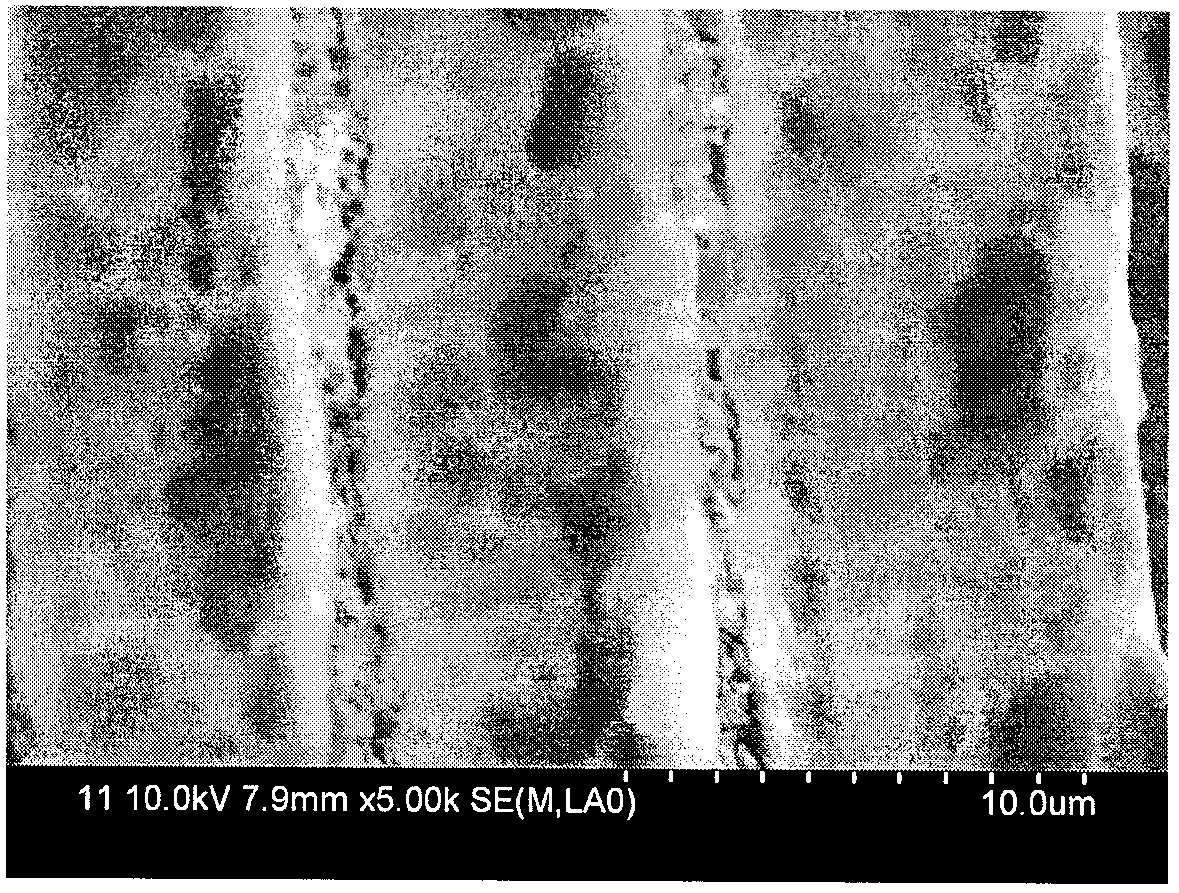

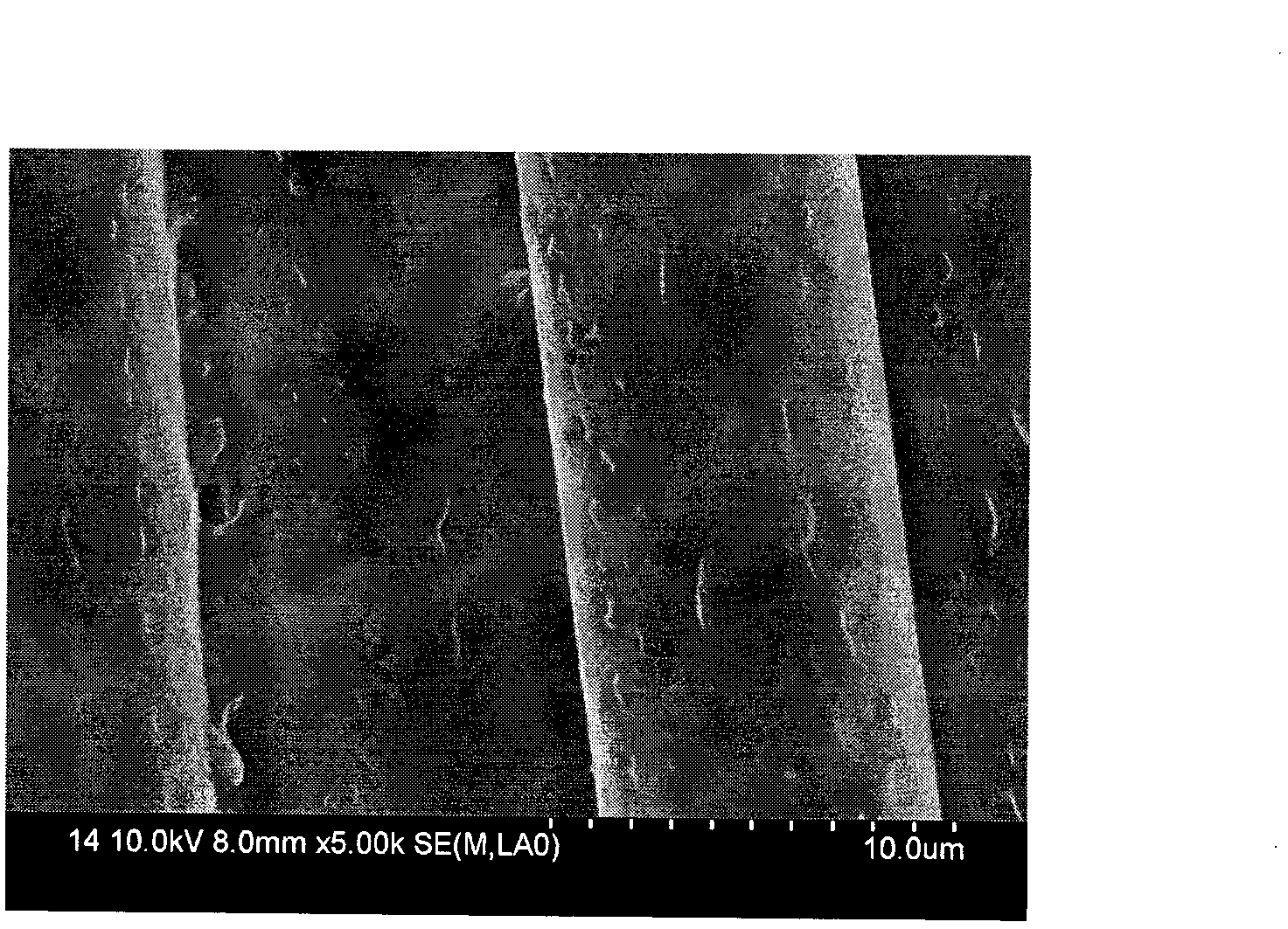

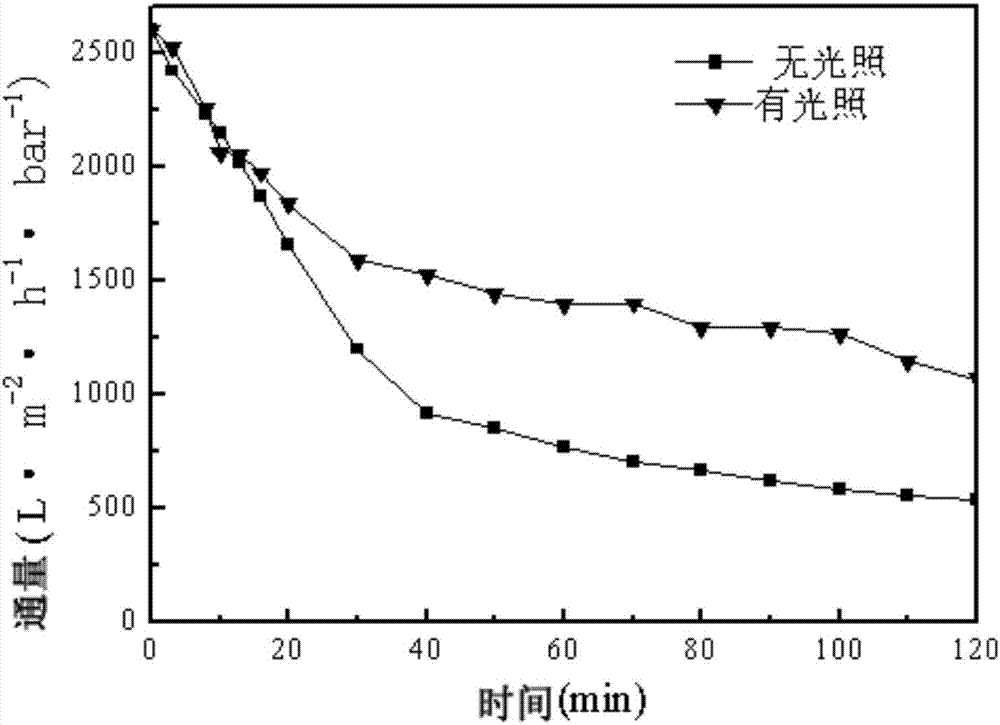

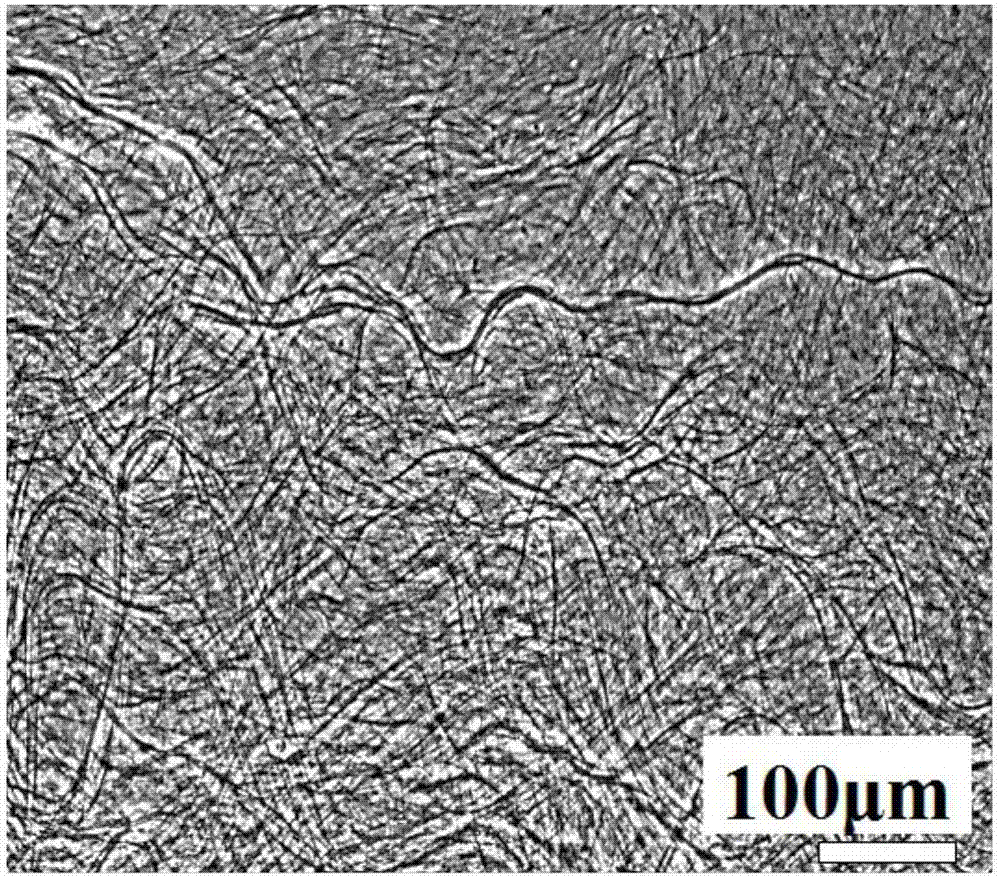

Attapulgite-graphite-like carbonitride composite hollow fiber microfiltration membrane with photocatalytic performance and preparation method and application thereof

ActiveCN106943890ARealize self-cleaningImprove throughputWater/sewage treatment by irradiationWater contaminantsCarbon compositesFiber

The invention relates to an attapulgite-graphite-like carbonitride composite hollow fiber microfiltration membrane with photocatalytic performance and a preparation method and application thereof. The preparation method comprises the following steps: adding attapulgite-graphite-like carbonitride composite particles into a solvent to prepare a polyethersulfone casting solution, extruding the casting solution through a spinning nozzle, passing through a section of air gap and entering coagulation bath for curing molding, and sintering to obtain the attapulgite-graphite-like carbonitride composite hollow fiber microfiltration membrane with photocatalytic performance. The hollow fiber microfiltration membrane is composed of fibrous attapulgite and a graphite-like carbonitride polymer with photocatalytic performance. By the photocatalytic performance of the graphite-like carbonitride, coupling of photocatalysis and membrane separation process can be realized. As the graphite-like carbonitride polymer is uniformly dispersed and immobilized on the attapulgite surface of the membrane through the chemical binding effect, the deficiency that granular graphite-like carbonitride is easy to agglomerate, hard to separate and difficult to reuse during the separate using process is effectively avoided.

Owner:HUAIYIN TEACHERS COLLEGE

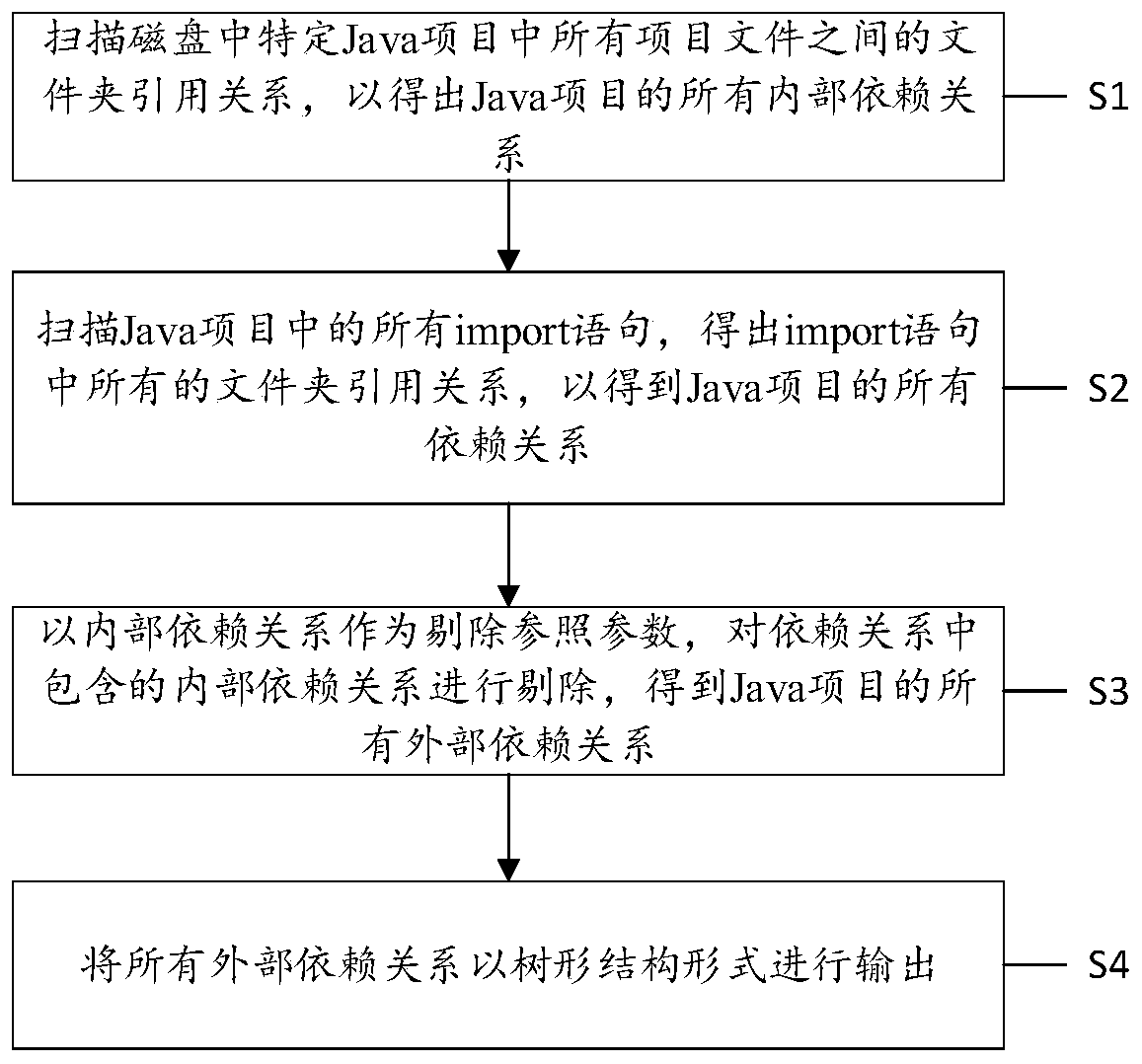

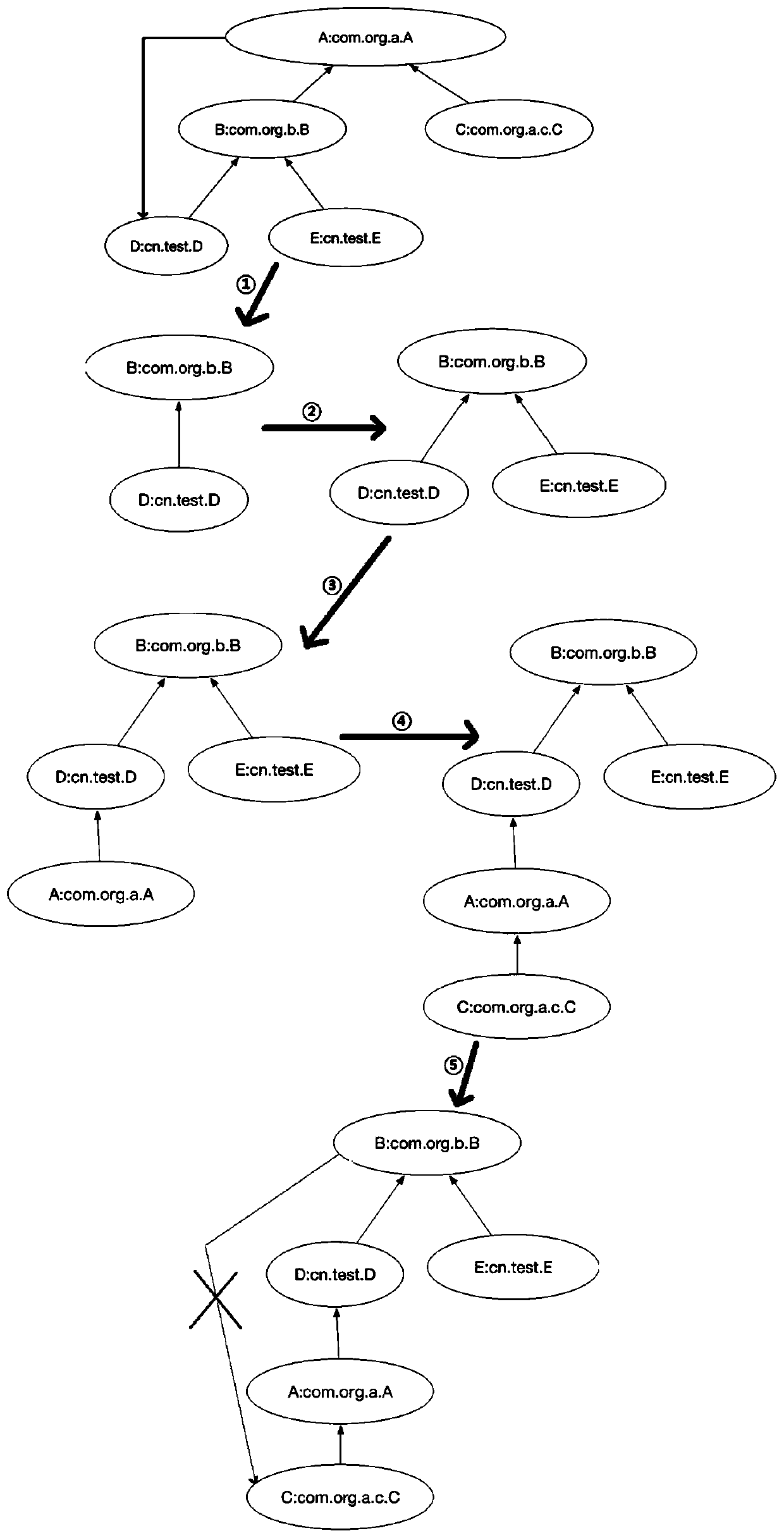

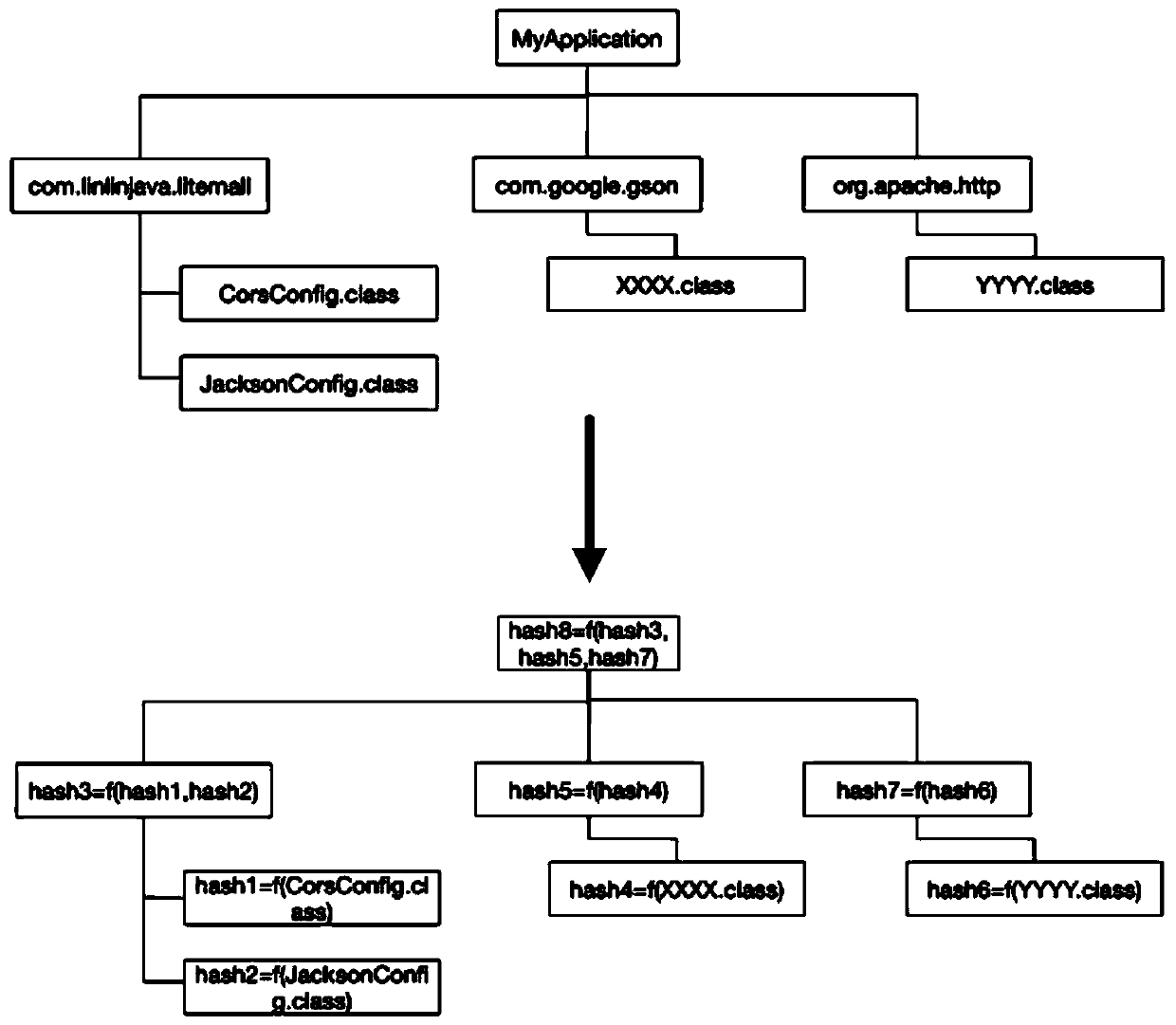

Dependency relationship detection method and device, computer device and readable storage medium

PendingCN110618931AGuaranteed to completely removeReduce workloadSoftware testing/debuggingWorkloadCode review

The invention provides a dependency relationship detection method and device, a computer device and a readable storage medium. The dependency relationship detection method comprises the following steps: scanning a disk file to obtain all internal dependency relationships in a Java project; and then, when or after the import statement is scanned to obtain all the dependency relationships, eliminating all the internal dependency relationships to obtain all the external dependency relationships in the Java project, and outputting all the external dependency relationships in a tree structure form.The whole project external dependency detection process is very simple and convenient. In addition, the complete elimination of the dependency relationship in the project is ensured during the detection, and a user can completely master all external dependence relationships of the Java project, so that the workload of manual code review is reduced, the working efficiency is improved. Meanwhile, atool for safety assessment is provided for a safety department, unstable factors can be found in time, and the whole software project is safer and more controllable in the development process.

Owner:重庆金融资产交易所有限责任公司

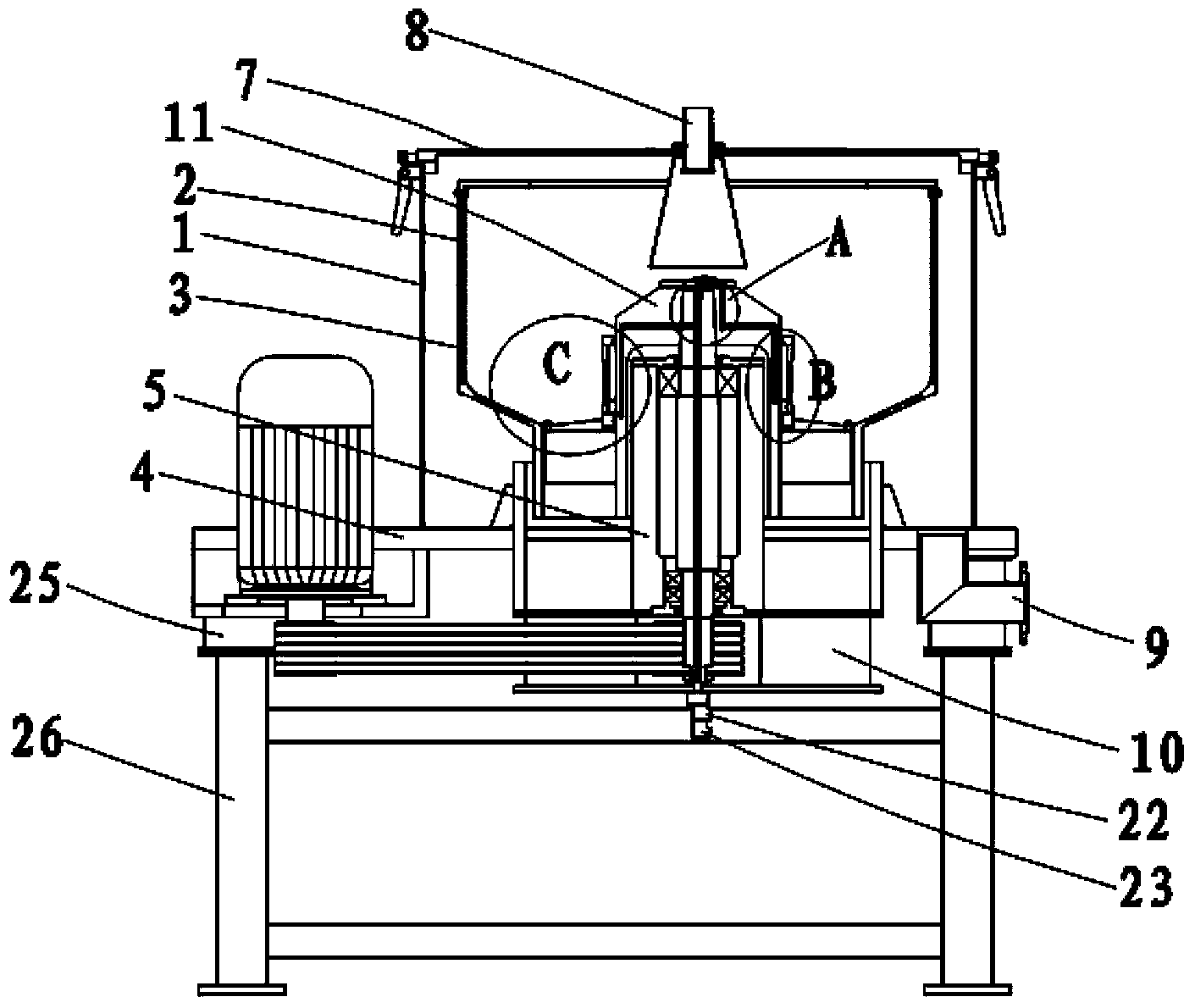

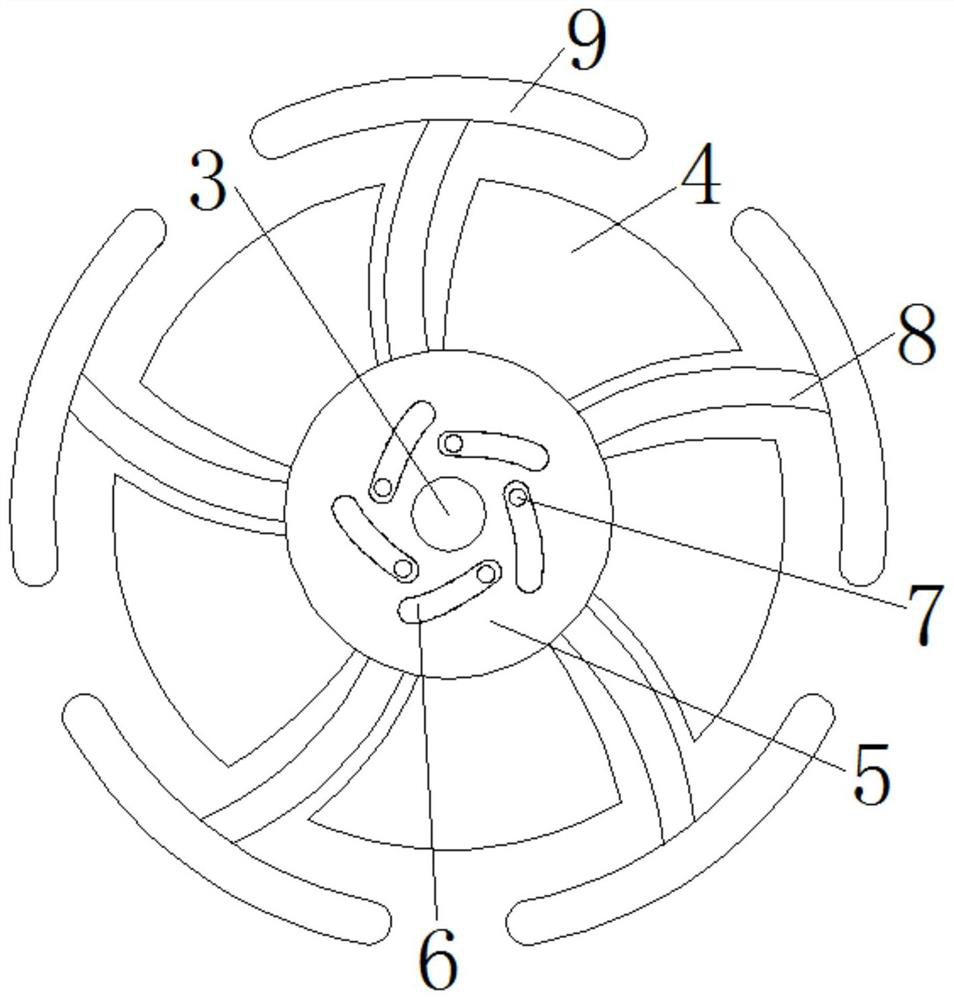

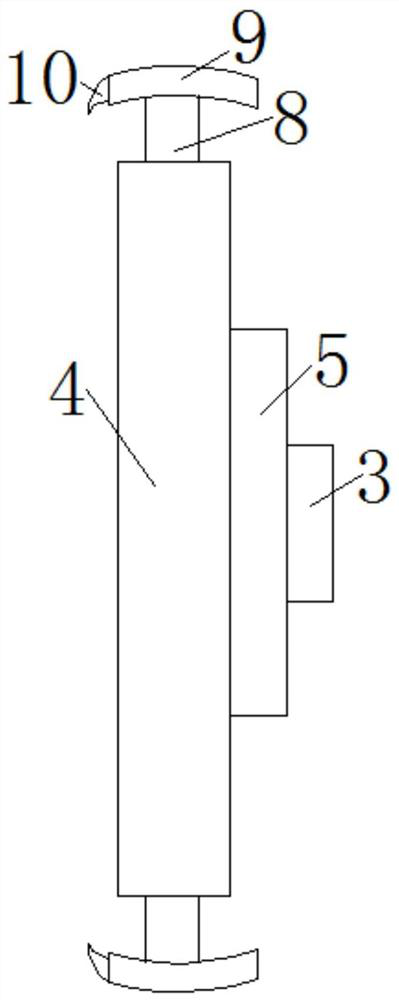

Unloading type centrifugal machine with filter bag conducting reciprocating vibration

The invention discloses an unloading type centrifugal machine with a filter bag conducting reciprocating vibration. A drum of the unloading type centrifugal machine is of a column-taper-column three-sectional combined type structure, a filter cake is extruded due to the contraction action of the taper section of the drum, and unloading of the filter cake is facilitated. The column section at the tail end of the drum has the guide function for the reciprocating filter bag, has the guide function on the filter cake at the same time, and guides the filer cake to a filter cake unloading port of a chassis of the drum. The unloading type centrifugal machine achieves unloading through the reciprocating vibration of the filter bag, traditional unloading structures such as a scraper and a spiral are completely removed, no mechanical scraping action can play on the filter cake, the shape of crystal particles in the filter cake cannot be damaged, the structure of the crystal particles of the filter cake can be completely kept, and the unloading type centrifugal machine is particularly suitable for being used on occasions where the crystal perfection of the filter cake needs to be kept. In addition, by means of the reciprocating vibration of the filter bag, complete unloading can be achieved, and no filter cake will be left on the filter bag.

Owner:HEFEI GENERAL MACHINERY RES INST

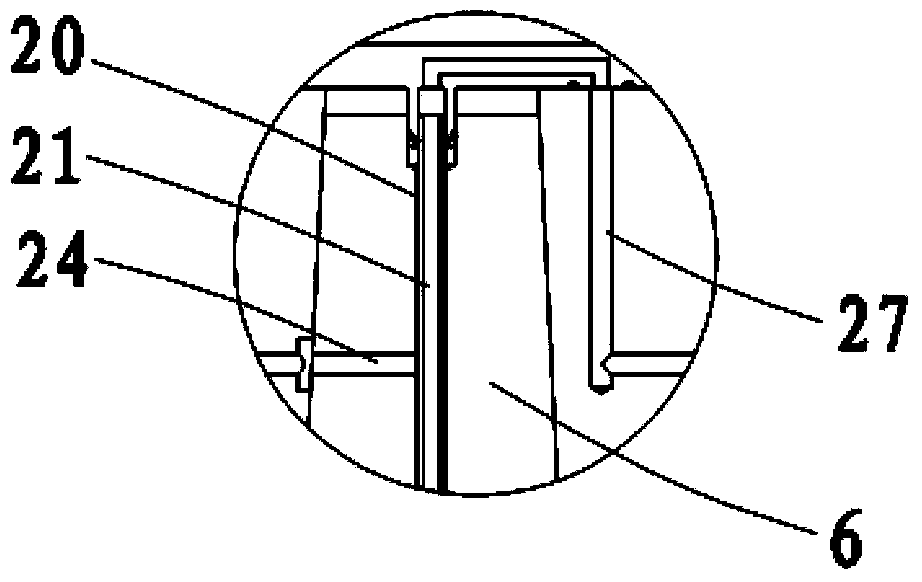

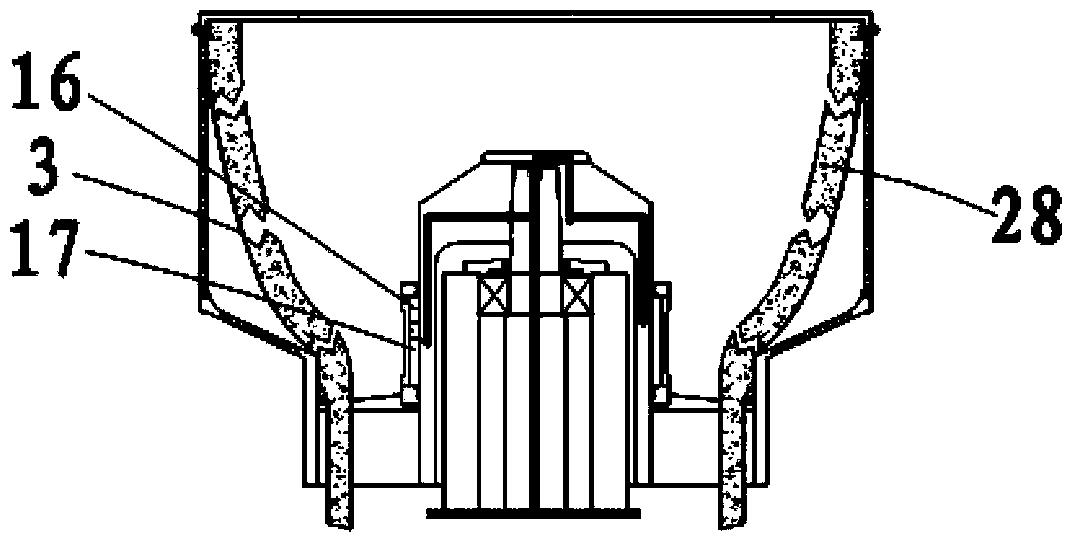

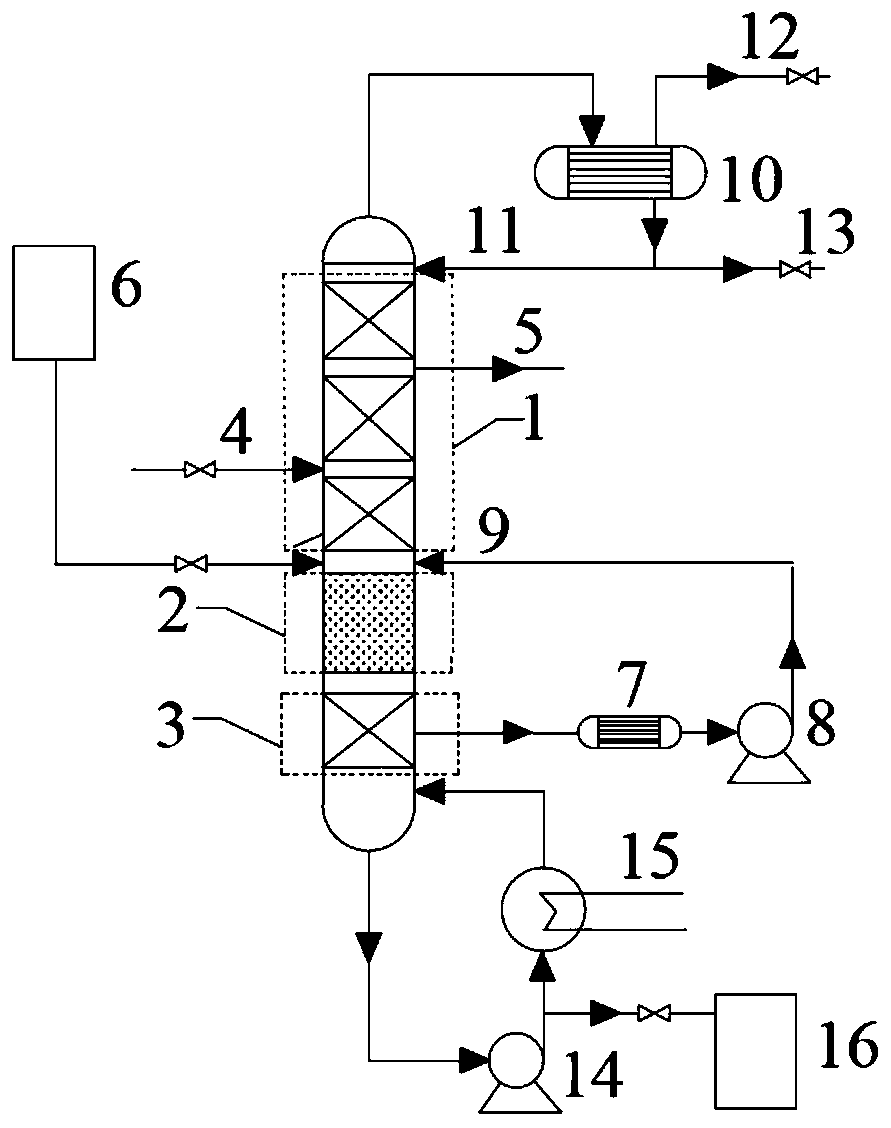

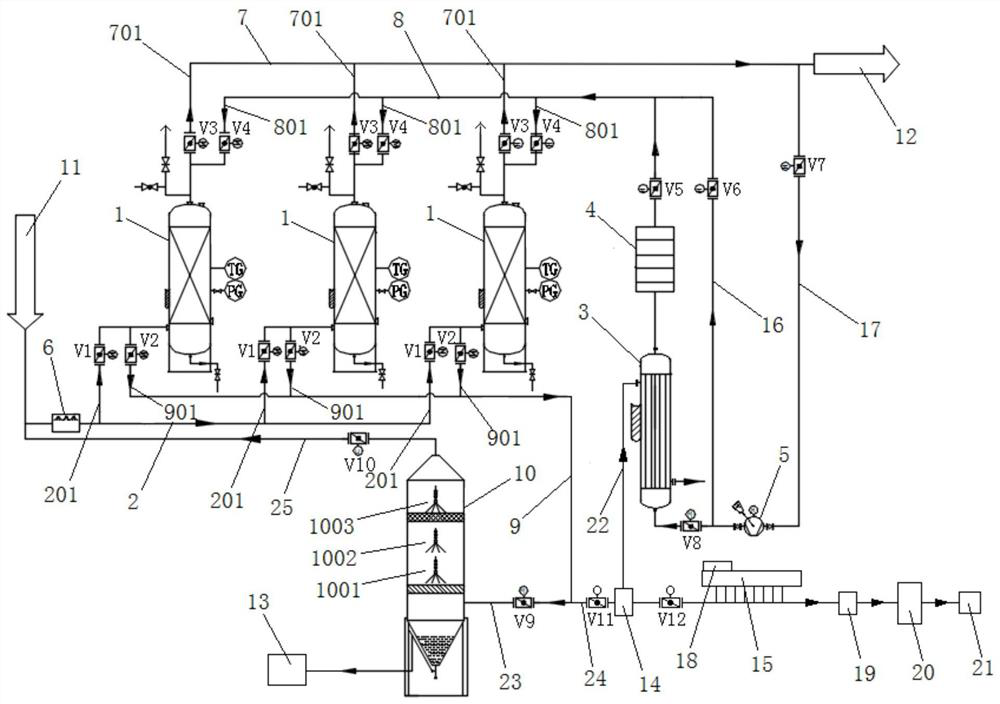

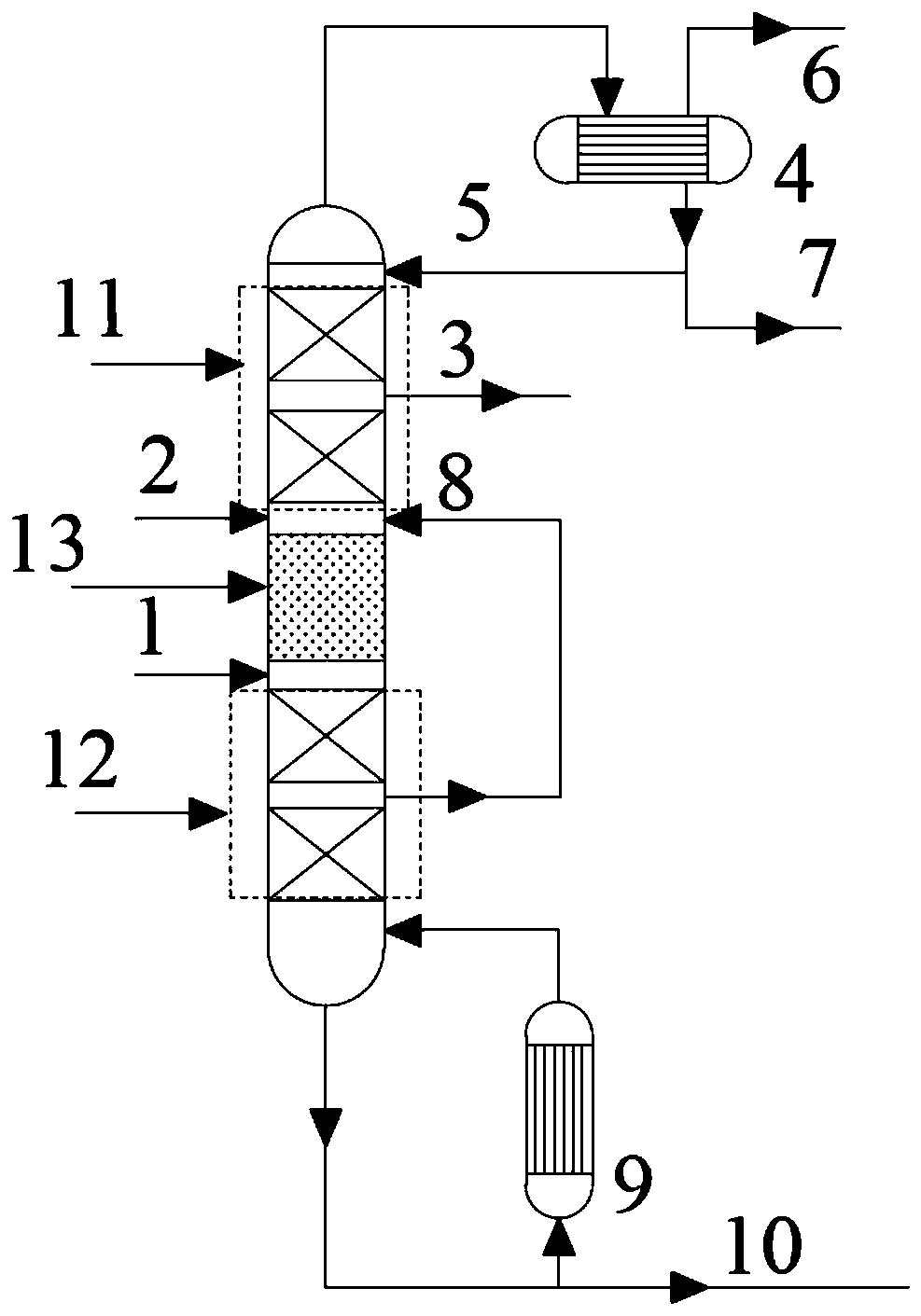

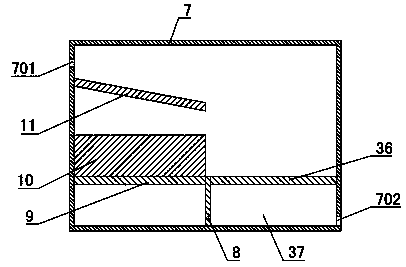

Reactive distillation purifying method and device for removing carbon-containing impurities in chlorosilane

InactiveCN110980742AGood removal effectReduce contentGroup 4/14 element organic compoundsChemical industryPtru catalystMethyltrichlorosilane

The intention provides a reactive distillation purifying method and device for removing carbon-containing impurities in chlorosilane, and belongs to the technical field of polycrystalline silicon production, wherein the reactive distillation tower device comprises a distillation section, a reaction section and a stripping section, the distillation section is filled with three sections of packing,the stripping section is filled with the packing, and the packing in the distillation section and the stripping section is structured packing; wherein a structural catalyst is arranged in the reactionsection, the stripping section is provided with a chlorine donor substance circulating device, a chlorosilane crude material is fed from the middle lower part of the distillation section, a chlorinedonor substance is fed from the upper part of the reaction section, and carbon-containing impurity methyl dichlorosilane in the chlorosilane crude material in the reaction section reacts with the chlorine donor under the action of the catalyst to generate high-boiling-point substance methyl trichlorosilane; the methyl trichlorosilane is finally extracted from the bottom of the tower, and high-purity chlorosilane is extracted from the side line of the middle upper part of the distillation section. The method solves the problem that the carbon-containing impurities in the chlorosilane are difficult to remove thoroughly under the existing process conditions, is simple to operate and low in investment cost, and the purity of the product chlorosilane can reach 99.999%.

Owner:TIANJIN UNIV

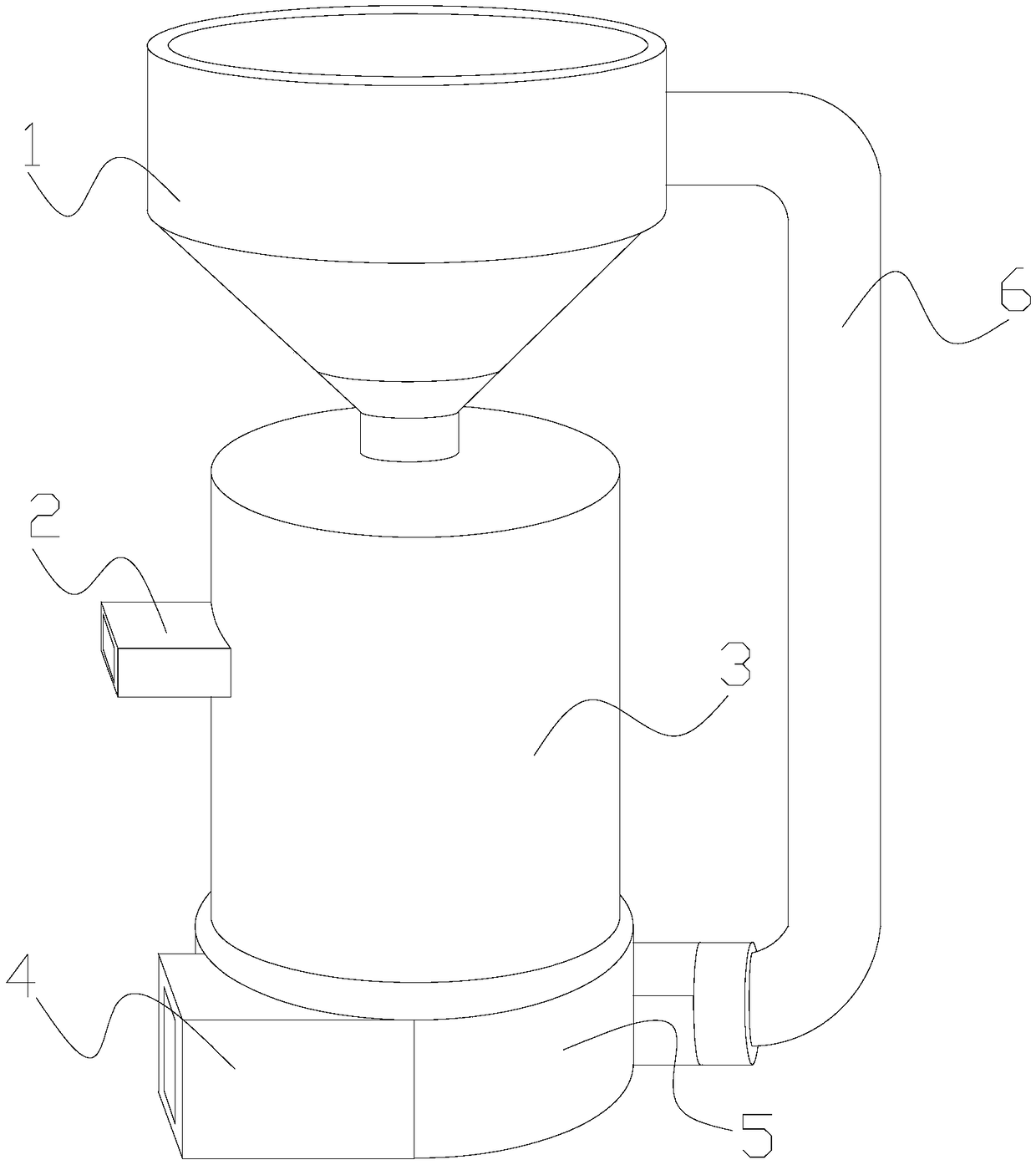

Rice husk removing device utilizing ultrasonic drying resonance

InactiveCN109395800AIntegrity guaranteedImprove separation efficiencyGrain huskingGrain polishingUltrasonic generatorSonication

The invention discloses a rice husk removing device utilizing ultrasonic drying resonance. The rice husk removing device structurally comprises a feeding hopper, a rice husk outlet, a rice husk removing device body, a brown rice outlet, a rice storage cavity and a circulating tube, and the feeding hopper is connected with the rice storage cavity through the circulating tube. According to the ricehusk removing device, ultrasonic waves are formed through an ultrasonic generator and an energy converter and transmitted to the surfaces of a metal tube, a rubber sleeve and a resonance plate; afterhusks of entering rice are heated by heat generated by ultrasonic wave transmission inside the metal tube and the rubber sleeve, the husks are embrittled and then are prone to being broken under impact force of a spring piece and a scraping tooth block, husk removing is conducted, and thus completeness of the rice is ensured; meanwhile, the ultrasonic waves are transmitted inside the resonance plate, thus the resonance plate is subjected to temperature increasing and electronic streaming, accordingly, static electricity is generated on the outer surface of the resonance plate, the falling-offrice is attached to the outer side of the resonance plate by electrostatic force, under the effect of an air blower, the rice husks move upwards along the outer side of the resonance plate to enter arice husk cavity, and the rice and husk separating efficiency is improved.

Owner:林阿碧

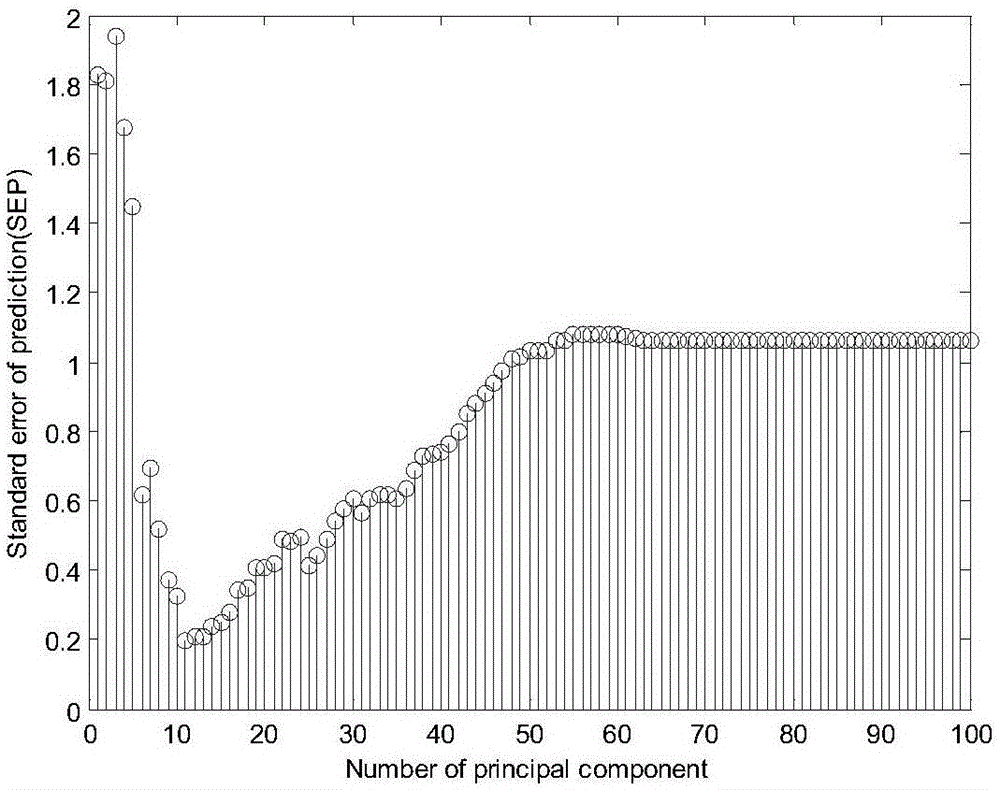

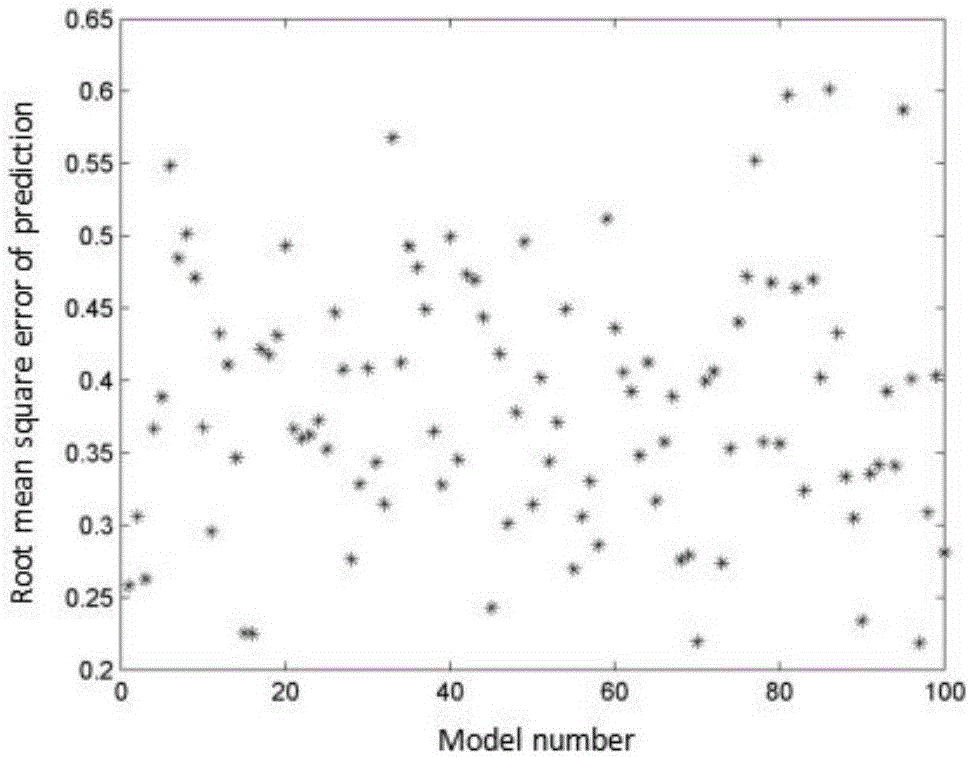

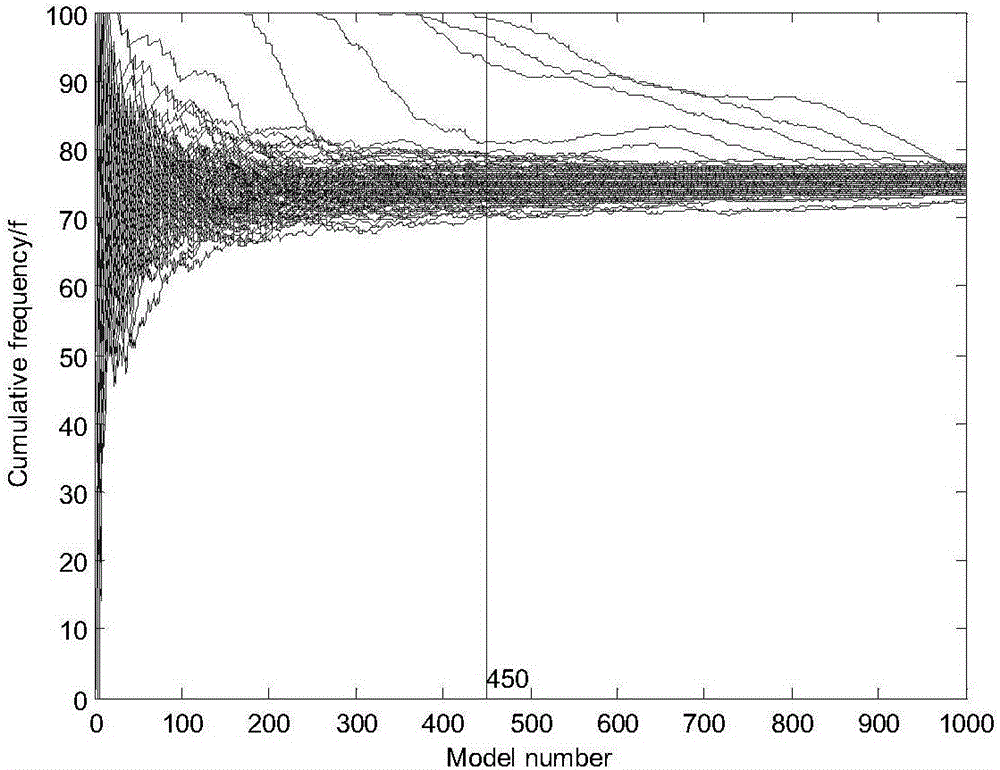

Detecting method for NIRS abnormal samples based on Monte Carlo cross validation

InactiveCN106485049ADifferentiateAccurate discriminationSystems biologySpecial data processing applicationsComputer scienceMonte carlo em

The invention provides a detecting method for NIRS abnormal samples based on Monte Carlo cross validation. The detecting method for NIRS abnormal samples based on Monte Carlo cross validation comprises the following steps: (1) confirming the optimal principal component of the pretreated spectroscopic data using the group-outside-judging method and establishing an O-PLSR prediction model; (2) judging the stability of the O-PLSR prediction model; (3) establishing a large number of O-PLSR models randomly by means of MCCV and recognizing the strong influence point; (4) distinguishing the abnormal values in the strong influence points by two-trial-judging method; (5) verifying whether the abnormal samples are completely removed or not by means of MCCV method again. The detecting method for NIRS abnormal samples based on Monte Carlo cross validation can verify the abnormal samples more comprehensively and accurately, therefore, the completely removing of the abnormal samples can be ensured.

Owner:HEILONGJIANG UNIV

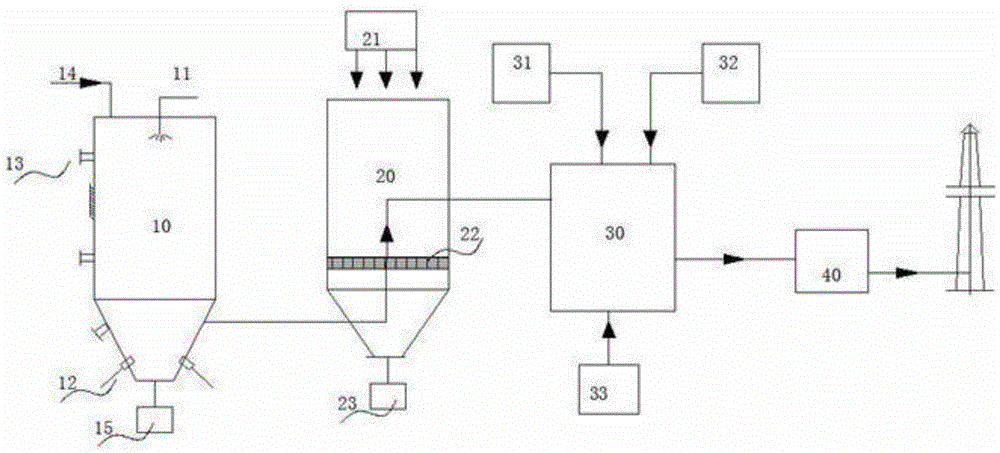

Method and device for treating waste gas of TFT glass substrate kiln

InactiveCN105674756AReduce nitrogen oxidesSimple structureGas treatmentDispersed particle filtrationNitric oxideCombustion chamber

The invention relates to a method and device for treating waste gas of a TFT glass substrate kiln. The device comprises a cooling tank, a dust removal box, a combustion chamber and an SCR reaction unit which are sequentially communicated; a first discharging opening for discharging mixtures and boric oxides is formed in the bottom of the cooling tank; a first waste gas inlet, a first waste gas outlet and a cooling medium inlet are formed in the cooling tank, and the first waste gas outlet is communicated with the dust removal box; a dust removal device is arranged in the dust removal box; and an air inlet, a natural gas inlet and a reducing agent inlet are formed in the combustion chamber. The method comprises the steps of firstly, removing the boric oxides in the waste gas, secondly, removing particle matter in the waste gas, thirdly, adopting a combustion manner to remove parts of the nitric oxides, and fourthly, adopting a catalytic deoxidizing reaction to remove the nitric oxides, completing treatment of the waste gas of the TFT glass substrate kiln, and performing discharging after the environment-friendly standard is achieved. The operation steps are simple, and various forms of boron and nitrogen oxides in the waste gas of the kiln can be effectively removed.

Owner:IRICO DISPLAY DEVICES

Bend coated steel machining method for angle-steel tower

InactiveCN107414433AGuarantee welding qualitySolve the unstable processing qualityEngineeringBase metal

A method for processing angle steel towers by hot-bending, comprising the following steps in turn: (1) machining a plane on the back side of the angle-steel hot-bending position, and drilling a process hole on the plane; (2) using Flame cutting cuts off the excess part of the angle steel leg, and the incision is connected to the lower edge of the process hole; (3) bend the angle steel according to the specified angle after fire bending; (4) weld the cut gap. The method of the present invention can not damage the base metal during cutting, and at the same time ensure that the angle steel chamfer at the bending position is completely removed; in this way, there will be no tearing damage during bending, and the welding quality is guaranteed, solving the problem of Solved the problem of unstable processing quality of the existing process of hot-batched steel.

Owner:HENAN DINGLI POLE TOWER

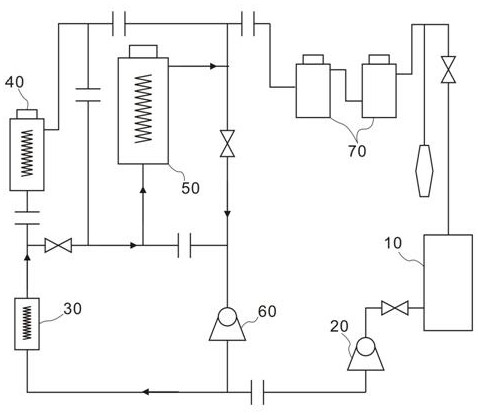

Blast furnace gas desulfurization purification system and method

PendingCN112940799AEfficient desulfurizationImprove adsorption efficiencyGas purification by catalytic conversionGas purification with selectively adsorptive solidsProcess engineeringSpray tower

The invention relates to a blast furnace gas desulfurization purification system and method. The system comprises a heating device, an alkali spraying tower, a sintering device and a plurality of adsorption towers, wherein each adsorption tower is filled with a purification medium, a gas inlet of each adsorption tower is connected with a gas outlet of a TRT in an on-off manner, and a gas outlet of each adsorption tower is connected with a purified gas user in an on-off manner; a regeneration gas outlet of the heating device is connected with a gas outlet of each adsorption tower in an on-off manner, and the regeneration gas introduced into the adsorption towers is heated through the heating device; a gas inlet of the alkali spraying tower is connected with a gas inlet of each adsorption tower, and a gas outlet of the alkali spraying tower is connected with a gas inlet of each adsorption tower; a gas inlet of the sintering device is connected with gas inlets of the adsorption towers, and a heat source outlet of the sintering device is connected with a heat source inlet of the heating device. The technical problems of poor blast furnace gas purification effect and high investment cost are solved.

Owner:CERI ENERGY & AIR PROTECTION TECH CO LTD +1

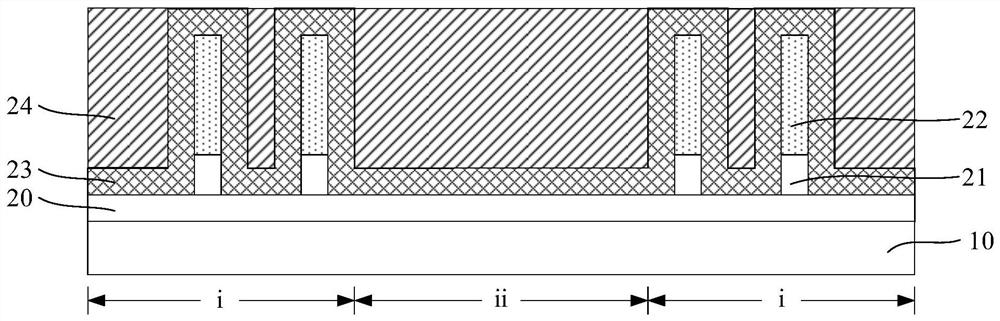

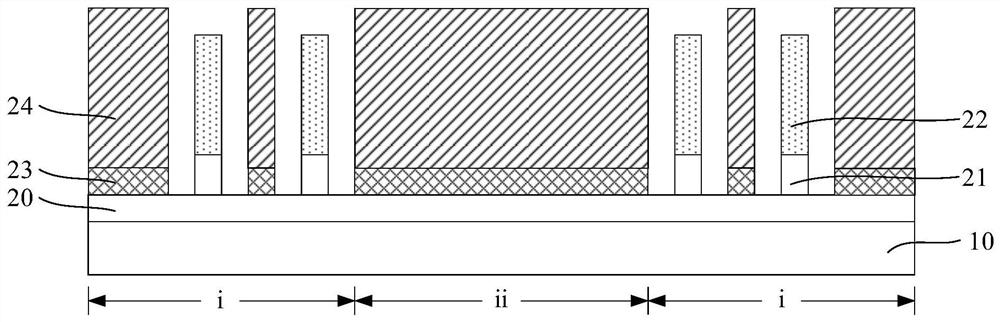

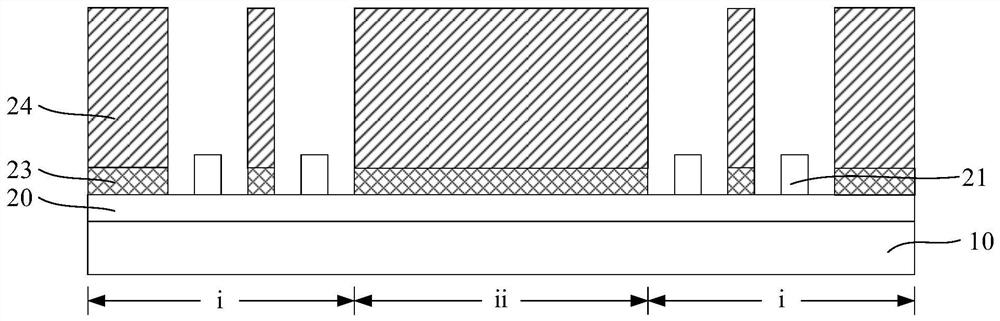

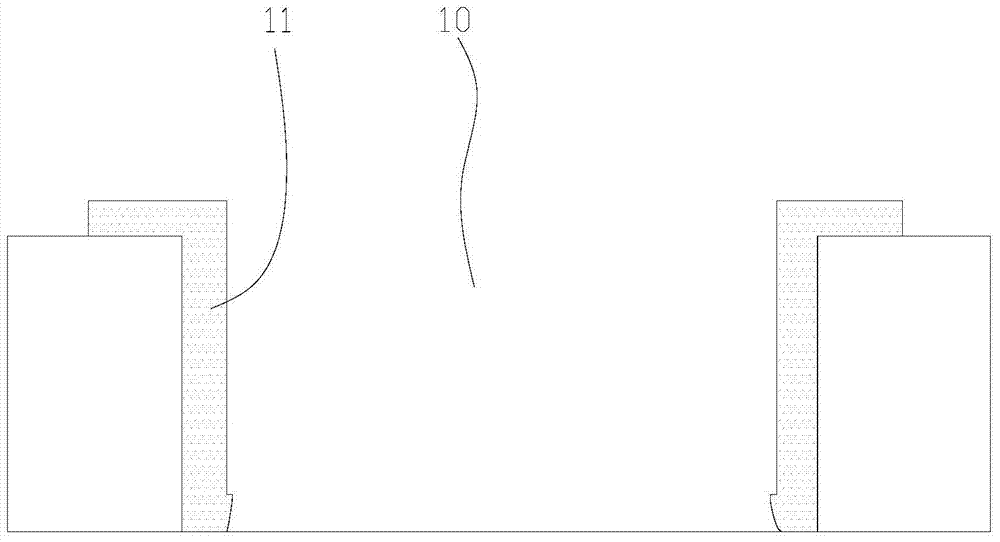

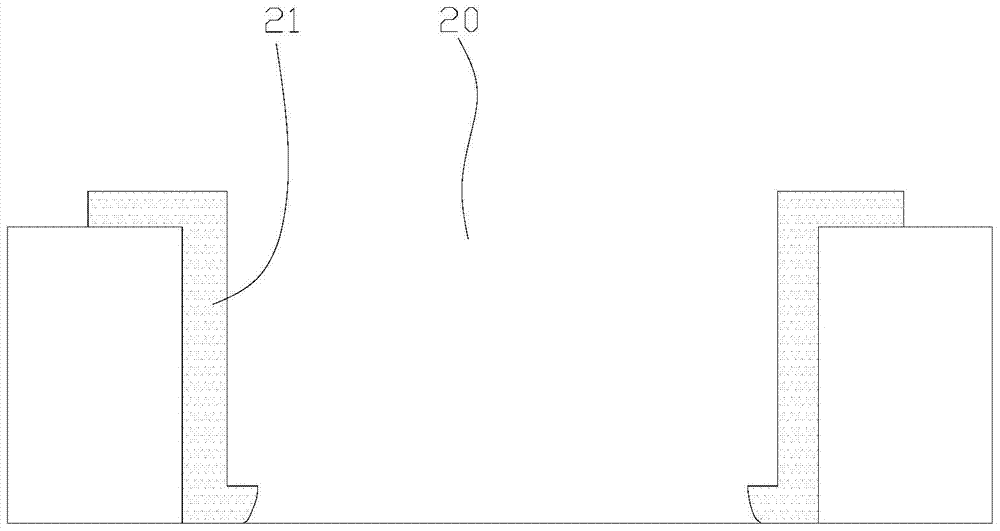

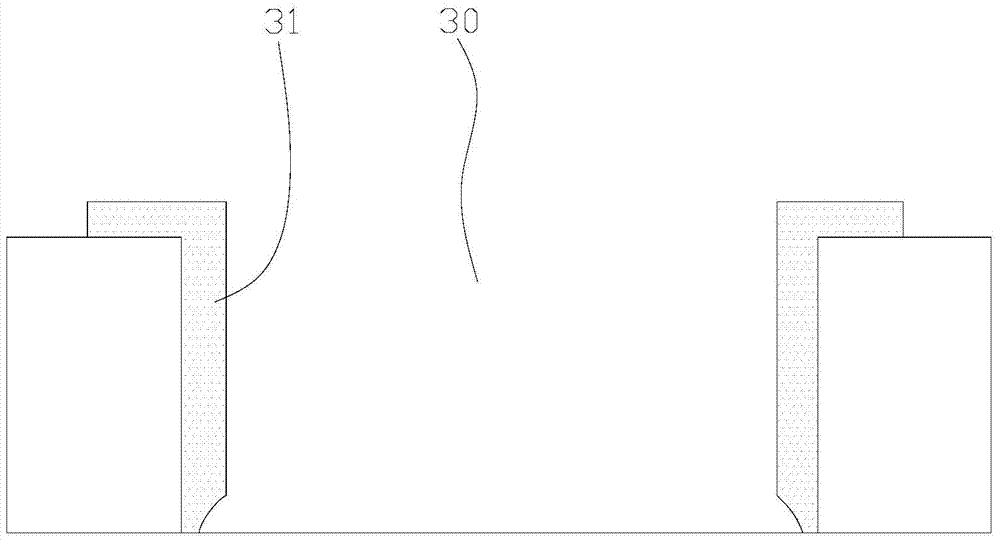

Alignment pattern, semiconductor structure with alignment pattern and manufacturing method of semiconductor structure

PendingCN111968962AQuality improvementReduce areaSemiconductor/solid-state device detailsSolid-state devicesSemiconductor structureEngineering

The invention relates to an alignment pattern, a semiconductor structure with the alignment pattern, and a manufacturing method of the semiconductor structure. The manufacturing method comprises the following steps of: arranging at least two standard pattern areas along a first direction, wherein each standard pattern area comprises at least two discrete sub-pattern areas, in the first direction,the distance between the adjacent sub-pattern areas in each standard pattern area is a first distance, the distance between the adjacent standard pattern areas is a second distance, and the second distance is larger than the first distance; and arranging shielding patterns, wherein the shielding patterns are located between the adjacent standard pattern areas, and gaps are formed between the shielding patterns and the adjacent standard pattern areas. According to the invention, the area of the open area in the alignment pattern can be reduced, and the defect problem caused by etching residuesis avoided, so that the alignment quality is improved.

Owner:CHANGXIN MEMORY TECH INC

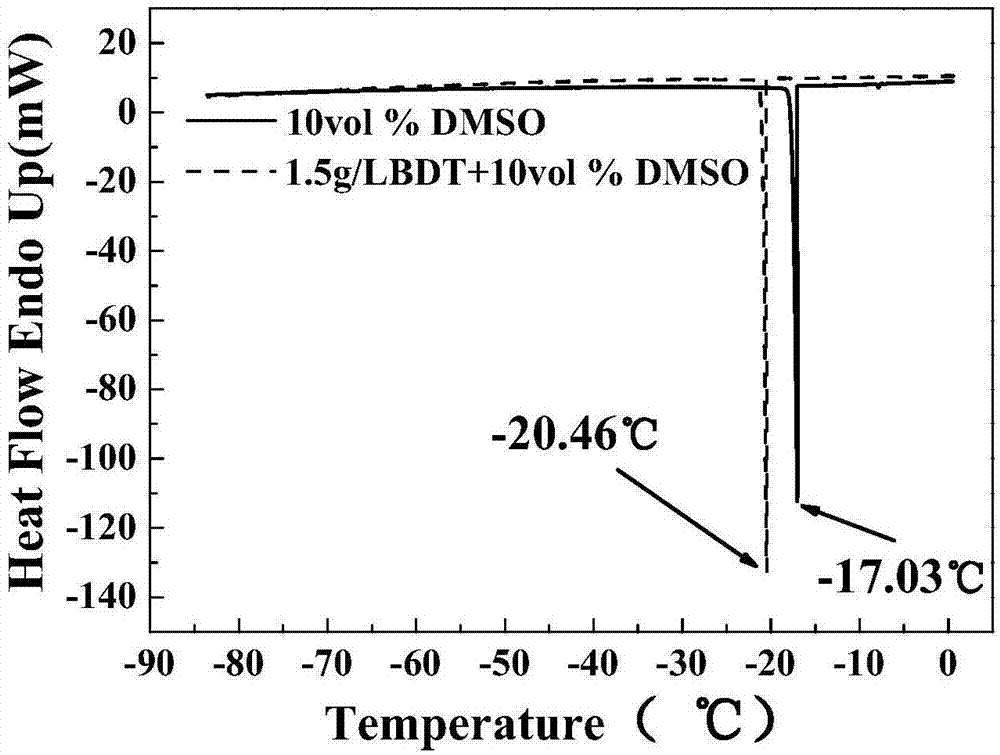

Method of cryopreserving Schwann cells by using supramolecular hydrogel in restricted space

The invention discloses a method of cryopreserving Schwann cells by using supramolecular hydrogel in a restricted space. The method comprises the following steps: digesting and centrifugalizing the Schwann cells attached to the wall, adding a cell full culture medium where a gel factor is dissolved and blowing the medium to obtain a Schwann cell suspension containing the gel factor; importing the obtained cell suspension and a cryopreserving protecting agent in a microchannel; placing the microchannel in an ice water bath at 3-5 DEG C and keeping balance for 4-5min; and finally, directly placing the microchannel in a programmed freezing box, and putting the programmed freezing box in a refrigerator at -82 DEG C to -78 DEG C. As a crosslinked network structure formed by the supramolecular hydrogel in the restricted space is relatively tighter compared with that in a non-restricted space, compared with supramolecular hydrogel out of the microchannel, the supramolecular hydrogel in the microchannel can better freeze and protect the cells. Compared with a microchannel device obtained a conventional soft etching method, a microfluidic device obtained by a glass capillary tube is lower in cost, simpler to manufacture and larger in cryopreserving size.

Owner:WUHAN UNIV OF TECH

Thermal-insulation material and preparation method thereof

ActiveCN109608156AImprove insulation effectImprove insulation performancePolyvinyl alcoholThermal insulation

The invention relates to the technical field of high-temperature high-pressure synthesis, and in particular relates to a thermal-insulation material and a preparation method thereof. The thermal-insulation material comprises the following raw materials: base powder and a polyvinyl alcohol aqueous solution, wherein the base powder comprises the following components: 65%-80% of sodium chloride, 10%-30% of magnesium oxide or zirconium oxide, and 3%-12% of graphite powder. The thermal-insulation material is prepared by the steps of weighing the raw material components according to above weight ratios, performing mixing and performing pressing. The thermal-insulation material provided by the invention has good thermal insulation and insulation performance, and can effectively solve the problemthat the product synthesized in a high-temperature high-pressure environment in the prior art is easily burned by heat radiation.

Owner:ZHENGZHOU HAOCHENG SUPERHARD TOOL +1

Production technology of russula vinosa lindblad powder

ActiveCN107411052ARich choiceSmall temperature differenceFood thermal treatmentFood preservationEngineeringFood material

The invention relates to a production technology of russula vinosa lindblad powder, and belongs to the field of production and processing of mushrooms. The production technology comprises five steps of performing cleaning, performing heating drying, lowering the temperature, performing ultrafine crushing, and performing sterilization and bagging, wherein the heating drying process is performed through control of procedures; and the ultrafine crushing is performed in the manner that the dried russula vinosa lindblad is transferred to an airflow type ultrafine crusher, airflows are used for crushing the russula vinosa lindblad, the air pressure is 0.2-0.4Mpa, and the ratio of air to solid is (2 to 1) to (3 to 1), so that the particle size of the obtained russula vinosa lindblad powder achieves 80[mu]m or below. Nutrient elements of the russula vinosa lindblad are reserved to the maximum extent, and the prepared russula vinosa lindblad powder can be rapidly prepared into various beverages and can also be added to various food materials, so that the nutrients of foods are increased. The russula vinosa lindblad powder has the efficacy of nourishing yin, invigorating the kidney, invigorating the brain and keeping young. The russula vinosa lindblad powder made by the method is long in storage time, convenient to transport and convenient to sell, and the business value of the russula vinosa lindblad is increased.

Owner:浦北县龙腾食品有限公司

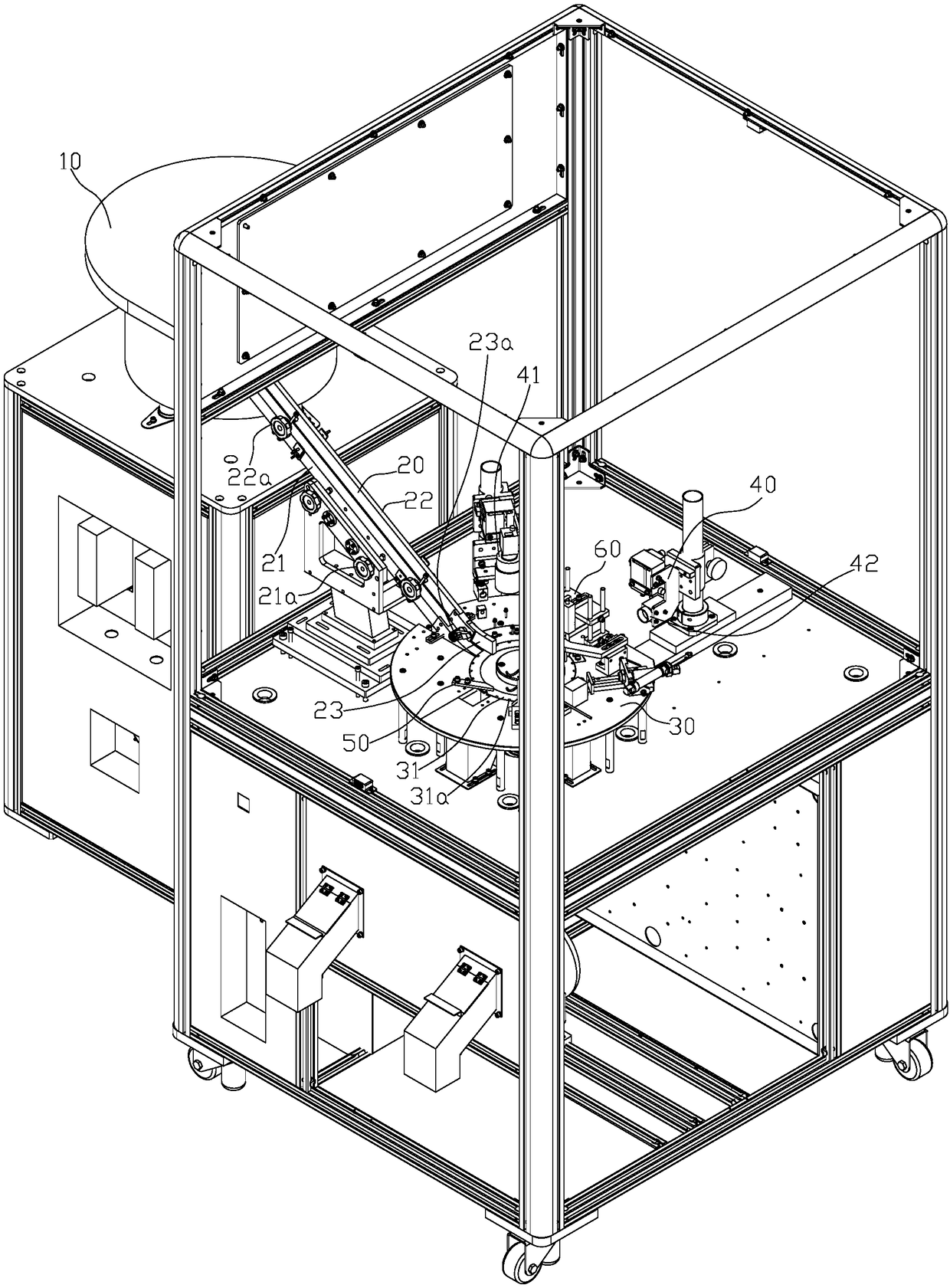

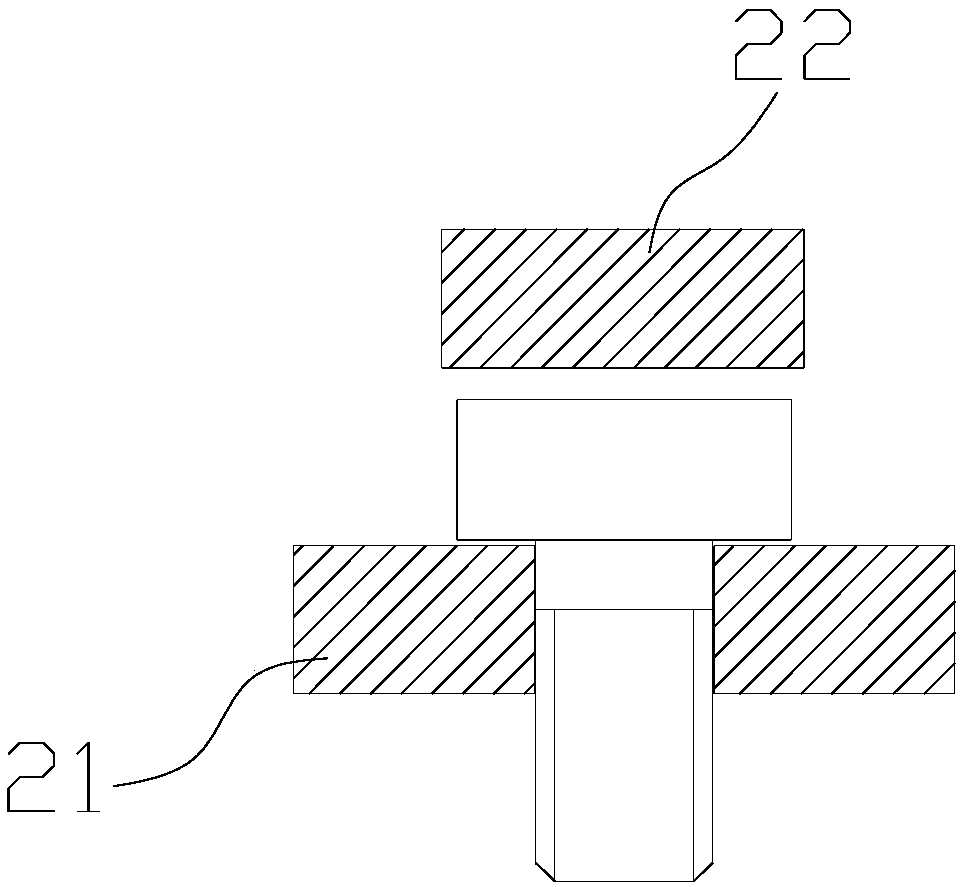

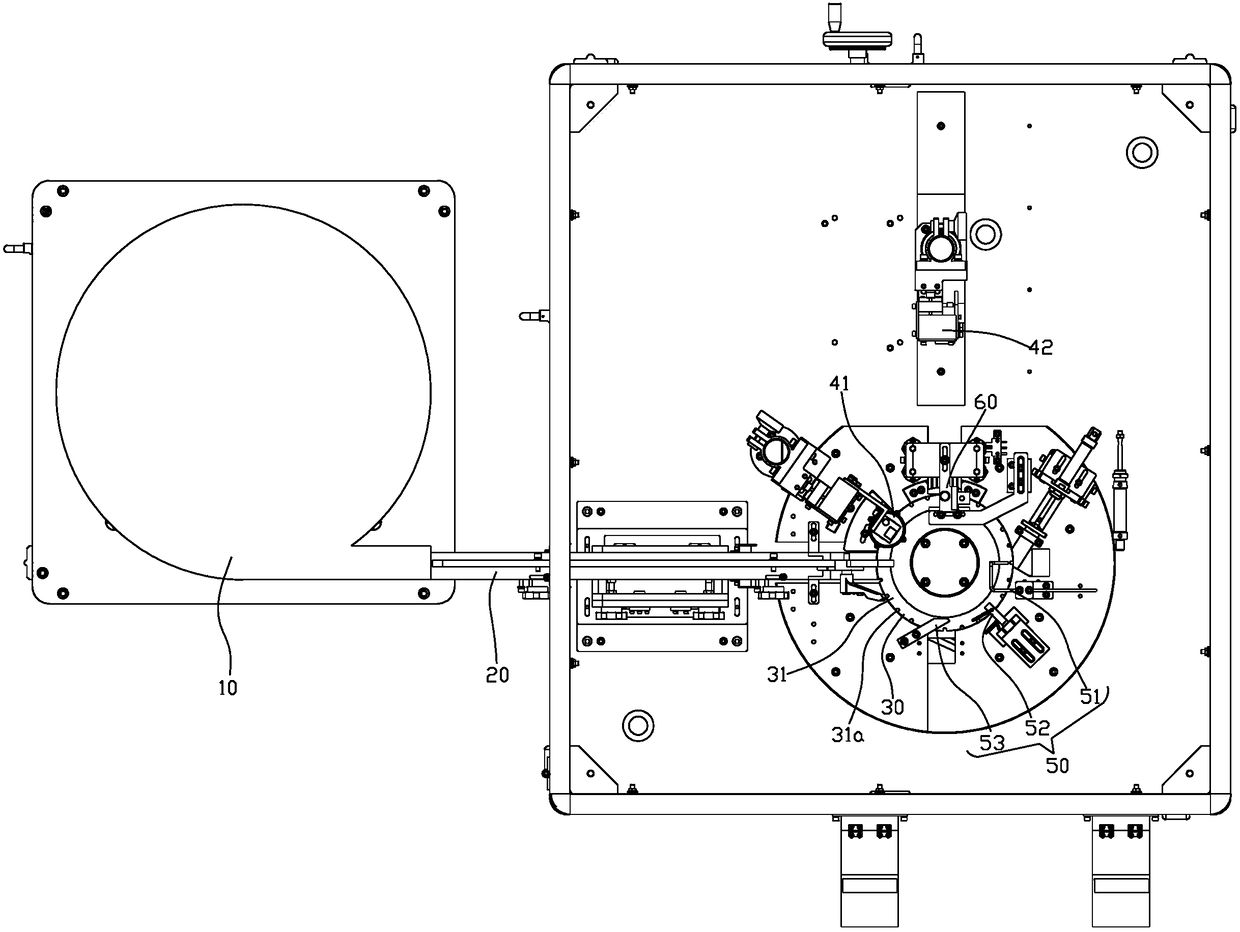

Chuck screw testing equipment

PendingCN108160512ANo shakingSmooth feedingOptically investigating flaws/contaminationUsing optical meansEngineeringInjection air

The invention relates to chuck screw testing equipment. The chuck screw testing equipment comprises a circular vibrator, a linear feeder, a circular rotating disc, a detection mechanism and a materialscreening mechanism, and the linear feeder includes two sliding rods arranged in parallel and symmetrical and a limiting pressure rod located directly above a gap of the two sliding rods; a first adjusting rotary knob is arranged outside the two sliding rods, and the first adjusting rotary knob controls the two sliding rods to be relatively close or far apart; a second adjusting rotary knob is arranged outside the limiting pressure rod, and the second adjusting rotary knob controls the limiting pressure rod to approach or move away from the two sliding rods; an arc-shaped limiting pressure head is arranged at the lower end of the limiting pressure rod, a third adjusting rotary knob is arranged on the arc-shaped limiting pressure head, and the third adjusting rotary knob controls the arc-shaped limiting pressure head to raise or lower; and the material screening mechanism comprises an air injection winkling gun, an anti-leakage and anti-winkling part and a qualified piece deflector rodwhich are arranged in sequence in the rotating direction of a glass disk, and a muzzle of the air injection winkling gun is located at the top of a U-shaped clamping slot.

Owner:合肥市雅视智能科技有限公司

Selecting process of regenerated polyester bottles

InactiveCN110843155AGuaranteed to completely removeGuaranteed qualityPlastic recyclingMechanical material recoveryPolyesterPolymer science

The invention provides a selecting process of regenerated polyester bottles. The selecting process comprises the following steps: A) disassembling polyester waste, selecting polyester bottles, and carrying out post-treatment on non-polyester bottles and impurities; B) cleaning the polyester bottles to remove label paper, bottle caps and impurities of the polyester bottles; C) manually selecting the cleaned polyester bottles to select qualified polyester bottles; and D) crushing and cleaning the polyester bottles obtained in the step C) to obtain regenerated polyester bottle sheets. According to the selecting process, impurities in the polyester waste are completely removed finally in a mode of preliminary selection, secondary selection and selection of selecting the polyester bottles first, and the selected polyester bottles are actually required polyester bottles, so that the quality of the regenerated polyester bottles is guaranteed.

Owner:ZHEJIANG HAILI ENVIRONMENTAL TECH CO LTD

Method and device for impurity removal and purification of dimethyldichlorosilane by reaction and rectification

InactiveCN110639221AHigh purityEfficient separationSilicon organic compoundsChemical industryPtru catalystSilanes

The invention relates to a method and device for impurity removal and purification of dimethyldichlorosilane by reaction and rectification. A dimethyldichlorosilane crude material enters a tower through an inlet pipeline in a reaction section, the temperature of a stripping section is controlled, and the dimethyldichlorosilane crude material enters the reaction section upwards in a gas phase form;a chlorine source reactant enters the tower through a chlorine source reactant inlet pipeline in the reaction section, the temperature of a rectification section is controlled, and the dimethyldichlorosilane crude material enters the reaction section downwards in a liquid phase form; hydrogen-containing silane impurities in the dimethyldichlorosilane crude material react with the chlorine sourcereactant under action of a catalyst to generate a high-boiling-point substance; after the reaction, the high-boiling-point substance is extracted from the tower bottom through a tower bottom extraction pipeline; the chlorine source reactant enters the tower through a reactant return pipeline in the stripping section to supplement the chlorine source reactant, and the condensed gas phase at the tower top is intermittently extracted through an outlet of a gas phase pipeline; a part of the condensed chlorine source reactant flows back to the tower top through a tower top return pipeline, and a part of the condensed chlorine source reactant is extracted through a tower top liquid phase extraction pipeline. Hydrogen-containing silane is enriched by 10-100 times to obtain a high-purity dimethyldichlorosilane product.

Owner:TIANJIN UNIV

Continuous treatment process for supercritical fluid anhydrous oil removal and whitening of polyester products

PendingCN114808320AGood whitening consistencyGood uniform mixing effectSucessive textile treatmentsSolvent treatment with solvent recoveryPolyesterWhitening Agents

The invention relates to a polyester product supercritical fluid anhydrous oil removal and whitening continuous treatment process which comprises the following steps: S2, enabling supercritical fluid to flow into a pretreatment kettle, stopping when the temperature reaches 40-60 DEG C and the pressure reaches 8-15MPa, then performing heat preservation and oil removal circulation treatment on the supercritical fluid in a first circulation system, and releasing pressure and discharging after the treatment is completed; and S3, enabling the supercritical fluid to enter a pretreatment kettle from the aid kettle, stopping when the temperature reaches 80-100 DEG C and the pressure reaches 16-22 MPa, then carrying out heat preservation whitening circulation treatment on the supercritical fluid dissolved with the solid whitening agent in a second circulation system, and after the treatment is completed, releasing pressure and discharging. The polyester product is deoiled before whitening treatment, supercritical anhydrous deoiling and whitening continuous treatment is adopted, no water is generated in the whole process, water and energy are saved, the whiteness of the treated polyester product reaches 180 or above, the problems of white spots, color spots, head and tail color difference and the like do not exist, and whitening consistency is good.

Owner:石狮市中纺学服装及配饰产业研究院

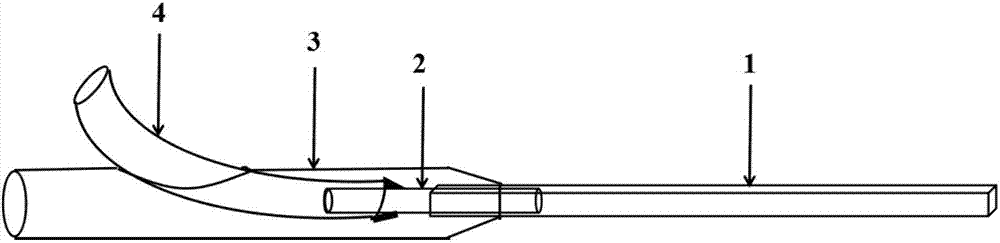

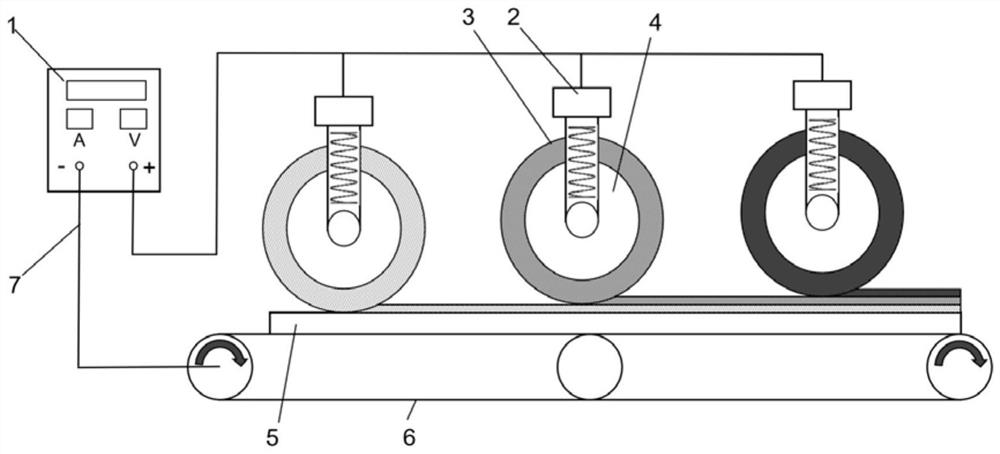

Device and method for preparing electrically assisted gradient coating on fuel cell plate base material

The invention relates to a device and method for preparing an electrically assisted gradient coating on a fuel cell plate base material, comprising a conveyor belt, a current controller, and a plurality of rolling assemblies, and the current controller is respectively connected to the conveyor belt and each rolling assembly, The rolling assembly includes a base roller, a roller cover and an adjustment device. The roller cover is set on the base roller, and the composition of the roller cover is the material to be coated; The Joule heat generated in the suite melts the material to be coated, and the material is coated on the surface of the metal substrate through the movement of the conveyor belt. By setting up multiple coating coating stations, the effective preparation of the gradient coating is obtained. Compared with the prior art, the invention has the advantages of smooth coating surface, good mechanical properties, one-time molding, convenient processing and high efficiency.

Owner:SHANGHAI JIAOTONG UNIV

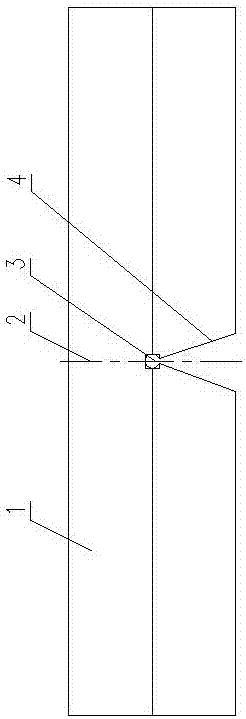

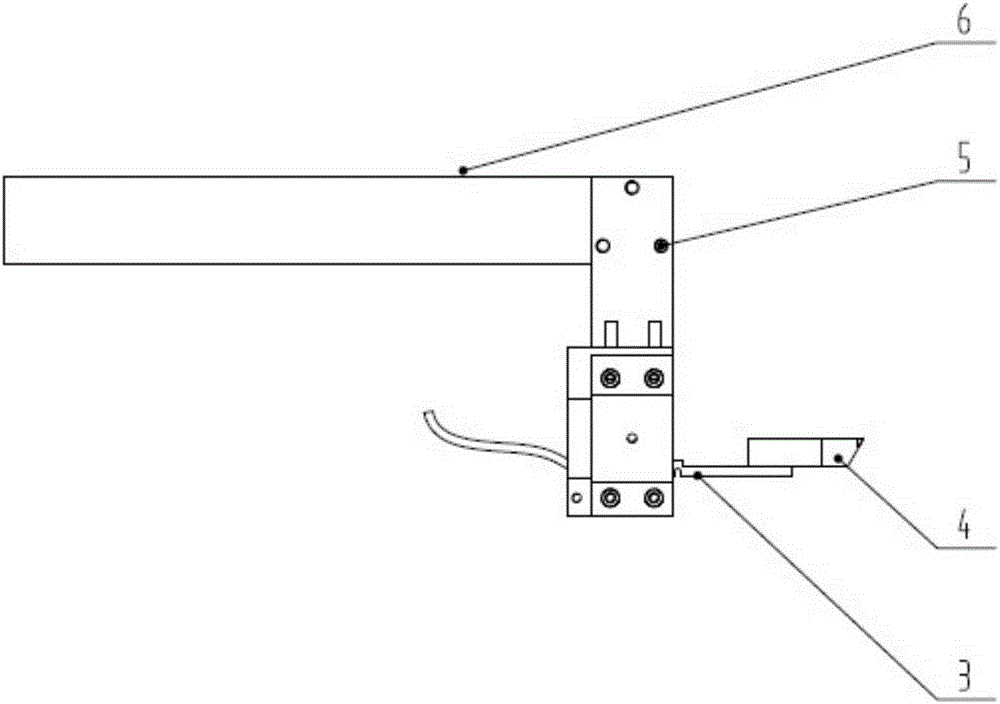

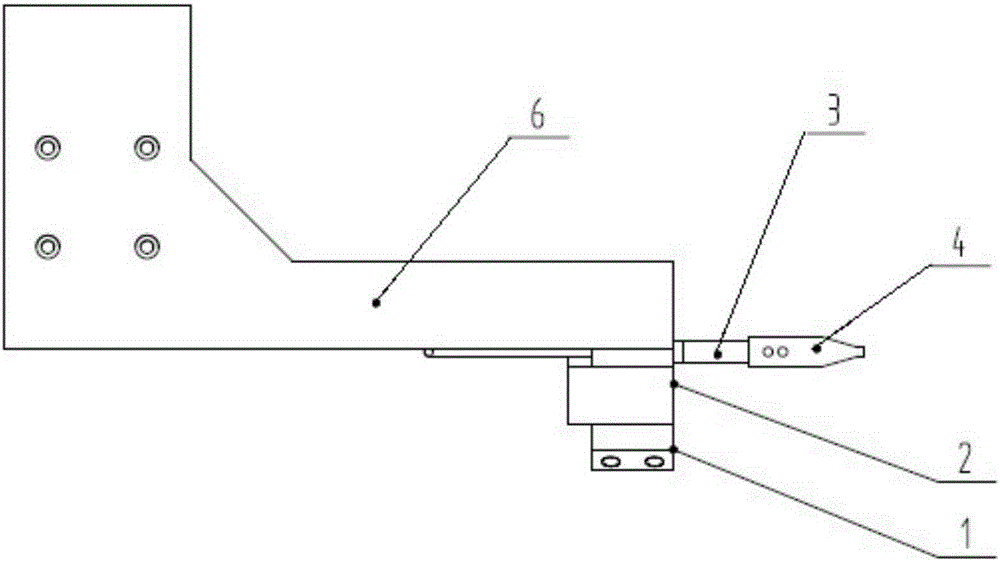

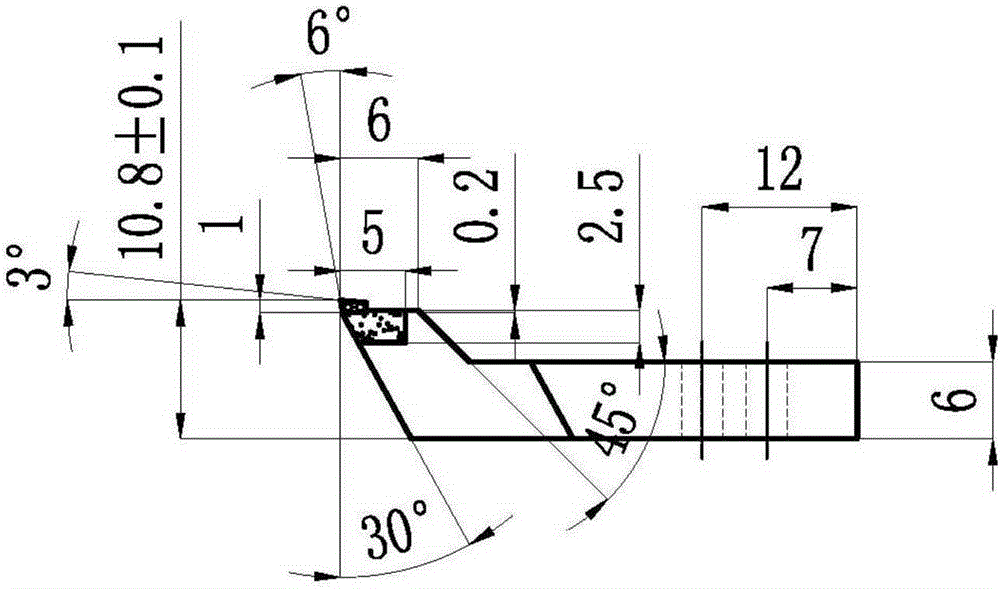

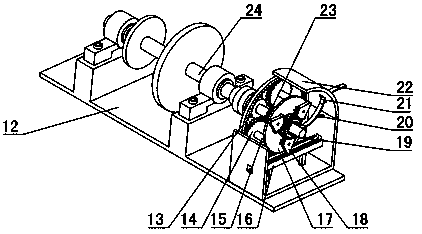

A tool system for online removal of tiny burrs on the working edge of a servo valve spool

ActiveCN104043842BAvoid easy removalSize Removal DifficultyAuxillary equipmentCutting insertsMicrometerEngineering

Disclosed is a tool system for online removal of tiny burrs on a servo valve element working edge. The tool system comprises a turning tool, a cantilever type force sensor, a clamp, an adjusting block and a bridge connection plate. The bridge connection plate is connected and installed on a motion control device. The clamp is connected with the bridge connection plate through the adjusting block. A groove is formed in the adjusting block. The clamp can move up and down along the groove so as to adjust the height of the clamp. One end of the cantilever type force sensor is provided with the turning tool, and the other end of the cantilever type force sensor is connected with the clamp. The turning tool comprises a base body and a blade, wherein the base body is a 40 Cr+ molybdenum block, the blade is made of artificial monocrystal diamond, the front angle of the turning tool is 3 degrees, the back angle of the turning tool is 6 degrees, the roughness of the front tool face and the back tool face is 0.01 micrometer, the radius of the edge opening of the cutting edge is smaller than 100 nanometers, the edge width is 4 millimeters, and the edge opening is sharp without tipping under the observation of a 1000-time magnifier. According to the tool system for online removal of the tiny burrs on the servo valve element working edge, the burrs on the valve element workpiece working edge can be effectively removed in an online mode, the precision of the working edge is ensured, the part rejection rate is reduced, meanwhile, production efficiency is improved, and the production cost is reduced.

Owner:SHANGHAI JIAO TONG UNIV +1

A kind of production method of rhododendron powder

ActiveCN107411052BRich choiceSmall temperature differenceFood thermal treatmentFood preservationBiotechnologyNutrition

The invention relates to a production technology of russula vinosa lindblad powder, and belongs to the field of production and processing of mushrooms. The production technology comprises five steps of performing cleaning, performing heating drying, lowering the temperature, performing ultrafine crushing, and performing sterilization and bagging, wherein the heating drying process is performed through control of procedures; and the ultrafine crushing is performed in the manner that the dried russula vinosa lindblad is transferred to an airflow type ultrafine crusher, airflows are used for crushing the russula vinosa lindblad, the air pressure is 0.2-0.4Mpa, and the ratio of air to solid is (2 to 1) to (3 to 1), so that the particle size of the obtained russula vinosa lindblad powder achieves 80[mu]m or below. Nutrient elements of the russula vinosa lindblad are reserved to the maximum extent, and the prepared russula vinosa lindblad powder can be rapidly prepared into various beverages and can also be added to various food materials, so that the nutrients of foods are increased. The russula vinosa lindblad powder has the efficacy of nourishing yin, invigorating the kidney, invigorating the brain and keeping young. The russula vinosa lindblad powder made by the method is long in storage time, convenient to transport and convenient to sell, and the business value of the russula vinosa lindblad is increased.

Owner:浦北县龙腾食品有限公司

A bypass baffle for limestone wet flue gas desulfurization

ActiveCN110201503BEfficient scrapingWill not scale easilyGas treatmentDispersed particle separationThermodynamicsEngineering

A bypass baffle for limestone wet flue gas desulfurization, comprising an air outlet, the inside of the air outlet is fixedly installed with a partition, the right side of the air outlet is movably installed with a rotating shaft, and the right end of the rotating shaft is hinged with a rotating blade. The right side of the leaf is movably installed with a fixed plate, and the outer surface of the fixed plate is provided with an arc groove. The inside of the arc groove is slidably installed with a fixed rod. There are curved plates. Through the combined use of the arc plate and the scraper hook, the dirt formed between the air outlet and the rotor blade can be effectively scraped off, ensuring that during the desulfurization process, there will be no easy fouling between the air outlet and the rotor blade. In this way, it is ensured that the rotor blade and the air outlet can always be tightly closed when they are opened and closed without gaps, which further ensures that the sealing in the boiler is good and will not cause negative pressure in the furnace of the boiler. Ease of use.

Owner:湖北点石成金创新技术有限公司

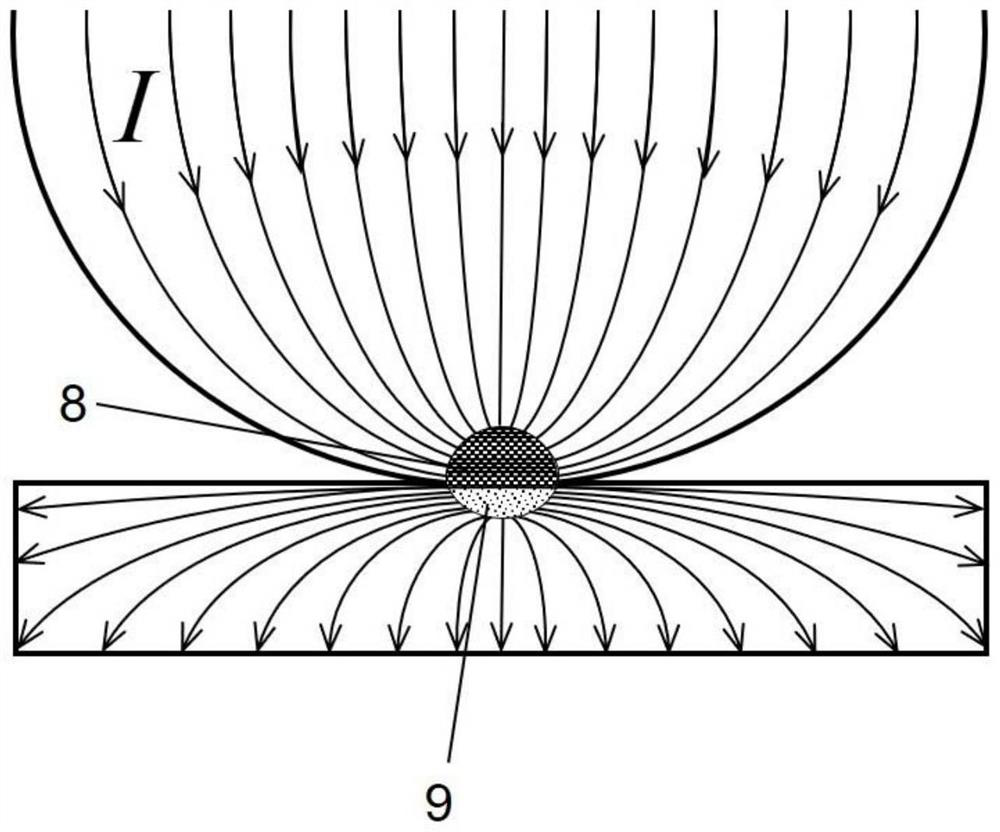

A method of manufacturing a pcb with bottomless copper metallized blind holes

InactiveCN104684280BImprove qualityGuaranteed removal effectPrinted circuit aspectsPrinted element electric connection formationEtchingCopper

The invention relates to the technical field of PCB manufacturing, in particular to a manufacturing method of a PCB with a base copper-free metallized blind hole. The manufacturing method comprises the following steps: firstly manufacturing a metallized blind hole, then performing pattern plating, adopting a depth controlled milling manner to remove a copper layer at the bottom of the hole before outer layer etching, and then etching the copper edge remaining at the bottom of the metallized blind hole through the outer layer etching, so that the milled edge is smooth, the problems that the copper edge remaining at the bottom of the base copper-free metallized blind hole is large in area and coarse can be avoided, and the quality of the base copper-free metallized blind hole is greatly improved; setting the perpendicular distance between the milled edge and the wall of the metallized blind hole to be 0.01-0.02 mm, and enabling the milled edge after outer layer etching to be basically flush with the hole wall; setting the depth controlled milling to be 0.1-0.11 mm deeper than the metallized blind hole, so as to ensure that the copper layer at the bottom of the hole is completely removed, and no influence is generated due to nonuniformity of the copper layer.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

Rust ring type corneal foreign body removing needle

The invention discloses a rust ring type corneal foreign body removing needle, and belongs to the technical field of medical instruments. The needle comprises a circumcision needle tube, a needle core, a holding handle and an adjusting wrench. By means of the mode, the problem that in the prior art, the rust ring is a part of the whole corneal lamellar collagenous fiber, the collagenous fiber needs to be cut off during removal, and the collagenous fiber of the rust ring foreign matter for a circle is difficult to cut off during needle tip sample removal or all other foreign matter removal at present can be solved. Corneal lamellar fibers are cut off after girdling, no obvious tight connection exists between layers relatively, separation is easy, and therefore the rust ring can be easily and completely scraped, cut and stripped through a rust ring scraping knife at the head end of the needle core.

Owner:永康市第一人民医院

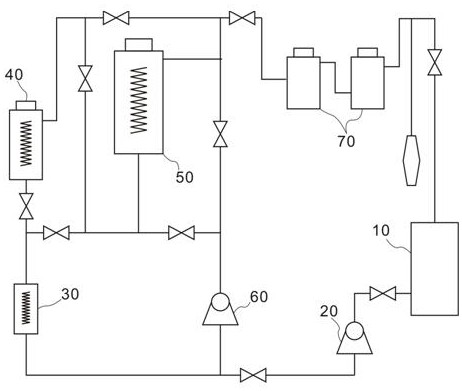

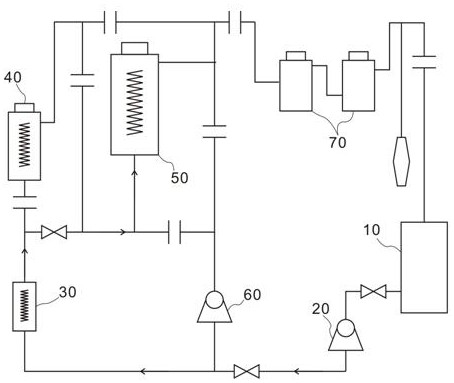

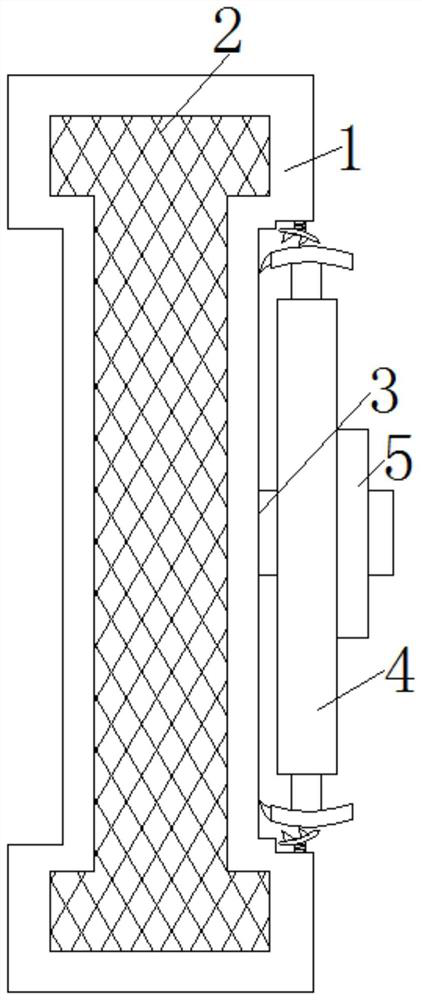

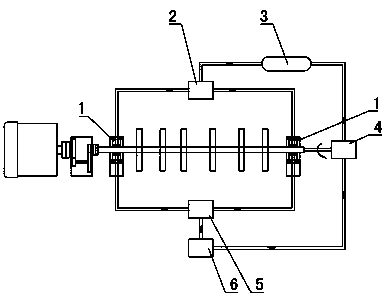

An Adaptive Circulating Lubrication System for Sliding Bearings

InactiveCN107366820BAffect lifeShort lifeValve arrangementsBearing componentsEngineeringSelf adaptive

The invention provides a self-adaptive circulating lubricating system for a sliding bearing and belongs to the technical field of bearing lubricating systems. The self-adaptive circulating lubricating system is characterized by comprising a filter (2), a pressure-cutting oil supply device (4) and a heat exchanger (6); the liquid outlet end of the filter (2) communicates with the liquid inlet end of the pressure-cutting oil supply device (4), and the liquid outlet end of the pressure-cutting oil supply device (4) communicates with the liquid inlet end of the heat exchanger (6); the sliding bearing (1) is provided with an oil inlet hole and an oil outlet hole, the liquid inlet end of the filter (2) communicates with the oil outlet hole of the sliding bearing (1), and the liquid outlet end of the heat exchanger (6) communicates with the oil inlet hole of the sliding bearing (1); and a rotary shaft for mounting the sliding bearing (1) is connected with the power input end of the pressure-cutting oil supply device (4). The self-adaptive circulating lubricating system for the sliding bearing has the beneficial effects that by simplifying an external circulating structure of the sliding bearing, lubricating oil is circulated by the adoption of the same power source, the capacity of a main drive device is fully utilized, the occupied area is saved, and the consumption of the electric energy is reduced.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com