Device and method for preparing electrically assisted gradient coating on fuel cell plate base material

A fuel cell plate and gradient coating technology, which is applied to fuel cells, devices for coating liquid on the surface, coatings, etc., can solve the problem of the difficulty in ensuring the flatness of the pressed sheet surface, the complete removal of the metal foil, and the coating Problems such as poor surface quality, to achieve the effect of strong bonding, low cost, and adjustable coating thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

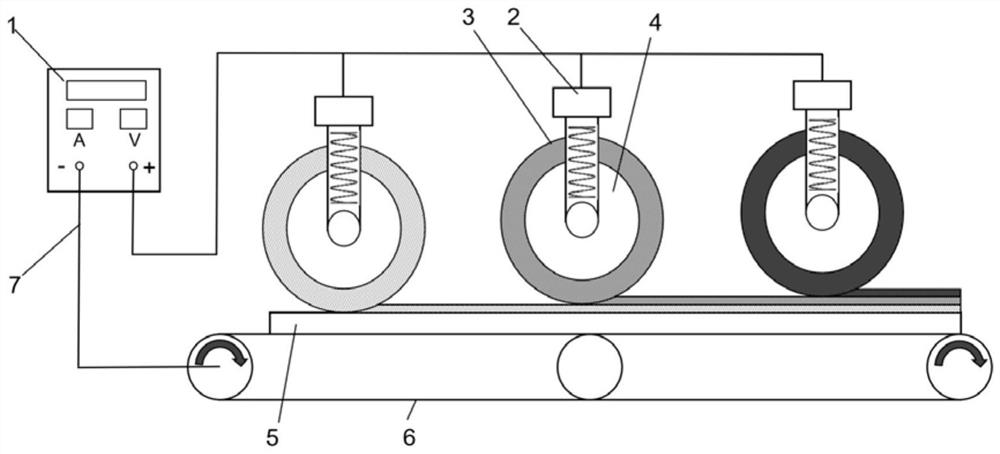

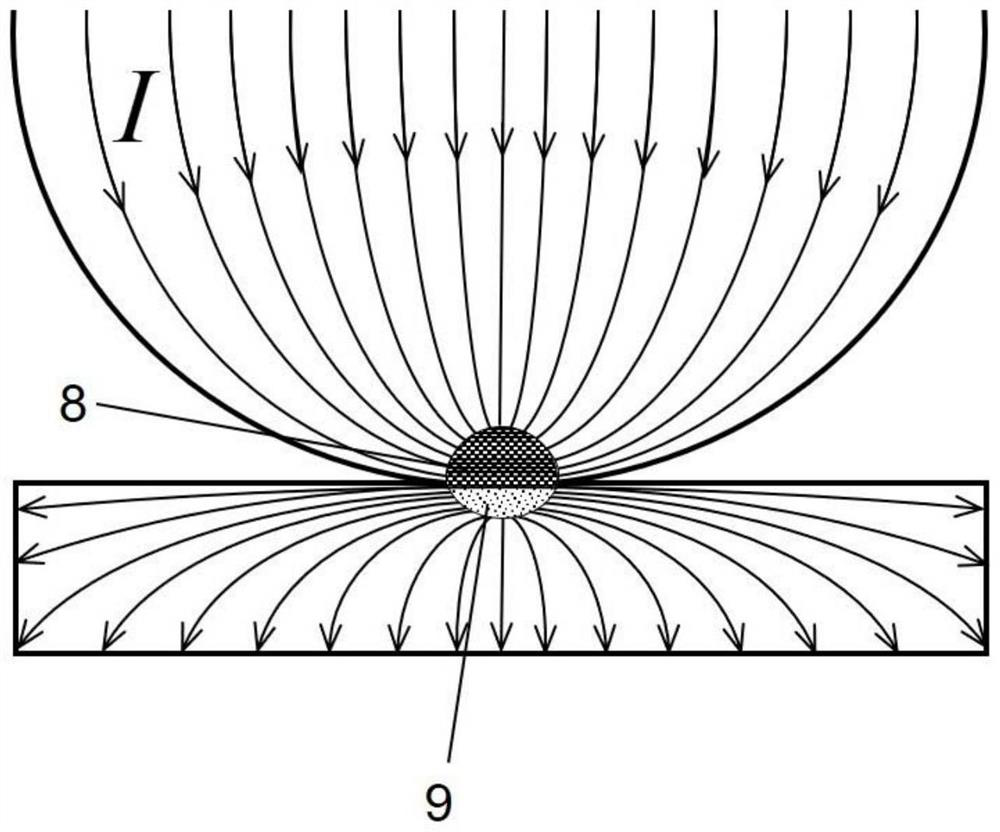

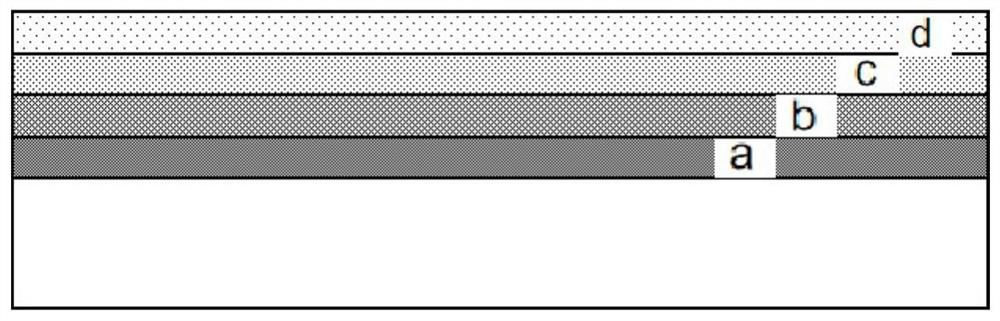

[0043] like figure 1 As shown, a device for preparing an electrically assisted gradient coating for a fuel cell electrode plate substrate includes a conveyor belt 6, a current controller 1, and a plurality of rolling components (the number of rolling components is determined according to the number of gradient coatings, this implementation In the example, four rolling assemblies are used as an example), the rolling assembly includes a base roll 4, a roll sleeve 3 and an adjusting device, the roll sleeve 3 is sleeved on the base roll 4, and the roll sleeve 3 and the base roll 4 The relative movement between the two is limited mainly by interference fit and pin fixing. In this embodiment, it is connected by means of bolts, and in the case of Figure 4-6 As shown, a groove is set on the base roller 4, and a corresponding groove is set on the roller sleeve 3. After the roller sleeve 3 is sleeved on the base roller 4, a plug 10 is inserted into the groove to fix the roller sleeve ...

Embodiment 2

[0056] like Figure 7 As shown, the difference from Embodiment 1 is that the conveyor belt 6 can be replaced with four fixed rollers 12 with the same outer diameter as the roller sleeve. The fixed rollers 12 have only one degree of freedom. The contacts 11 are connected to the metal substrate 5 . The rotation of the fixed roller 12 drives the metal substrate 5 to move horizontally.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com