LED epitaxial layer growth method and LED chip acquired in method

A technology of LED chip and growth method, applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of LED device failure, leakage, reduction of hole concentration, etc., and achieve the effect of improving antistatic ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

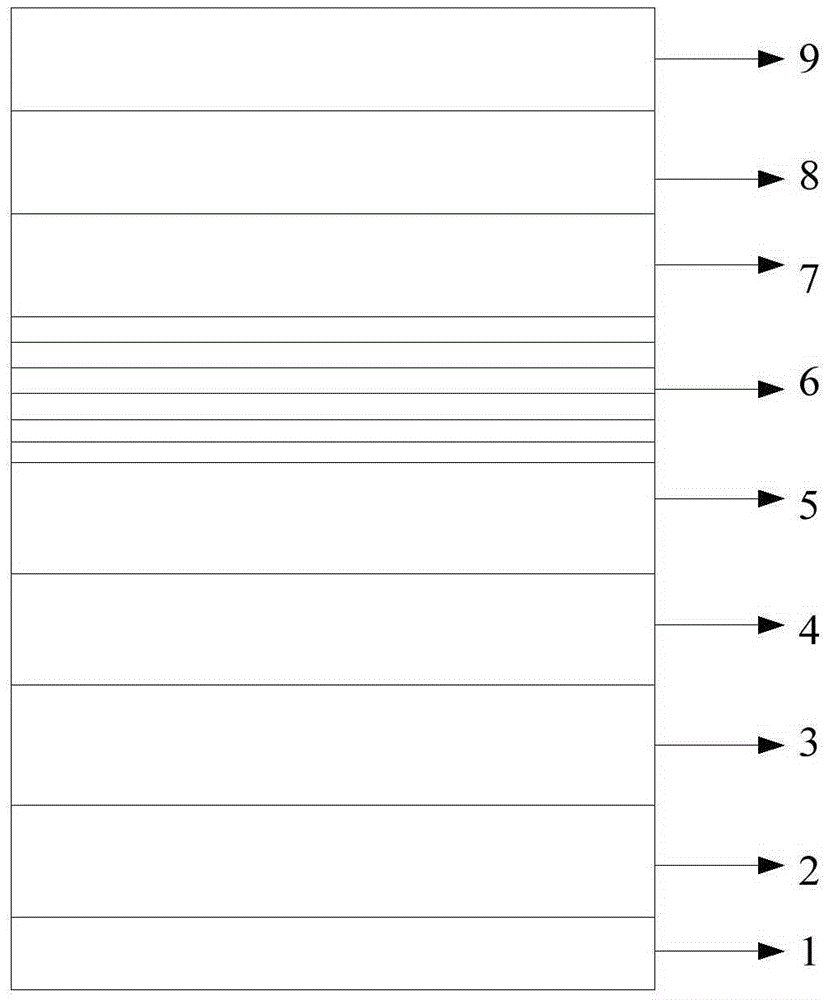

[0048] The present invention uses MOCVD to grow GaN epitaxial layer, adopts high-purity H 2 or high purity N 2 or H 2 and N 2 Mixed gas as carrier gas, high purity NH 3 As the N source, the metal-organic source trimethylgallium (TMGa) is used as the gallium source, trimethylindium (TMIn) is used as the indium source, and the P-type dopant is magnesiumocene (Cp 2 Mg), the substrate is a patterned substrate or a sapphire substrate, and the reaction pressure is between 100mbar and 850mbar. The specific growth method is as follows (for the epitaxial structure, please refer to figure 1 ):

[0049] 1. Treat the substrate: raise the temperature to 1230°C-1280°C, and treat the substrate for 4min-8min;

[0050] 2. Growth of low-temperature buffer layer GaN: reduce the temperature to 520°C-590°C, 2 growing a buffer layer with a thickness of 20nm-35nm on the above substrate under atmosphere;

[0051] 3. Growth of undoped GaN layer: raise the temperature of the reaction chamber to...

Embodiment 2

[0092] The present invention also provides an LED chip obtained by the method for growing the LED epitaxial layer, the substrate of the LED chip sequentially includes:

[0093] Buffer layer: the thickness is 20nm-35nm;

[0094] Undoped GaN layer: the thickness is 2μm-3.5μm;

[0095] N-type GaN layer doped with Si: the thickness is 2μm-3.5μm, and the doping concentration of Si is 8×10 18 atoms / cm 3 ~1.5×10 19 atoms / cm 3 ;

[0096] MQW active layer: including 11-18 overlapping units, each overlapping unit sequentially includes an InGaN well layer with a thickness of 2nm-3.5nm and a GaN barrier layer with a thickness of 8nm-13nm;

[0097] Electron blocking layer: including 4-8 overlapping units, each overlapping unit sequentially includes a P-type AlGaN barrier layer with a thickness of 2.8nm-5nm and an InGaN potential well layer with a thickness of 2.5nm-4nm;

[0098] Mg-doped P-type GaN layer: including a first P-type GaN layer with a thickness of 40nm-80nm, a second P-ty...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com