Continuous treatment process for supercritical fluid anhydrous oil removal and whitening of polyester products

A supercritical fluid and treatment technology, applied in the field of dyeing and finishing, can solve the problems of complex composition of three-phase system, color difference between head and tail, whitening, etc., achieve good whitening consistency, reduce the amount of whitening agent, and whitening cycle shortened effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The present embodiment provides a continuous treatment process for supercritical fluid anhydrous degreasing and whitening of polyester products, and the steps are as follows:

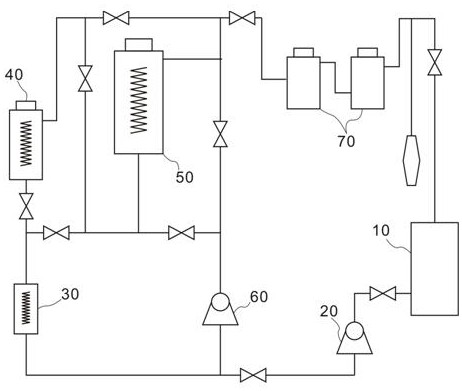

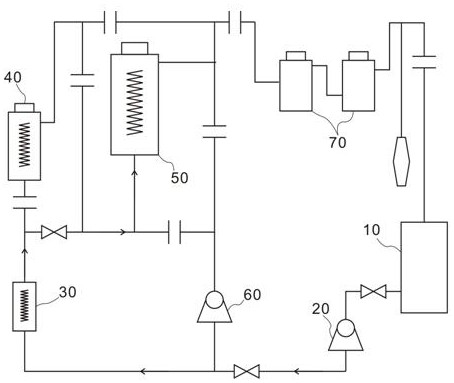

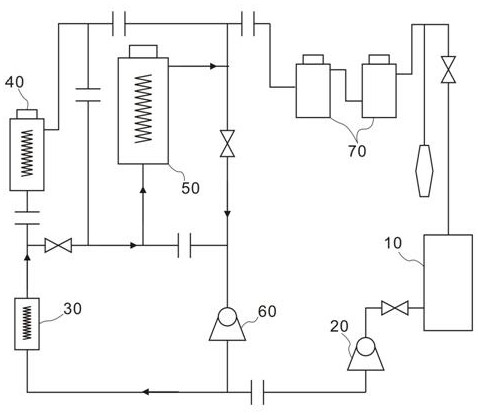

[0032] S1. Build a supercritical processing system, which includes CO 2 Storage tank 10, high pressure pump 20, heater 30, auxiliary kettle 40, pretreatment kettle 50, circulation pump 60 and separation and recovery device, the gas recovery outlet of the separation and recovery device and CO 2 The storage tank 10 is connected, and the high pressure pump 20 is in the CO 2 Between the outlet of the storage tank 10 and the heater 30, the system also includes pipes and control valves on the pipes, such as figure 1 shown. Before treatment, add fluorescent whitening agent OB-1 in the auxiliary tank of auxiliary kettle 40, and the dosage is 0.3% o.w.f., and the polyester yarn is wound in the bobbin and installed in the pre-treatment kettle 50;

[0033] S2, check and adjust to the initial state (such ...

Embodiment 2

[0036] The present embodiment provides a continuous treatment process for supercritical fluid anhydrous degreasing and whitening of polyester products, and the steps are as follows:

[0037] S1. Build a supercritical processing system, which includes CO 2 Storage tank 10, high pressure pump 20, heater 30, auxiliary kettle 40, pretreatment kettle 50, circulation pump 60 and separation and recovery device, the gas recovery outlet of the separation and recovery device and CO 2 The storage tank 10 is connected, and the high pressure pump 20 is in the CO 2 Between the outlet of the storage tank 10 and the heater 30, the system also includes a pipeline and a control valve on the pipeline. Before the treatment, the fluorescent whitening agent KCB was added into the auxiliary tank of the auxiliary kettle 40, and the dosage was 0.1% o.w.f., and the polyester fiber was wound in the bobbin and installed in the pre-treatment kettle 50;

[0038] S2, check and adjust to the initial state,...

Embodiment 3

[0041] The present embodiment provides a continuous treatment process for supercritical fluid anhydrous degreasing and whitening of polyester products, and the steps are as follows:

[0042] S1. Build a supercritical processing system, which includes CO 2 Storage tank 10, high pressure pump 20, heater 30, auxiliary kettle 40, pretreatment kettle 50, circulation pump 60 and separation and recovery device, the gas recovery outlet of the separation and recovery device and CO 2 The storage tank 10 is connected, and the high pressure pump 20 is in the CO 2 Between the outlet of the storage tank 10 and the heater 30, the system also includes a pipeline and a control valve on the pipeline. Before the treatment, the fluorescent whitening agent KCB was added in the auxiliary tank of the auxiliary kettle 40, and the dosage was 0.5% o.w.f., and the polyester fabric was wound in the bobbin and installed in the pre-treatment kettle 50;

[0043] S2, check and adjust to the initial state, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com