Preparation method of AgAlO2/TiO2 photocatalytic material

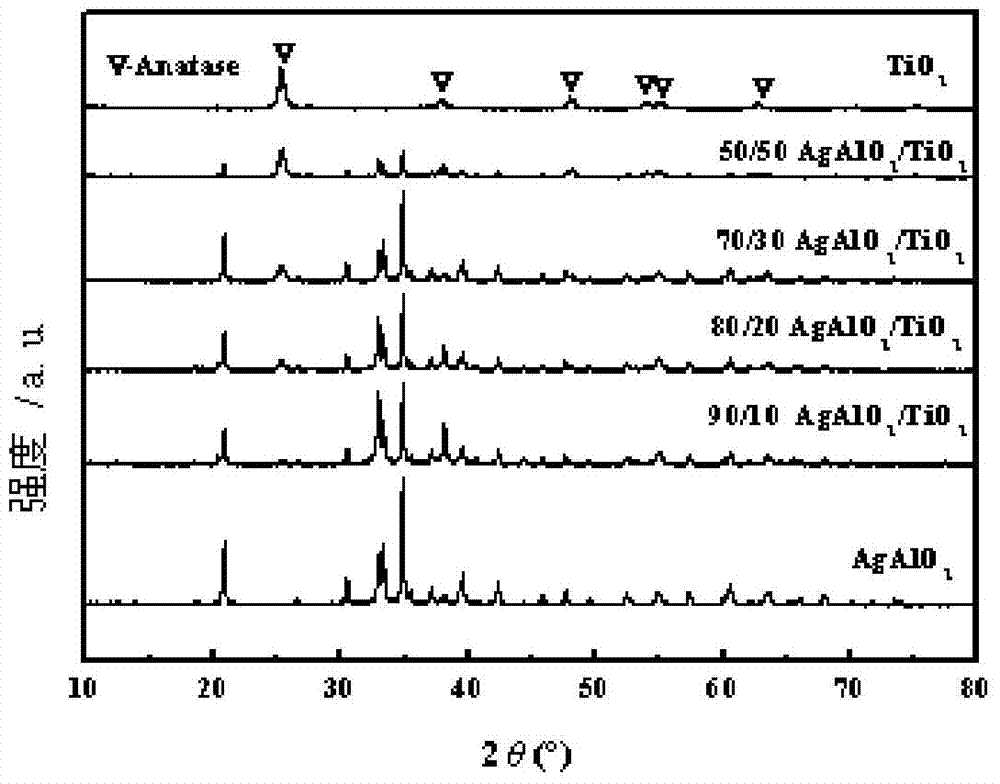

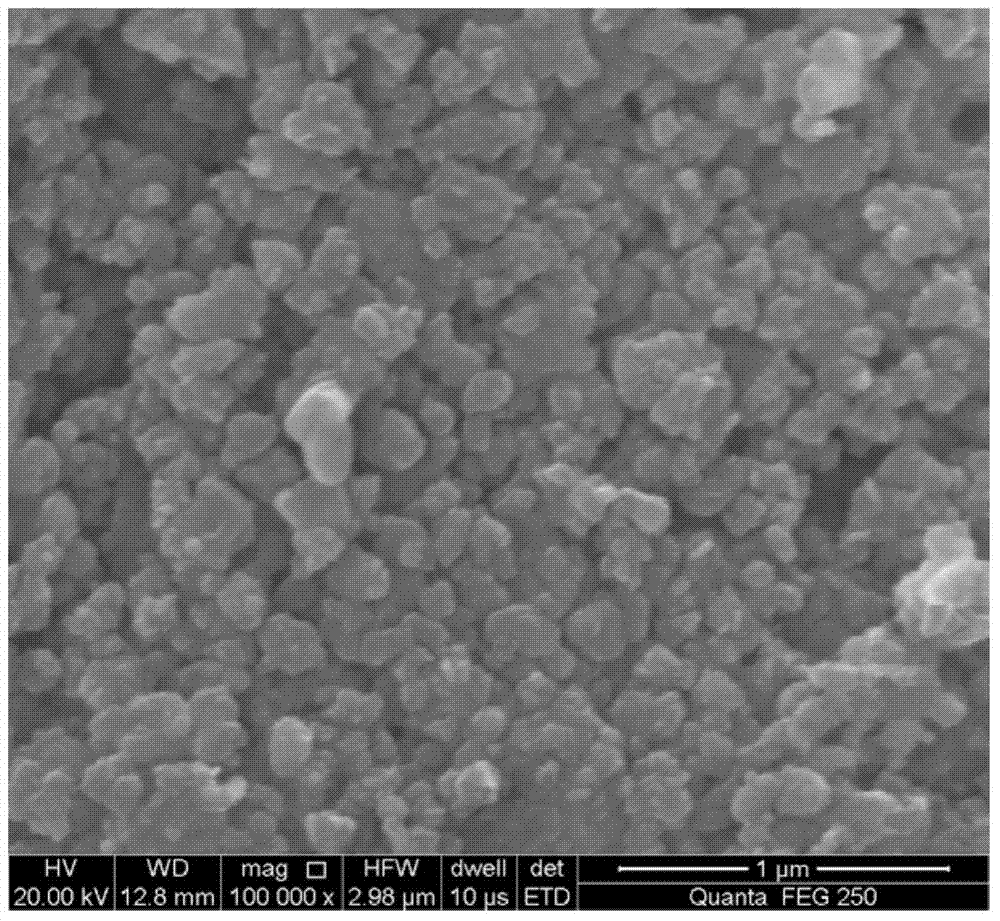

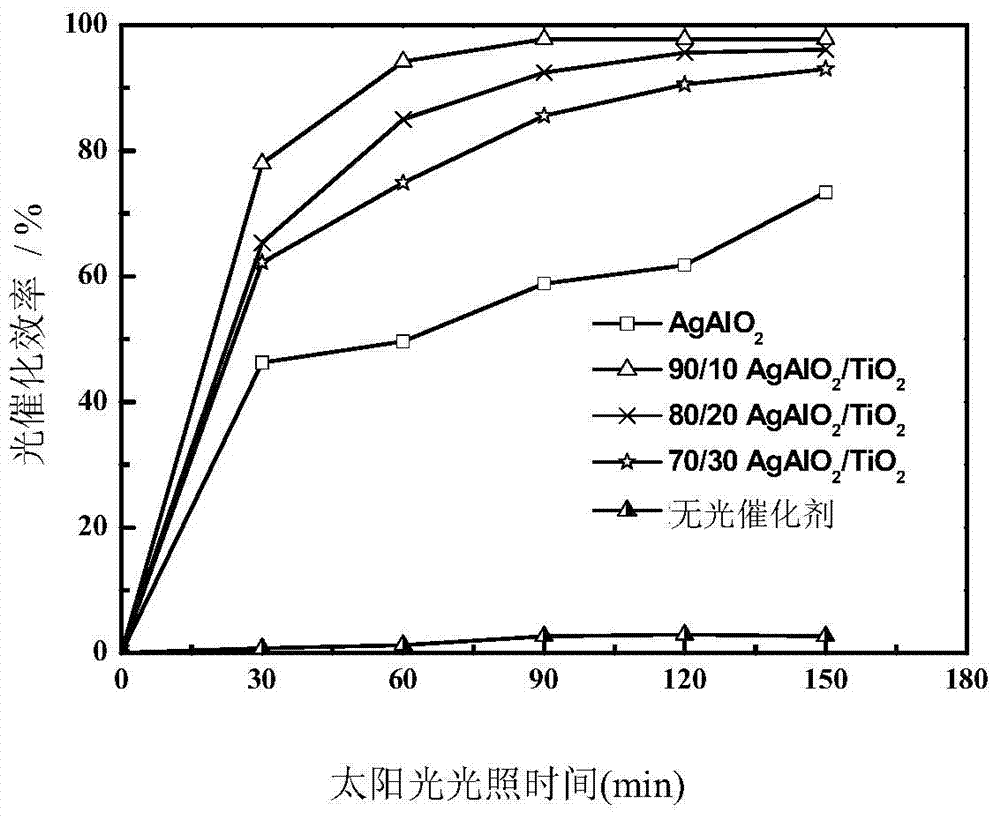

A photocatalytic material and gel method technology, which is applied in the field of preparation of AgAlO2/TiO2 heterogeneous photocatalytic materials, can solve the problems of poor ability to degrade organic pollutants, insufficient sunlight absorption, and reduced photoelectric conversion efficiency, etc. Achieving the effect of uniform particle size, good reproducibility and good visible light catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Preparation of TiO by sol-gel method 2

[0029] Butyl titanate is used as the source material, and absolute ethanol is used as the solvent. Mix 34g of tetrabutyl titanate and 36.8g of absolute ethanol evenly, mechanically stir for 1h in a water bath at 40°C, and use concentrated HNO 3 Adjust the pH between 1.5-2, then add 3.6g of deionized water into the mixed solution at a rate of 3 drops / second with a glue-tip dropper, continue mechanical stirring for 1.5h in a water bath at room temperature, and place the prepared sol A light yellow gel was obtained for a period of time, dried in a constant temperature drying oven at 70°C for 5h, ground, and calcined at 450°C for 3h to obtain the product n-type TiO 2 ;

[0030] (2) Preparation of NaAlO by sol-gel method 2

[0031] CH 3 COONa·3H 2 O and Al(NO 3 ) 3 9H 2 O is mixed evenly according to the molar ratio of 1:1 (molar mass is 0.01mol), then mixed with 60ml of ethylene glycol solvent, added 1g of surfactant po...

Embodiment 2

[0036] (1) Preparation of TiO by sol-gel method 2

[0037] Butyl titanate is used as the source material, and absolute ethanol is used as the solvent. Mix 34g of tetrabutyl titanate and 36.8g of absolute ethanol evenly, mechanically stir for 1h in a water bath at 40°C, and use concentrated HNO 3 Adjust the pH between 1.5-2, then slowly add 3.6g of deionized water into the mixed solution with a rubber dropper, continue to mechanically stir for 1.5h in a water bath at room temperature, and let the prepared sol stand for a period of time to obtain a light yellow color Gel, dried in a constant temperature drying oven at 70°C for 5h, ground, and calcined at 450°C for 3h to obtain the product TiO 2 .

[0038] (2) Preparation of NaAlO by sol-gel method 2

[0039] CH 3 COONa·3H 2 O and Al(NO 3 ) 3 9H 2 O is mixed evenly according to the molar ratio of 1:1 (molar mass is 0.01mol), then mixes with 60ml ethylene glycol solvent, adds 1gCTAB, stirs with a glass rod for 15min to m...

Embodiment 3

[0044] (1) Preparation of TiO by sol-gel method 2

[0045] Butyl titanate is used as the source material, and absolute ethanol is used as the solvent. Mix 34g of tetrabutyl titanate and 36.8g of absolute ethanol evenly, mechanically stir for 1h in a water bath at 40°C, and use concentrated HNO 3 Adjust the pH between 1.5-2, then slowly add 3.6g of deionized water into the mixed solution with a rubber dropper, continue to mechanically stir for 1.5h in a water bath at room temperature, and let the prepared sol stand for a period of time to obtain a light yellow color Gel, dried in a constant temperature drying oven at 70°C for 5h, ground, and calcined at 450°C for 3h to obtain the product TiO 2 .

[0046] (2) Preparation of NaAlO by sol-gel method 2

[0047] CH 3 COONa·3H 2 O and Al(NO 3 ) 3 9H 2 After O is mixed evenly according to the molar ratio of 1:1 (molar mass is 0.01mol), then mix with 60ml ethylene glycol solvent, add 1gP123, stir it with a glass rod for 15min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com