Particle sieving device for production of complex fertilizer anti-caking agents

An anti-caking agent and screening device technology, applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of affecting the screening effect, leaving a lot, inconvenient cleaning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

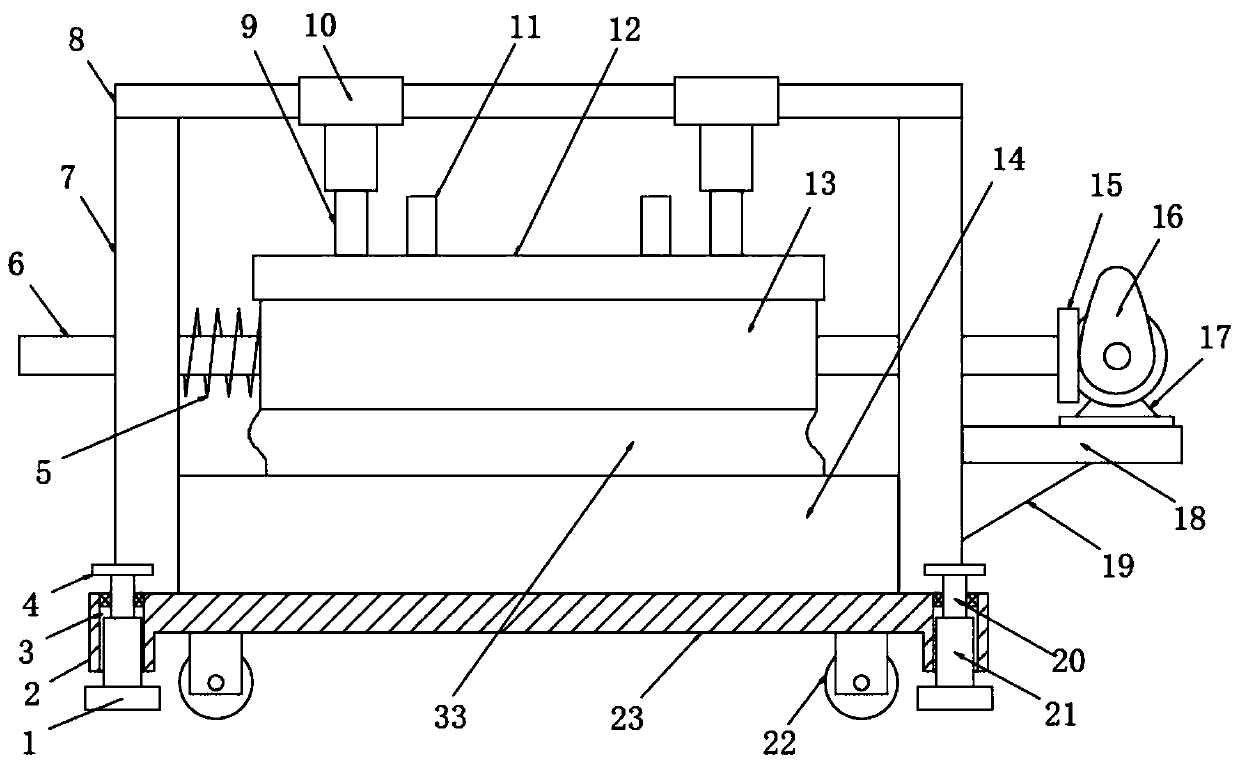

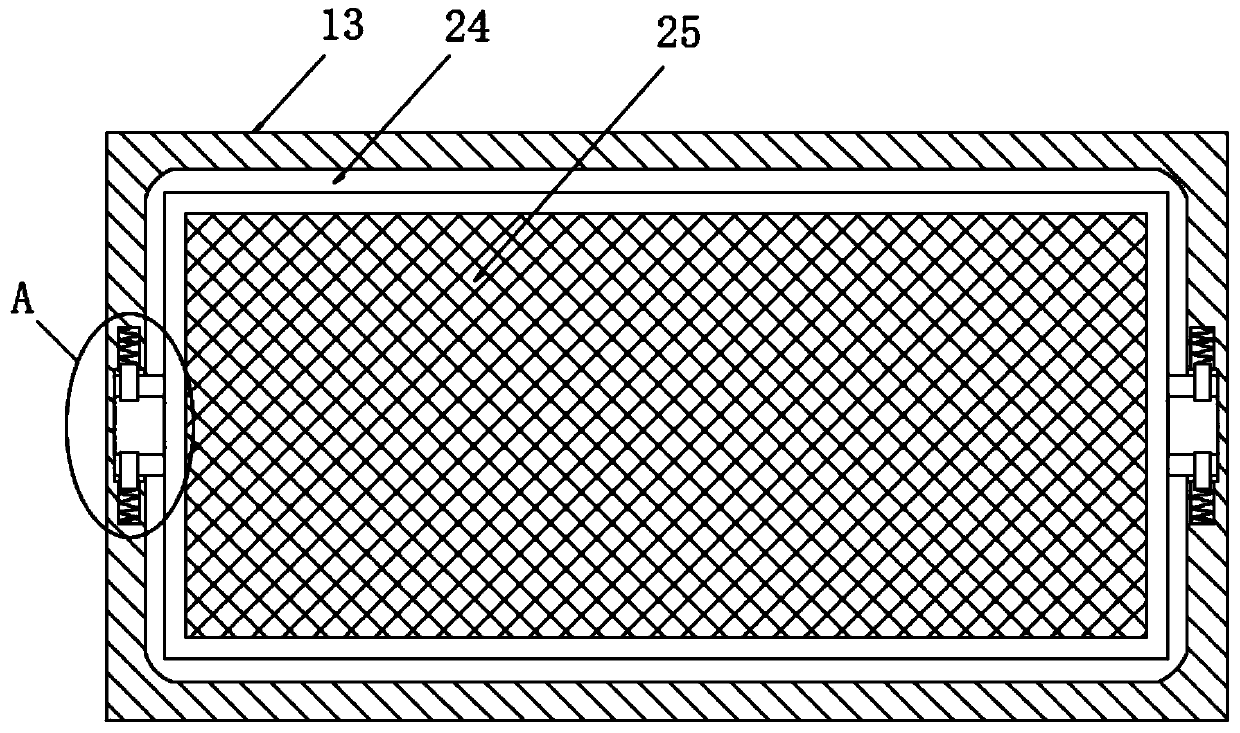

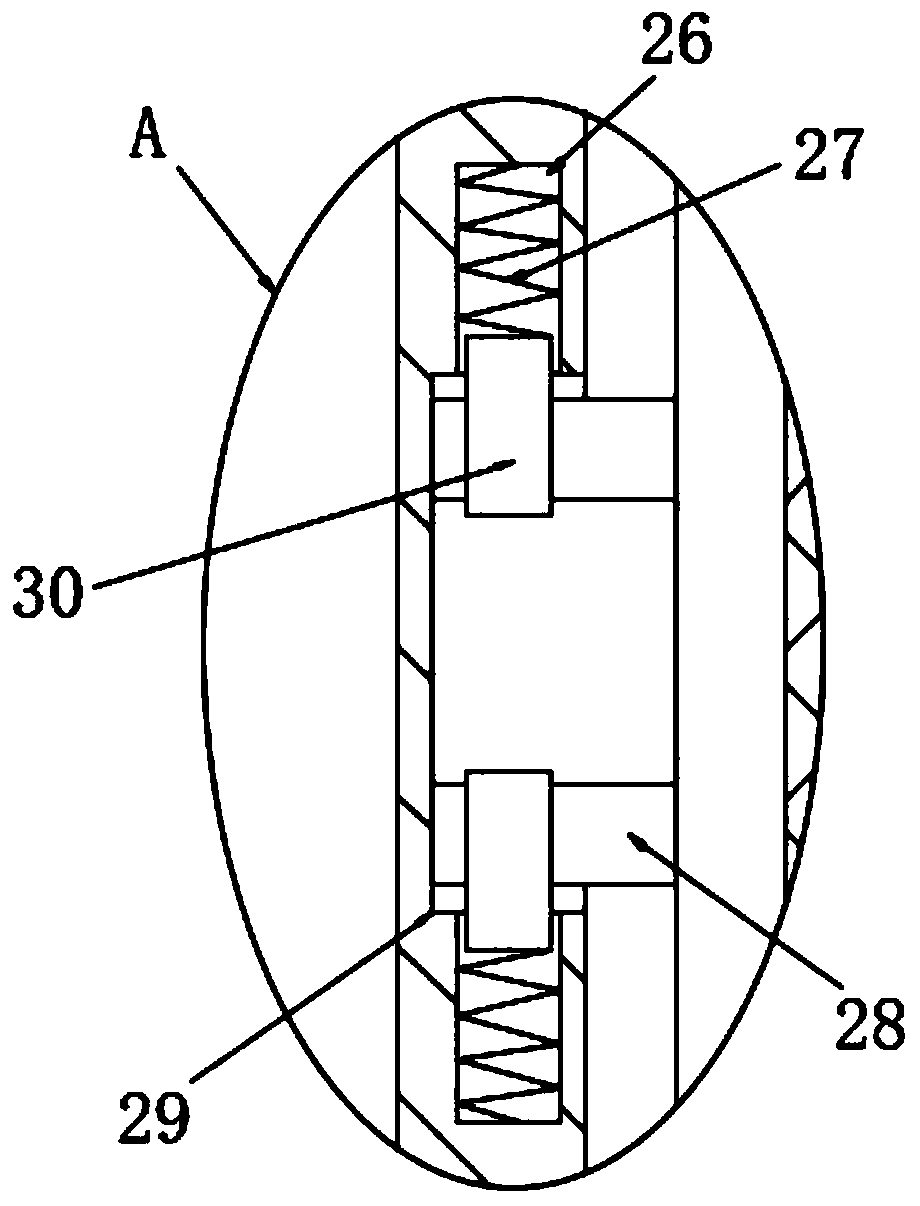

[0023] see Figure 1-4 , a particle screening device for compound fertilizer anti-caking agent production, including a mounting base 2, the upper surface of the mounting base 2 is respectively fixed with a holding box 14 and two vertical plates 7, and the vertical plates 7 are located on both sides of the holding box 14 , and one side of any vertical plate 7 is fixedly installed with a fixed plate 18, and the upper surface of the fixed plate 18 is fixedly equipped with a drive motor 17, and a cam 16 is sleeved on the outside of the output shaft of the drive motor 17, and the inside of each vertical plate 7 The movable rods 6 are symmetrically arranged, and one end of the two movable rods 6 on the right side is fixedly connected with a limit plate 15 corresponding to the cam 16, and one end of the four movable rods 6 is fixedly connected with a screening box 13, and the screening box Between 13 and the riser 7, the first return spring 5 is fixedly fixed symmetrically, and the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com