Low-nitrogen combustion device and method

A low-nitrogen combustion and combustion chamber technology, which is applied in the direction of combustion methods, burners, burners, etc., can solve the problems of increased nitrogen oxide emissions, uneven gas distribution, and increased emissions, and achieve stable combustion and stable combustion. The effect of large flame area and high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

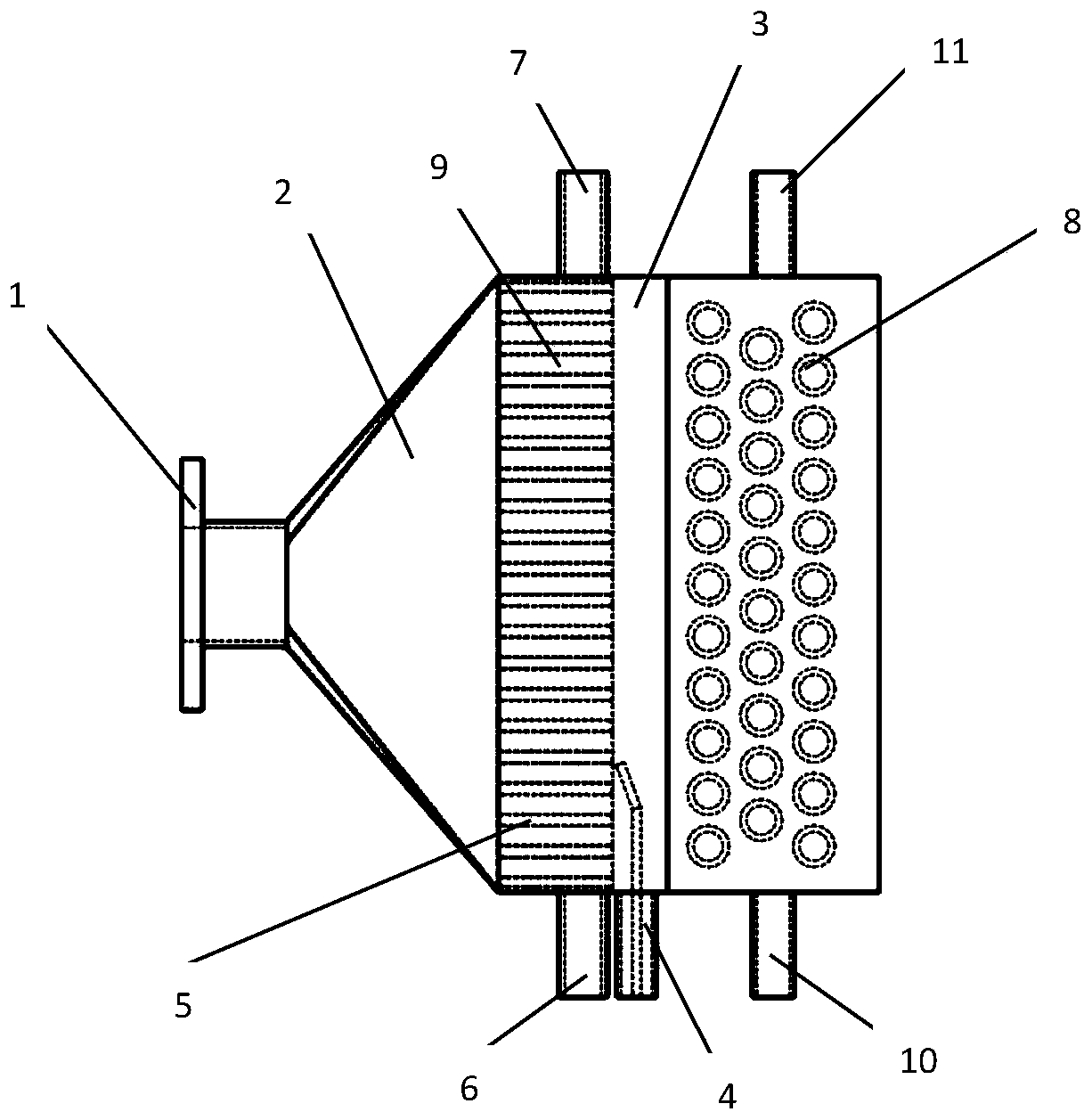

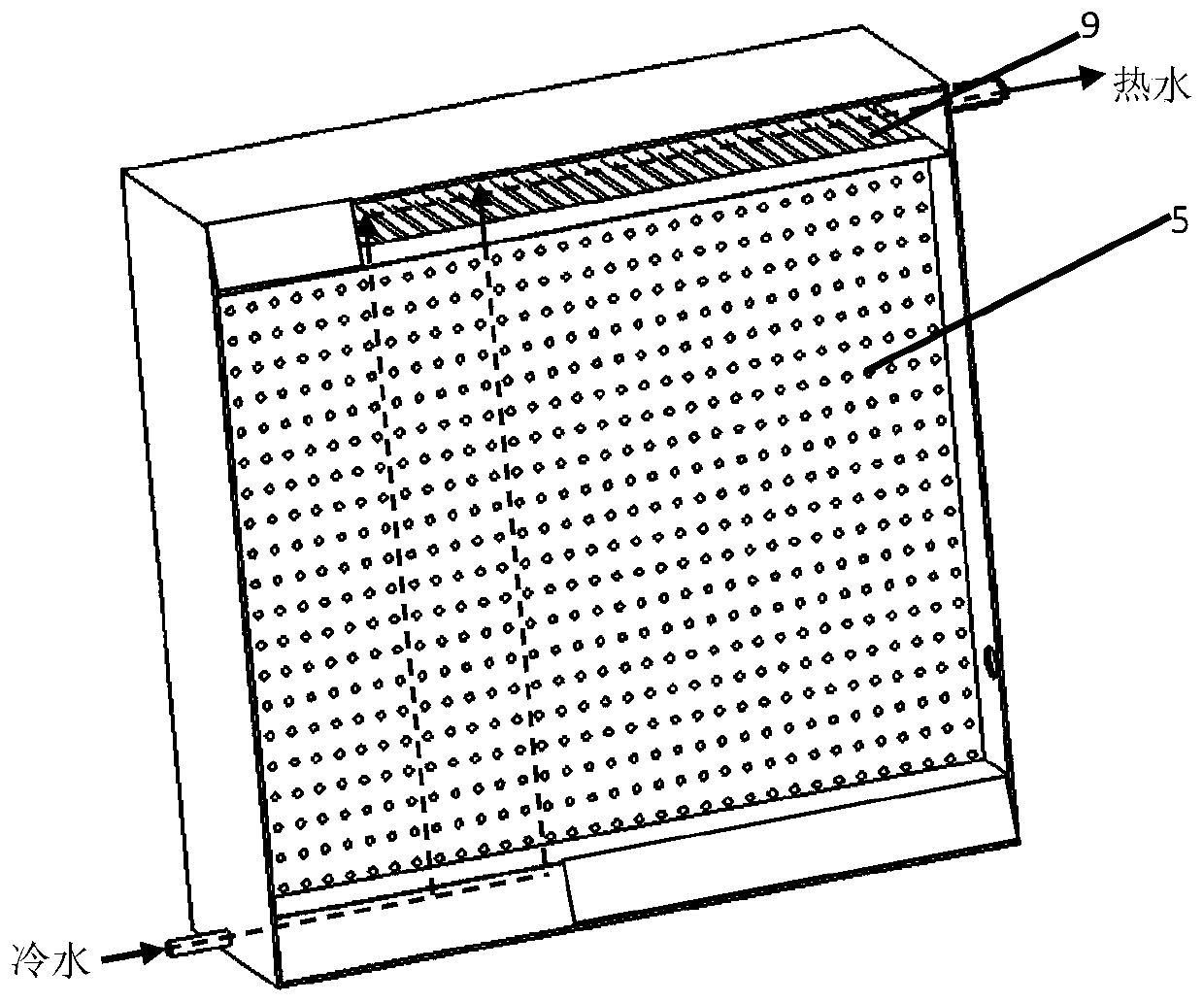

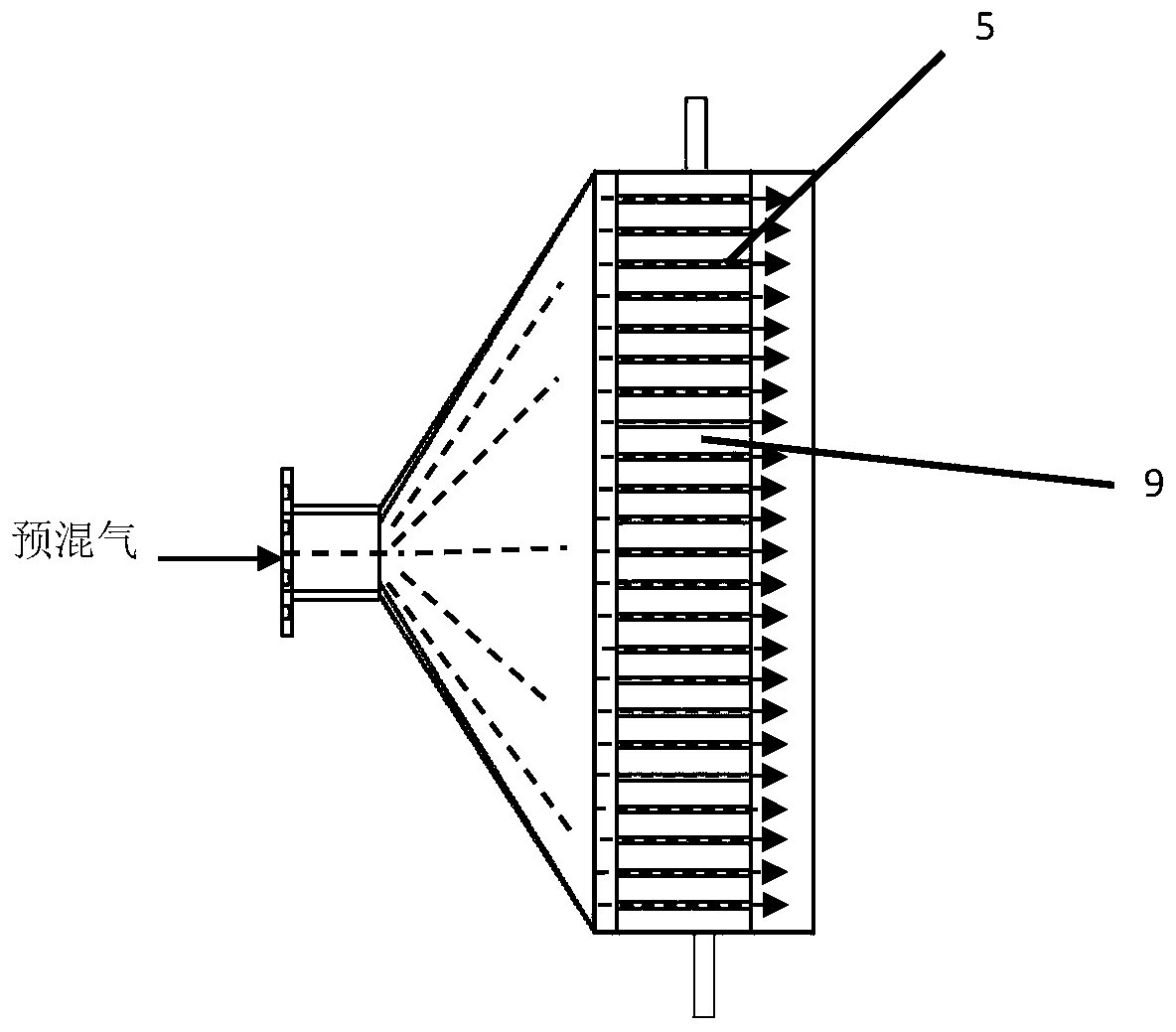

[0046] Such as figure 1 As shown, in a low-nitrogen combustion device of the present invention, the outer side is the outer casing 1. When the device is started, the air and fuel gas are fully premixed before entering the low-nitrogen combustion device, and the premixed gas first passes through the outer casing 1. The inlet of the gas enters into the gas dividing chamber 2. The gas dividing chamber 2 has the function of equalizing flow and pressure. After the premixed gas enters the gas dividing chamber 2, the whole gas dividing chamber 2 is quickly filled, and the flow and pressure equalization is realized in the gas dividing chamber 2. The gas mixing pipe 5 (cylindrical tube) passing through the anti-backfire cavity 9 enters the combustion chamber 3, and is ignited by the ignition needle 4 on the back side of the anti-backfire cavity 9 and burns stably in the combustion chamber 3. The flue gas produced by the combustion flows laterally through the heat exchange tube bank 8, an...

Embodiment 2

[0053] The device structure and related parameters are basically the same as those of Embodiment 1, except that the distance between each mixing tube in the rectangular arrangement is set to be 15 mm in the horizontal direction and 8 mm in the longitudinal direction. The distance between the anti-tempering cavity 9 and the heat exchange tube 8 is 42 mm.

[0054] For the above device, when the flow rate of the premixed gas is changed between 4m / s-10m / s, the emissions of nitrogen oxides, carbon monoxide and other exhaust gases after combustion are investigated. The specific measurement results are shown in Table 2 below.

[0055] Table 2 Test results of combustion product composition at different gas flow rates

[0056]

[0057] It can be seen from Table 1 and Table 2 that the horizontal spacing c of the mixing pipe is reduced from 20mm to 15mm, while ensuring that the flow rate of the premixed gas remains unchanged from 4m / s-10m / s, the longitudinal spacing b is increased from 5mm to 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com