Attapulgite-graphite-like carbonitride composite hollow fiber microfiltration membrane with photocatalytic performance and preparation method and application thereof

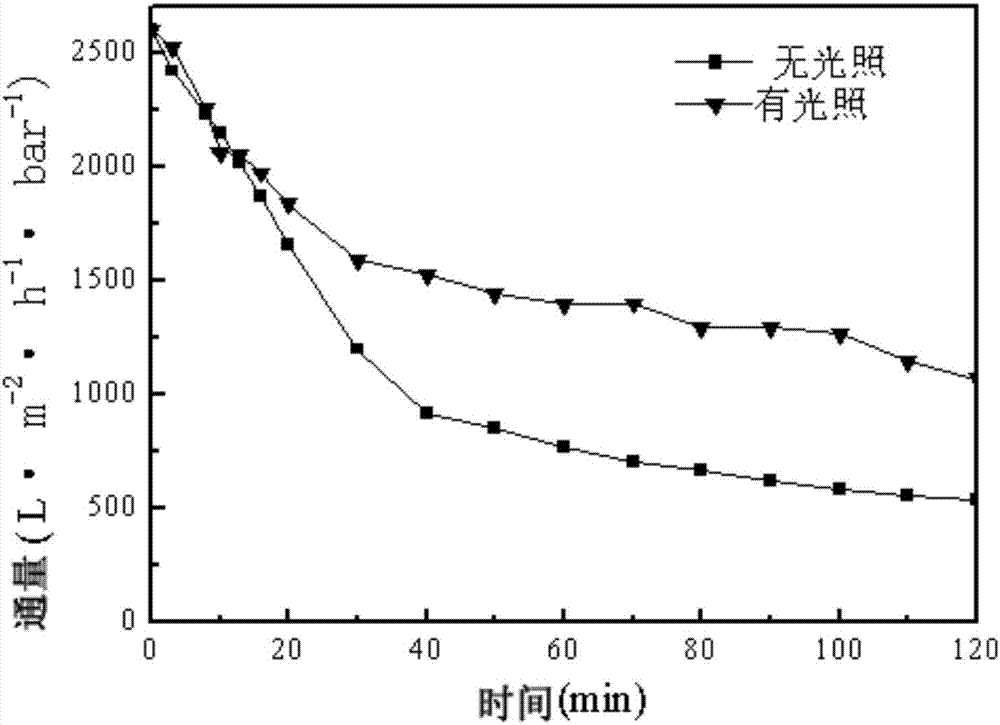

A graphite phase carbon nitride and attapulgite technology, applied in chemical instruments and methods, ultrafiltration, membrane technology, etc., can solve the problems of low recycling rate, difficult separation, and difficult dispersion, etc., to maintain process characteristics and treatment. ability, improve the photocatalytic degradation rate, and ensure the effect of complete removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The preparation method adopts the phase inversion method combined with the roasting technology to prepare the hollow fiber ceramic membrane. The specific steps include: 1) Add attapulgite-graphite-like phase carbon nitride composite material particles and ceramic matrix particles into the solvent, and stir them evenly after ultrasonication. Add polyethersulfone, ball mill evenly, add porogen, stir evenly at room temperature, and vacuum degas to obtain casting solution; 2) Phase inversion process, that is, casting solution passes through spinning device, casting solution and core solution, Formed under the action of flocculant, and soaked in the external flocculant for a certain period of time to complete the phase transformation of solvent / non-solvent. 3) In the process of drying and sintering, the film with complete phase inversion is taken out from the external coagulation bath and dried naturally; the dried film is fired at a certain temperature to make it have corres...

Embodiment 1

[0059] Example 1 Preparation of attapulgite-graphite-like phase carbon nitride composite material

[0060] Weigh 3.02g of silane coupling agent-modified attapulgite and disperse it in 1000mL of deionized water, ultrasonically disperse; then add 6.01g of melamine, stir, condense and reflux at 80°C for 2h; then freeze-dry for 48h, grind and add to the quartz boat , the quartz boat was placed in the tube furnace, and the temperature was programmed in the tube furnace under the air atmosphere. The temperature rise program was as follows: room temperature was raised to 500 °C for 0.5 h, kept at 500 °C for 2 h, then continued to be heated to 520 °C for 2 min, and kept After 2 hours, the temperature was naturally lowered, and it was fully ground to a powder form to obtain an attapulgite-graphite-like phase carbon nitride composite material (for the preparation method, refer to patent document CN106179447A).

Embodiment 2

[0062] Preparation of attapulgite-graphite-like phase carbon nitride composite hollow fiber microfiltration membrane: Add 170 g of 1-methyl-2-pyrrolidone and 22 g of nano-alumina particles, attapulgite-graphite-like phase to a 500ml reagent bottle in sequence 28g of carbon nitride composite material, stirred evenly after 10 minutes of ultrasonication, added 25g of polyethersulfone, ball milled for 72 hours, then added 5 g of polymethylpyrrolidone K23-27, continued stirring for 6 hours, and vacuum degassed for 4 hours to obtain a stable casting Membrane fluid.

[0063]Add the casting solution and the core solution deionized water into the stainless steel syringe of the high-pressure syringe pump, turn on the injection pump, let the core solution deionized water and the casting solution pass through the spinning head, and the casting solution is at the exit of the spinning head The spinning process parameters are: the air gap is 15 cm respectively, and the core liquid flow rate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com