A method of making a conductive filter bag

A manufacturing method and filter bag technology, applied in separation methods, chemical instruments and methods, and dispersed particle filtration, etc., can solve problems such as failure, poor conductivity, and unsatisfactory conductivity, and achieve the effect of preventing breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

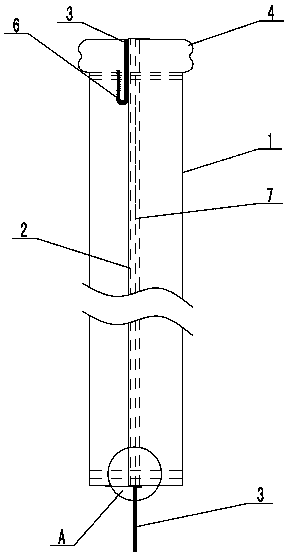

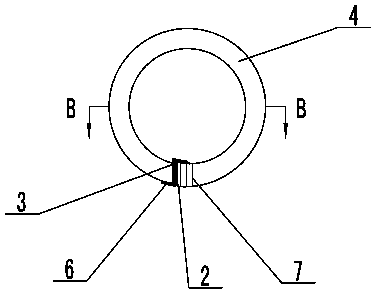

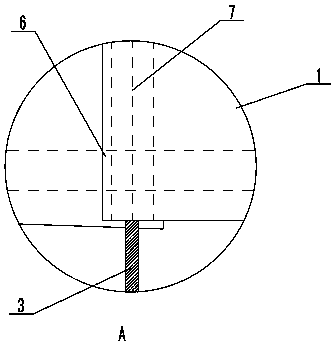

[0033] Refer to attached Figure 1~4 : A conductive filter bag, comprising a bag body 1 and a bag bottom sewn on the bottom of the bag body 1, a double-layer lap 2 for sewing is distributed on the bag body 1, and a conductive filter is arranged inside the double-layer lap 2. The belt 3 and the conductive belt 3 are fixed by the suture 7 sewn on the double-layer lap; the upper opening of the bag body 1 is provided with an annular skeleton, the annular skeleton includes an elastic ring, and the upper edge of the bag body 1 is folded inward and fixed to form a flanging 4. The elastic ring is set in the flange 4 . The top of the conductive strip 3 is exposed from the top of the double-layer lap 2, and is wound from the inside of the bag body 1 to the outside of the bag body 1, and then fixed on the bag body 1 below the annular frame; exposed and placed outside the bag body 1 . The conductive strip 3 is sewn and fixed on the bag body 1 below the elastic ring. There are three sut...

Embodiment 2

[0040] The structure of the conductive filter bag of this embodiment is the same as that of Embodiment 1, except that the bottom end of the conductive strip 3 is 150 mm long from the bottom of the double-layer lap, and the top of the conductive strip 3 is 200 mm long from the top of the double-layer lap 2. The width of the conductive strip 3 is 3mm, and the conductive strip 3 is made of bare copper flat wire. The double-layer lap 2 is formed by lapping the side walls of the upper and lower layers of the bag body 1, and the width of the double-layer lap 2 is 15mm.

[0041] The bottom of the bag 8 is circular, and the circumference of the circle of the bottom of the bag 8 is sewn and fixed with the edge of the bottom of the bag body 1, or two parallel sutures can be used to sew and fix the bottom of the bag body 1 to form the bottom of the bag 8.

[0042] The manufacturing method of this embodiment includes the following steps:

[0043] a) Conductive belt 3 and bag body 1 blank...

Embodiment 3

[0048] The structure of the conductive filter bag of this embodiment is the same as that of Embodiment 1, except that the bottom end of the conductive strip 3 exposes a length of 100 mm from the bottom end of the double-layer lap, and the top of the conductive strip 3 exposes a length of 150 mm from the top of the double-layer lap 2. The width of the conductive strip 3 is 4mm, and the conductive strip 3 is made of bare copper flat wire. The double-layer lap 2 is formed by overlapping the side walls of the upper and lower layers of the bag body 1, and the width of the double-layer lap 2 is 18 mm.

[0049] The bottom 8 of the bag is circular, and the circumference of the circle of the bottom 8 is sewn and fixed to the bottom edge of the bag body 1 . Alternatively, two parallel sutures 7 can be used to sew and fix the bottom end of the bag body 1 to form the bottom 8 of the bag.

[0050] The manufacturing method of this embodiment includes the following steps:

[0051] a) Conduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com