Mask for laser direct writing and etching method of mask

A technology of laser direct writing and masking, applied in optics, originals for photomechanical processing, instruments, etc., can solve problems such as unfavorable coating process, low anti-laser damage threshold, difficult to control pattern accuracy, etc., to ensure line accuracy , Strong laser ablation ability, good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

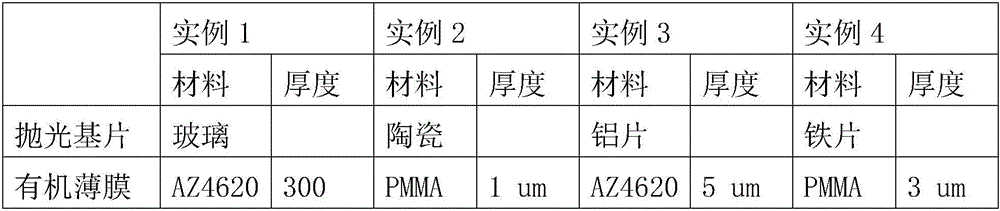

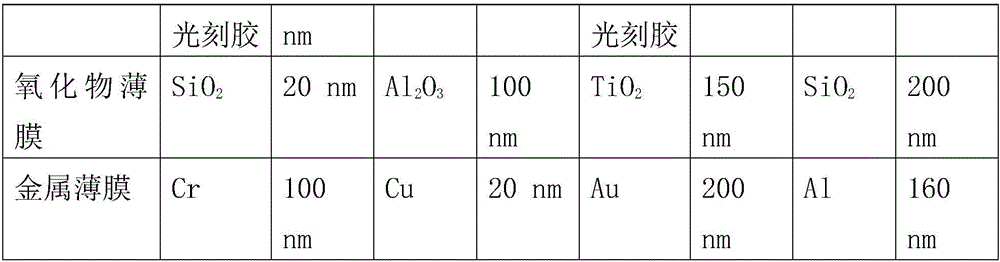

[0035] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation of the laser direct writing mask and its etching method according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. , structure, feature and effect thereof, detailed description is as follows. In the following description, different "one embodiment" or "embodiment" do not necessarily refer to the same embodiment. Furthermore, the particular features, structures, or characteristics of one or more embodiments may be combined in any suitable manner.

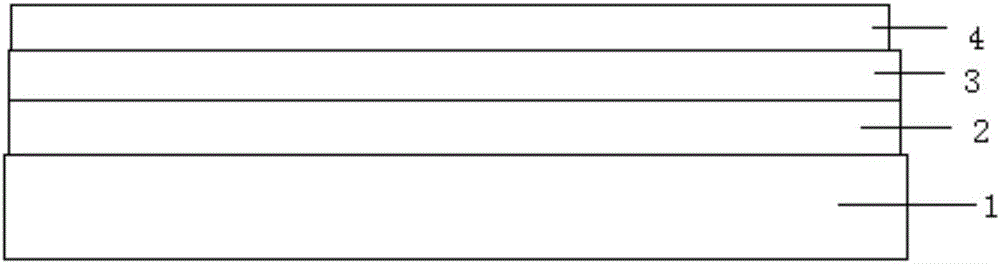

[0036] Such as figure 1 As shown, a kind of mask for laser direct writing proposed by an embodiment of the present invention, it comprises:

[0037] polishing substrate 1;

[0038] An organic thin film 2 attached to the surface of the polished substrate;

[0039] An oxide film 3 deposited on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com