Method and device for treating waste gas of TFT glass substrate kiln

A waste gas treatment and glass substrate technology, applied in waste heat treatment, gas treatment, separation methods, etc., can solve problems such as unstable capacity, low denitrification efficiency, difficult cleaning, etc., achieve reduction of nitrogen oxides, good treatment effect, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

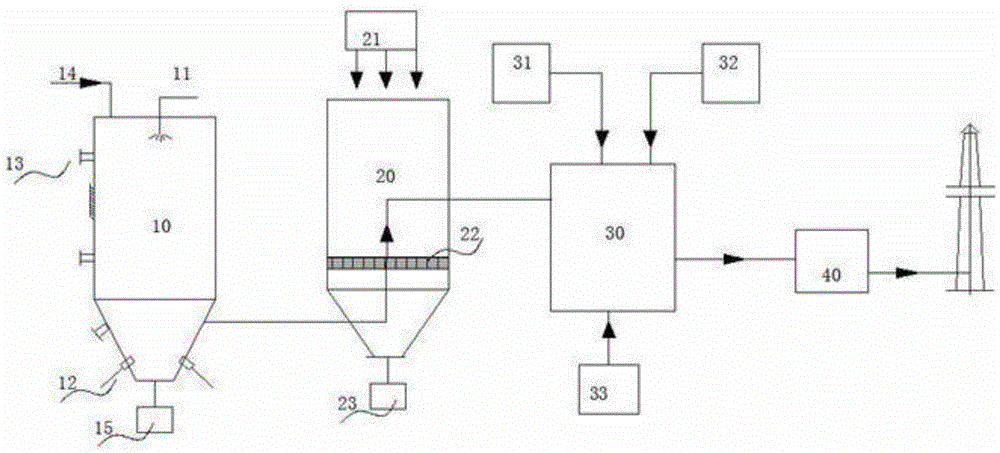

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0033] see figure 1 , the present invention includes sequentially connected cooling tank 10, dust removal box 20, combustion chamber 30 and SCR reaction unit 40, cooling tank 10 is mainly used to remove boron oxide in kiln exhaust gas; dust removal box 20 can be several groups.

[0034] Wherein, the upper part of the cooling tank 10 is cylindrical, and the first waste gas inlet 14 and the cooling medium inlet 11 are provided on the top of the cylindrical shape; Hopper 15, the bottom of the inverted cone is connected to the first hopper 15 by opening the first discharge port for discharging the batch material and boron oxide; are connected; the side wall of the inverted tapered structure is provided with a heater 12 outside, and the heater 12 can be two and symmetrically arranged or more arranged, and the deposited condensate is heated to a flowable molten st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com