P-type delafossite structure semiconductor material-based plane structure perovskite solar cell and preparation thereof

A solar cell and planar structure technology, applied in the field of solar cells, can solve problems such as efficiency record growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

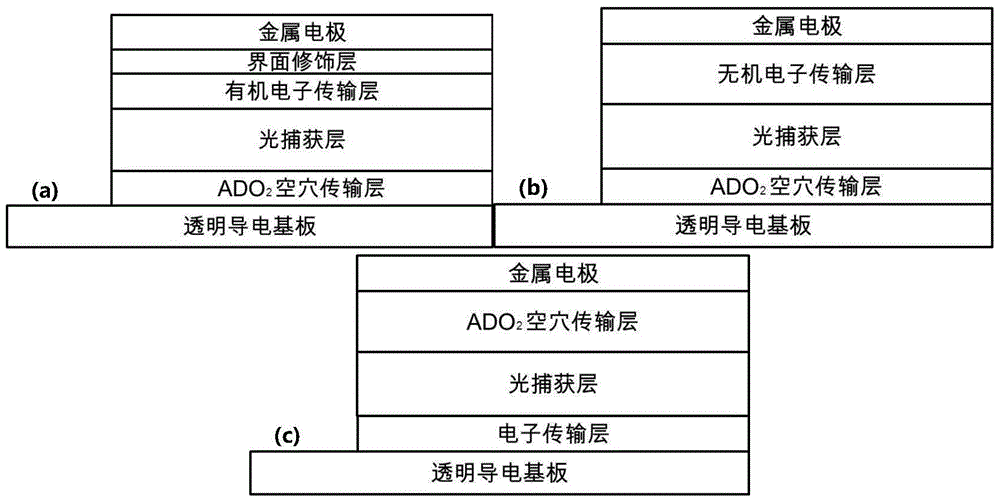

[0051] In one embodiment of the present invention, a kind of preparation method of planar structure perovskite solar cell is provided, such as figure 1 As shown in (a), the solar cell includes a transparent conductive glass substrate or a flexible transparent conductive film substrate, the above-mentioned hole transport layer, the above-mentioned light harvesting layer, an organic electron transport layer, and an interface modification layer from bottom to top And metal electrode, its specific steps are as follows:

[0052] 1) Ultrasonic cleaning of FTO transparent conductive glass or ITO transparent conductive glass or PET flexible transparent conductive film or PI flexible transparent conductive film with deionized water, ethanol and acetone in sequence, and then treated with ultraviolet ozone to obtain a clean substrate;

[0053] 2) in step 1) spin coating or spraying or scraping described ADO on the clean substrate surface 2 The precursor solution of type semiconductor ma...

Embodiment 1a

[0077] Such as figure 1 Shown in (a), the first kind of planar structure perovskite solar cell involved in the present invention consists of substrate (FTO conductive glass or ITO conductive glass or PET flexible transparent conductive film or PI flexible transparent conductive film), CuGaO 2 It is composed of a hole transport layer, a light harvesting layer, an organic electron transport layer, an interface modification layer and a metal electrode. The specific preparation steps are as follows:

[0078] Step 1) Substrate preparation: ultrasonically clean FTO conductive glass or ITO conductive glass or PET flexible transparent conductive film or PI flexible transparent conductive film with deionized water, ethanol and acetone in sequence, and then treat with ultraviolet and ozone for 15 to 30 minutes to obtain Substrate, spare.

[0079] Step 2) CuGaO 2 Hole-transporting thin films (i.e. CuGaO 2 Hole transport layer) preparation: with CuGaO 2 Nanosheets and ethanol or glyco...

Embodiment 1b

[0085] Such as figure 1 Shown in (b), the second planar structure perovskite solar cell involved in the present invention consists of substrate (FTO conductive glass or ITO conductive glass or PET flexible transparent conductive film or PI flexible transparent conductive film), CuGaO 2 It consists of a hole transport layer, a light harvesting layer, an inorganic electron transport layer and a metal electrode, and the specific preparation steps are as follows:

[0086] Step 1) Substrate preparation: ultrasonically clean FTO conductive glass or ITO conductive glass or PET flexible transparent conductive film or PI flexible transparent conductive film with deionized water, ethanol and acetone in sequence, and then treat with ultraviolet and ozone for 15 to 30 minutes to obtain Substrate, spare.

[0087] Step 2) CuGaO 2 Hole-transporting thin films (i.e. CuGaO 2 Hole transport layer) preparation: with CuGaO 2 Nanosheets and ethanol or glycol ether are used as sources, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com