Modular cleaning and drying integrated equipment based on nut processing

A modular, nut-based technology, which is applied in applications, food processing, food science, etc., can solve the problems of affecting the performance of nuts, the deterioration of the taste of nuts, and the tendency of anti-moisture, etc., so as to facilitate subsequent storage, clean thoroughly, and reduce labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

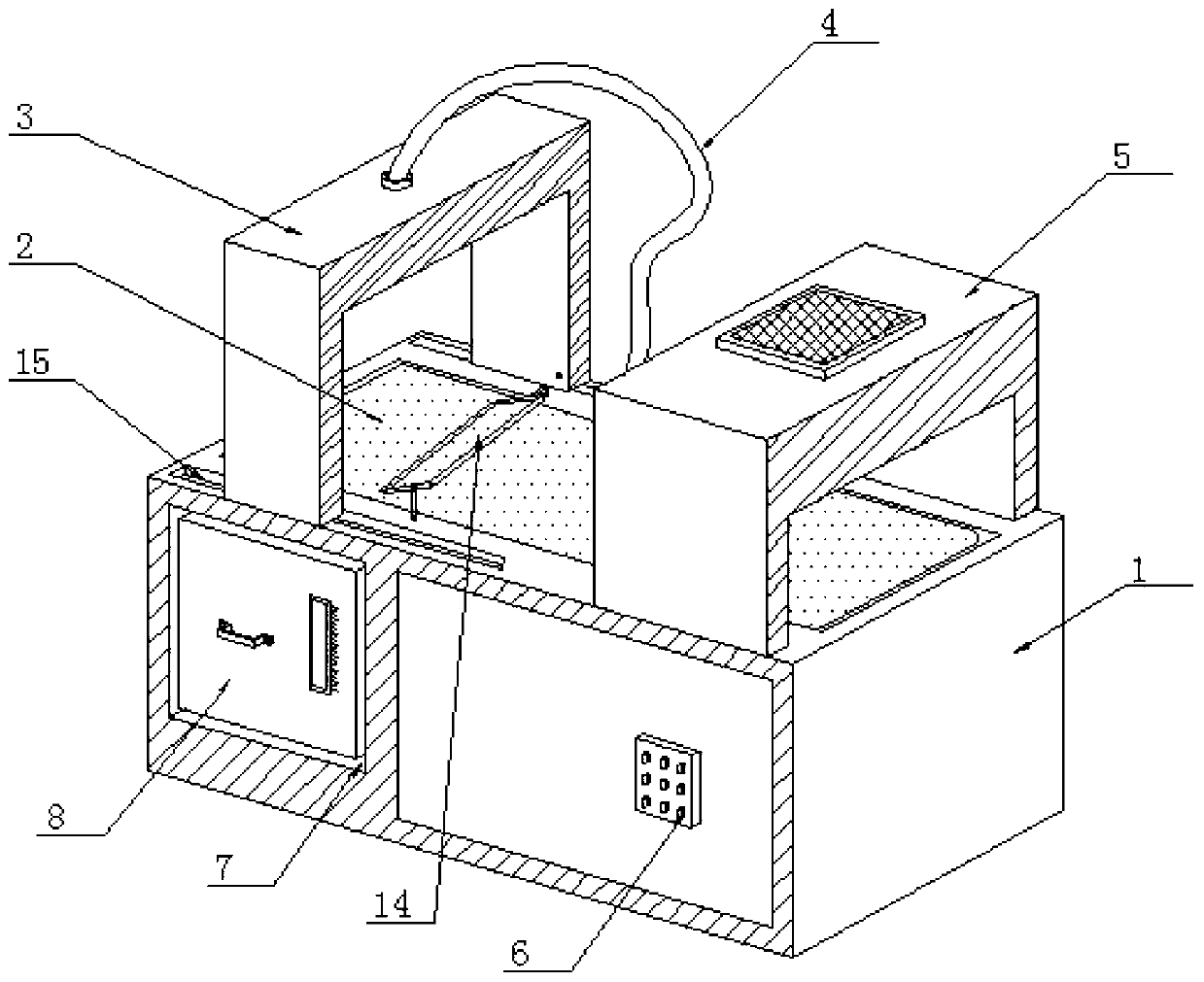

[0033] see Figure 1~6 , in an embodiment of the present invention, a modular cleaning and drying integrated equipment based on nuts processing includes a processing table 1, a cleaning assembly, a drying assembly and a controller 6, wherein the processing table 1 is a cavity structure , and the upper end of the inner cavity of the processing table 1 is provided with a conveyor belt 2, the feeding end of the conveyor belt 2 is provided with the cleaning assembly, and the discharge end of the conveyor belt 2 is provided with the drying assembly; its characteristics is that

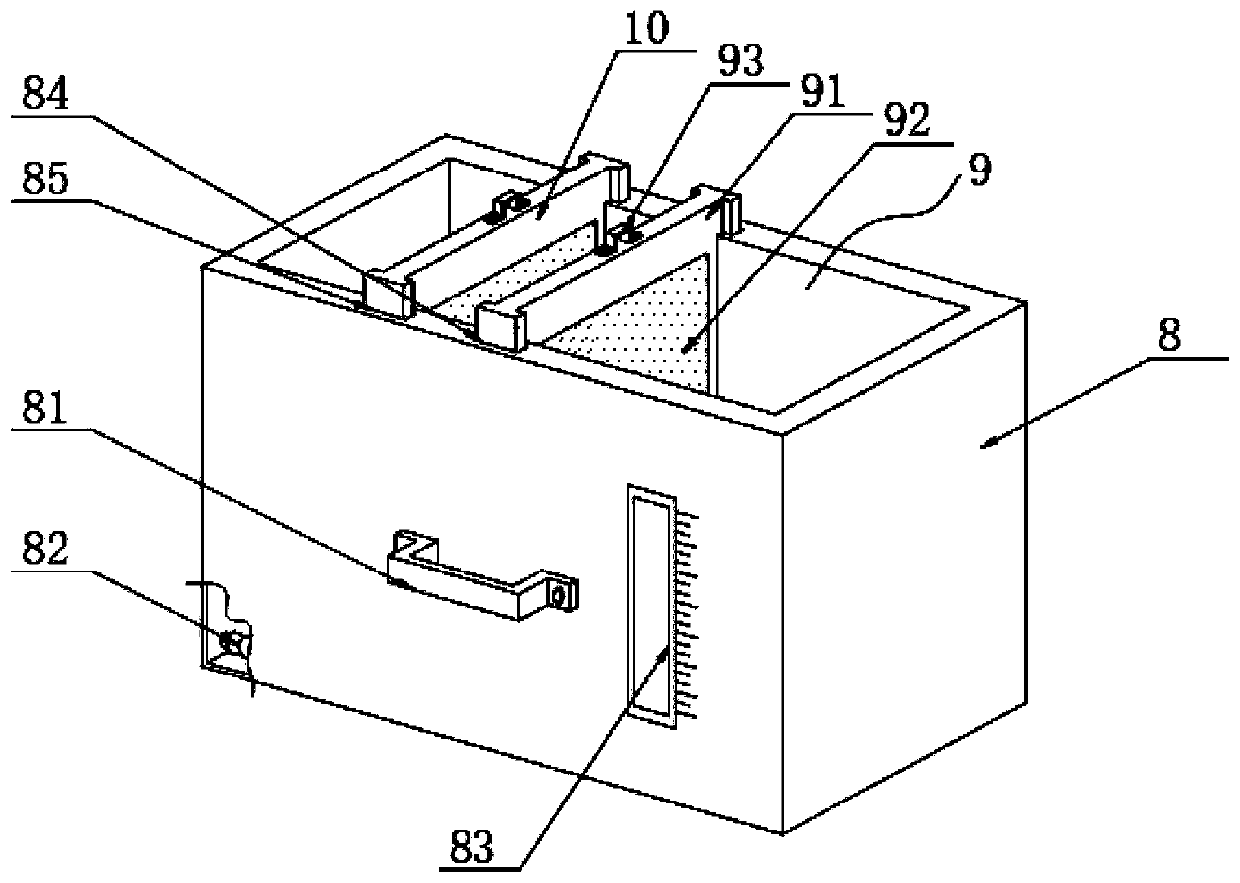

[0034] The cleaning assembly includes an upper cleaning assembly 3 and a lower cleaning assembly 16, the upper cleaning assembly is located above the conveyor belt 2, and the lower cleaning assembly is located below the conveyor belt 2;

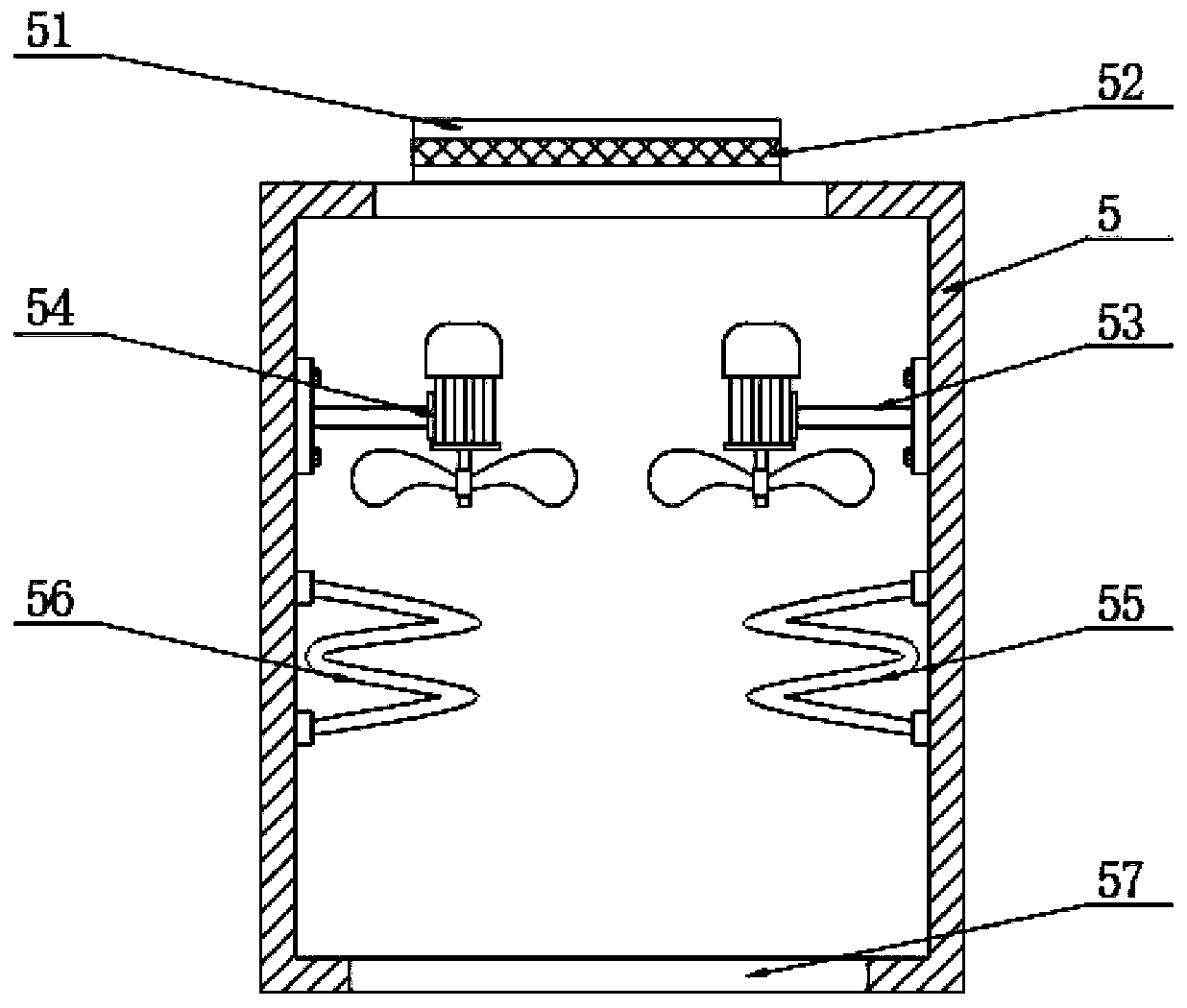

[0035] The drying assembly includes an upper drying assembly 5 and a lower drying assembly 17, the upper drying assembly is located above the conveyor belt 2, and the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com