Delafossite structured CuMnO2 powder and preparation method and application thereof

A delafossite and powder technology, which is applied in the field of copper-copper iron ore structure CuMnO2 powder and its preparation, can solve the problems of unfavorable large-scale industrial production, complicated process and high cost, and achieves the advantages of being suitable for large-scale preparation, good repeatability and reaction consumption. short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) 0.01 mol of Cu (NO 3 ) 2 ·3H 2 O and 0.01 mol of Mn (NO 3 ) 2 4H 2 O was dissolved in deionized water (40 mL) to make it a saturated solution, then 0.02 mol of citric acid and 0.5 g of PEG20000 were added, and the whole mixture was fully stirred to dissolve to obtain Cu-containing 2+ and containing Mn 2+ aqueous solution; then slowly add NH 3 ·H 2 O, adjust the pH value of the solution in the range of 2-3, and obtain the reaction precursor after fully stirring.

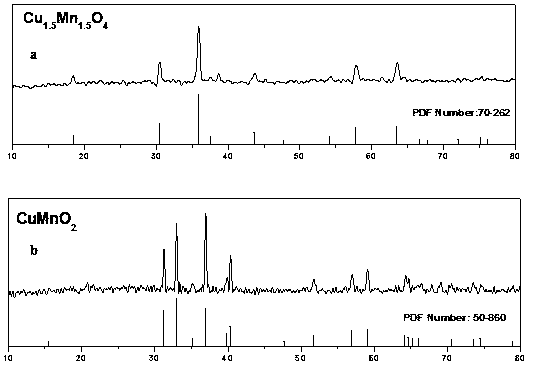

[0033] (2) Put the precursor solution in a drying oven and dry it at 110 °C for 24 h. The obtained powder was ground with an agate mortar, and then the sample was placed in a muffle furnace, and the temperature was raised at a rate of 5 °C / min. After being kept at 900 °C for 5 h, it was cooled in the furnace, and finally the sample was placed in N 2 In the atmosphere furnace of the atmosphere, the temperature was raised to 1100 °C at a rate of 5 °C / min for 2 h, and then cooled with the furnace to o...

Embodiment 2

[0035] This embodiment provides a delafossite structure CuMnO 2 The preparation method of the powder, except that the consumption of citric acid is 0.04mol, all the other steps and conditions are consistent with Example 1.

[0036] This example can successfully prepare CuMnO with delafossite structure 2 powder.

Embodiment 3

[0038]This embodiment provides a delafossite structure CuMnO 2 The preparation method of the powder is consistent with that of Example 1 except that 1 g of PEG2000 is selected.

[0039] This example can successfully prepare CuMnO with delafossite structure 2 powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com