Delafossite structure material and preparation method thereof, and perovskite solar cell

A technology of solar cells and structural materials, applied in chemical instruments and methods, circuits, photovoltaic power generation, etc., to achieve the effect of compound reduction, excellent conductivity and thermal stability, and device efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] 2. Some embodiments of the present invention provide a method for preparing the above-mentioned delafossite structural material, comprising the steps of:

[0043] (1) Dissolving copper nitrate, gallium nitrate, magnesium nitrate and surfactant in deionized water respectively to form a mixed first solution. Alternatively, the surfactant, copper nitrate and magnesium nitrate are sequentially added to the gallium nitrate solution to form a first mixed solution.

[0044] In the above first solution, the concentrations of copper nitrate, gallium nitrate, magnesium nitrate and surfactant are all in the range of 0.01mol / L-0.1mol / L. When the concentration of each substance in the first solution is lower than 0.01 mol / L, the subsequent reaction will be insufficient. When the concentration of any substance in the first solution is higher than 0.1 mol / L, the size of the subsequent reaction product is large and inhomogeneous.

[0045] The aforementioned nitrates may be anhydrous or...

Embodiment 1

[0085] Preparation of Mg@CuGaO 2 Material.

[0086] Weigh 150mg of Cu(NO 3 ) 2 ·3H 2 O, 200mg of Ga(NO 3 ) 3 ·H 2 O, 20mg of Mg(NO 3 ) 2 , 60 mg of sodium dodecylsulfonate and 68 mg of NaOH were respectively dissolved in 3 mL of deionized water to form a clear first solution with a pH value of 3.5.

[0087] The above solution was mixed and stirred for 2 hours until a uniform solution was obtained, 3 mL of polyethylene glycol was added to the uniform solution, and the stirring was continued until uniformly mixed to form a second solution.

[0088] The obtained solution was poured into a hydrothermal reaction kettle, and then the reaction kettle was placed in an oven at 230° C. for 10 h.

[0089] The reaction product was taken out, washed with deionized water, diluted ammonia water with a concentration of 0.05 mol / L, and absolute ethanol in sequence, and then dried to obtain a powder product.

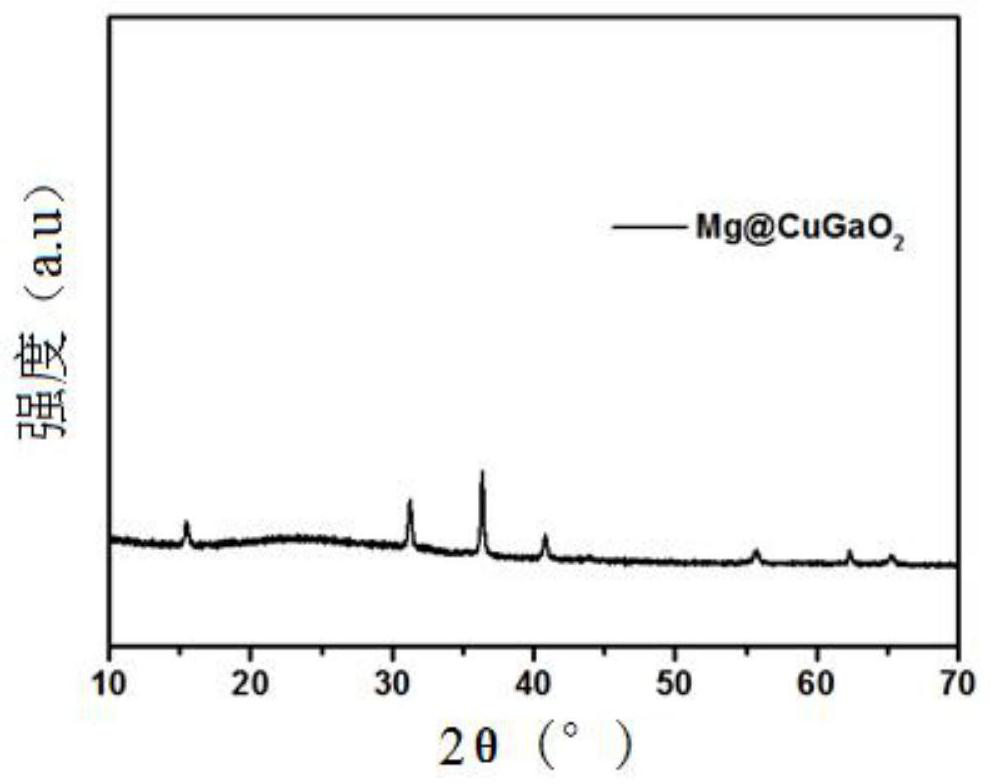

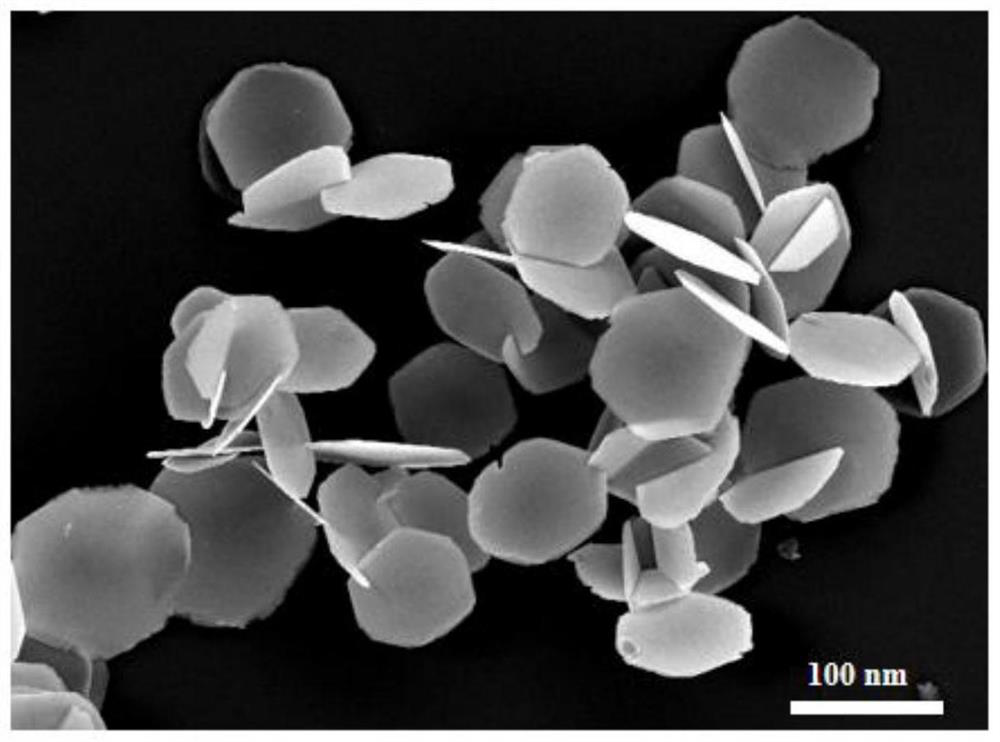

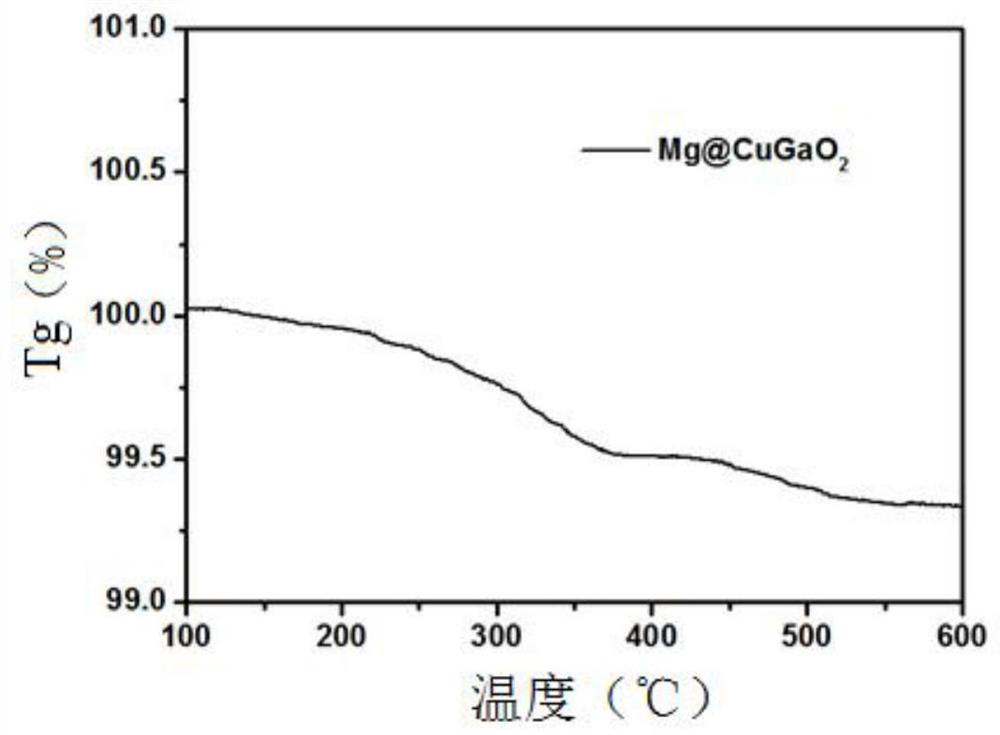

[0090] The obtained powder product was confirmed to be Mg@CuGaO by X-ray di...

Embodiment 2

[0092] Preparation of Mg@CuGaO 2 nanomaterials.

[0093] Weigh 200mg of Cu(NO 3 ) 2 ·3H 2 O, 250mg of Ga (NO 3 ) 3 ·H 2 O, 10mg of Mg(NO 3 ) 2 , 40 mg of sodium dodecylsulfonate (SDS) and 50 mg of NaOH were respectively dissolved in 5 mL of deionized water to form a clear first solution with a pH value of 3.

[0094] The above solution was mixed and stirred for 4 hours until a uniform solution was obtained, 2 mL of ethylene glycol was added to the uniform solution, and the stirring was continued until uniformly mixed to form a second solution.

[0095] The obtained solution was poured into a hydrothermal reaction kettle, and then the hydrothermal reaction kettle was placed in an oven at 200° C., and reacted for 50 hours to obtain a solid-liquid two-phase reaction product.

[0096] Take out the solid phase reaction product, wash the solid phase reaction product with deionized water, diluted ammonia water with a concentration of 0.01mol / L, and absolute ethanol in sequen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com