A method of manufacturing a pcb with bottomless copper metallized blind holes

A technology for metallized blind holes and manufacturing methods, which is applied in the fields of printed circuit manufacturing, electrical connection formation of printed components, electrical components, etc., can solve copper edge roughness, make non-metallized blind holes into bottomless copper metallized blind holes, Affect the quality of bottomless copper metallized blind holes, etc., to avoid large area and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

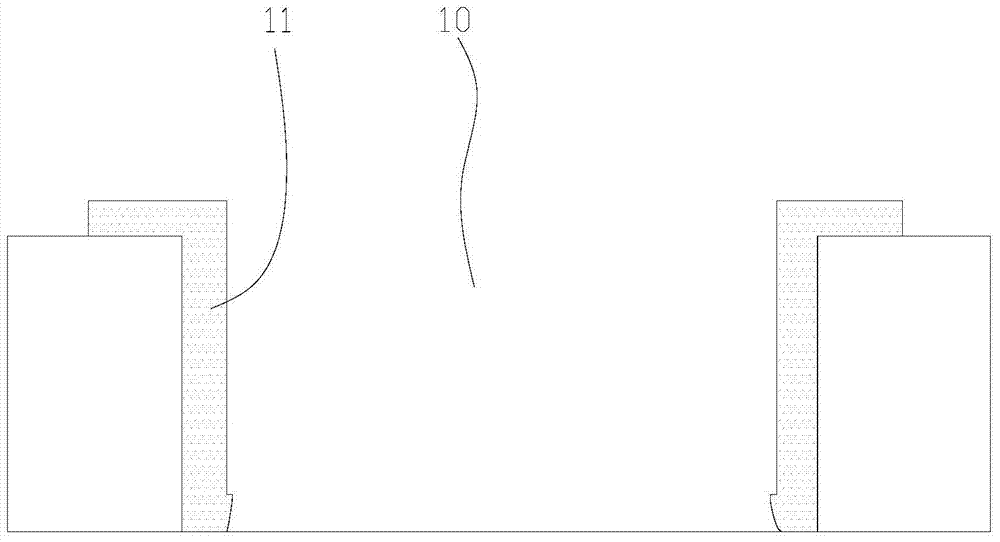

Embodiment 1

[0018] This embodiment provides a method for manufacturing a PCB with bottomless copper metallized blind holes. The specific manufacturing steps are as follows:

[0019] (1) Pressing to form a multi-layer board

[0020] Firstly, as in the PCB production process of the prior art, the raw materials of the PCB are cut to obtain a core board, and then the inner layer circuit is produced on the core board by using a negative film process. Through the AOI inspection of the inner layer, check whether there are defects such as open and short circuits, line gaps, and line pinholes in the inner layer lines, and products without defects enter the lamination process.

[0021] Carry out browning treatment on the core board, then stack the core board, prepreg and outer copper foil according to the design data, and then select appropriate pressing conditions according to the Tg of the board material, and press the stacked boards into one to form a multilayer board.

[0022] (2) Making meta...

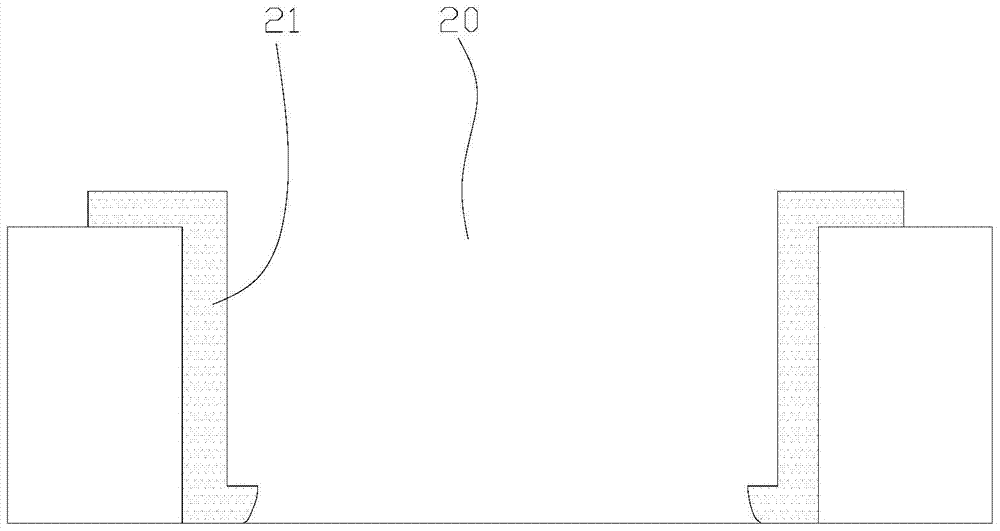

Embodiment 2

[0033] This embodiment provides a method for manufacturing a PCB with bottomless copper metallized blind holes. The specific manufacturing steps are basically the same as those in Embodiment 1, the difference being that: the metallized blind holes are cut through controlled depth milling. When the copper layer at the bottom of the hole is removed, the vertical distance between the milling edge and the wall of the metallized blind hole is 0.03mm, that is, when the copper at the bottom of the hole is milled, the milling edge shrinks 0.03mm inward compared to the single side of the hole wall.

[0034] The schematic diagram of the cross-sectional structure of the bottomless copper metallized blind hole 20 produced is as follows figure 2 shown. The milled edge becomes smooth after the outer layer is etched, but the milled edge obviously protrudes from the hole wall 21 , so that the residual copper edge area at the bottom of the bottomless copper metallized blind hole 20 is relativ...

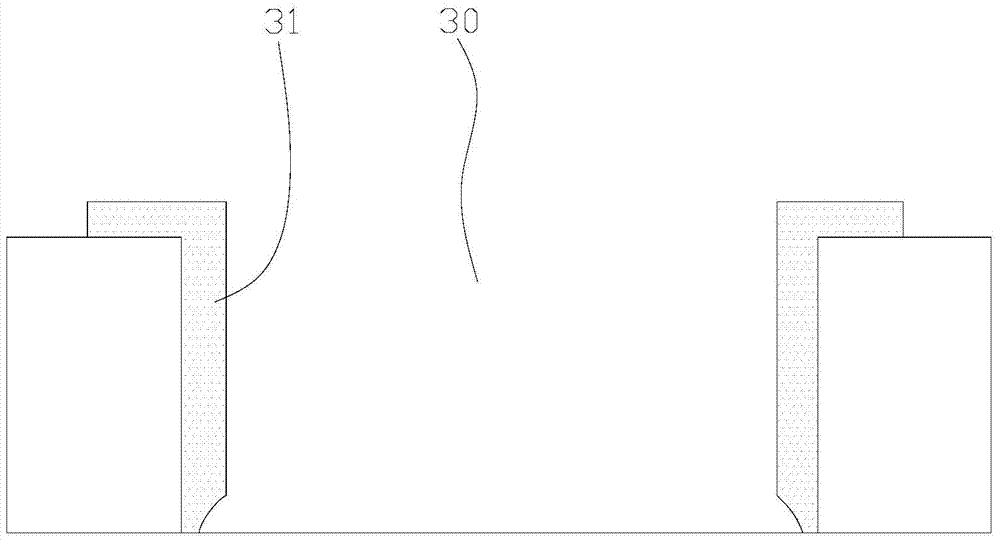

Embodiment 3

[0036] This embodiment provides a method for manufacturing a PCB with bottomless copper metallized blind holes. The specific manufacturing steps are basically the same as those in Embodiment 1, the difference being that: the metallized blind holes are cut through controlled depth milling. When the copper layer at the bottom of the hole is removed, the vertical distance between the milling edge and the hole wall of the metallized blind hole is 0.005mm, that is, when the copper at the bottom of the hole is milled, the milling edge shrinks 0.005mm from the single side of the hole wall.

[0037] The schematic diagram of the section structure of the bottomless copper metallized blind hole 30 produced is as follows image 3 shown. The milling edge becomes smooth after the outer layer is etched, but the milling edge is obviously recessed into the hole wall 31 .

[0038] In other embodiments, when the copper layer at the bottom of the metallized blind hole is removed by controlled de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com