Patents

Literature

164results about "Electrode coatings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rhodium electrocatalyst and method of preparation

The invention relates to a novel rhodium sulfide catalyst for the reduction of oxygen in industrial electrolyzers. The catalyst is highly resistant towards corrosion and poisoning by organic species, thus resulting particularly suitable for use in aqueous hydrochloric acid electrolysis, when technical grade acid containing organic contaminants is employed.

Owner:DE NORA SPA

Catalytic materials, electrodes, and systems for water electrolysis and other electrochemical techniques

InactiveUS20100101955A1Low costDiminish and limit useElectrostatic separatorsCell electrodesHydrogenOxygen

Catalysts, electrodes, devices, kits, and systems for electrolysis which can be used for energy storage, particularly in the area of energy conversion, and / or production of oxygen, hydrogen, and / or oxygen and / or hydrogen containing species. Compositions and methods for forming electrodes and other devices are also provided.

Owner:SUN CATALYTIX CORP +1

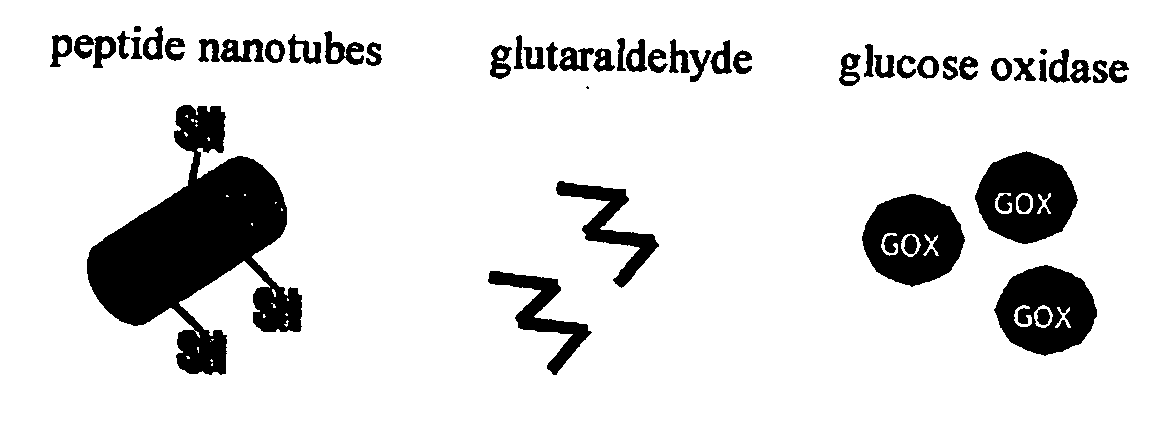

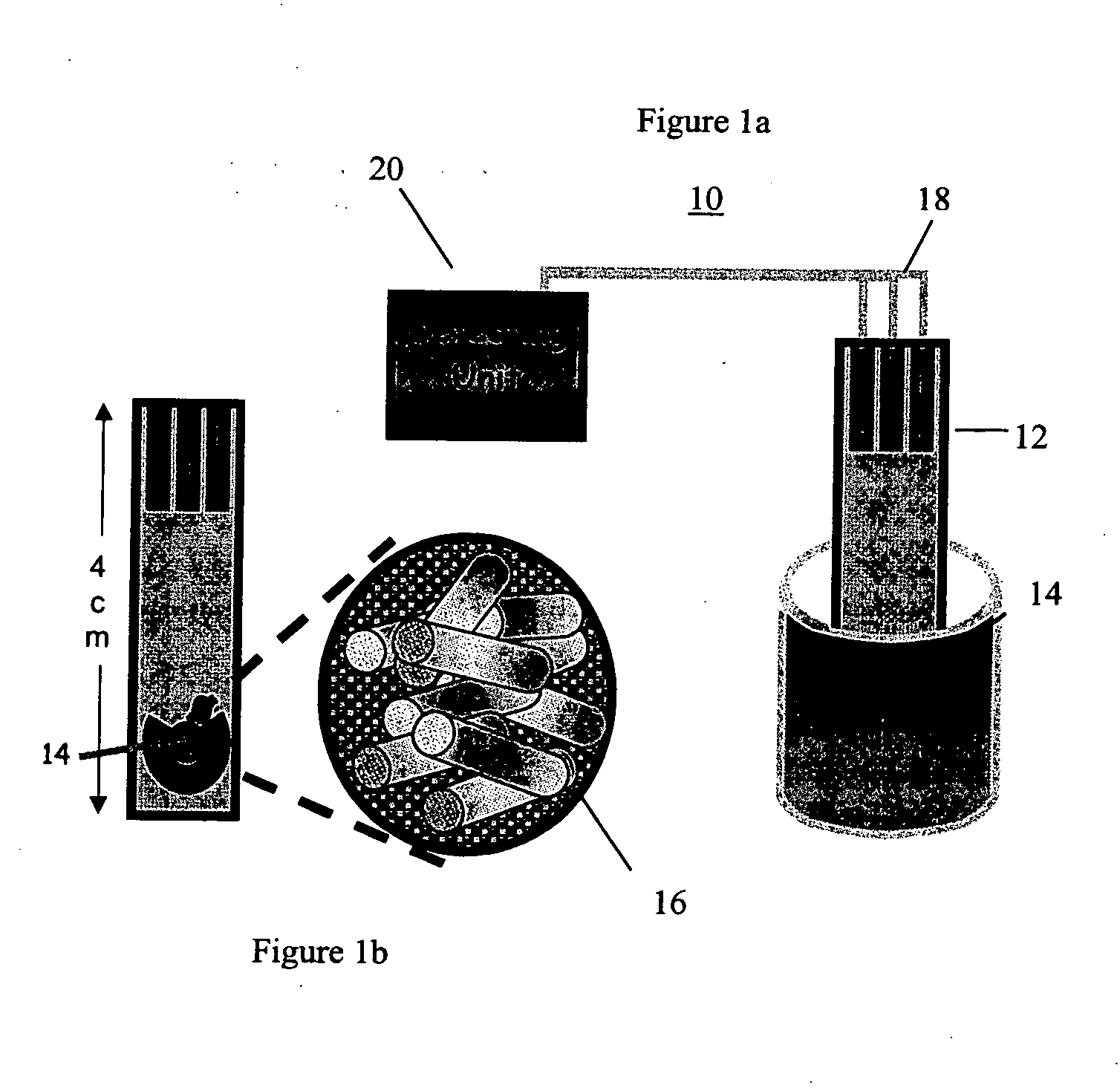

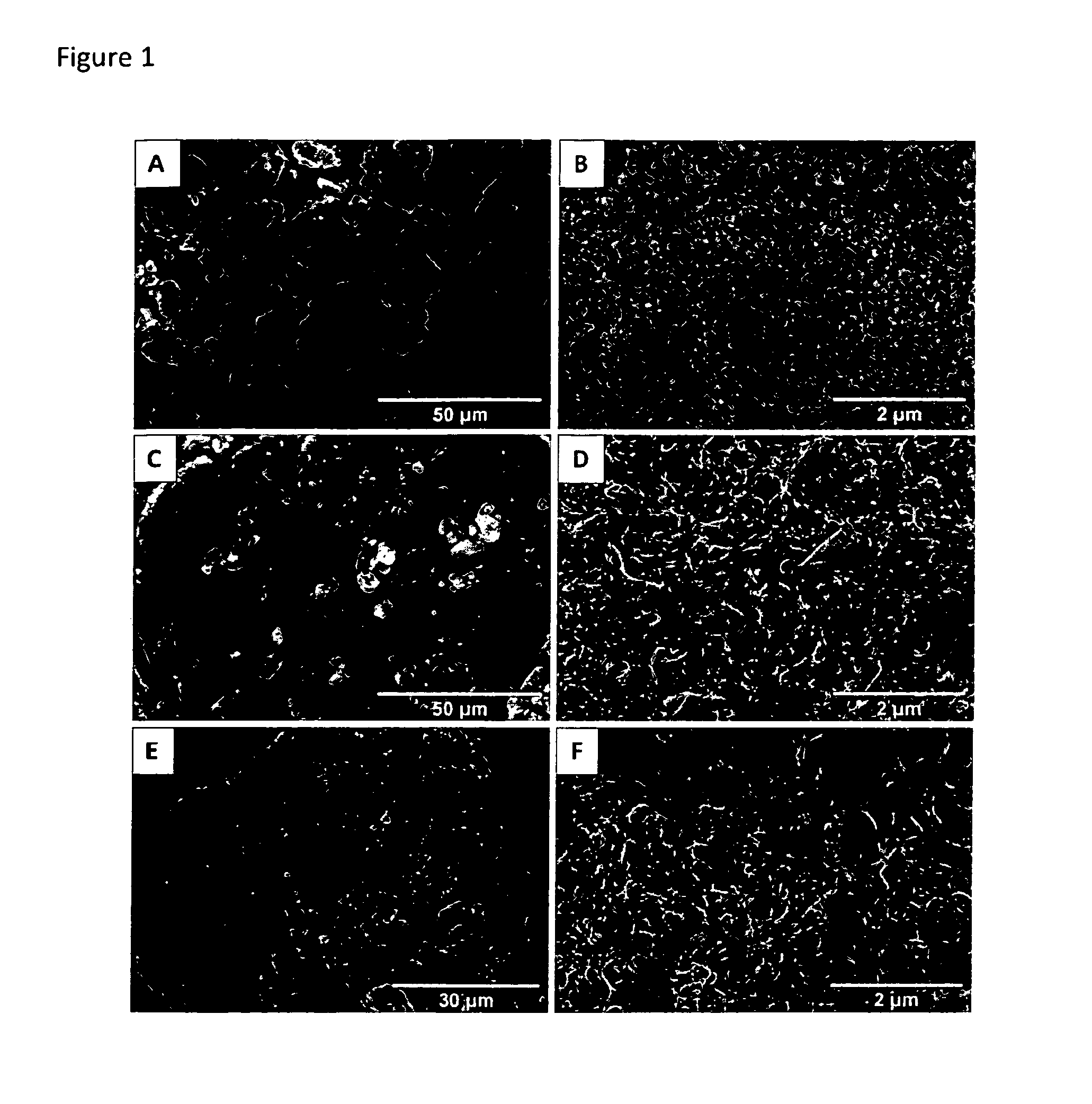

Peptide nanostructure-coated electrodes

InactiveUS20070138007A1Highly suitableHigh sensitivityImmobilised enzymesBioreactor/fermenter combinationsSensor arrayElectrochemical response

An electrode coated with peptide nanostructures, composed of self-assembled peptides, is disclosed. The electrode is capable of conducting a response current resulting from an electrochemical reaction. The electrode can form a part of an electrochemical cell, a detector and a sensor array. Methods utilizing an electrochemical cell, a detector or a sensor array comprising the electrode for detecting an Analyte in a sample and kits containing same are also disclosed.

Owner:RAMOT AT TEL AVIV UNIV LTD

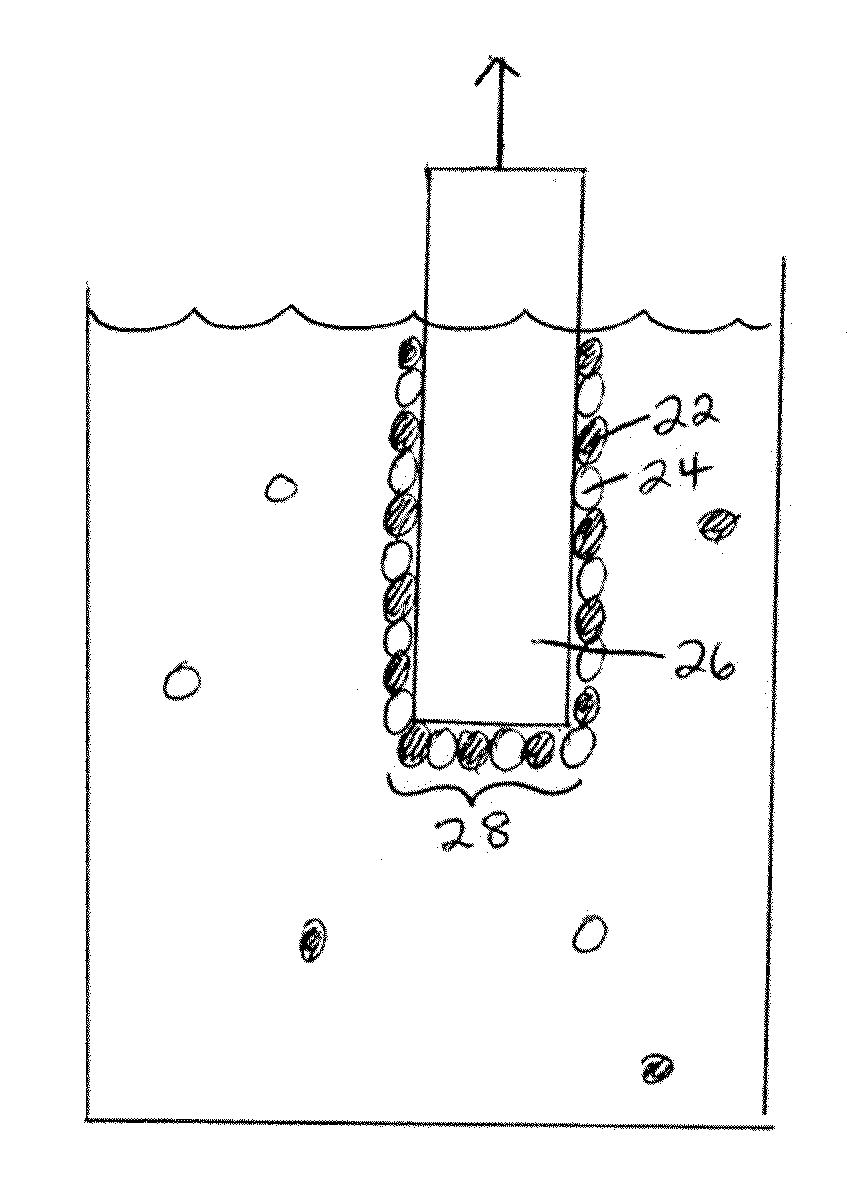

Gated electrodes for electrolysis and electrosynthesis

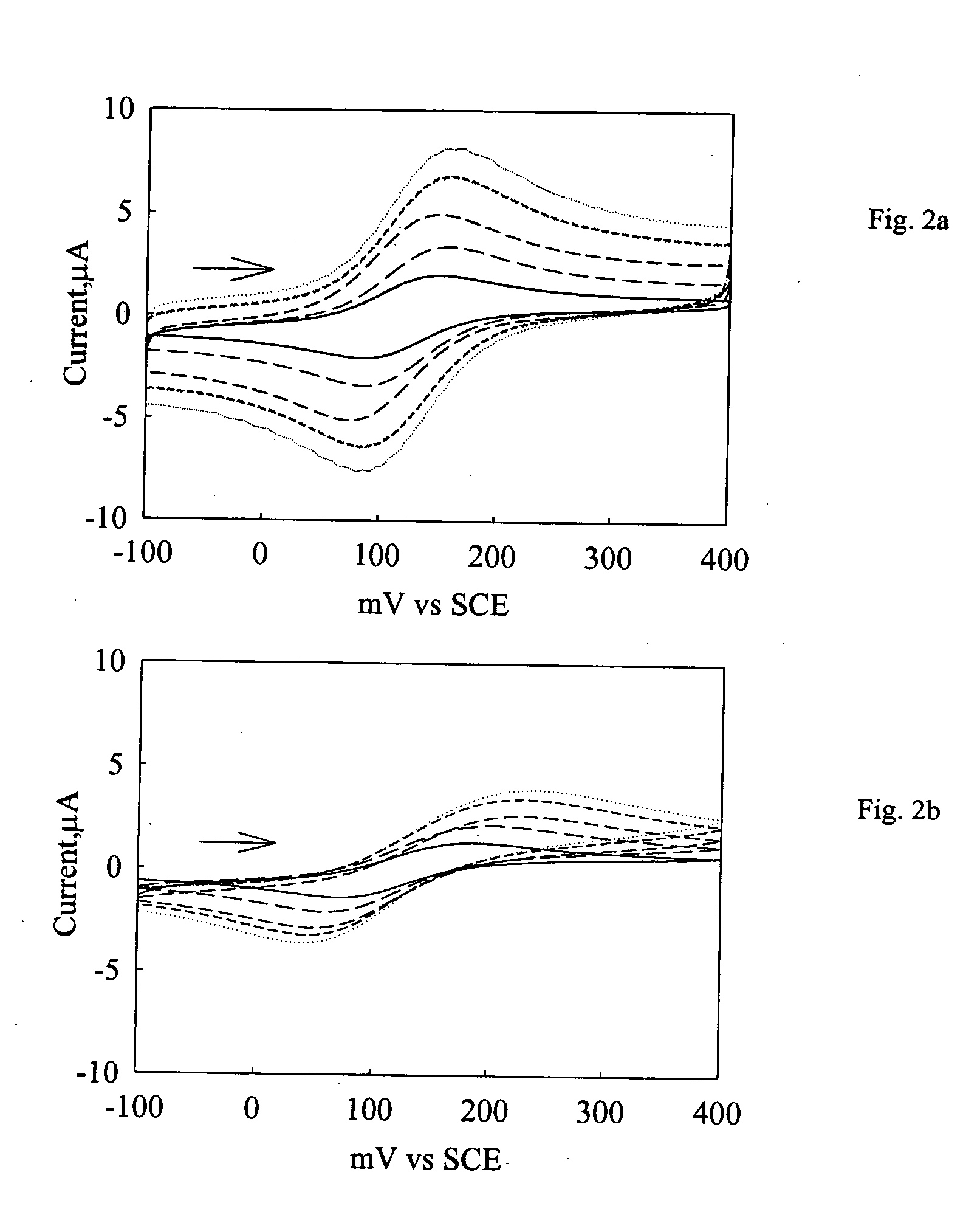

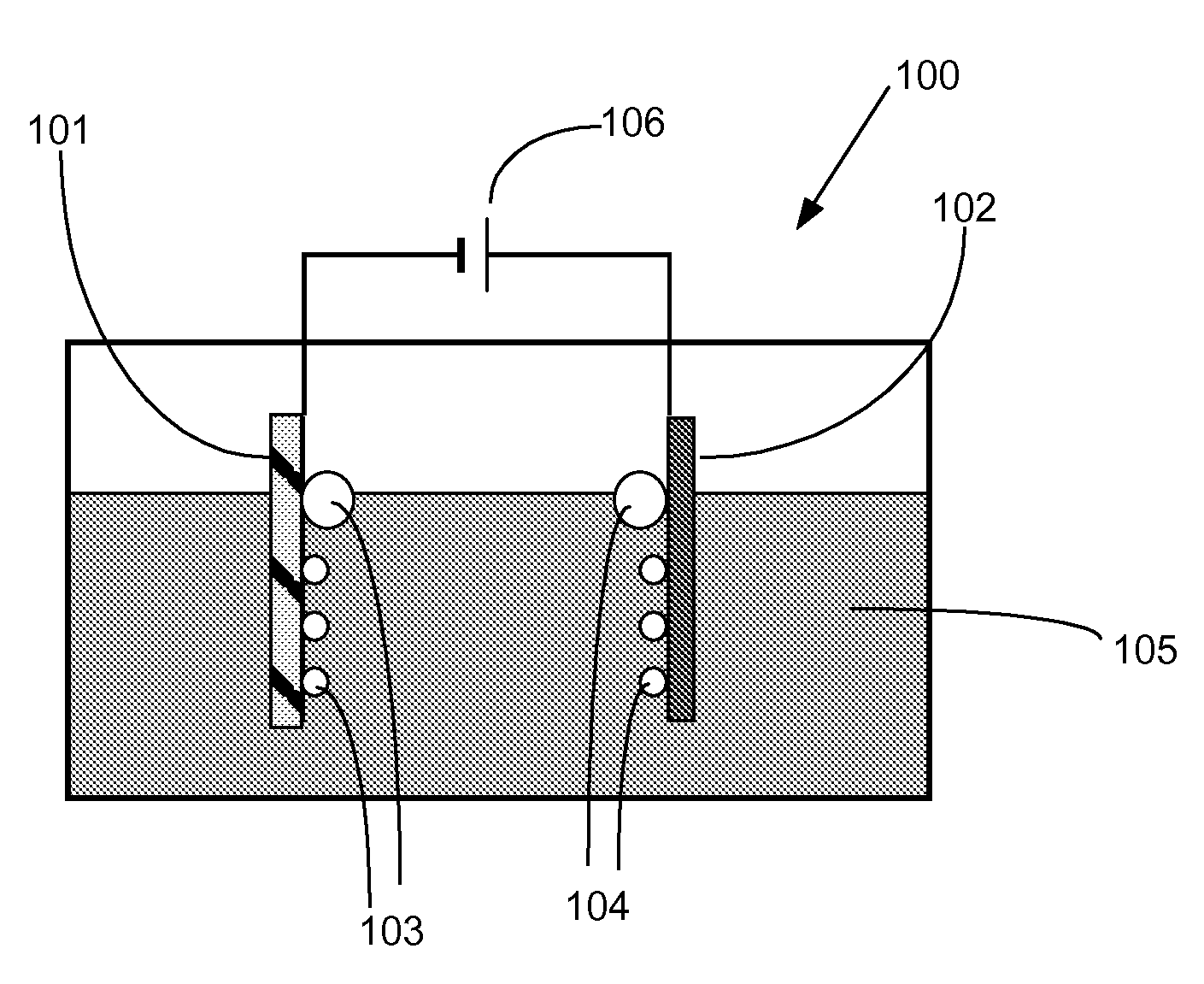

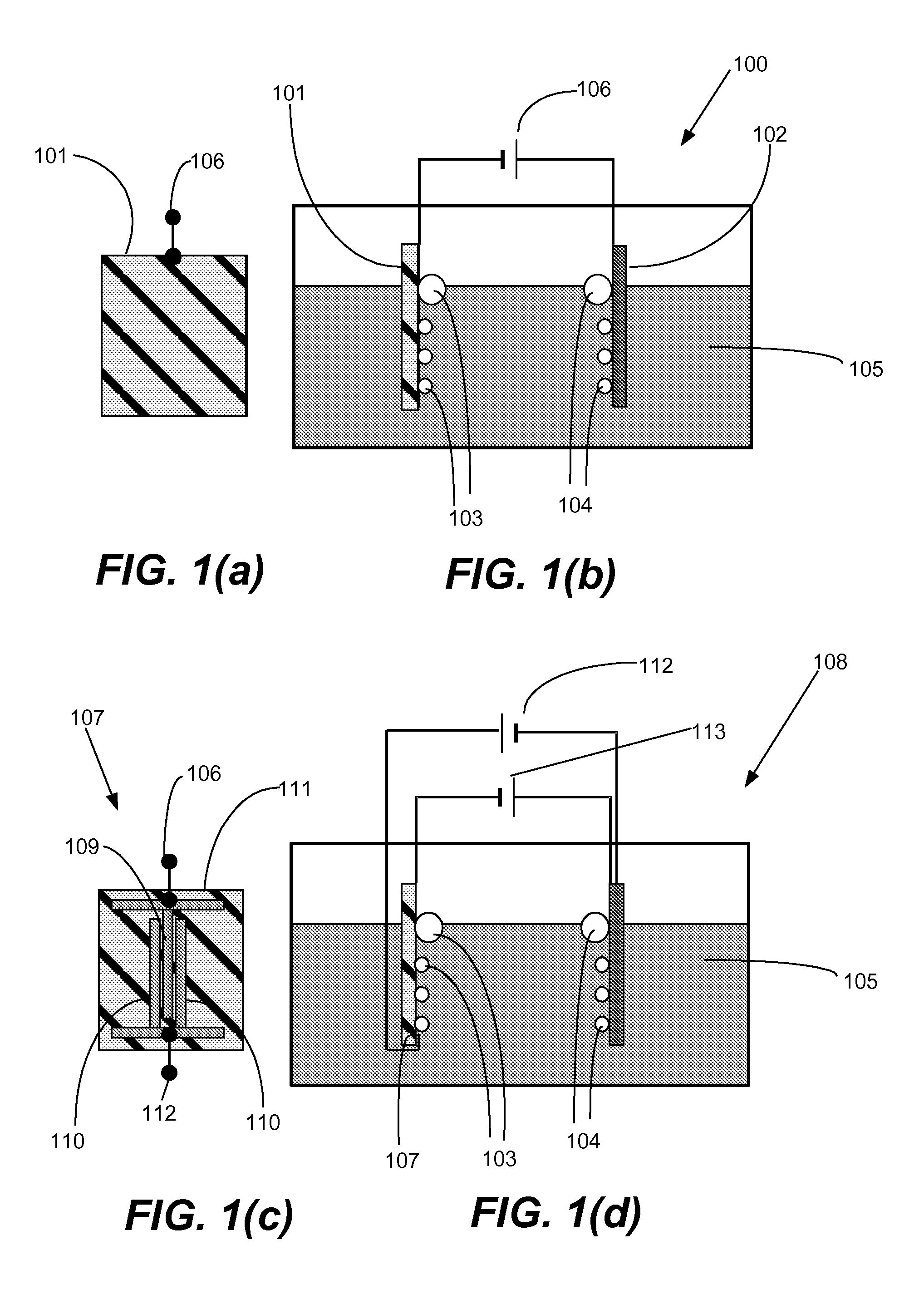

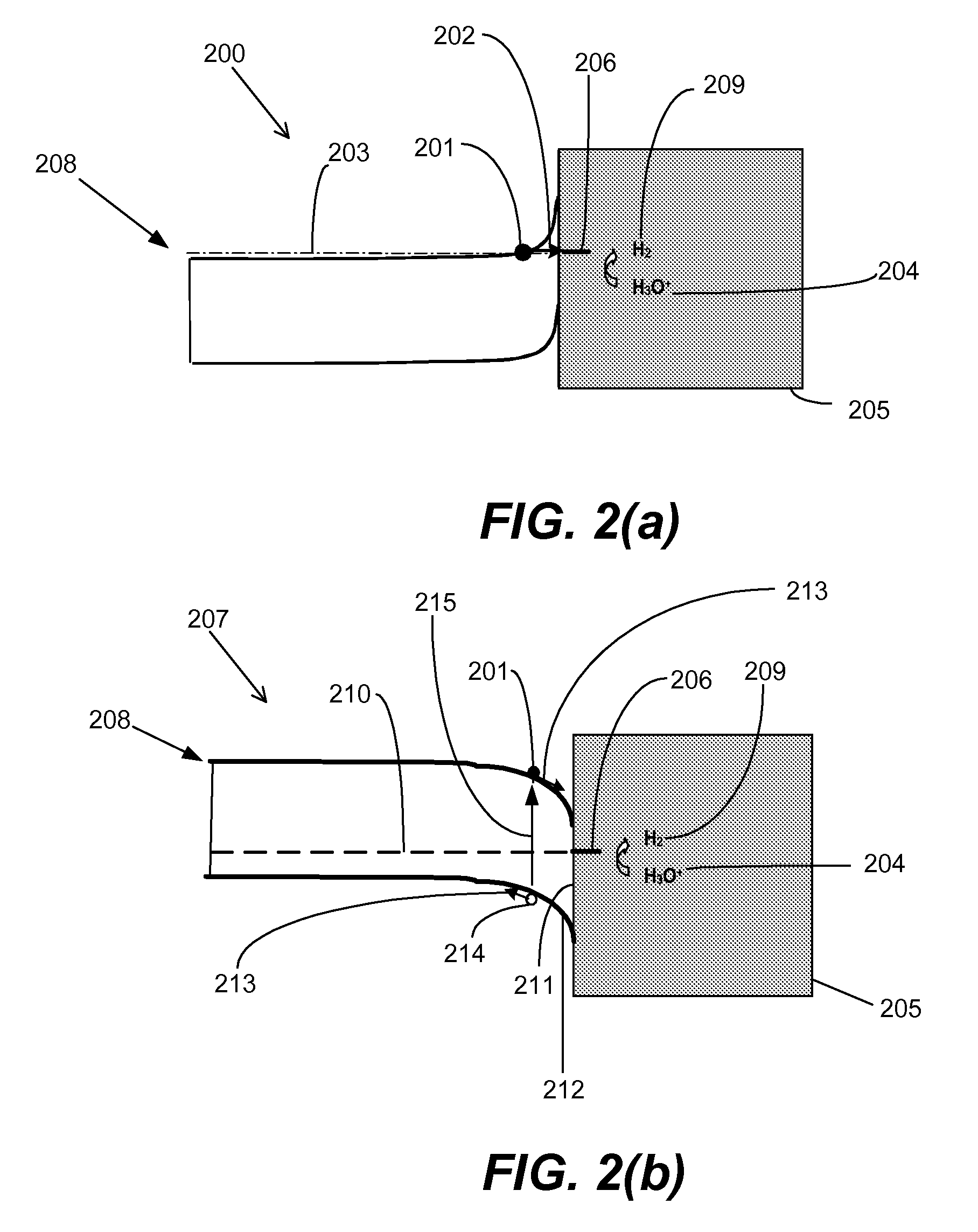

InactiveUS20080116080A1Good effectEnhanced charge transferCellsPhotography auxillary processesOvervoltageElectricity

A gated electrode structure for altering a potential and electric field in an electrolyte near at least one working electrode is disclosed. The gated electrode structure may comprise a gate electrode biased appropriately with respect to a working electrode. Applying an appropriate static or dynamic (time varying) gate potential relative to the working electrode modifies the electric potential and field in an interfacial region between the working electrode and the electrolyte, and increases electron emission to and from states in the electrolyte, thereby facilitating an electrochemical, electrolytic or electrosynthetic reaction and reducing electrode overvoltage / overpotential.

Owner:RGT UNIV OF CALIFORNIA

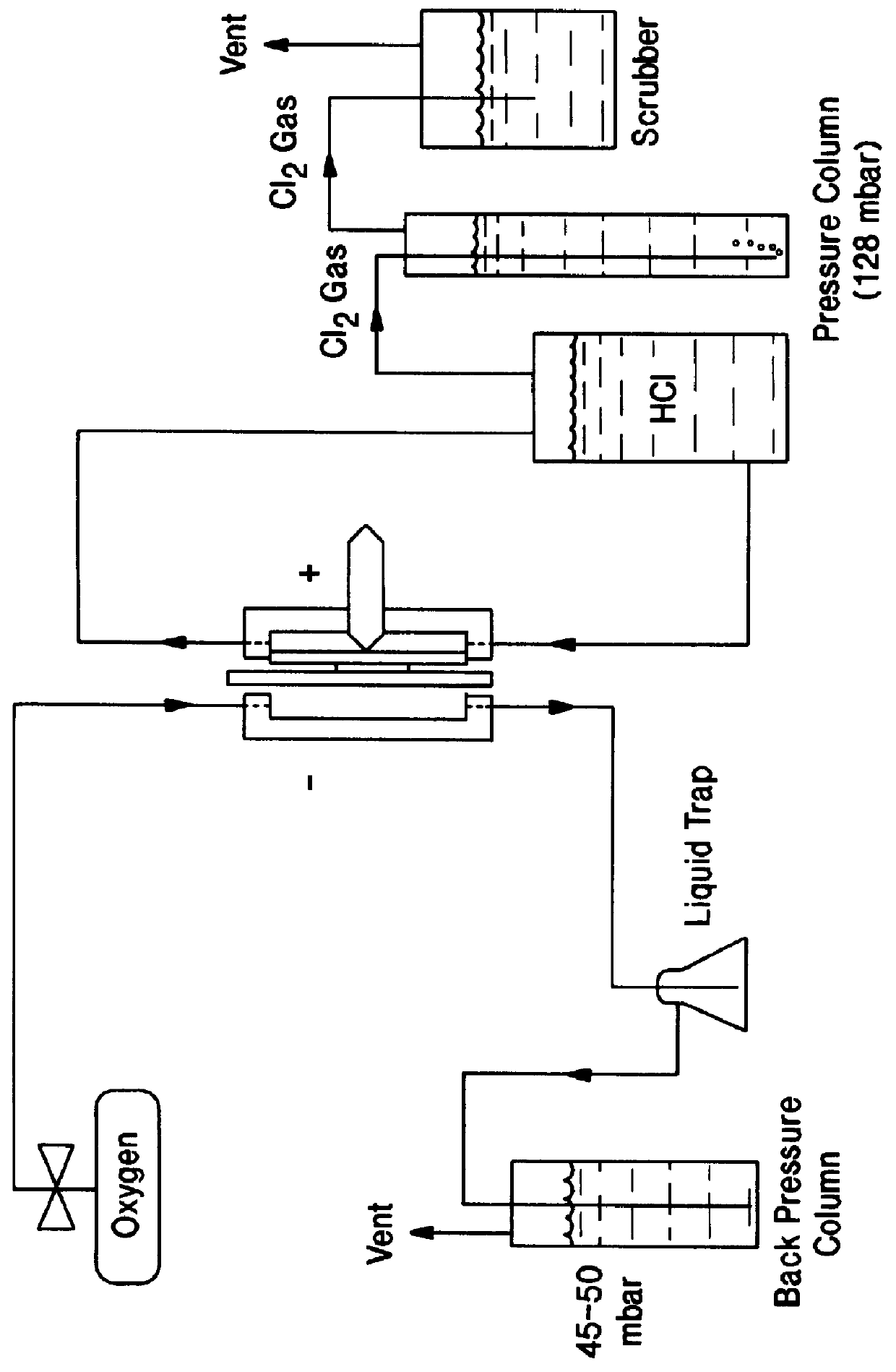

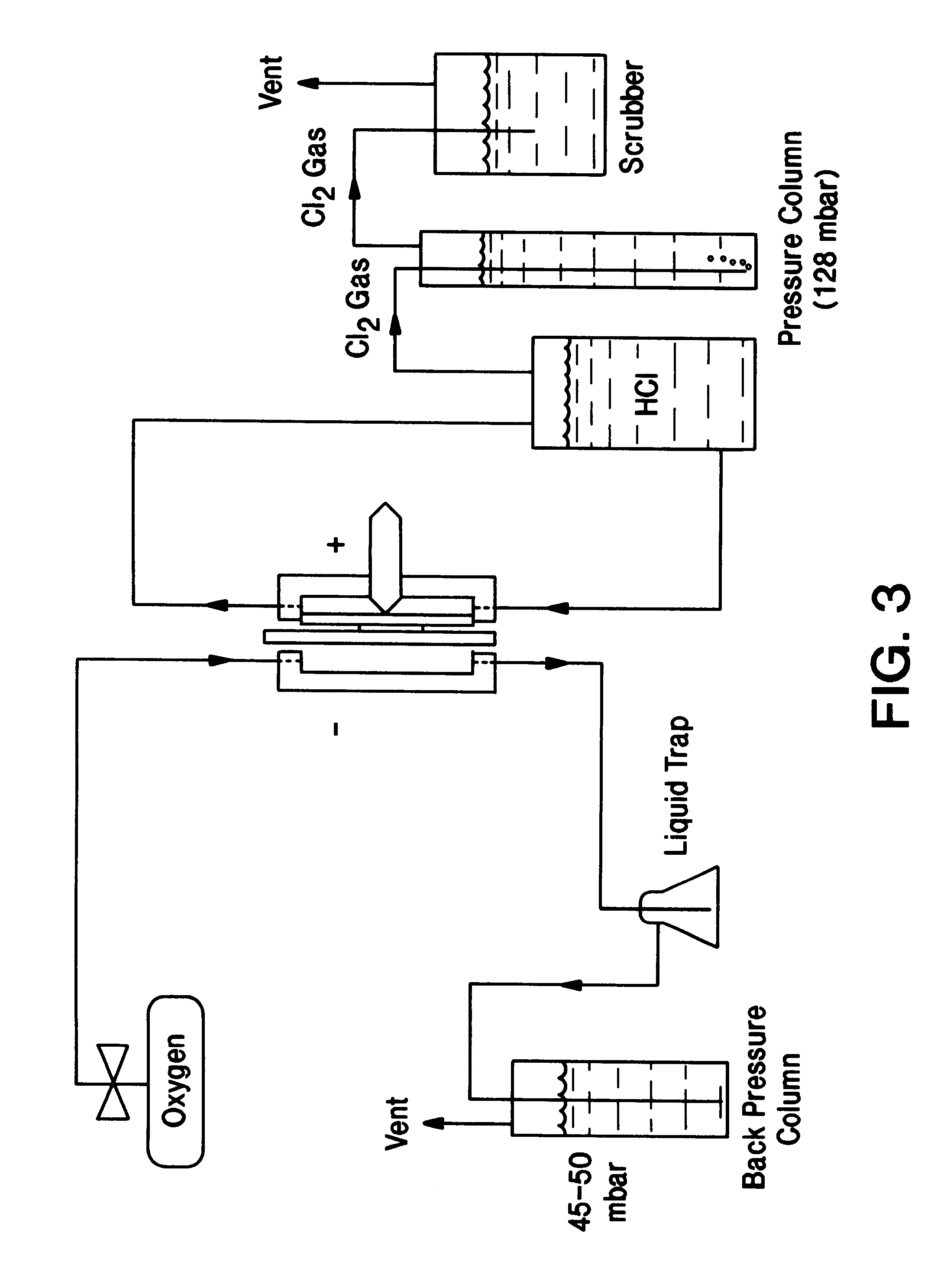

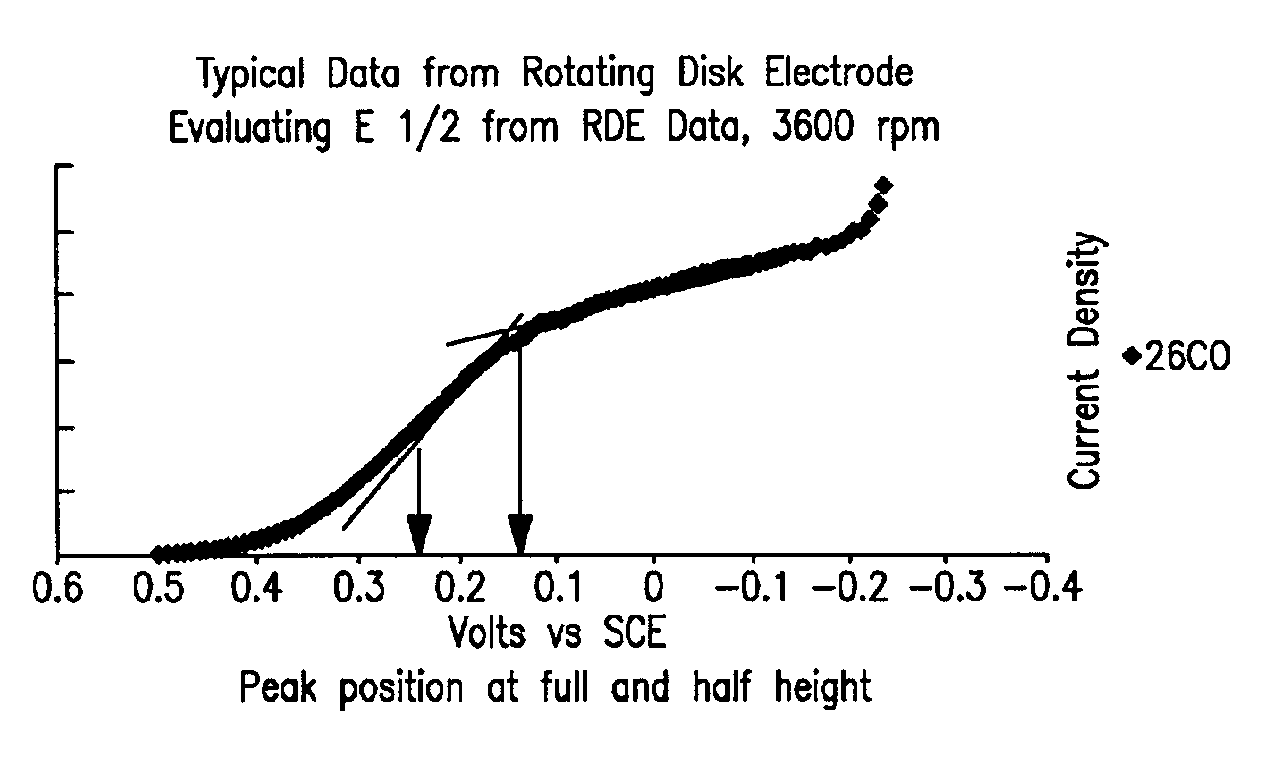

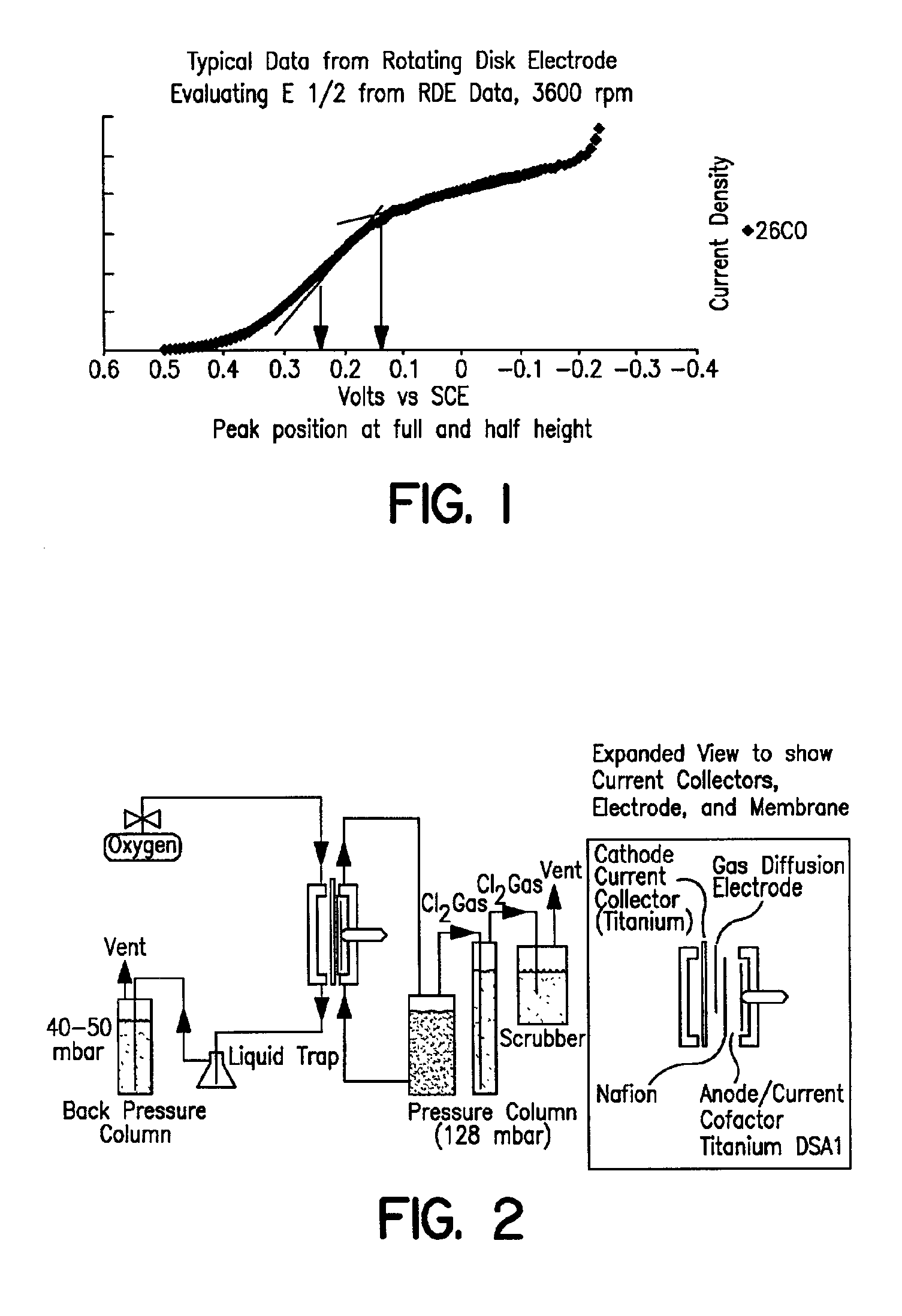

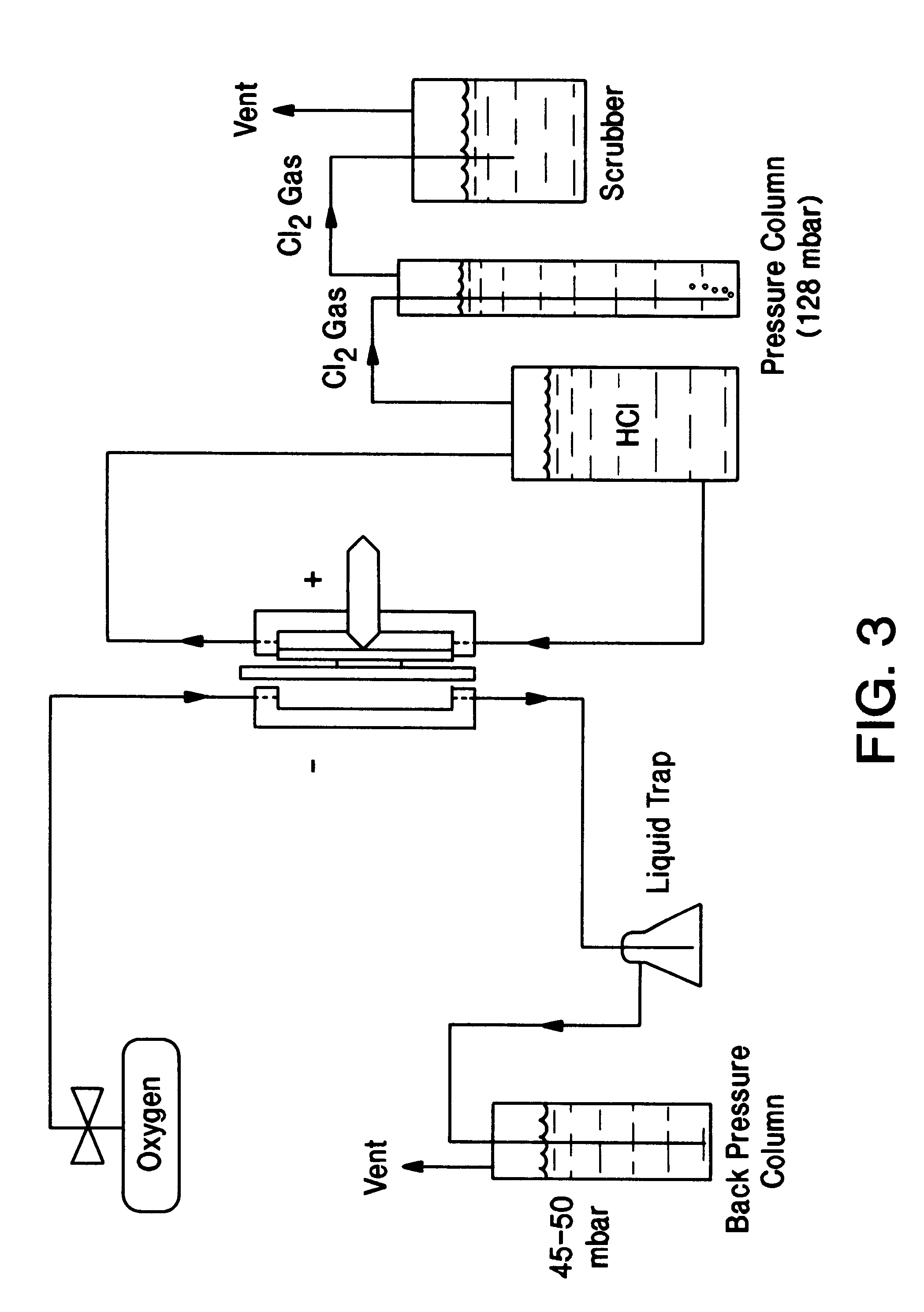

Process for the electrolysis of technical-grade hydrochloric acid contaminated with organic substances using oxygen-consuming cathodes

InactiveUS6402930B1Prevent further reactionHighly corrosive mediaCellsPhysical/chemical process catalystsElectrolysisCoating

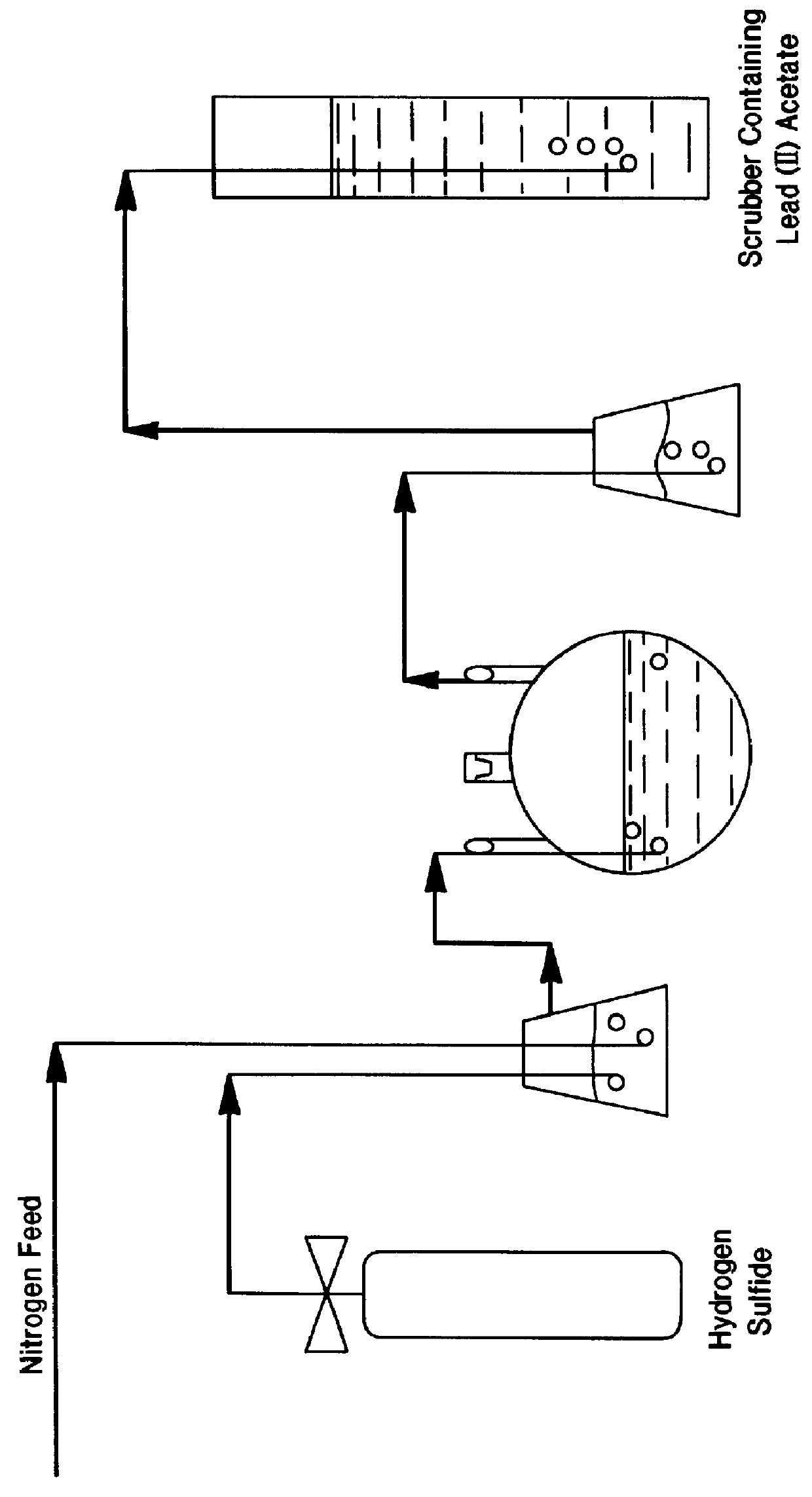

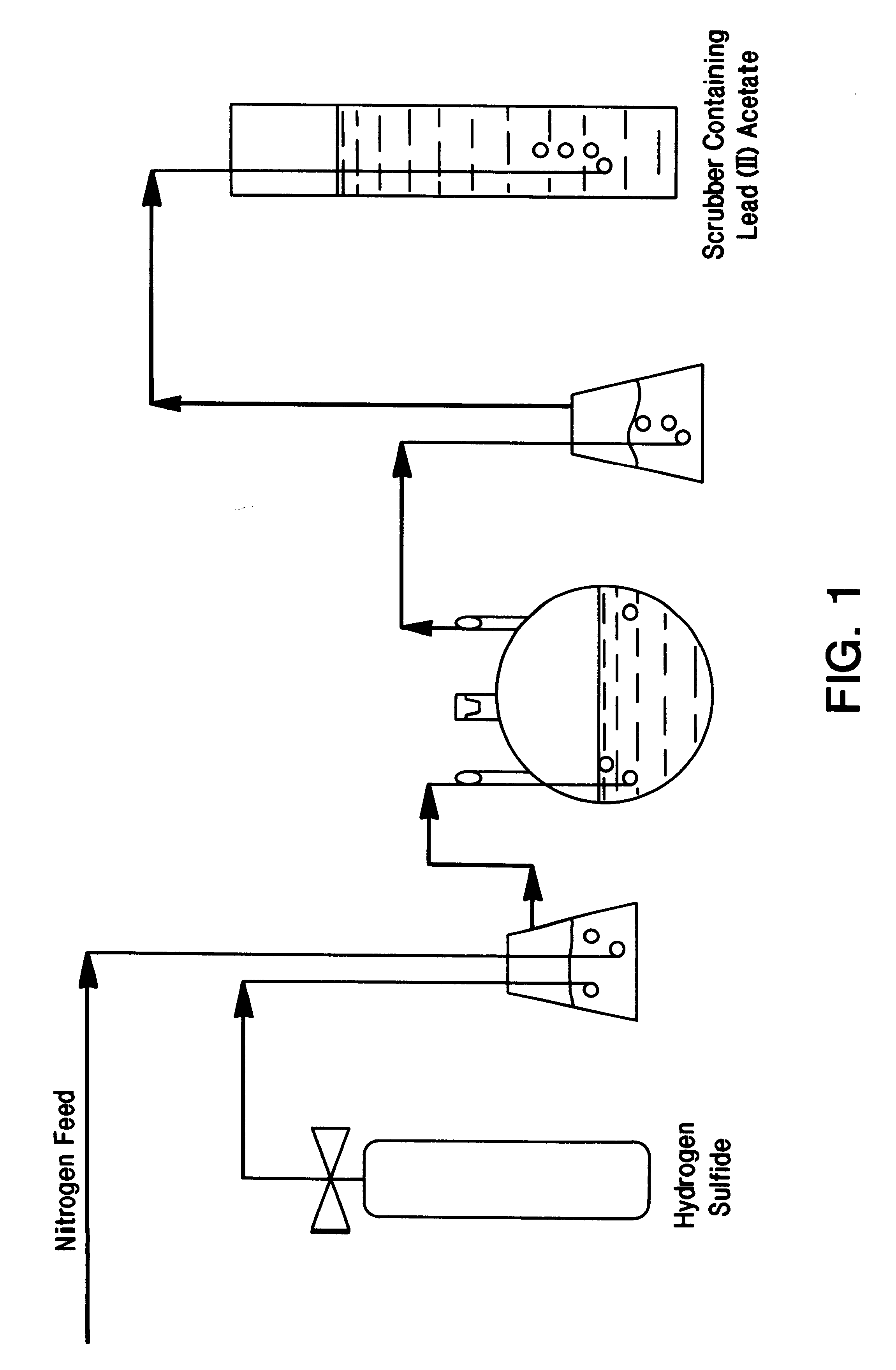

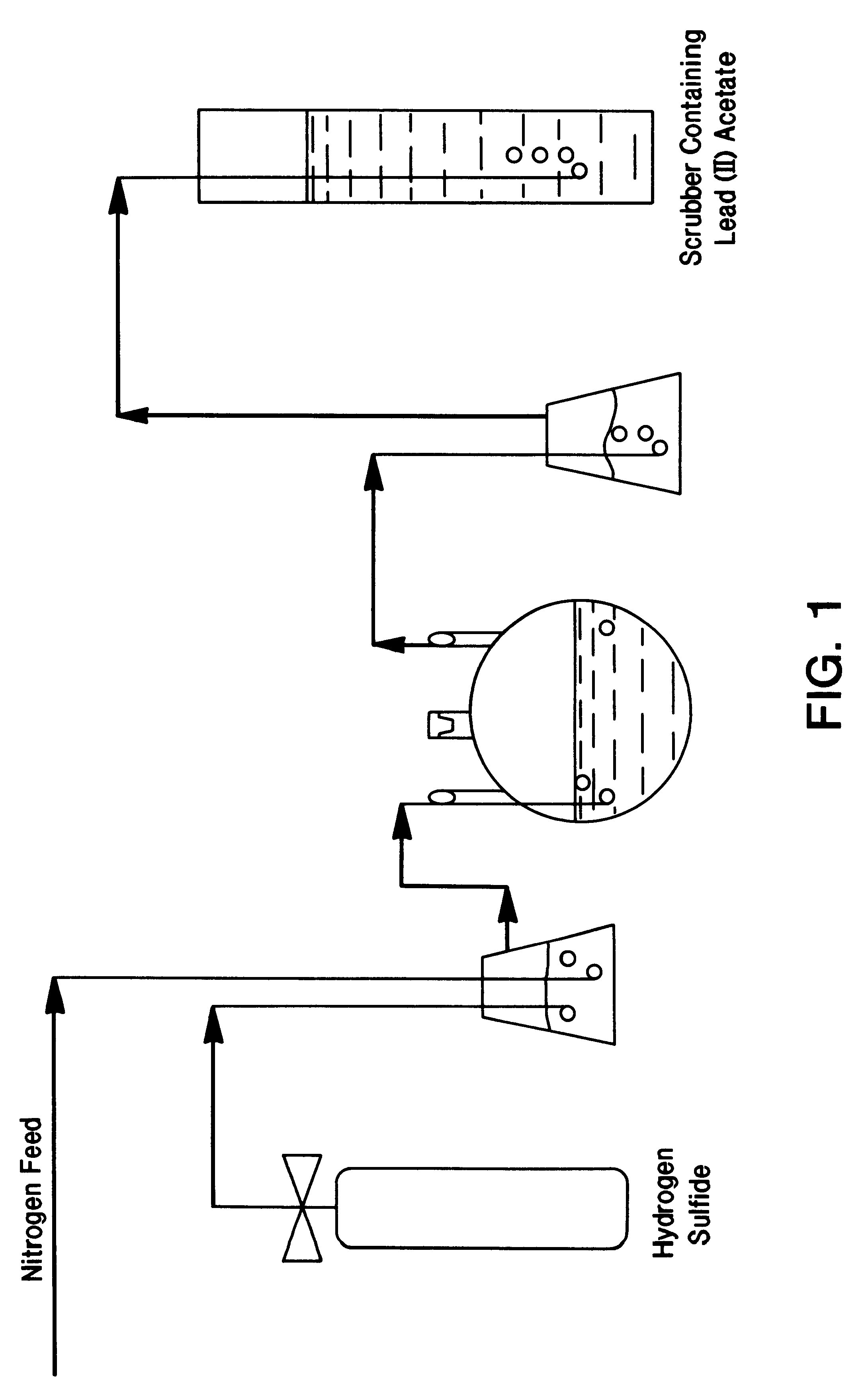

A process for electrolyzing an aqueous solution of hydrochloric acid to chlorine in an electrochemical cell provided with an anode compartment and a cathode compartment including at least one gas diffusion cathode comprising an electrically conductive web provided on at least one side thereof with a coating of a catalyst for the electroreduction of oxygen comprising rhodium sulfide and optionally containing at least one fluorinated binder incorporated therein, comprising introducing aqueous hydrochloric acid containing contaminant species into the anode compartment and oxygen into the cathode compartment while impressing a direct electric current on the cell.

Owner:COVESTRO DEUTSCHLAND AG +1

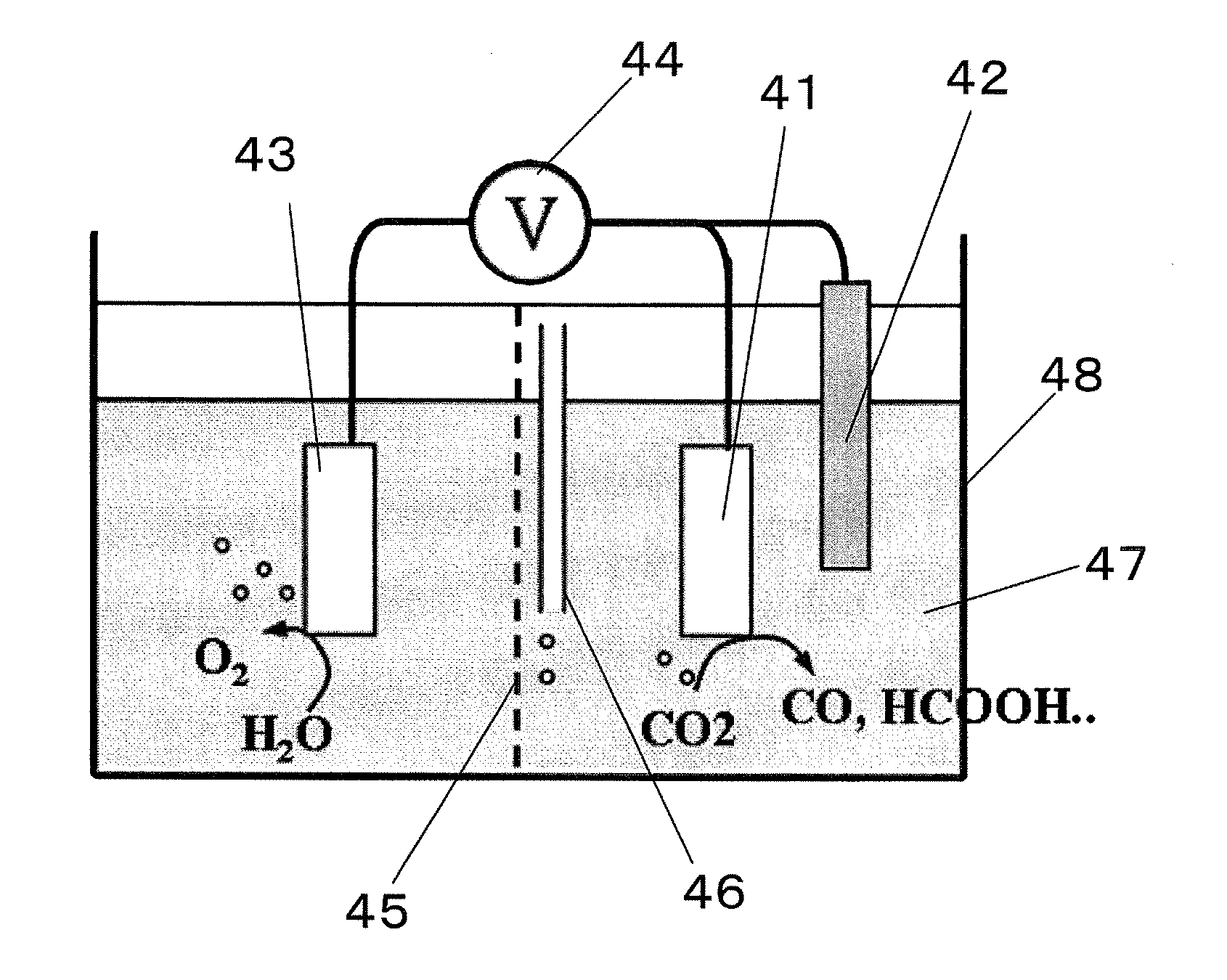

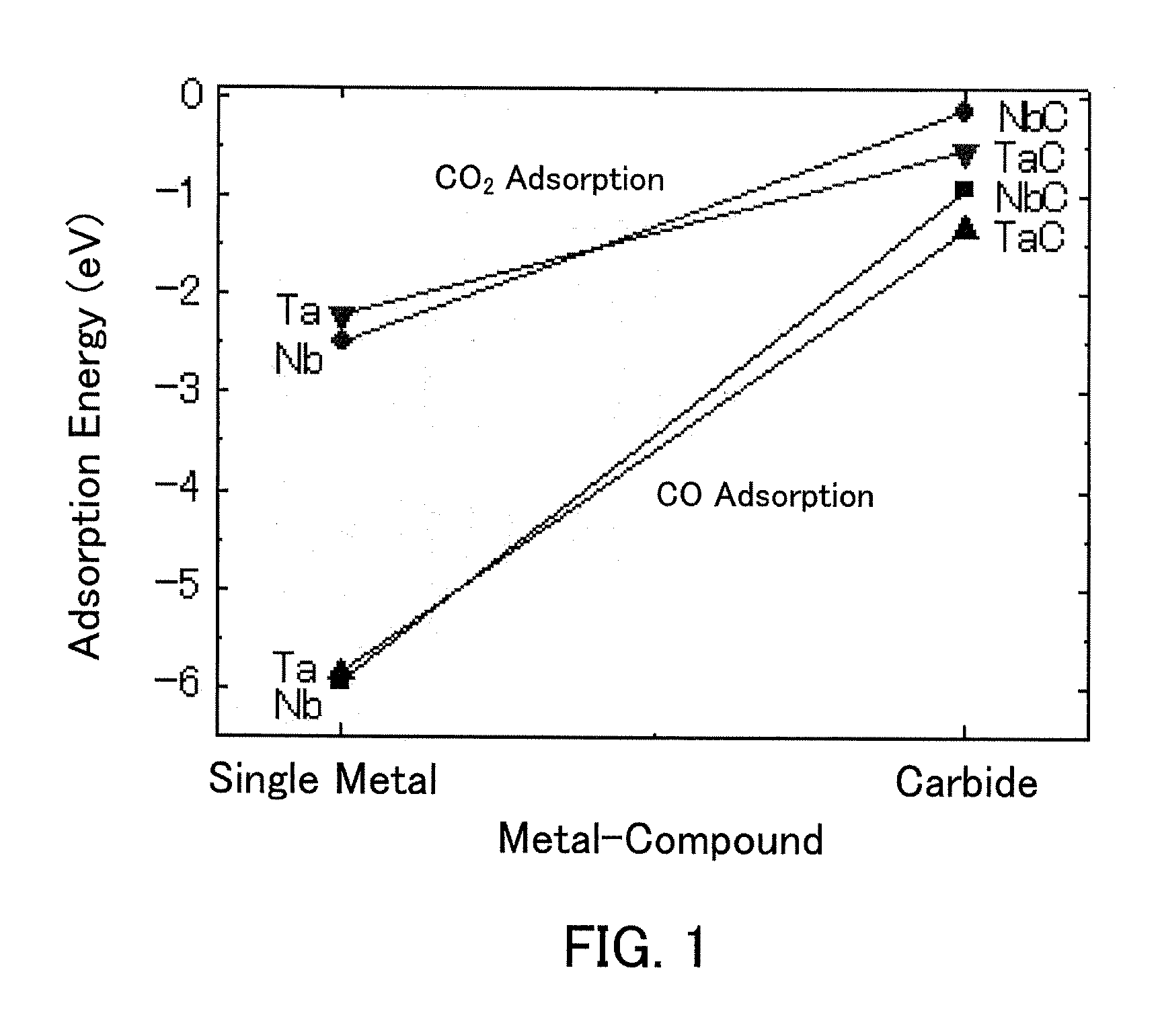

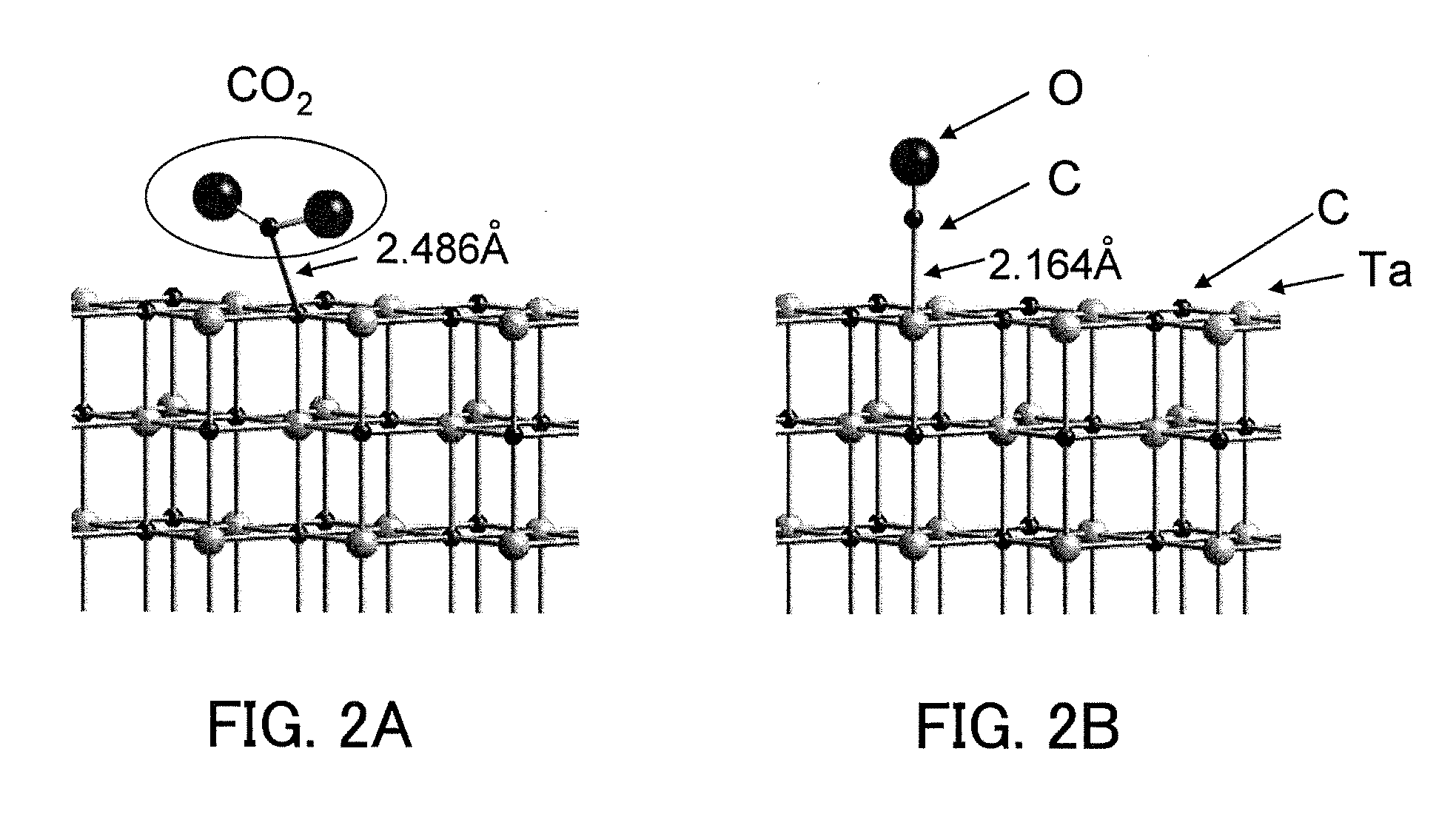

Carbon dioxide reduction method, and carbon dioxide reduction catalyst and carbon dioxide reduction device used for the method

The carbon dioxide reduction method of the present invention is a method including steps of: bringing an electrode (working electrode) containing a carbide of at least one element selected from Group V elements (vanadium, niobium, and tantalum) into contact with an electrolytic solution; and introducing carbon dioxide into the electrolytic solution to reduce the introduced carbon dioxide by the electrode. The material contained in the electrode, that is, the material containing a carbide of at least one element selected from Group V elements (vanadium, niobium, and tantalum) is the carbon dioxide reduction catalyst of the present invention.

Owner:PANASONIC CORP

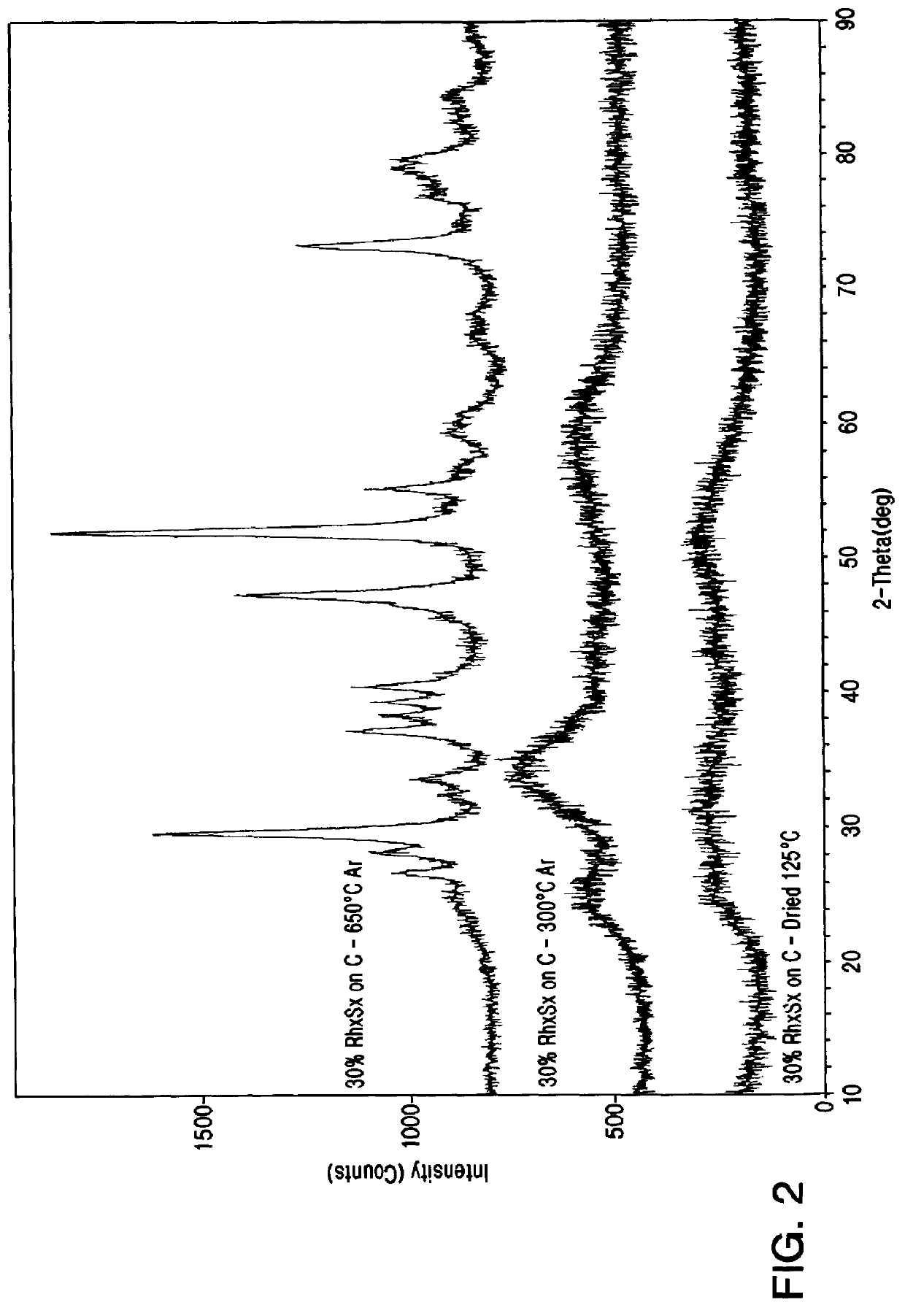

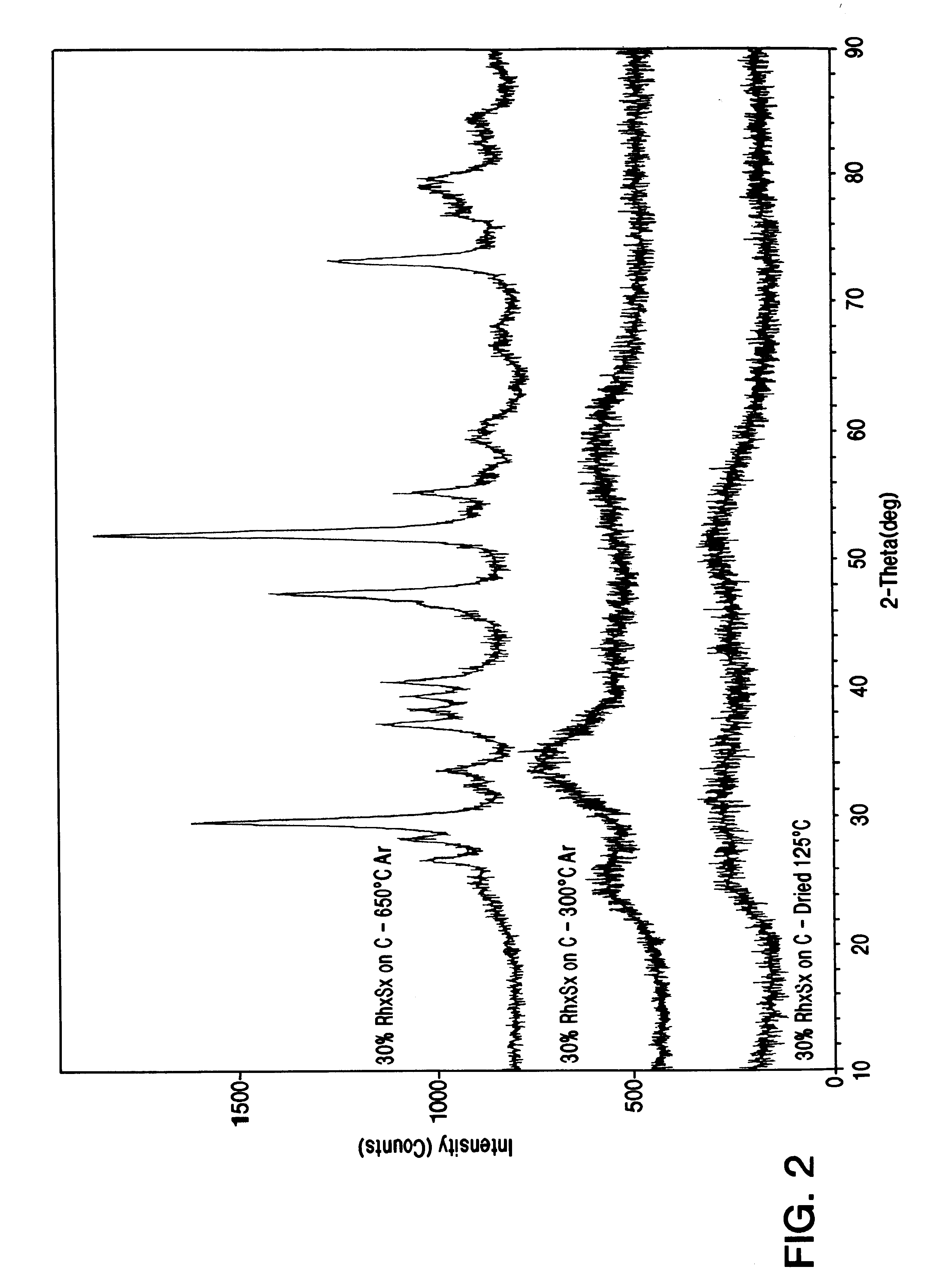

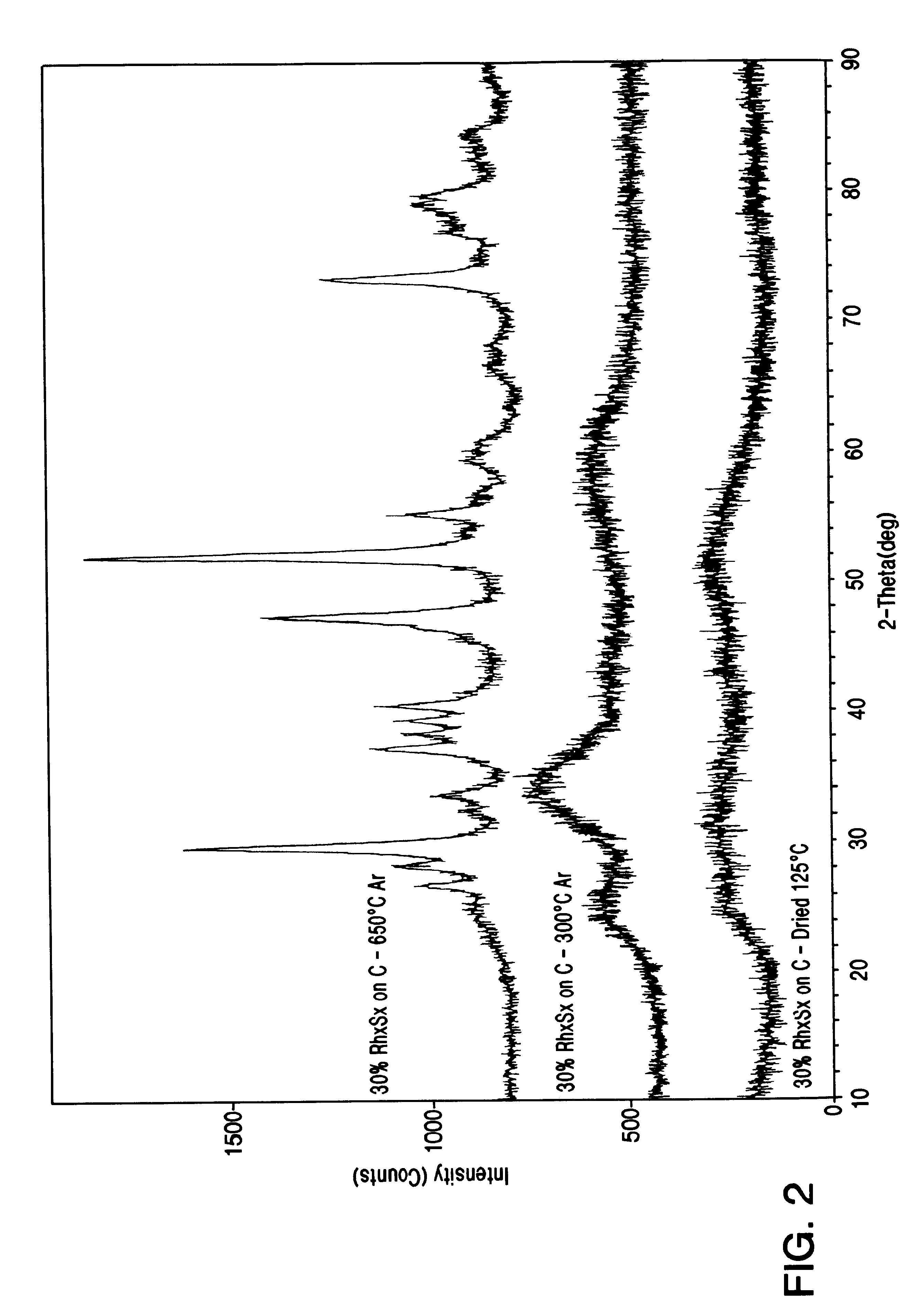

Rhodium electrocatalyst and method of preparation

InactiveUS6855660B2Lower and more consistent operating voltagesImprove performanceMachining electrodesCellsAqueous solutionRhodium salt

Owner:IND DE NORA SPA

Synthesis of noble metal, sulphide catalysts in a sulfide ion-free aqueous environment

A noble metal sulfide catalyst obtained by reaction of a precursor of at least one noble metal with a thionic species in an aqueous environment essentially free of sulfide ions useful as an electrocatalyst in the depolarized electrolysis of hydrochloric acid.

Owner:ELECTRIC TECHNOLOCY

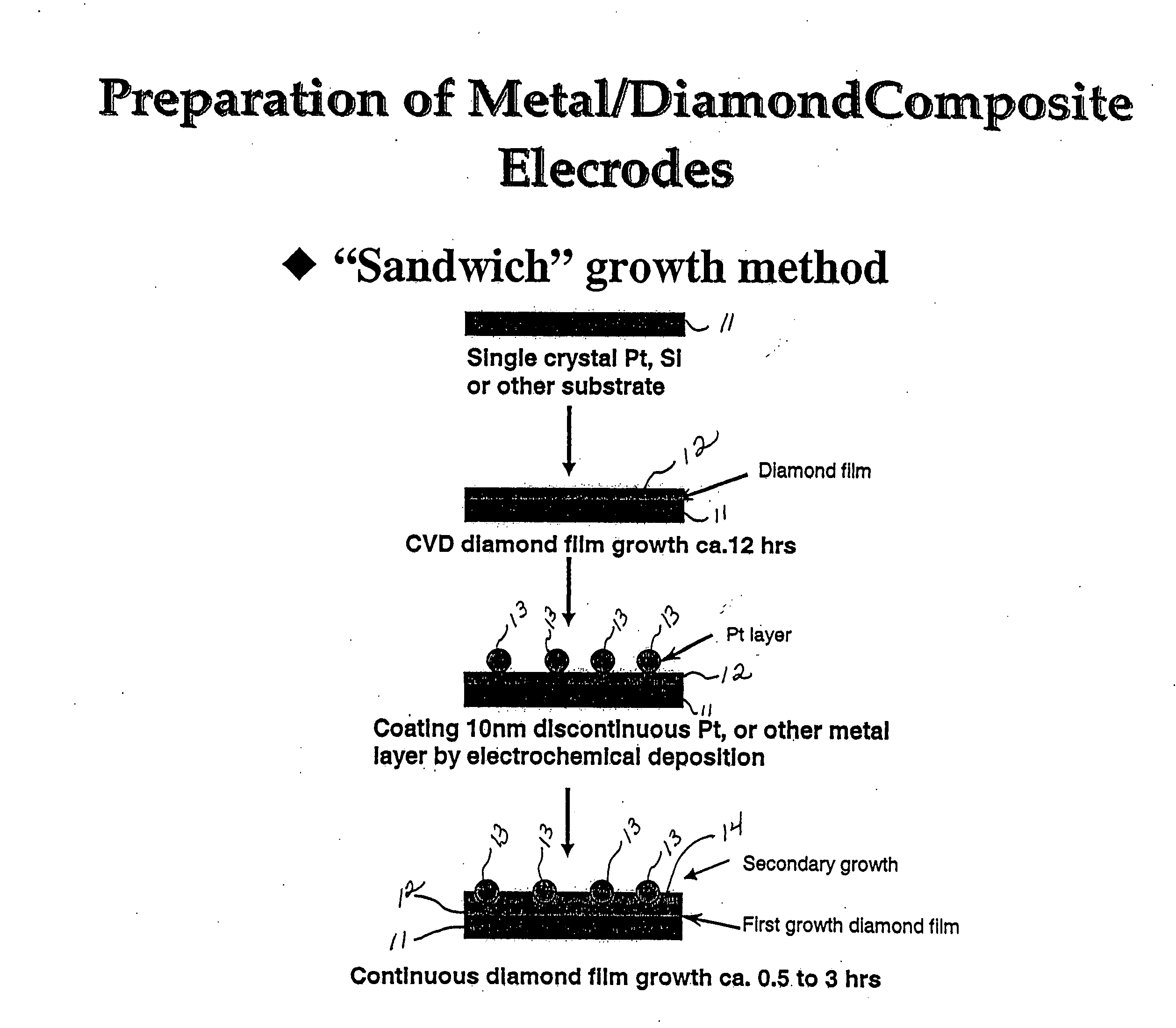

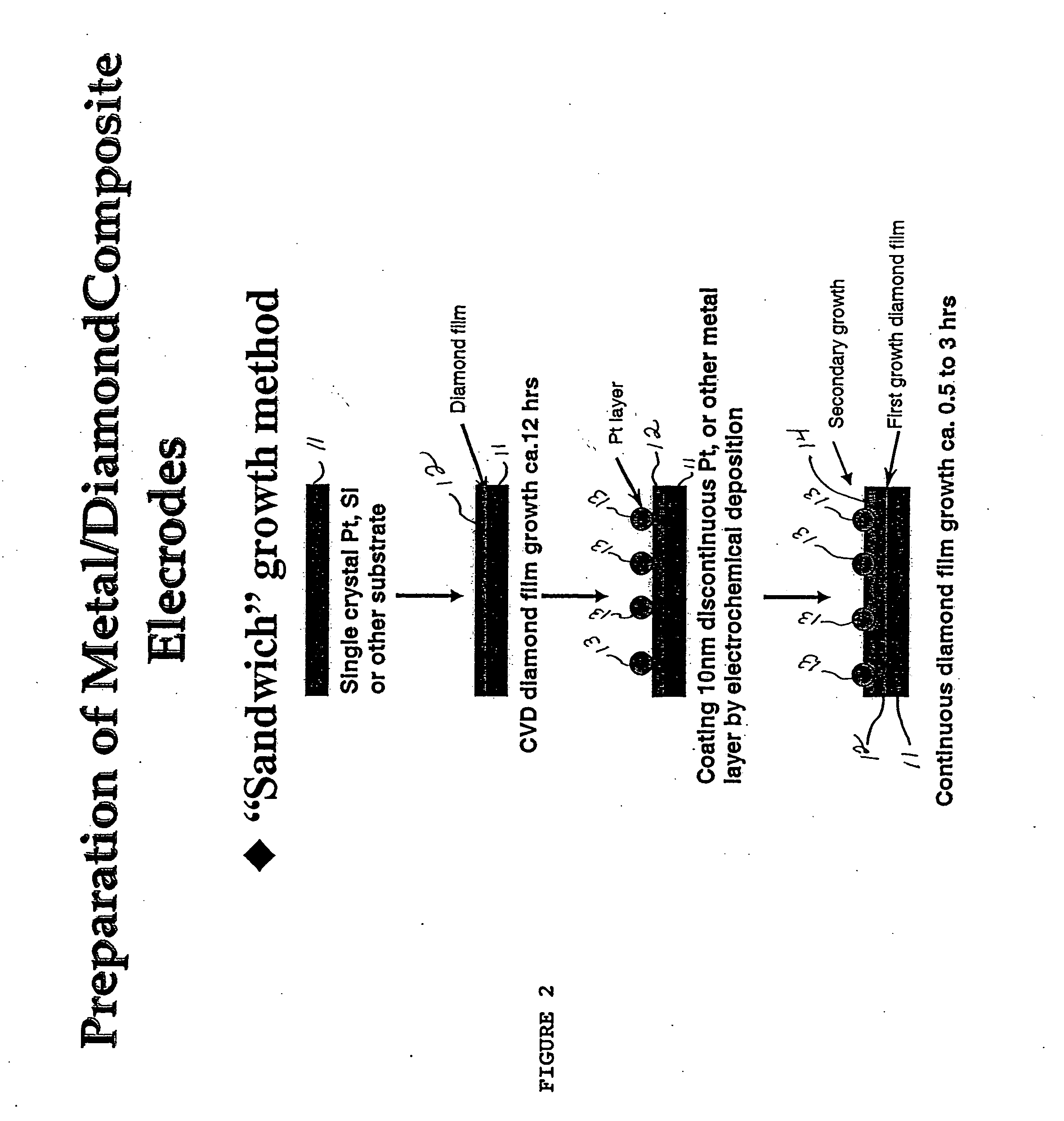

Electrically conductive diamond electrodes

InactiveUS20060175953A1From normal temperature solutionsUltra-high pressure processesHydrogenDiamond electrodes

An electrically conductive diamond electrode and process for preparation thereof is described. The electrode comprises diamond particles coated with electrically conductive doped diamond preferably by chemical vapor deposition which are held together with a binder. The electrodes are useful for oxidation reduction in gas, such as hydrogen generation by electrolysis.

Owner:MICHIGAN STATE UNIV

Catalyst for oxygen reduction

Owner:IND DE NORA SPA

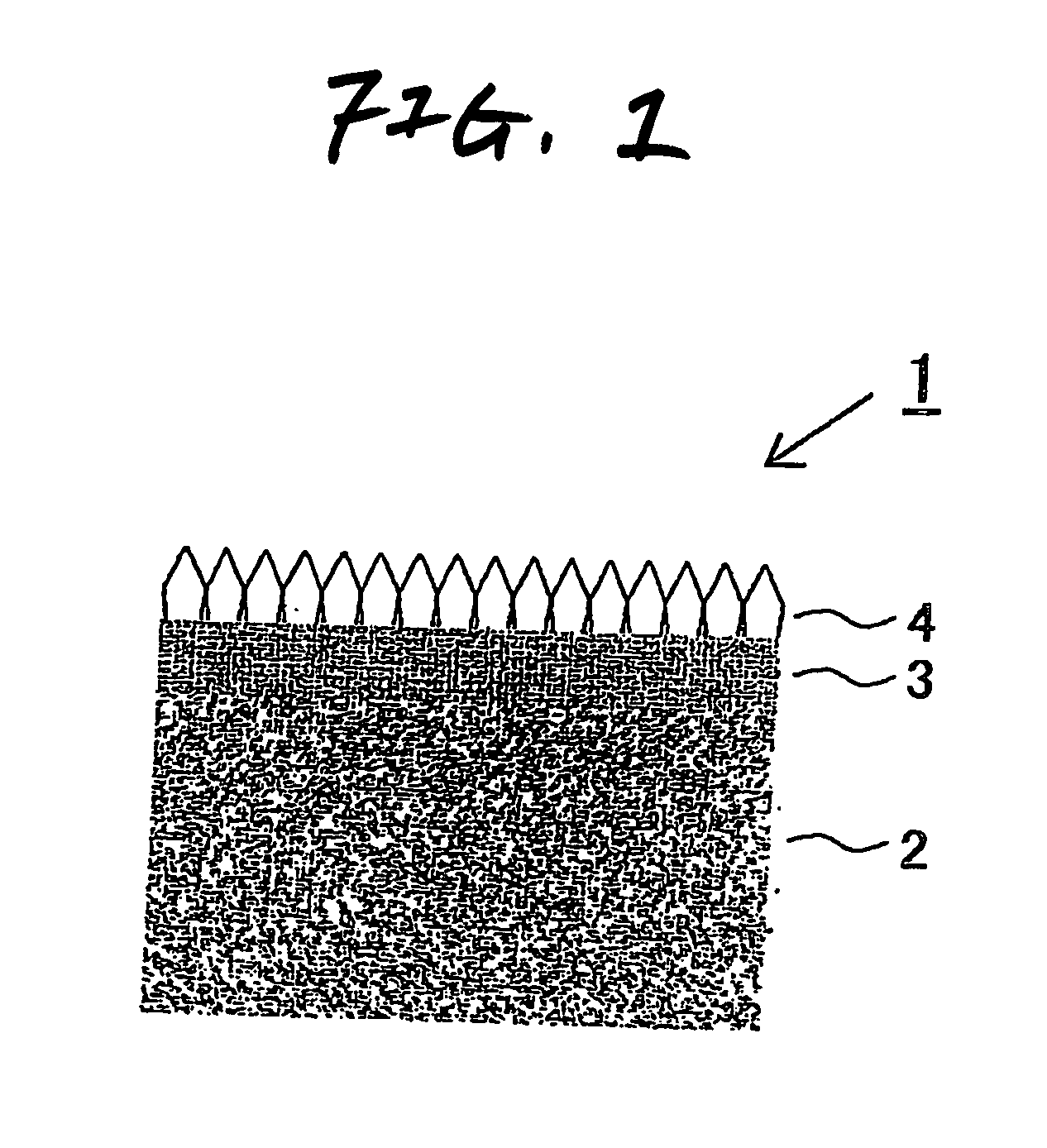

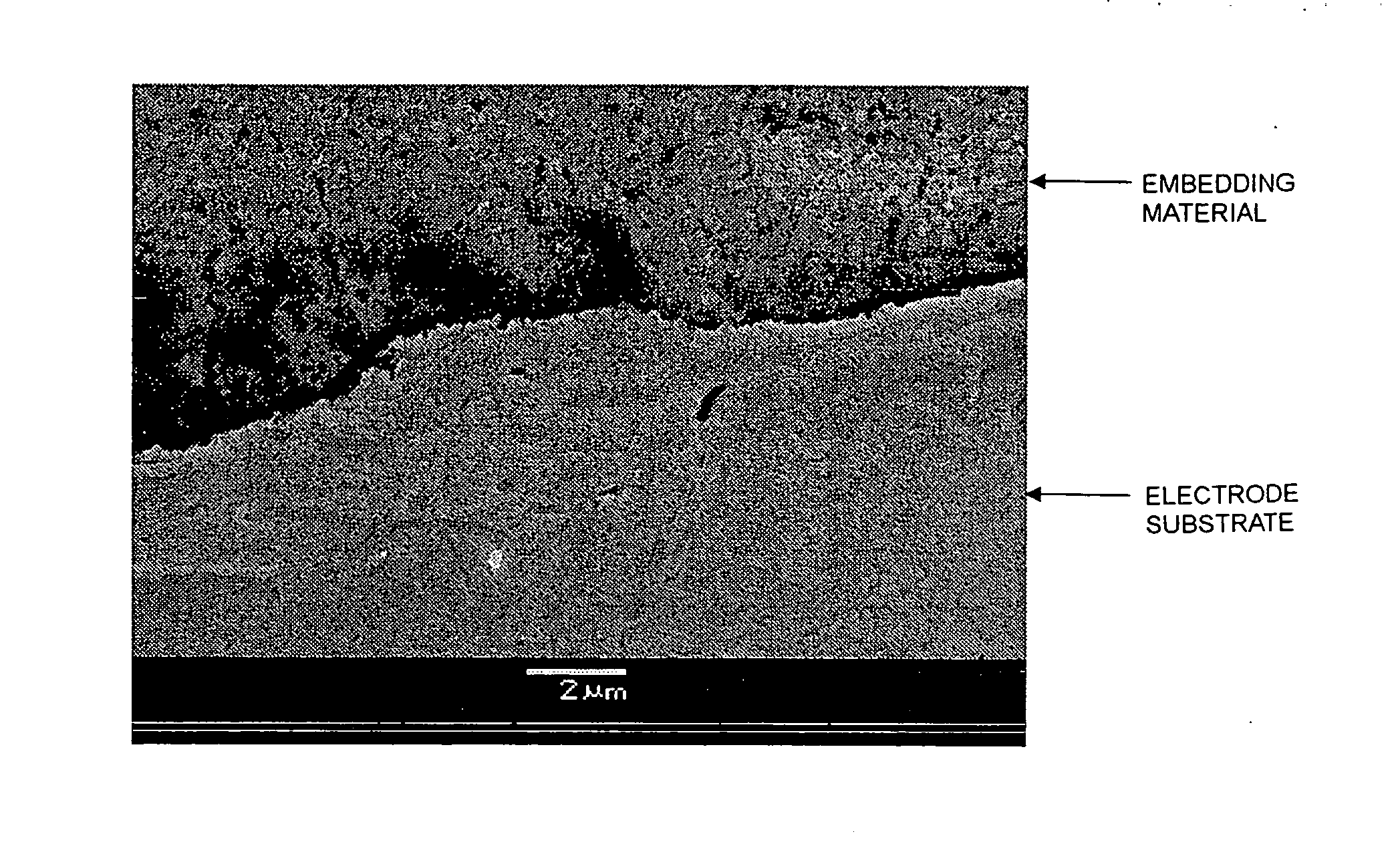

Conductive diamond electrode and process for producing the same

ActiveUS20070031694A1Improvement in substrate stabilityExcellent in economical efficiencyMachining electrodesWater/sewage treatmentDiamond electrodesNiobium

The present invention provides a conductive diamond electrode having: a conductive substrate; a coating layer formed on a surface of the conductive substrate, the coating layer containing one of a metal and an alloy each including at least one of niobium and tantalum; and a conductive diamond layer formed on a surface of the coating layer, and a process for producing the conductive diamond electrode.

Owner:DE NORA PERMELEC LTD

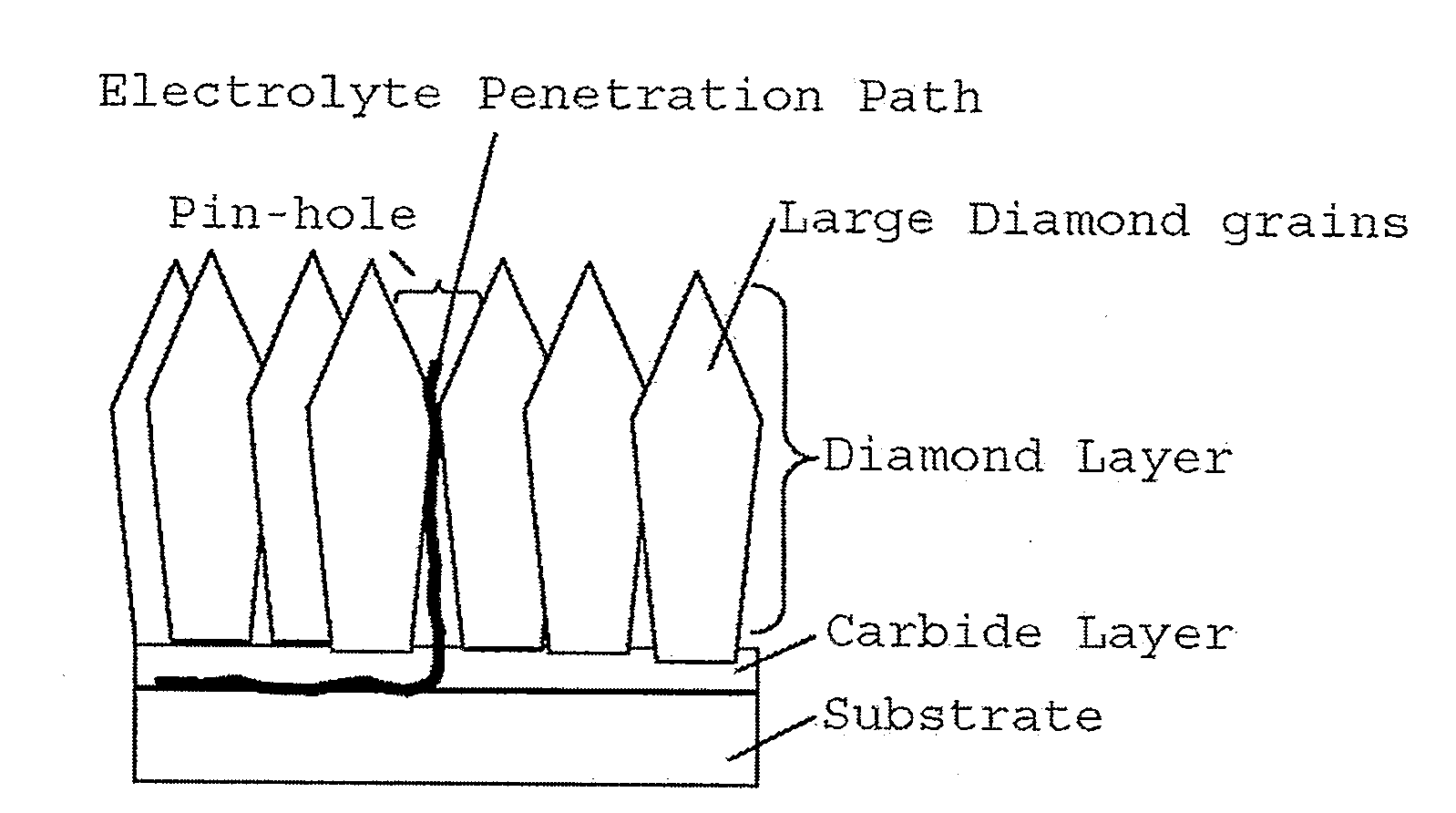

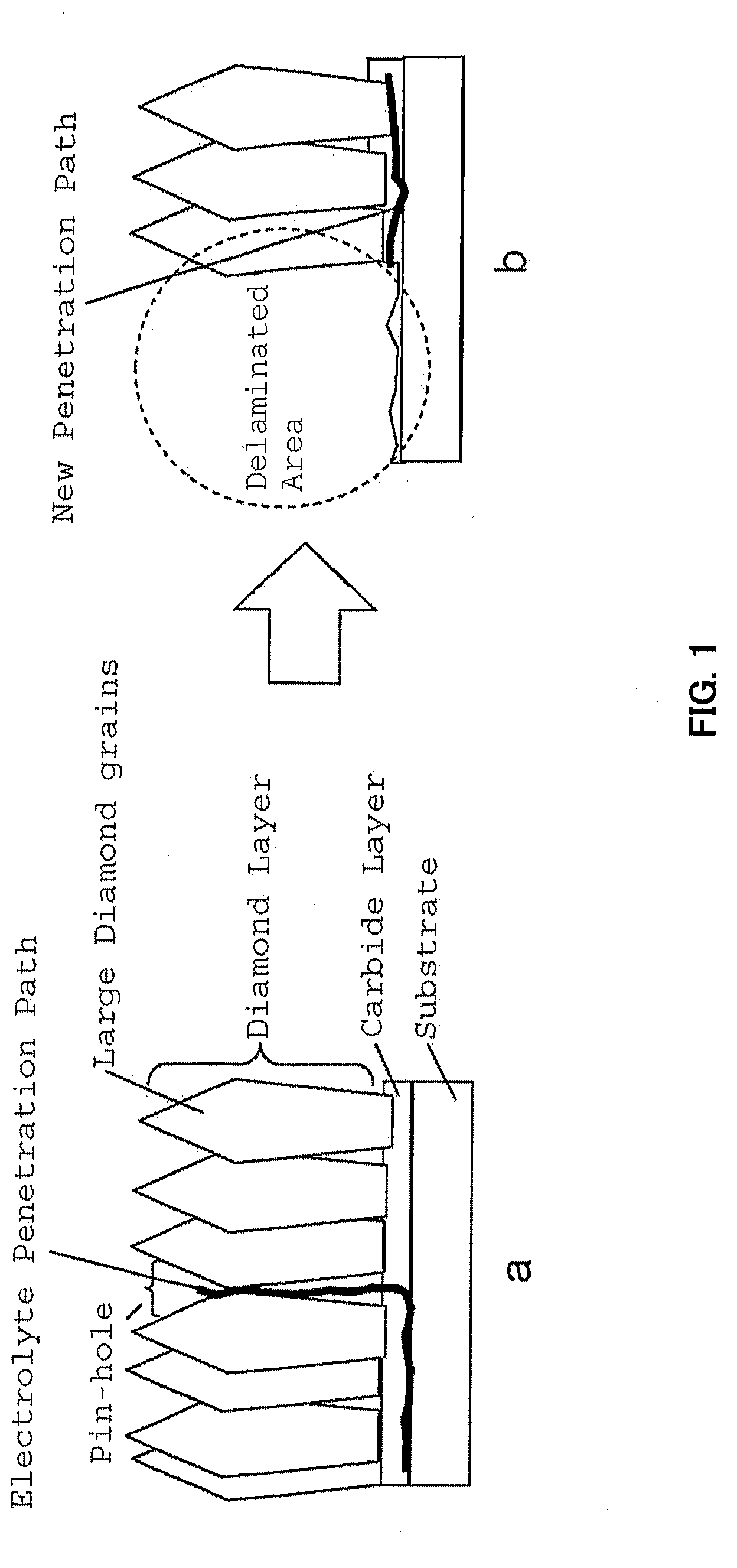

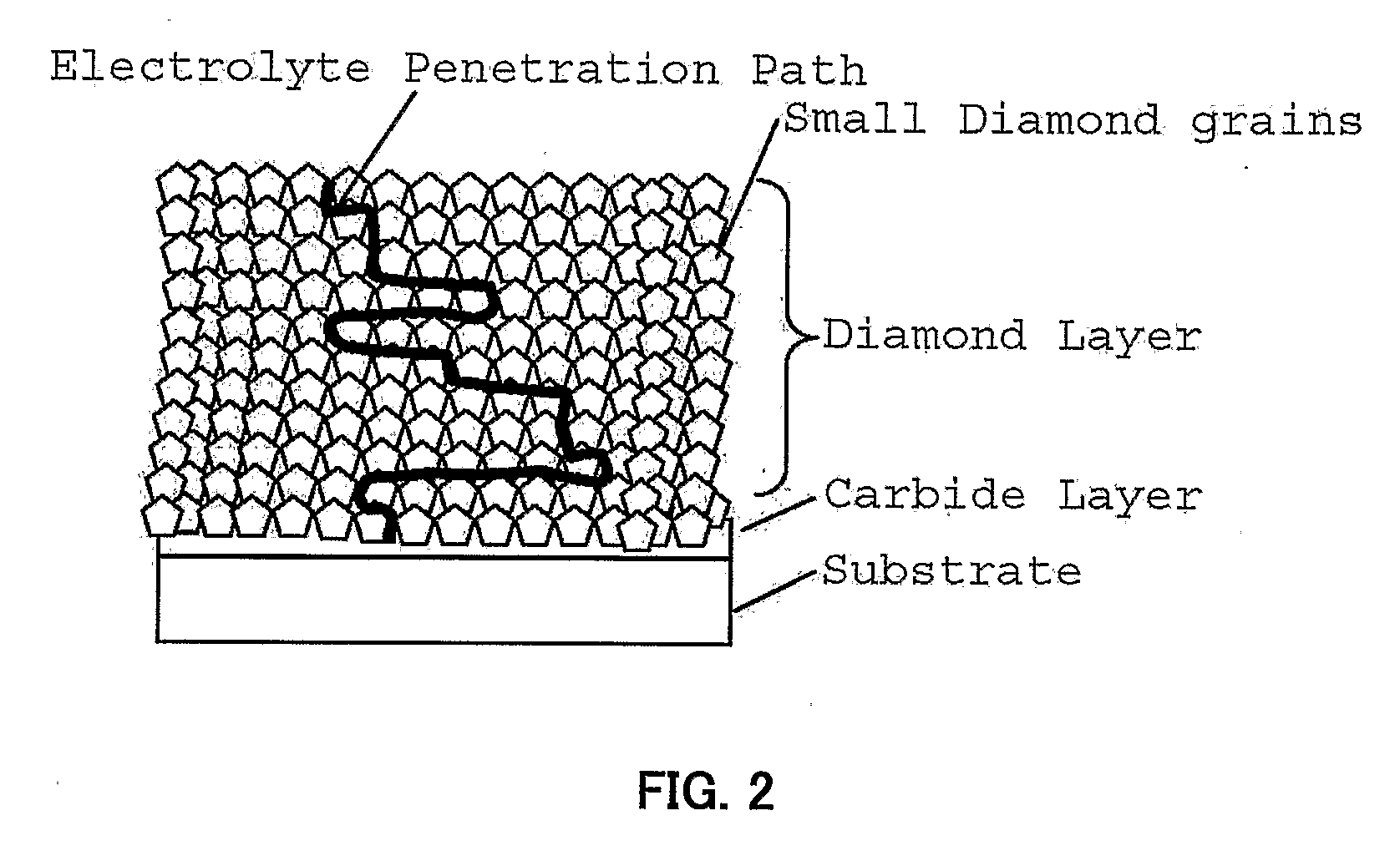

Method for production of diamond electrodes

InactiveUS20090324810A1Reduced stabilityReduced life-timeSpecial surfacesChemical vapor deposition coatingElectrochemical responseDiamond electrodes

The invention is related to the method for production of diamond electrode with improved stability for use in electrochemical reaction. The method concerns to the production of diamond electrodes where the diamond layer is composed of small sized grain, avoiding the delamination problems found in conventional diamond electrodes.

Owner:EBARA CORP +1

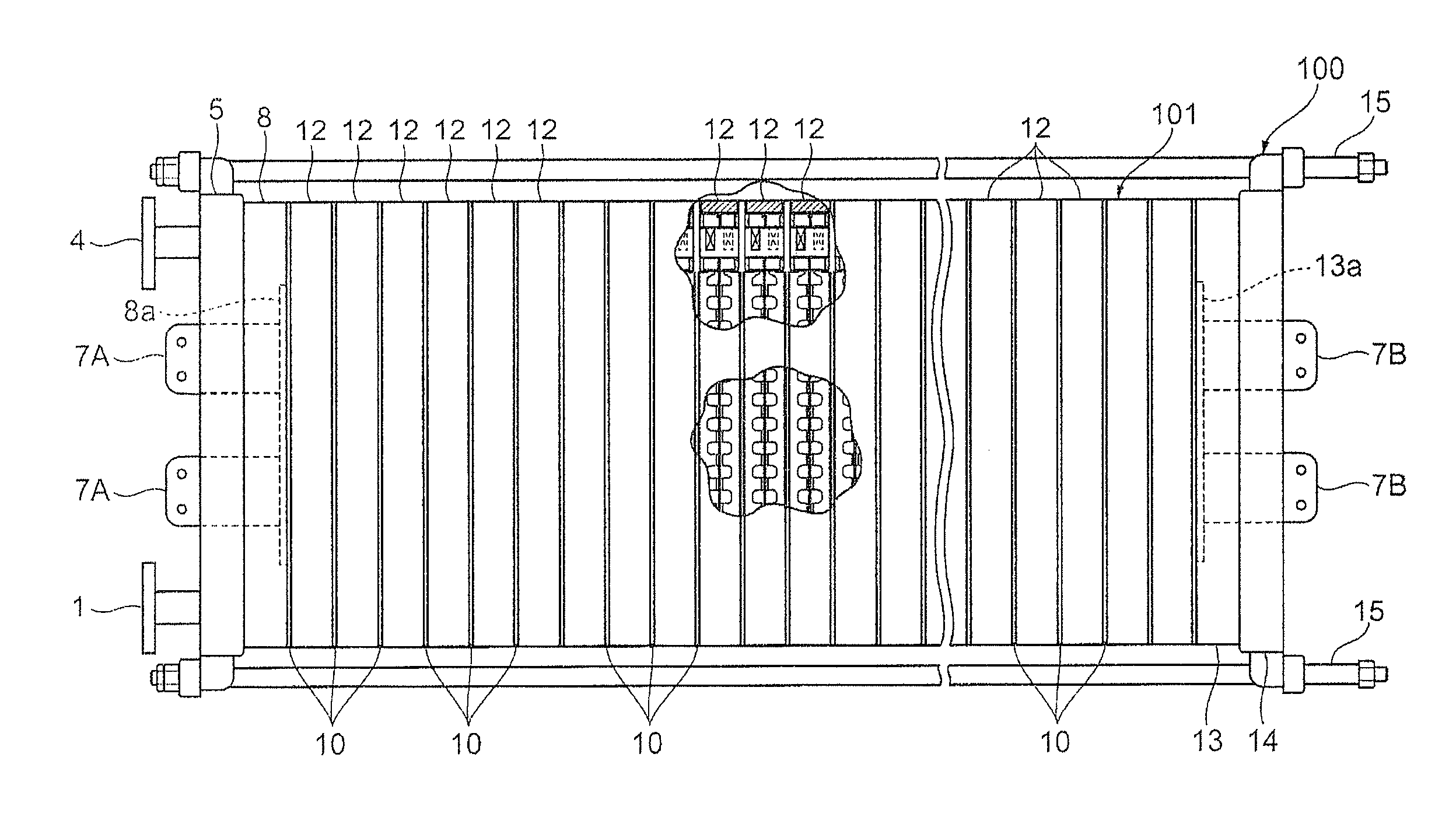

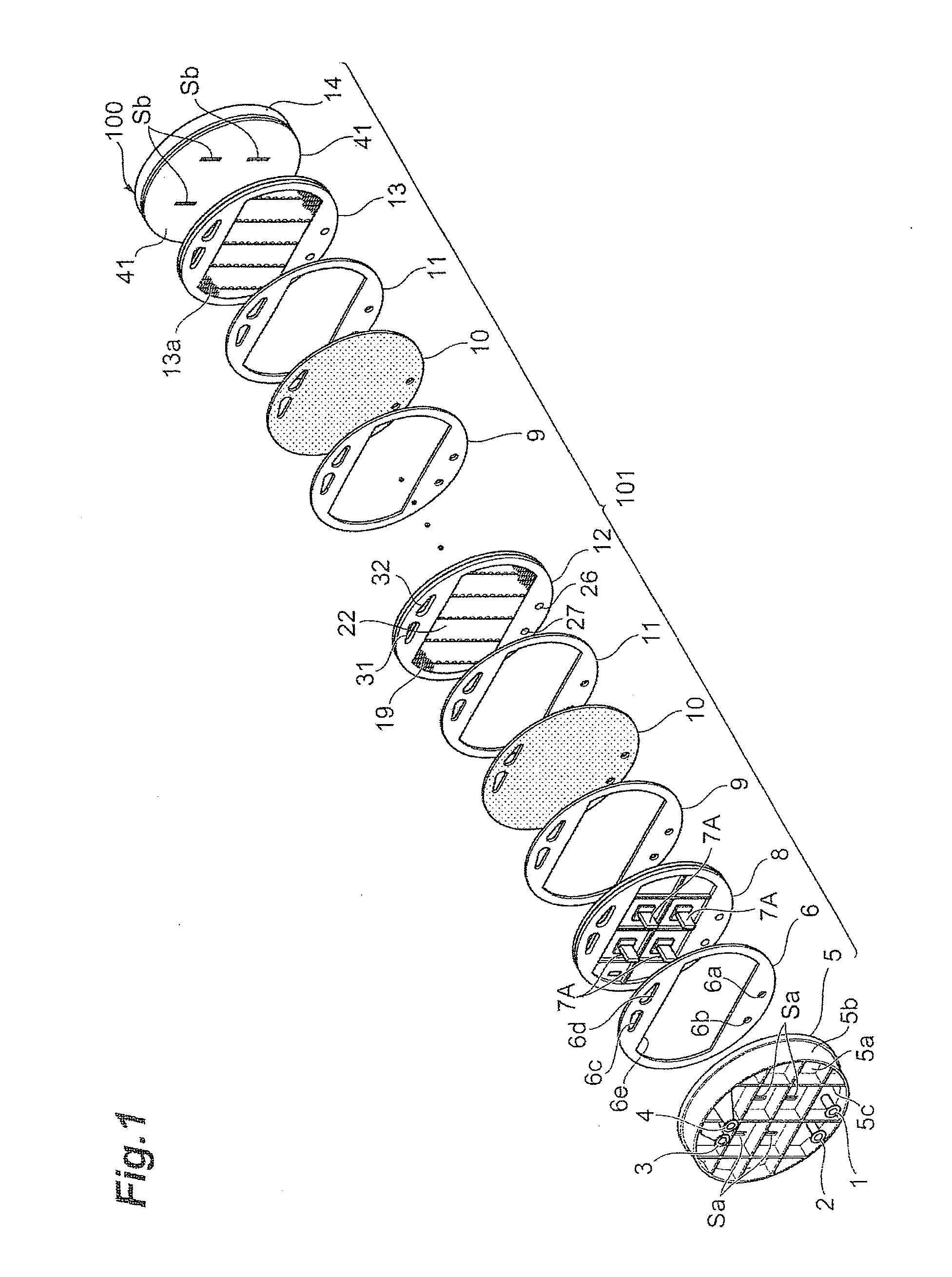

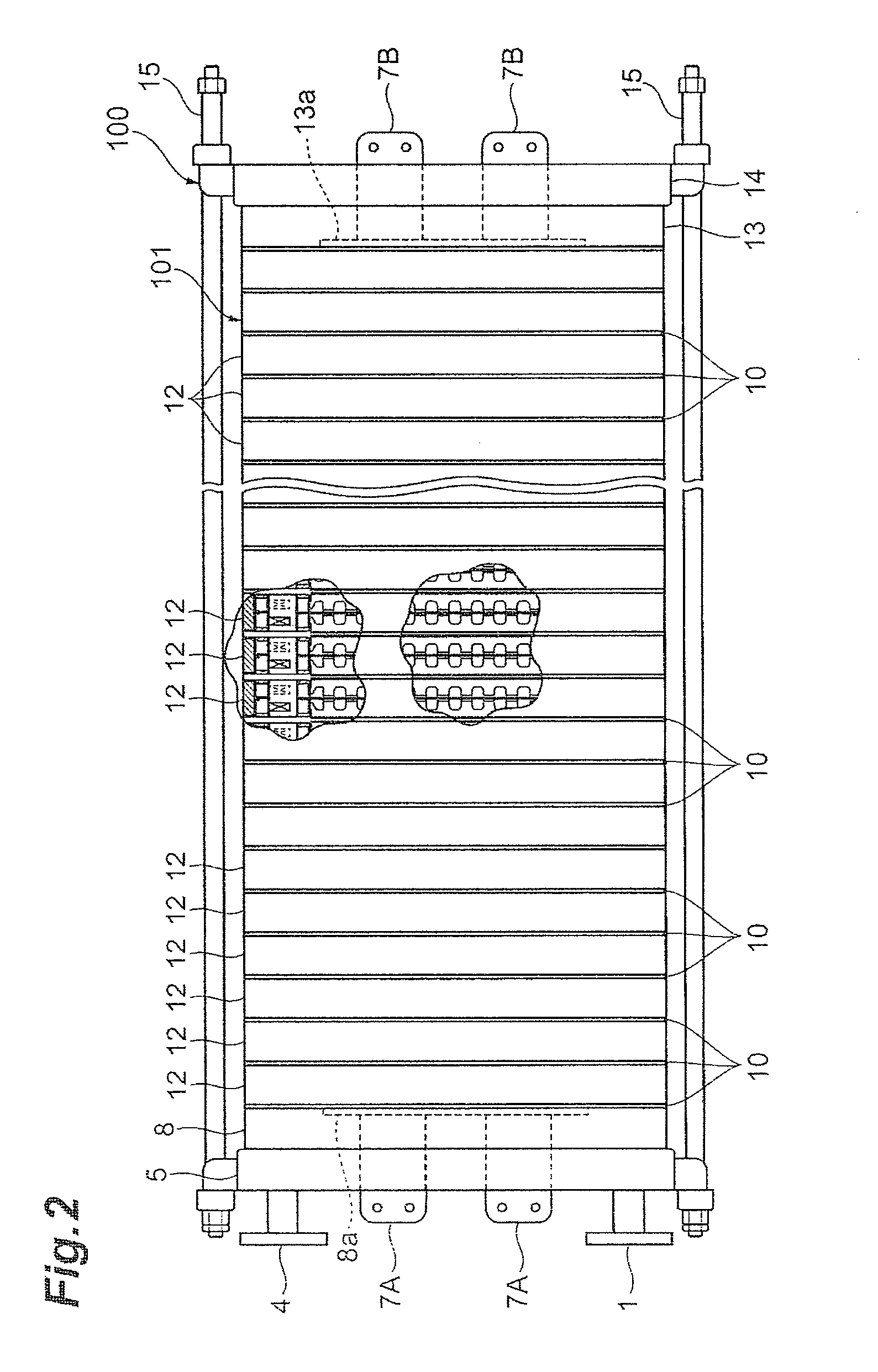

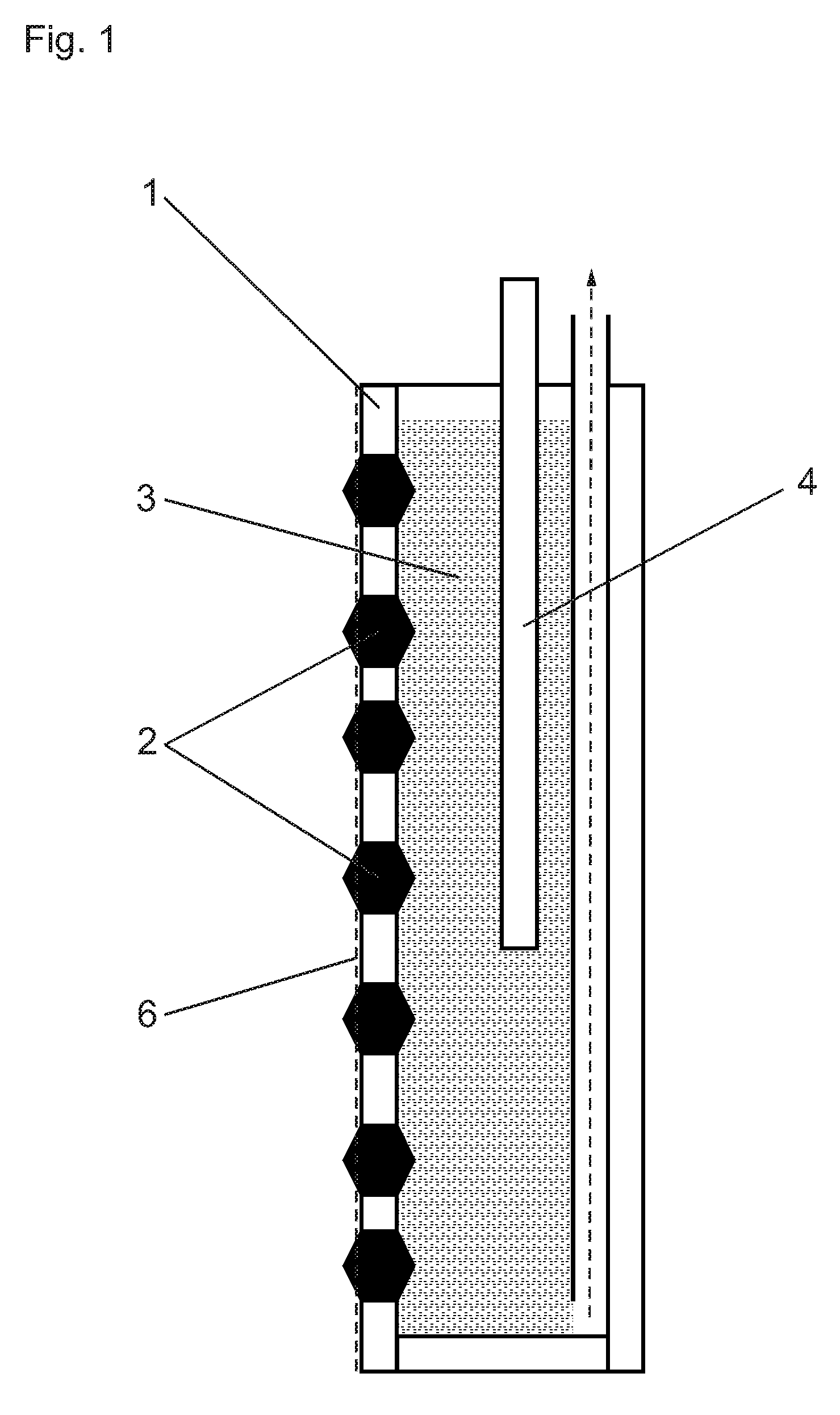

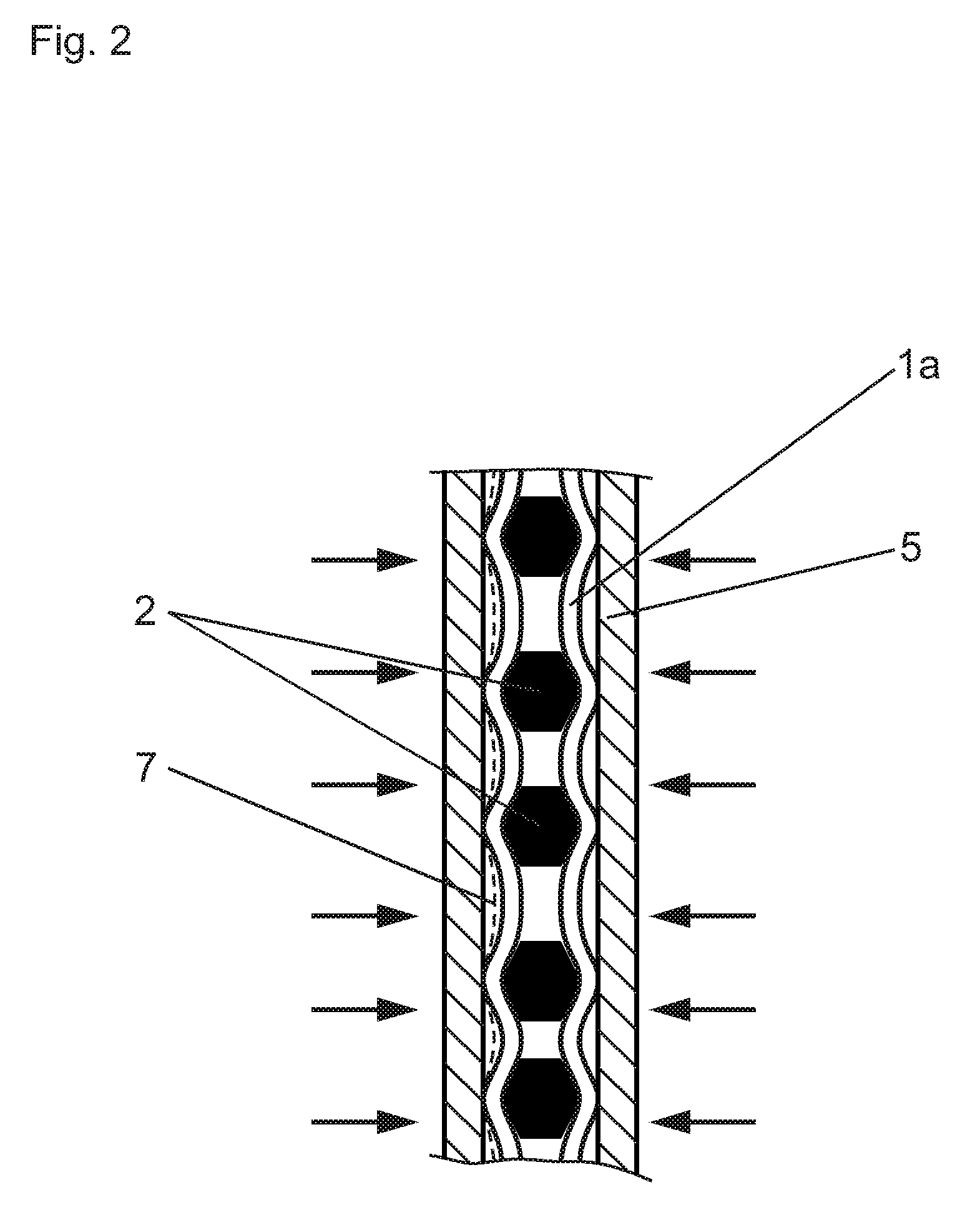

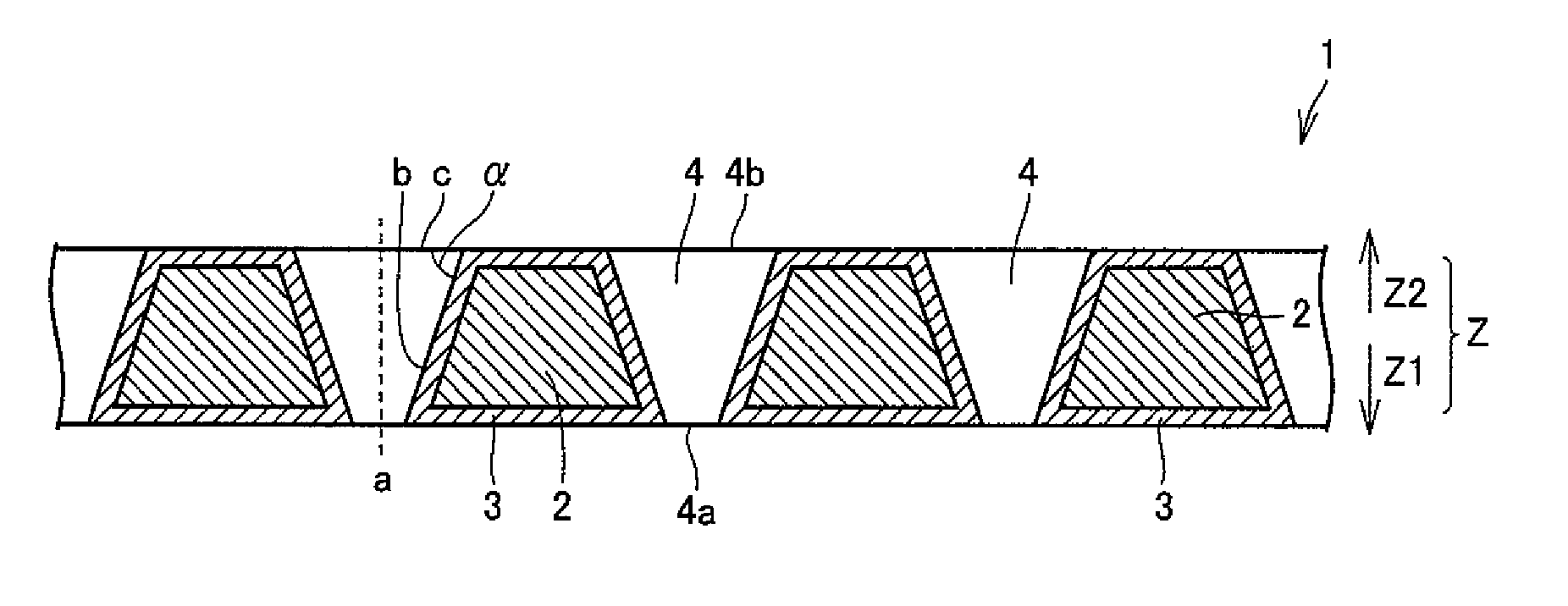

Bipolar alkaline water electrolysis unit and electrolytic cell

ActiveUS20150203976A1Easy to assembleReduce facility costsCellsElectrode shape/formsAlkaline waterHydrogen

A bipolar alkaline water electrolysis unit incorporated in an electrolytic cell for electrolyzing an electrolytic solution of alkaline water to obtain oxygen and hydrogen, the bipolar alkaline water electrolysis unit including an oxygen generating anode, a hydrogen generating cathode, a conductive partition wall that separates the anode and the cathode from each other, and an outer frame that surrounds the conductive partition wall, wherein a gas and electrolytic solution passage is provided at an upper portion of the conductive partition wall and / or the outer frame, and an electrolytic solution passage is provided at a lower part of the conductive partition wall and / or the outer frame.

Owner:ASAHI KASEI KK

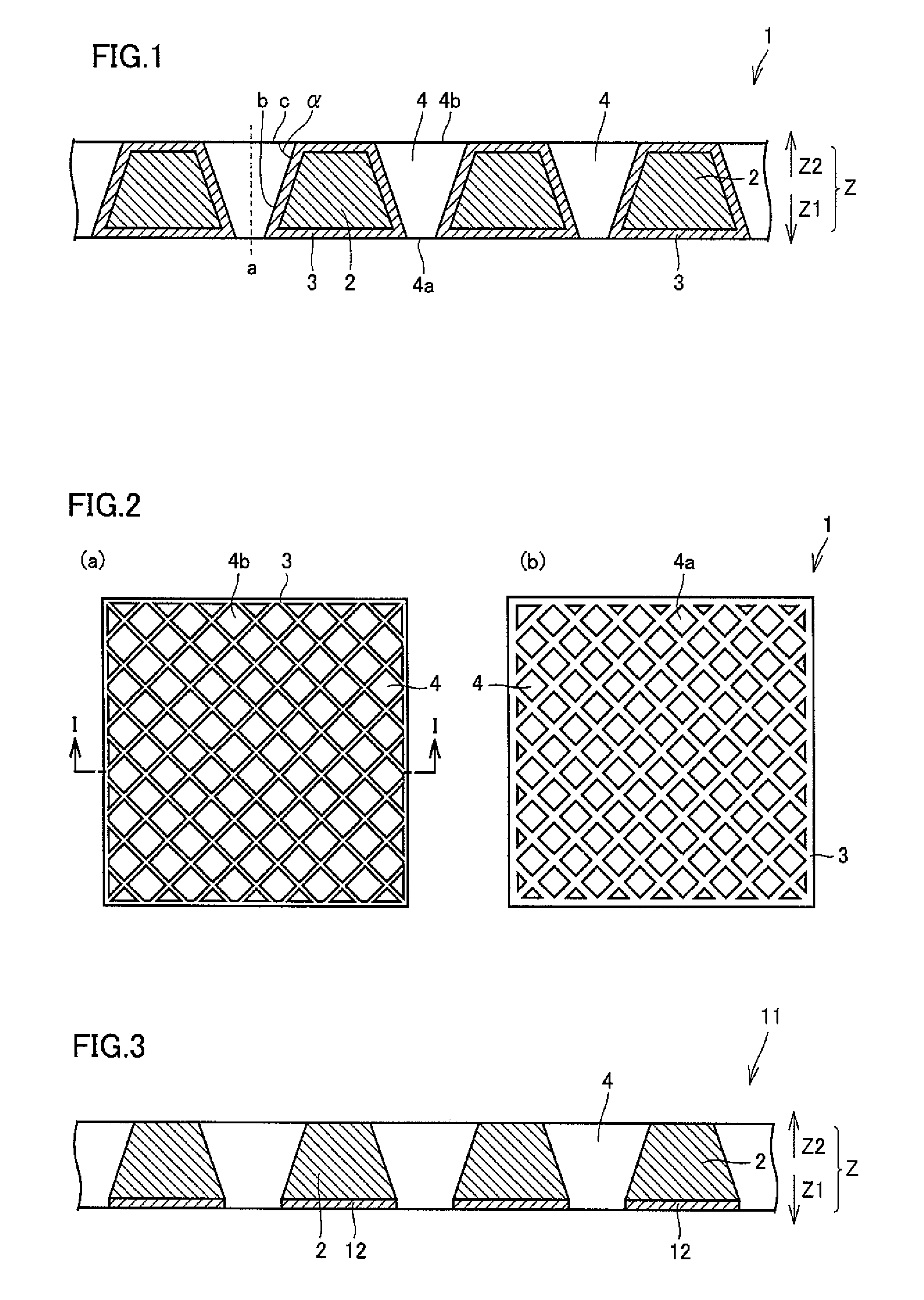

Diamond electrode, method for producing same, and electrolytic bath

InactiveUS20090301865A1Low production costImprove electrolysis efficiencyCellsElectrode shape/formsDiamond electrodesSilicon

A diamond electrode includes a conductive silicon substrate having a plurality of pores. The diamond electrode also includes a conductive diamond covering the conductive silicon substrate. The inner wall surfaces of the plurality of pores are at an angle of 60° to 85° with respect to a substrate of the conductive silicon substrate.

Owner:SUMITOMO ELECTRIC HARDMETAL CORP

Conductive diamond electrode and process for producing the same

ActiveUS7273536B2Increased durabilityMachining electrodesSurface reaction electrolytic coatingDiamond electrodesAlloy

A conductive diamond electrode including an electrode substrate comprising a material selected from the group consisting of a valve metal and an alloy based on the valve metal, at least a surface of the metal or alloy having been subjected to plasticization processing, or heat treatment in vacuum or inert atmosphere; and a conductive diamond film formed on the plasticization processed surface of the electrode substrate. When the electrode substrate is subjected to plasticization processing and heat treatment, peeling resistance of the conductive diamond film is improved, thereby an electrode life is prolonged.

Owner:DE NORA PERMELEC LTD

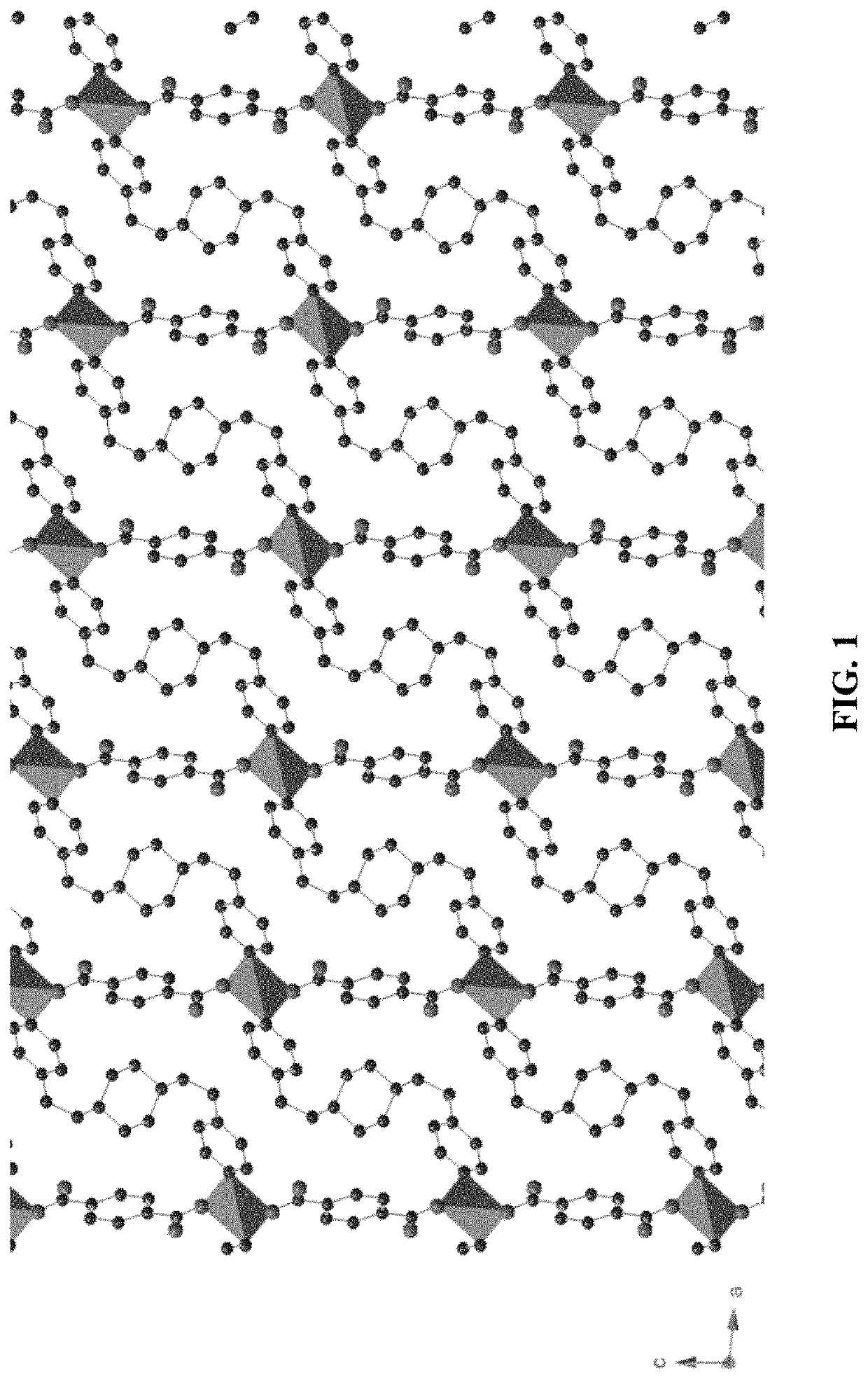

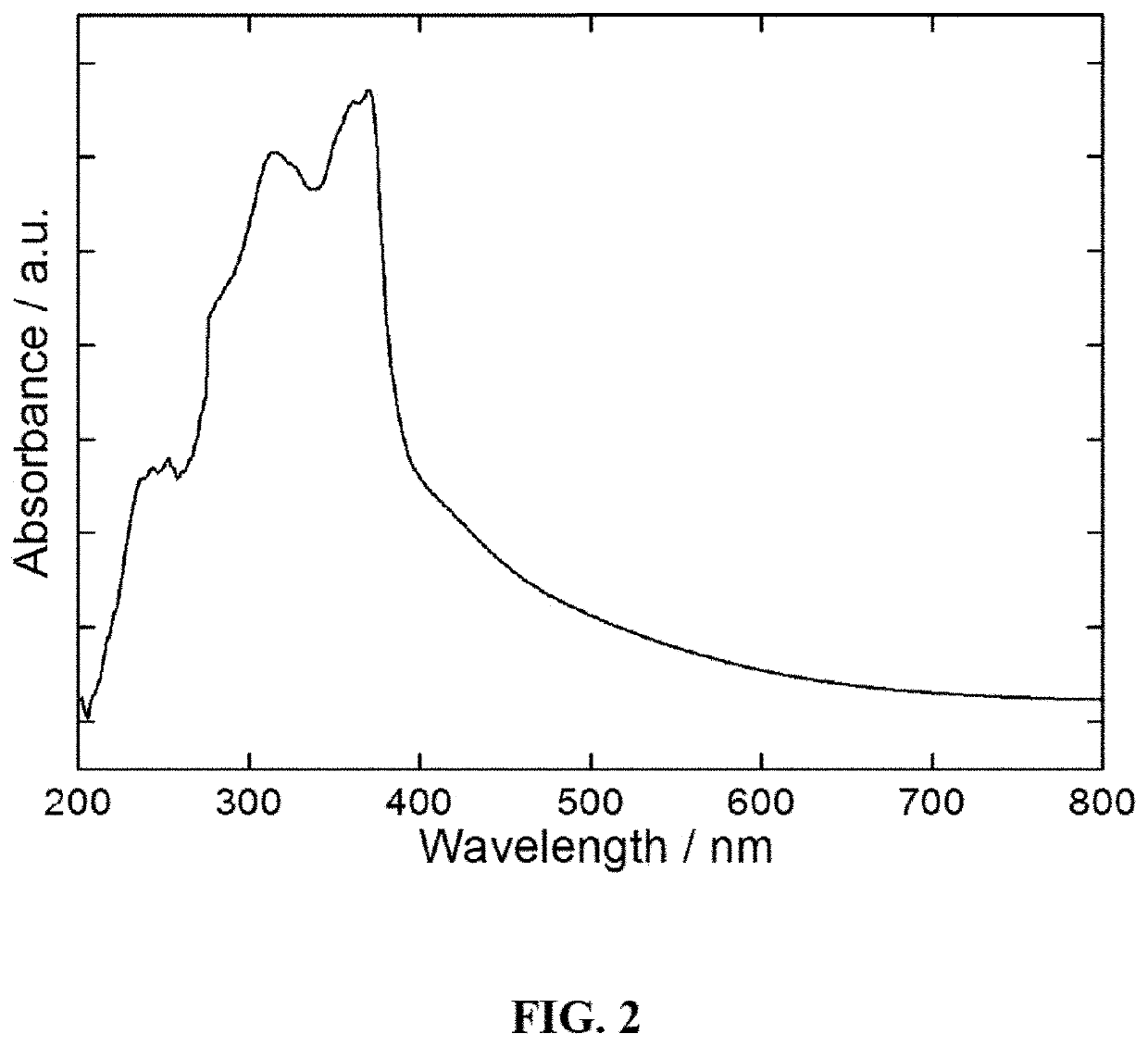

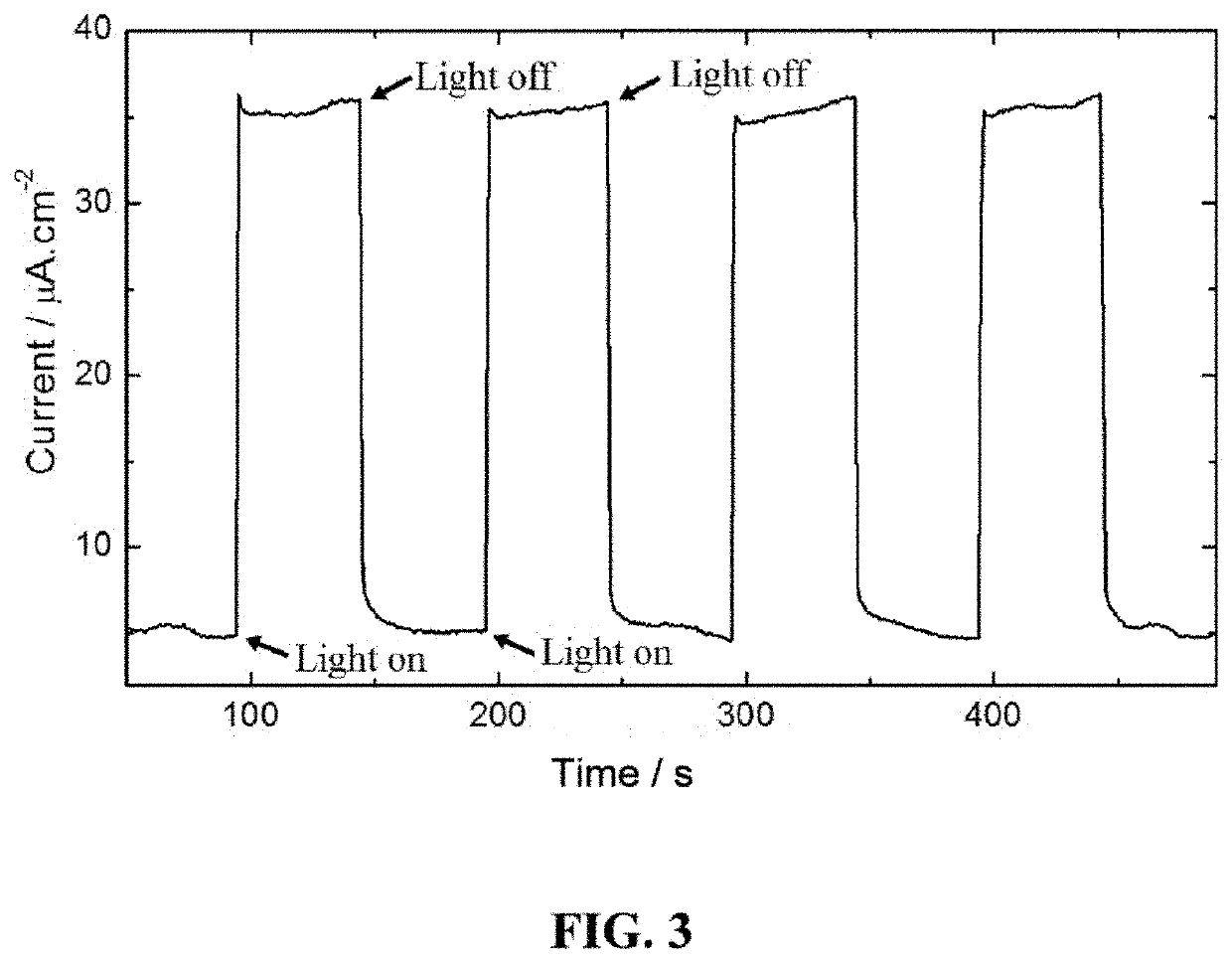

Water stable zinc-based metal organic framework and method of use

ActiveUS20200190114A1Organic-compounds/hydrides/coordination-complexes catalystsEnergy inputMetal-organic frameworkEngineering

A zinc-based metal organic framework and method of making is described. The zinc-based metal organic framework is in the form of an interpenetrating diamondoid framework where each Zn2+ ion center is linked with four other Zn2+ ion centers in a distorted tetrahedral geometry. The linking occurs through diamine and dicarboxylic acid linkers. The zinc-based metal organic framework may be deposited on a transparent conducting film and used as a photoelectrode for photoelectrochemical water splitting.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

Conductive diamond electrode and process for producing the same

ActiveUS20050186345A1Increased durabilityMachining electrodesLiquid separation by electricityElectrical resistance and conductanceDiamond electrodes

A conductive diamond electrode including an electrode substrate comprising a material selected from the group consisting of a valve metal and an alloy based on the valve metal, at least a surface of the metal or alloy having been subjected to plasticization processing, or heat treatment in vacuum or inert atmosphere; and a conductive diamond film formed on the plasticization processed surface of the electrode substrate. When the electrode substrate is subjected to plasticization processing and heat treatment, peeling resistance of the conductive diamond film is improved, thereby an electrode life is prolonged.

Owner:DE NORA PERMELEC LTD

Electrolytic anode and method for electrolytically synthesizing fluorine containing substance using the electrolytic anode

ActiveUS20060219570A1Synthetic strongSuppress generationMachining electrodesElectrical-based machining electrodesSubstance useFluoride

The present invention provides an electrolytic anode for use in electrolytically synthesizing a fluorine-containing substance by using an electrolytic bath containing a fluoride ion including: an electroconductive substrate having a sure including an electroconductive carbonaceous material; and an electroconductive carbonaceous film having a diamond structure, the electroconductive carbonaceous film coating a part of the electroconductive carbonaceous substrate, and a method for electrolytically synthesizing a fluorine-containing substance using the electrolytic anode.

Owner:TOYO TANSO KK +1

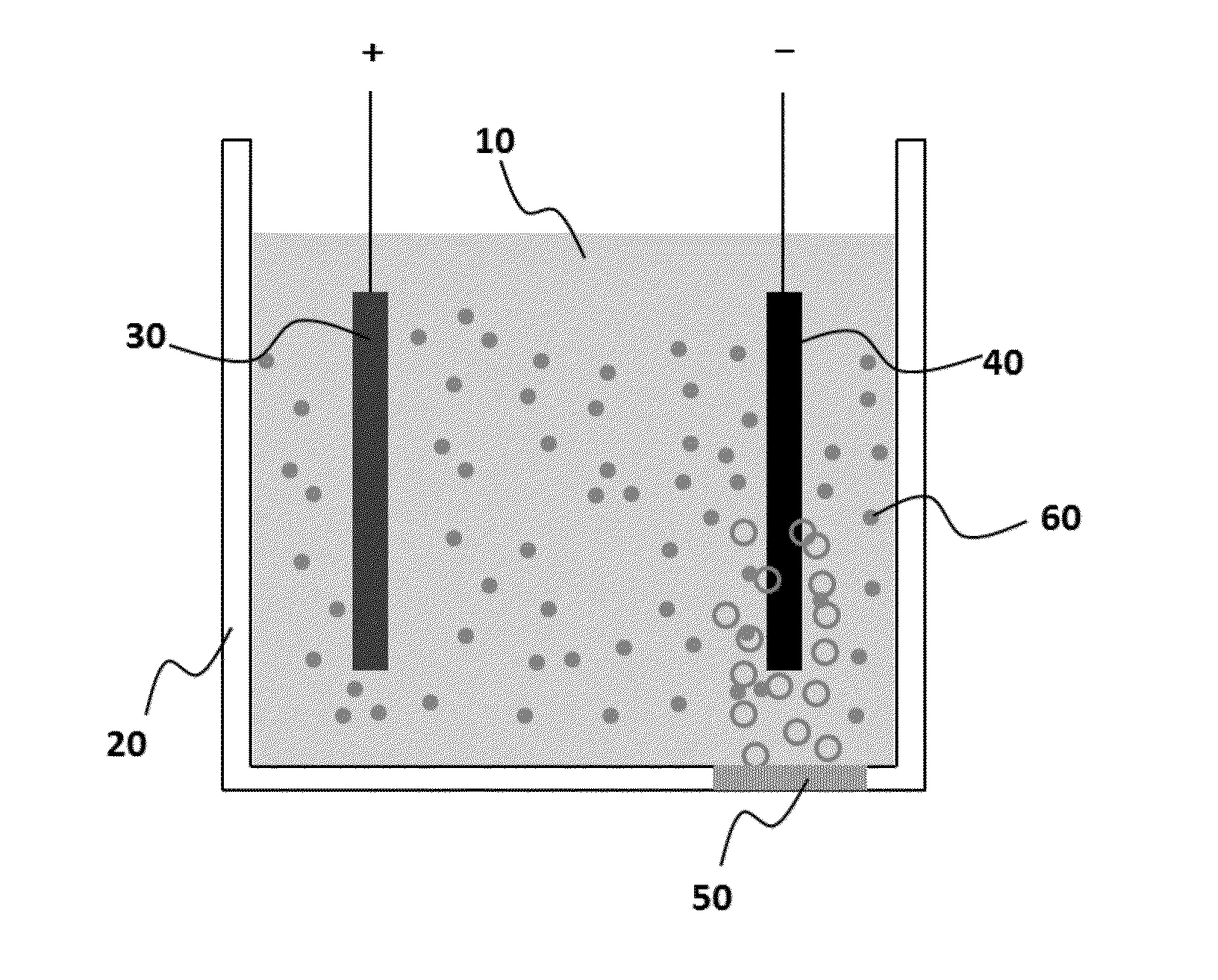

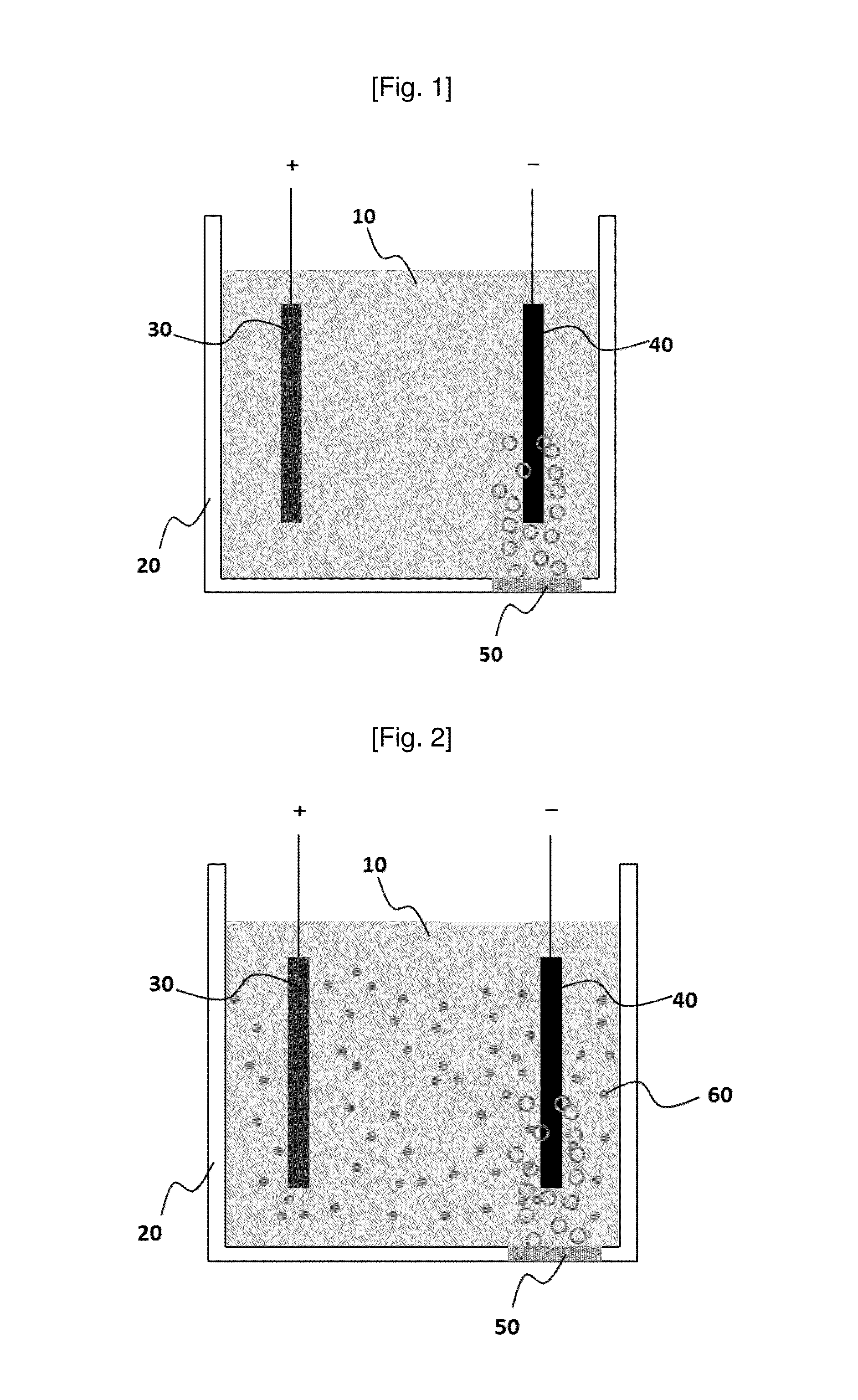

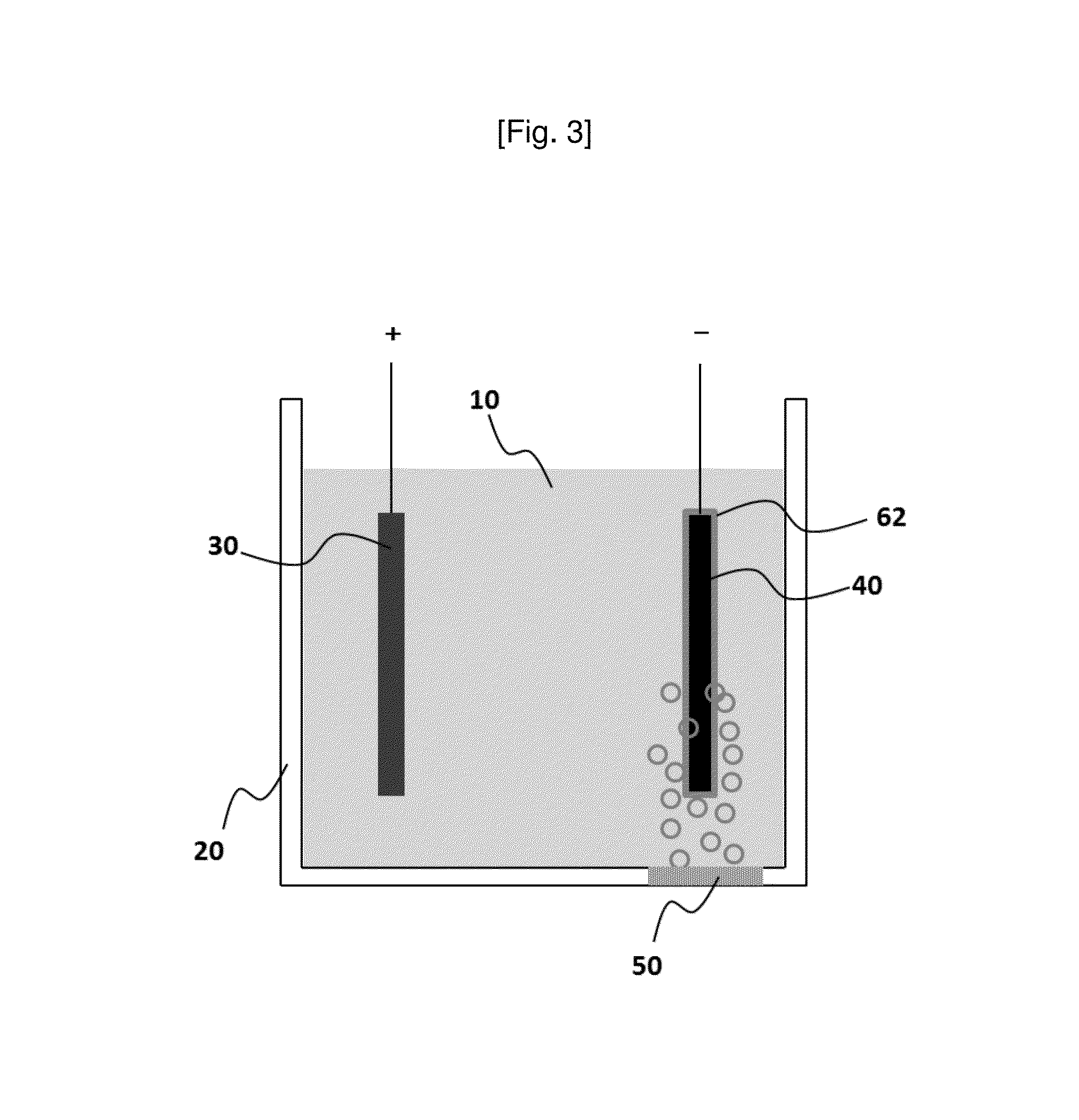

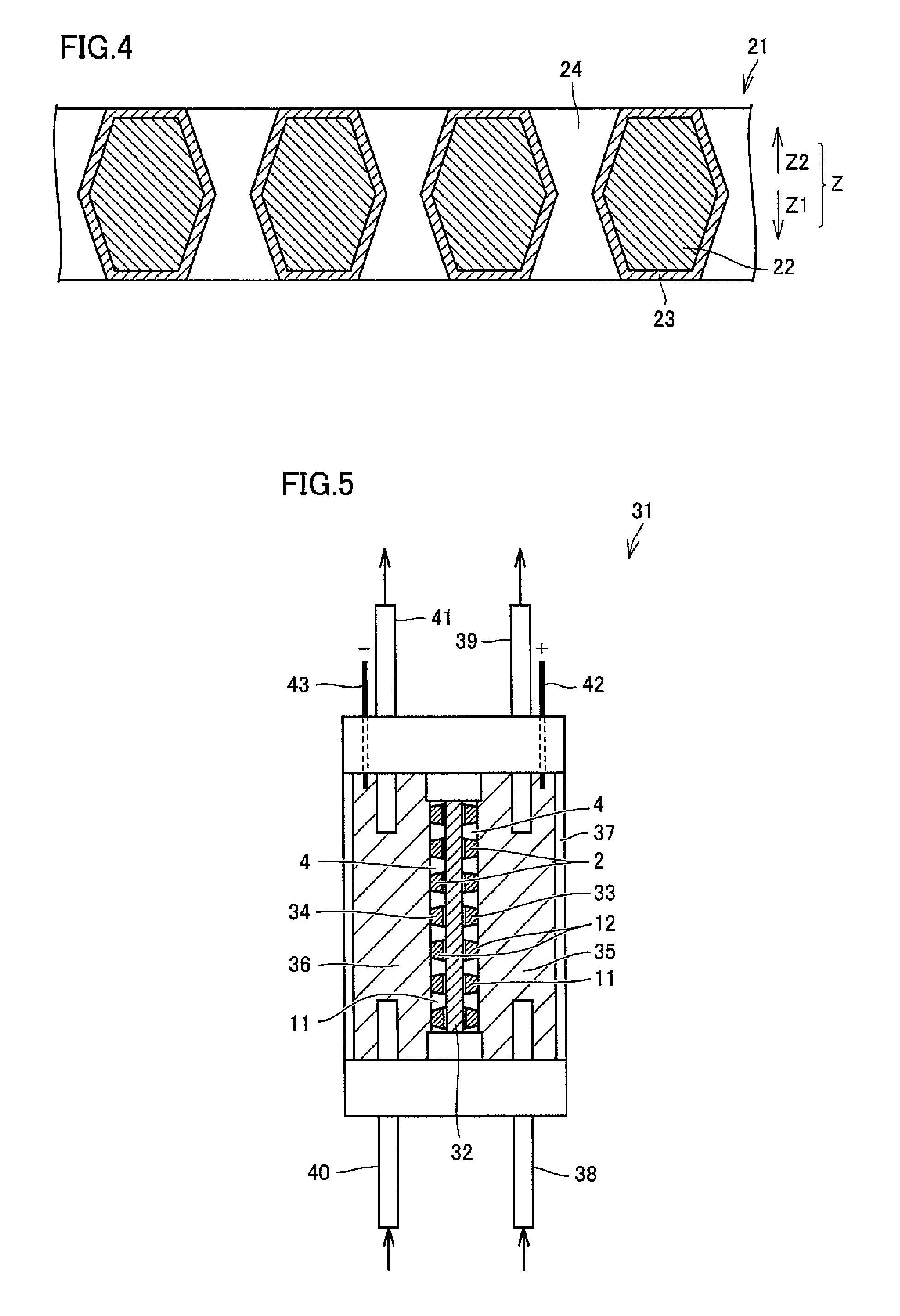

Apparatus for synthesizing ammonia

ActiveUS20160138176A1Easy to controlIncrease productionCellsElectrode coatingsElectrochemistryAmmonia

The present disclosure relates to an ammonia synthesis apparatus, and more particularly, to an electrochemical ammonia synthesis apparatus using an aqueous solution or a molten liquid of an alkali metal as an electrolyte. According to one or more embodiments, when an aqueous solution or a molten liquid of an alkali metal is used as an electrolyte in an ammonia synthesis apparatus, compositions, sizes, and shapes of an electrode and an electrolyte may be easily controlled, and thus a yield of ammonia synthesis may improve.

Owner:KOREA INST OF ENERGY RES

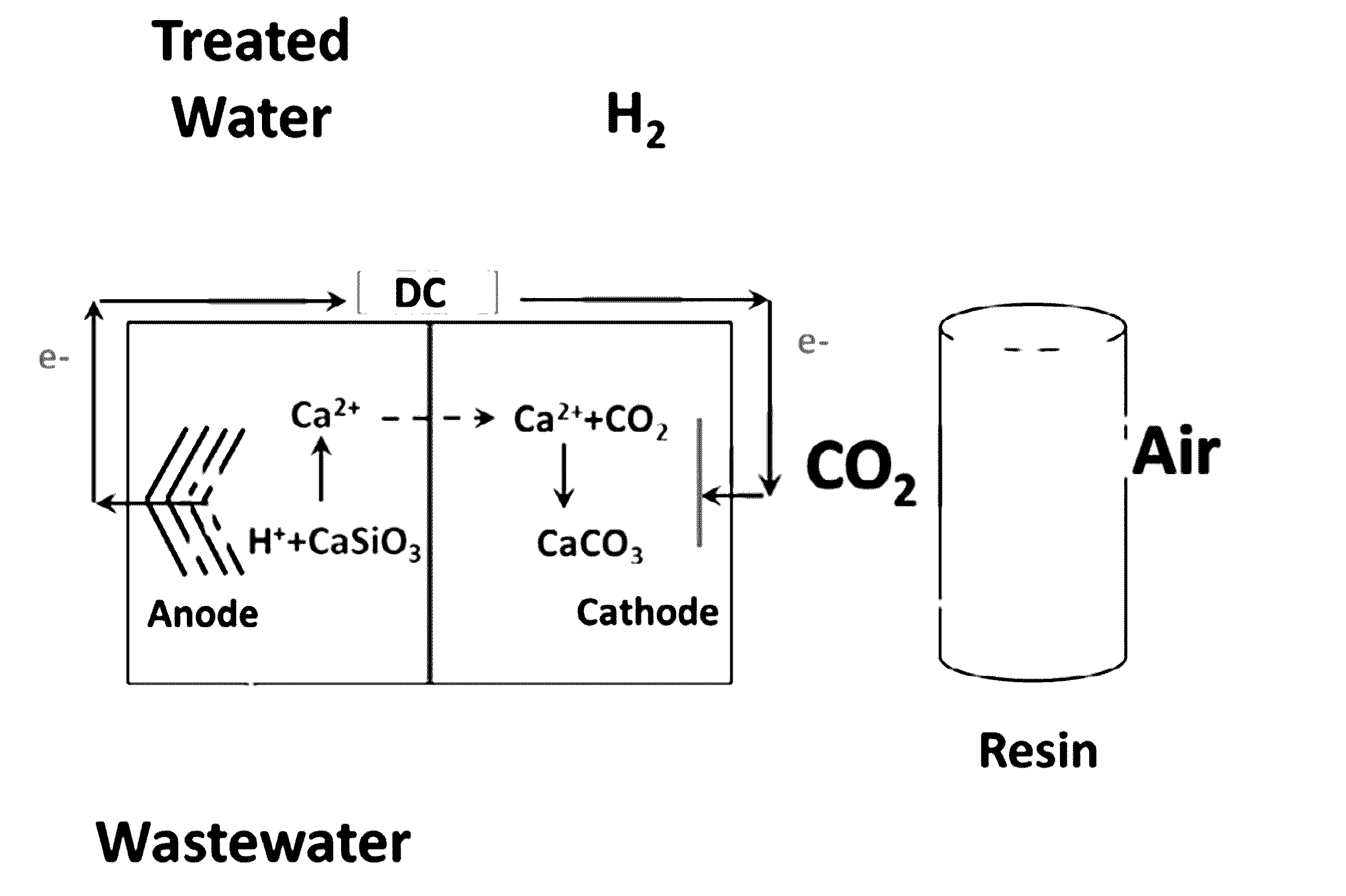

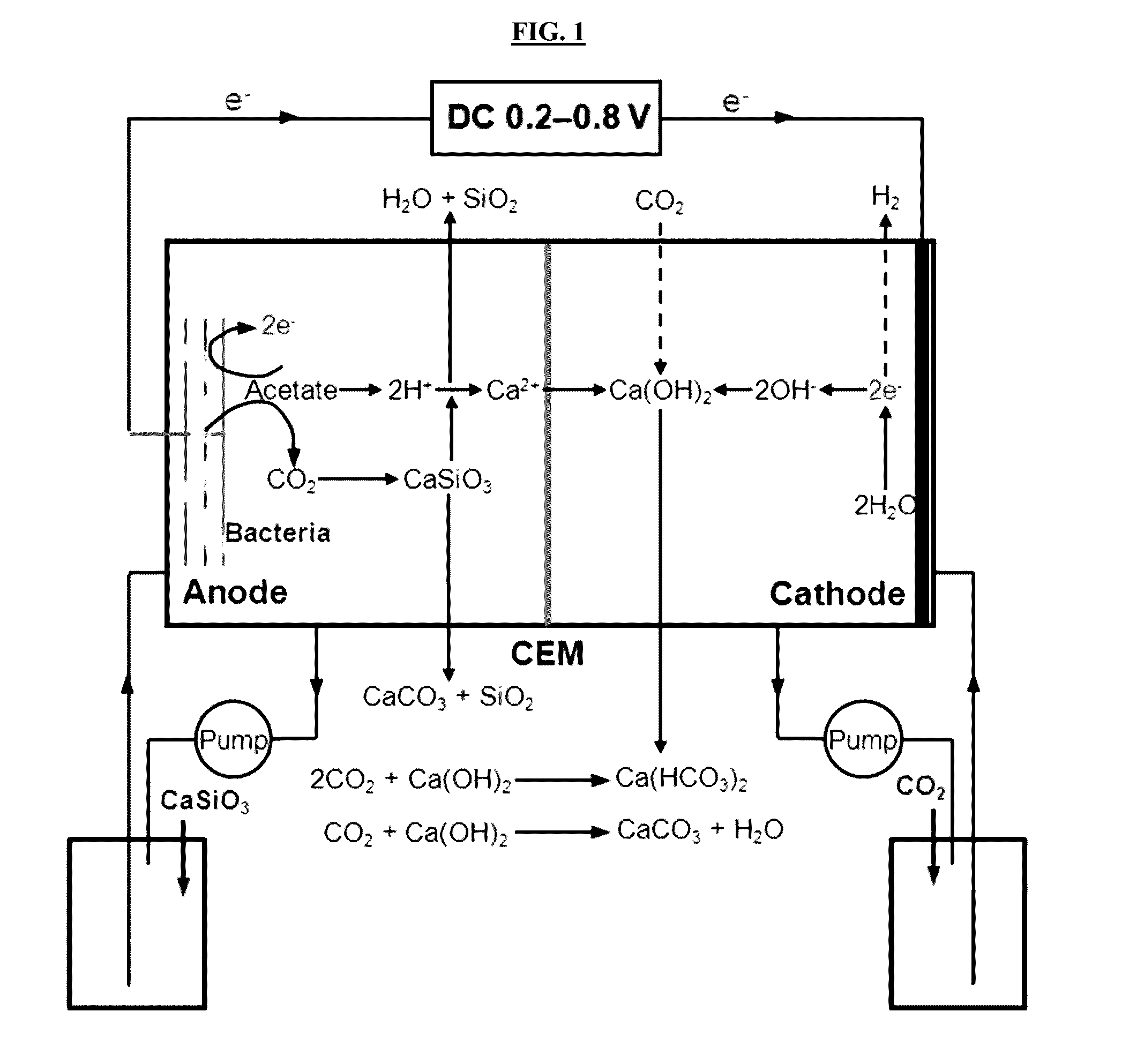

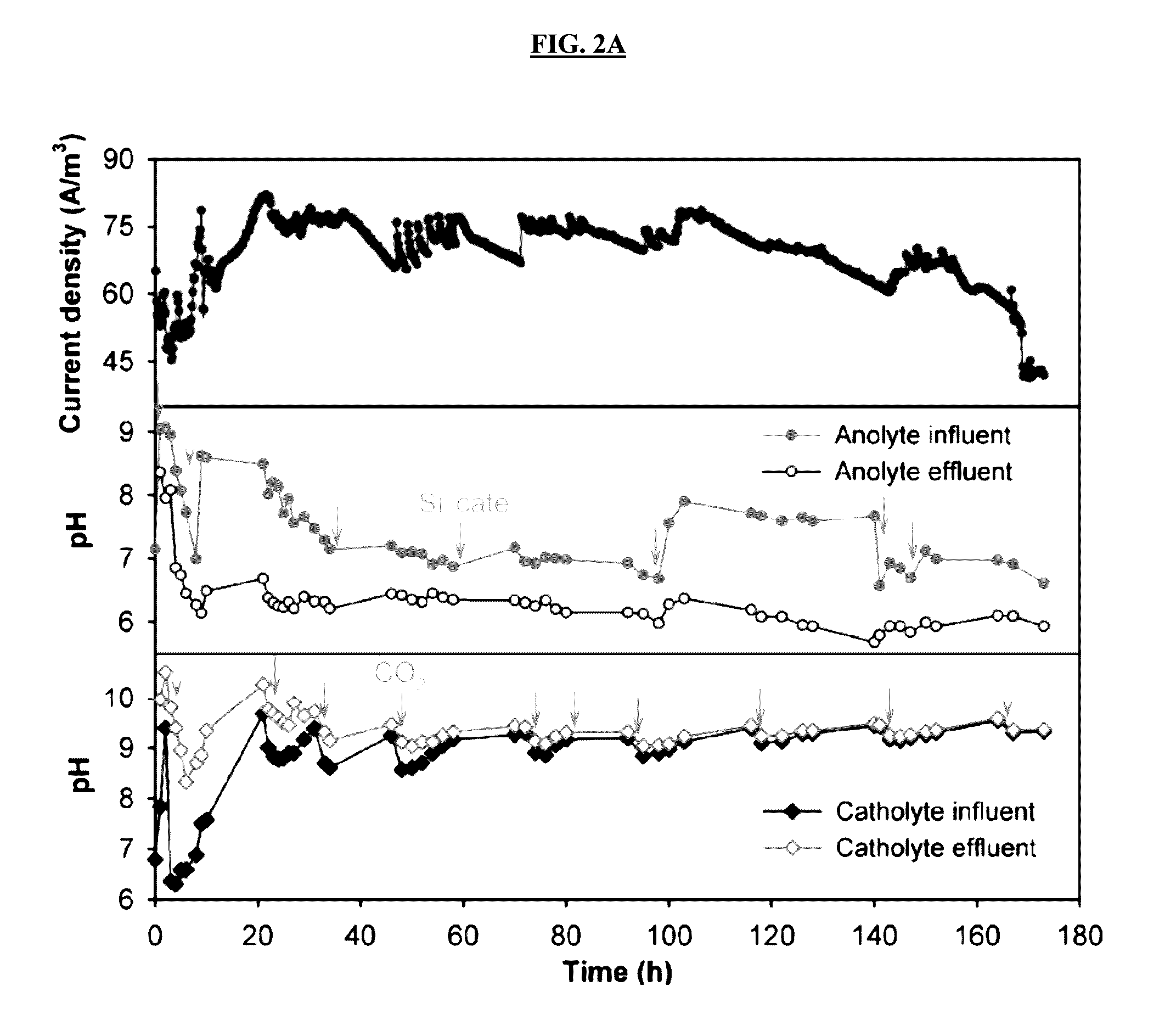

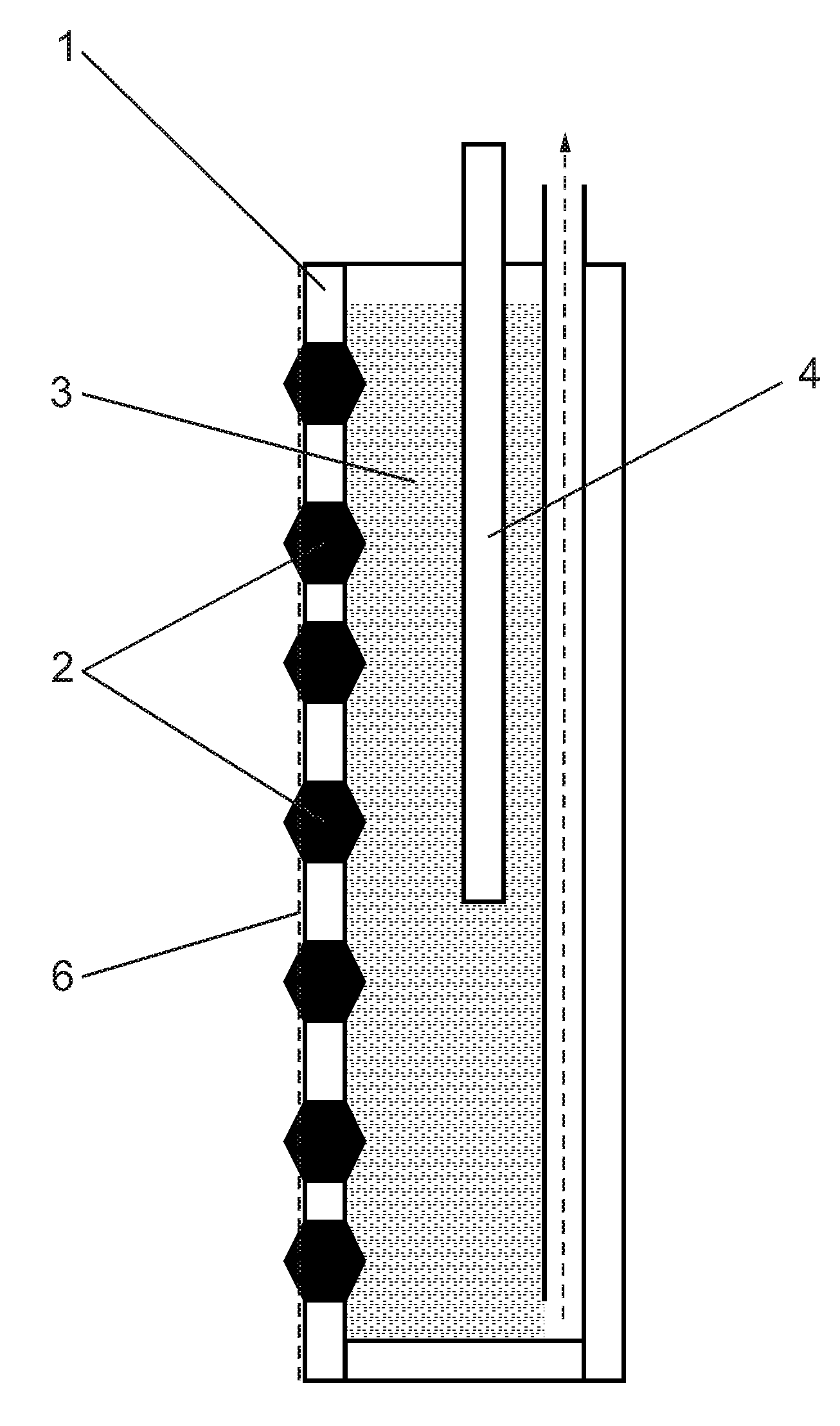

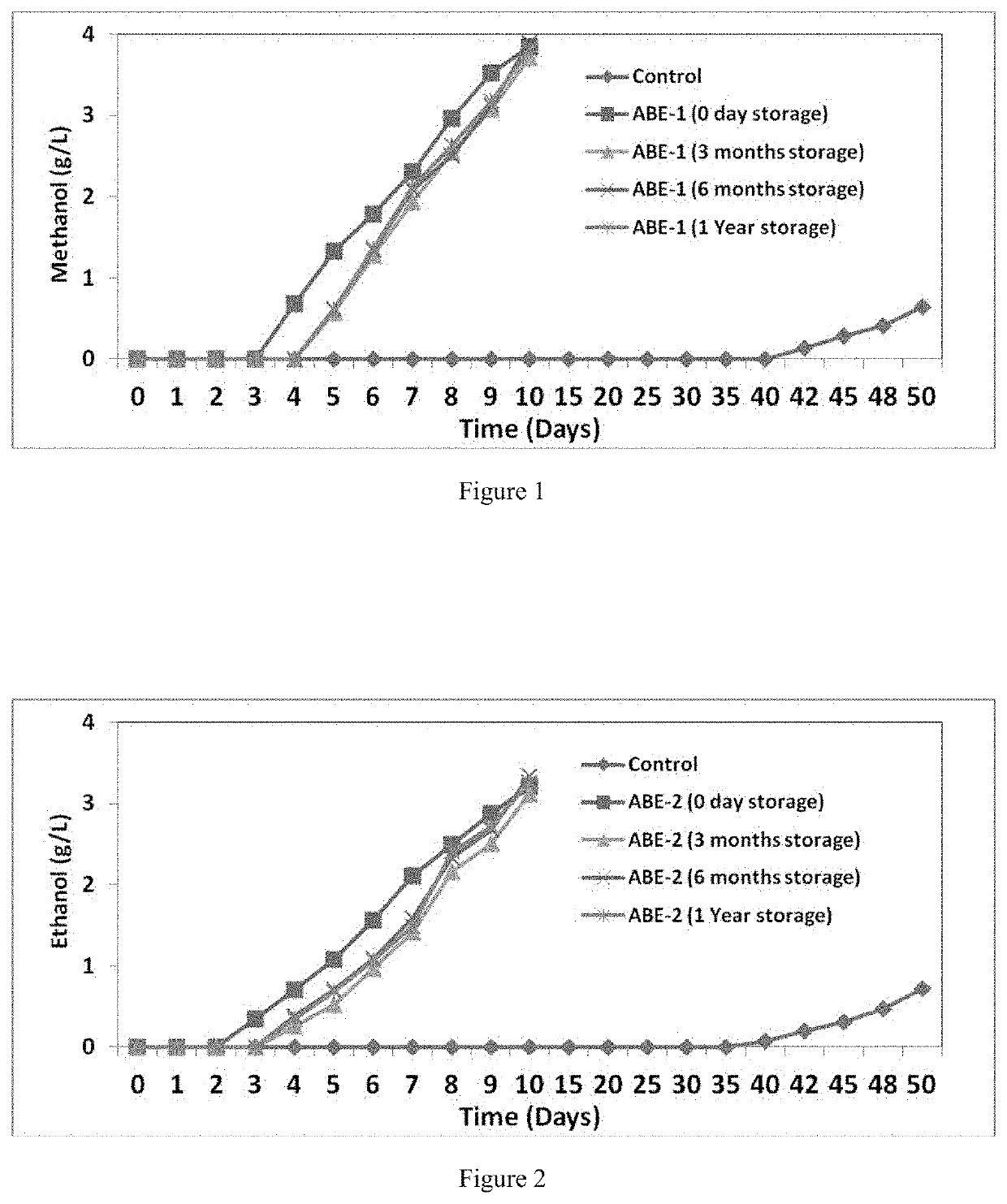

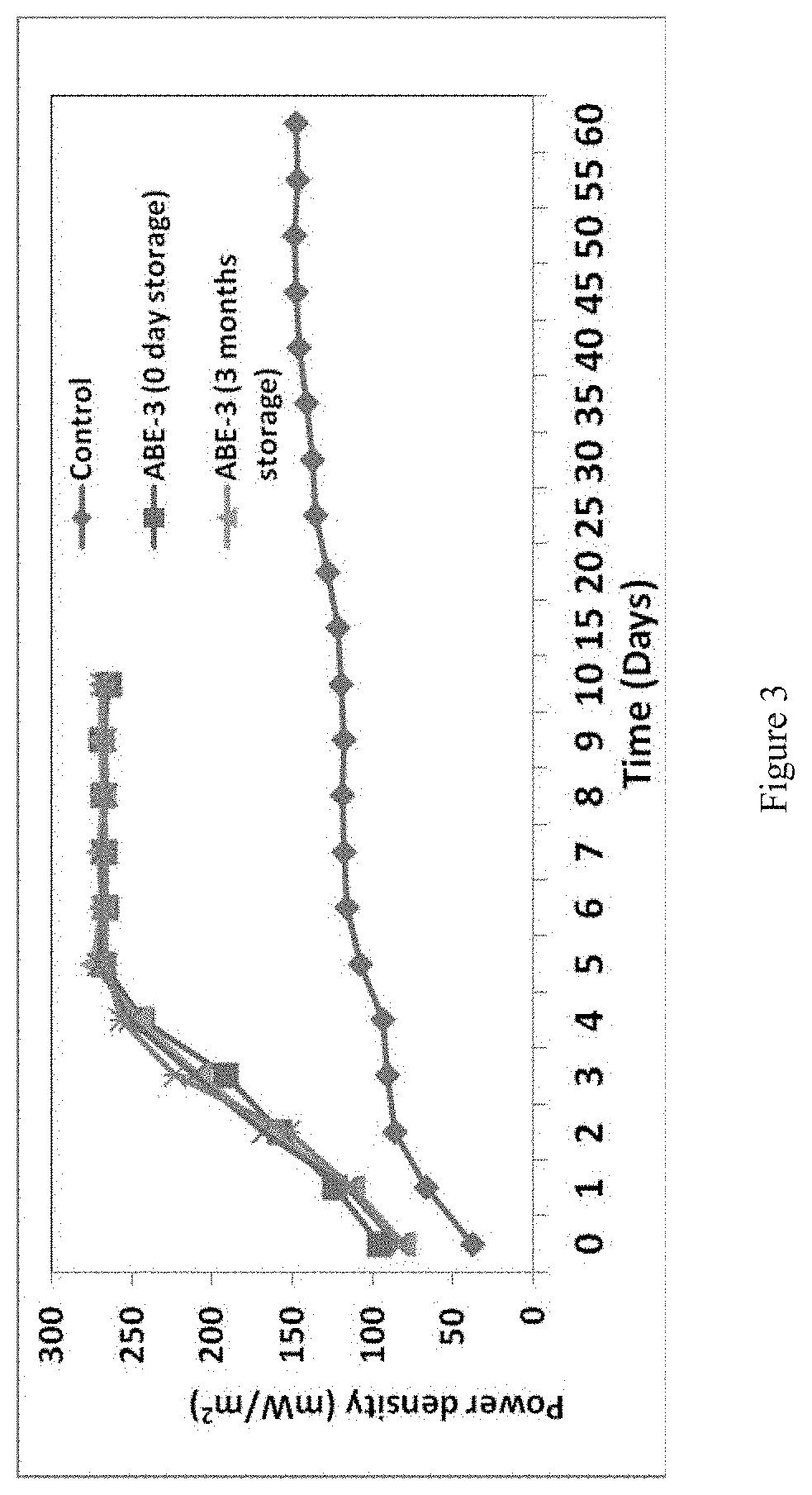

Carbon dioxide capture and storage electrolytic methods

ActiveUS20160362800A1Less solubleTreatment by combined electrochemical biological processesSeawater treatmentHydrogenWastewater

The present invention relates to the unexpected discovery of systems for capturing carbon dioxide and producing hydrogen gas. In certain embodiments, the system treats wastewater. In certain embodiments, the system captures and sequesters CO2 as carbonate salts.

Owner:UNIV OF COLORADO THE REGENTS OF

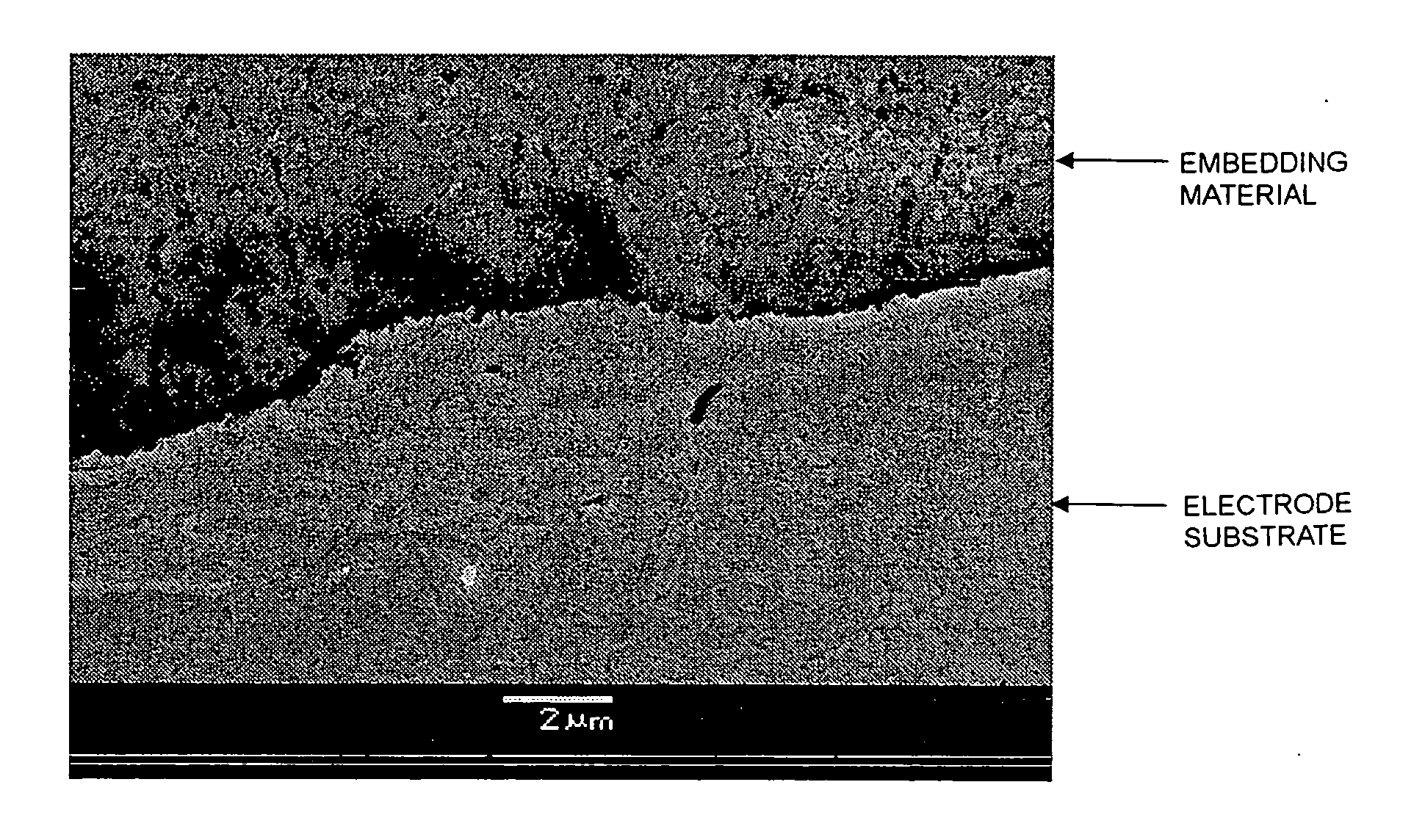

Method for the production of a diamond electrode, and diamond electrode

ActiveUS20100170783A1Smooth connectionSimple processMachining electrodesCell electrodesDiamond electrodesConductive materials

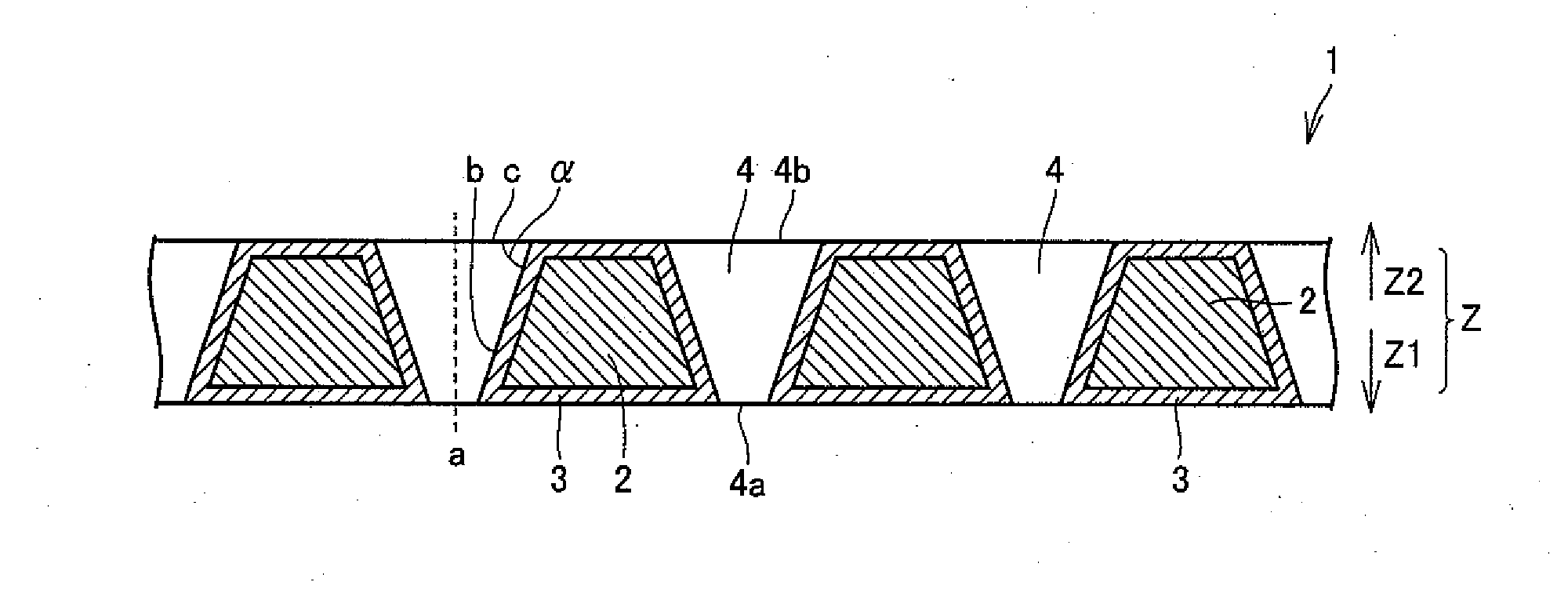

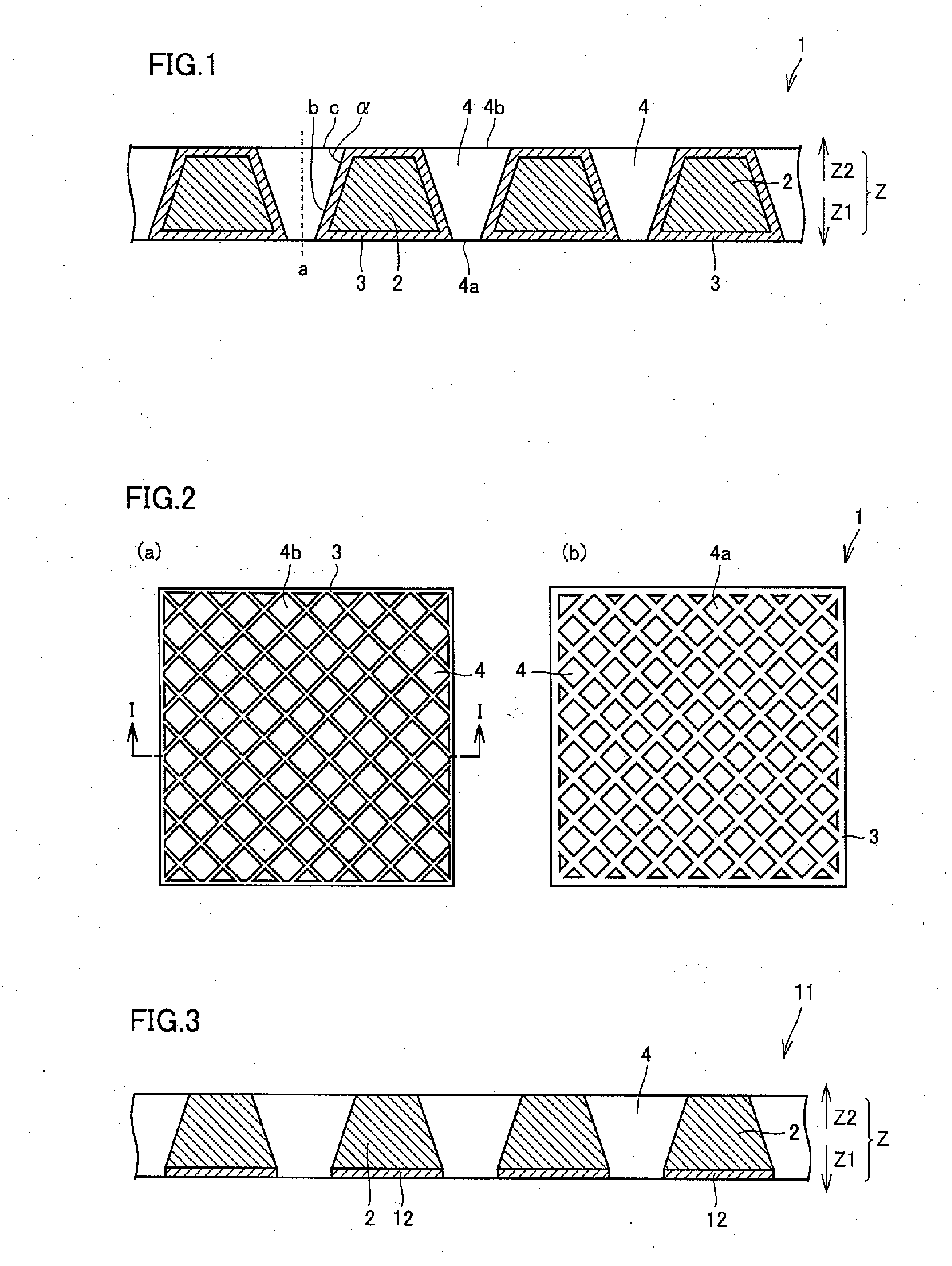

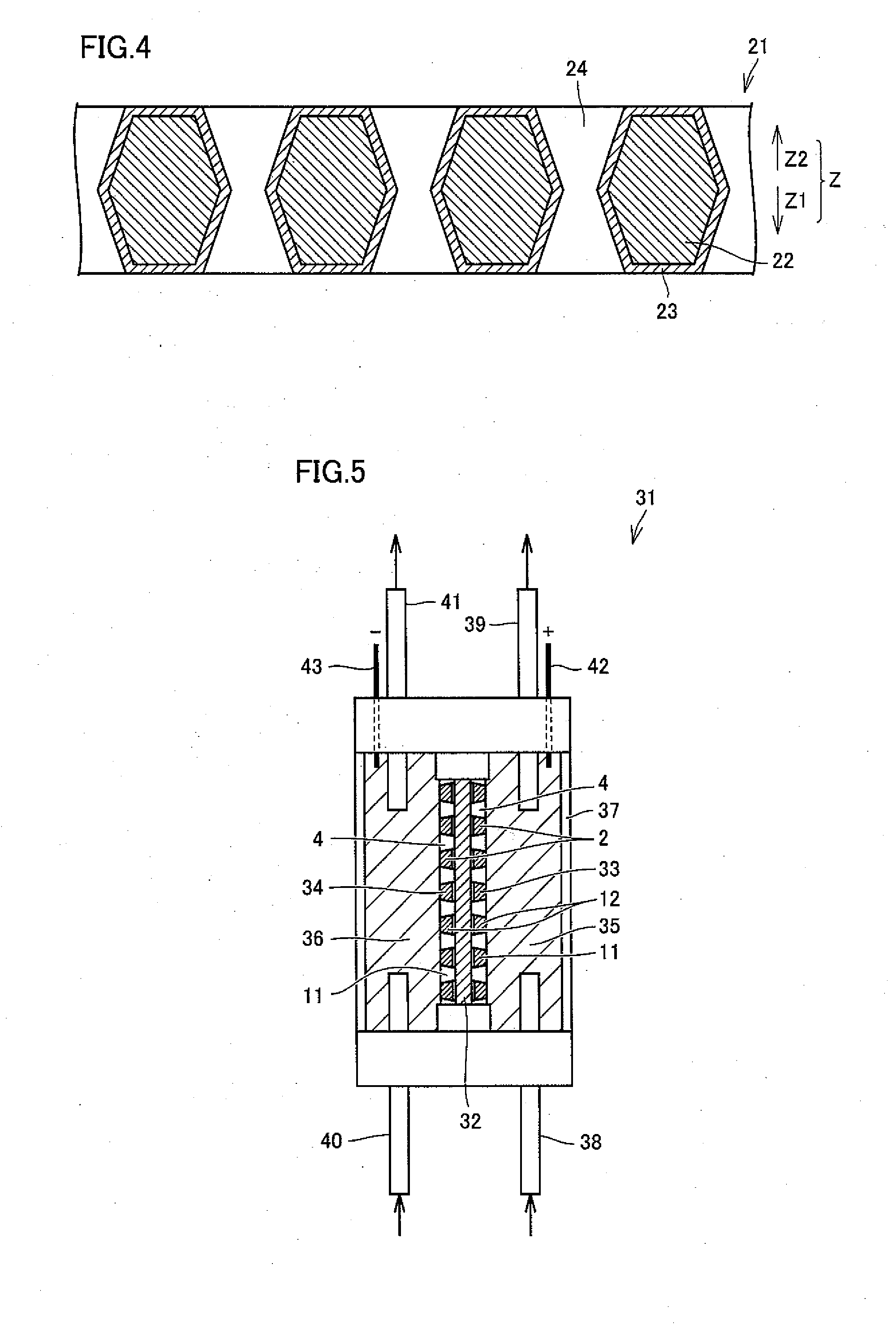

A method for producing a diamond electrode comprising synthetically produced and electrically conductive (doped) diamond particles, which are embedded into a support layer of electrically non-conductive material. The doped diamond particles are introduced as a single layer between two films that form the support layer, the films then being permanently connected to each other and the diamond particles being exposed on both sides of the support layer.

Owner:PRO AQUA DIAMANTELEKTRODEN PRODN

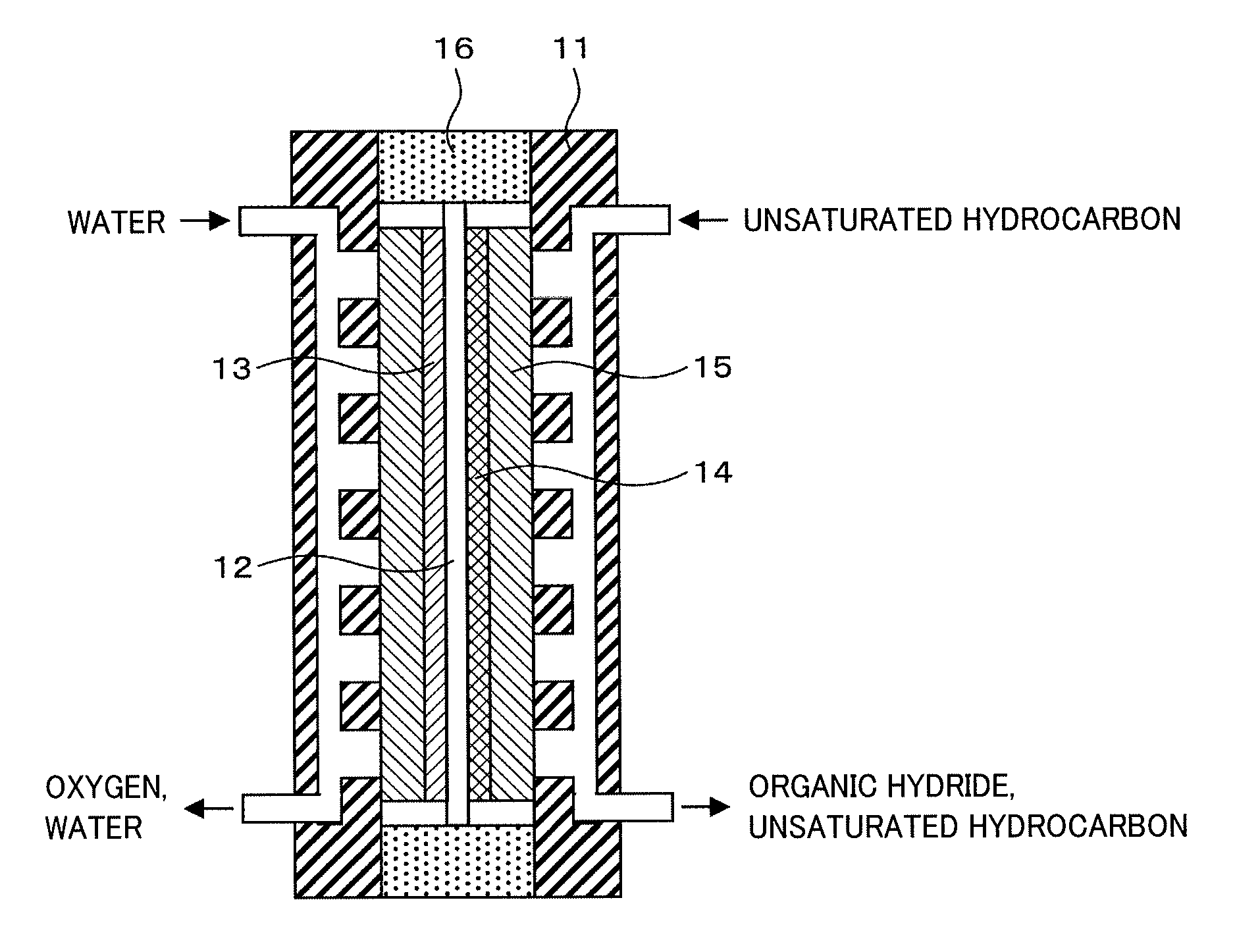

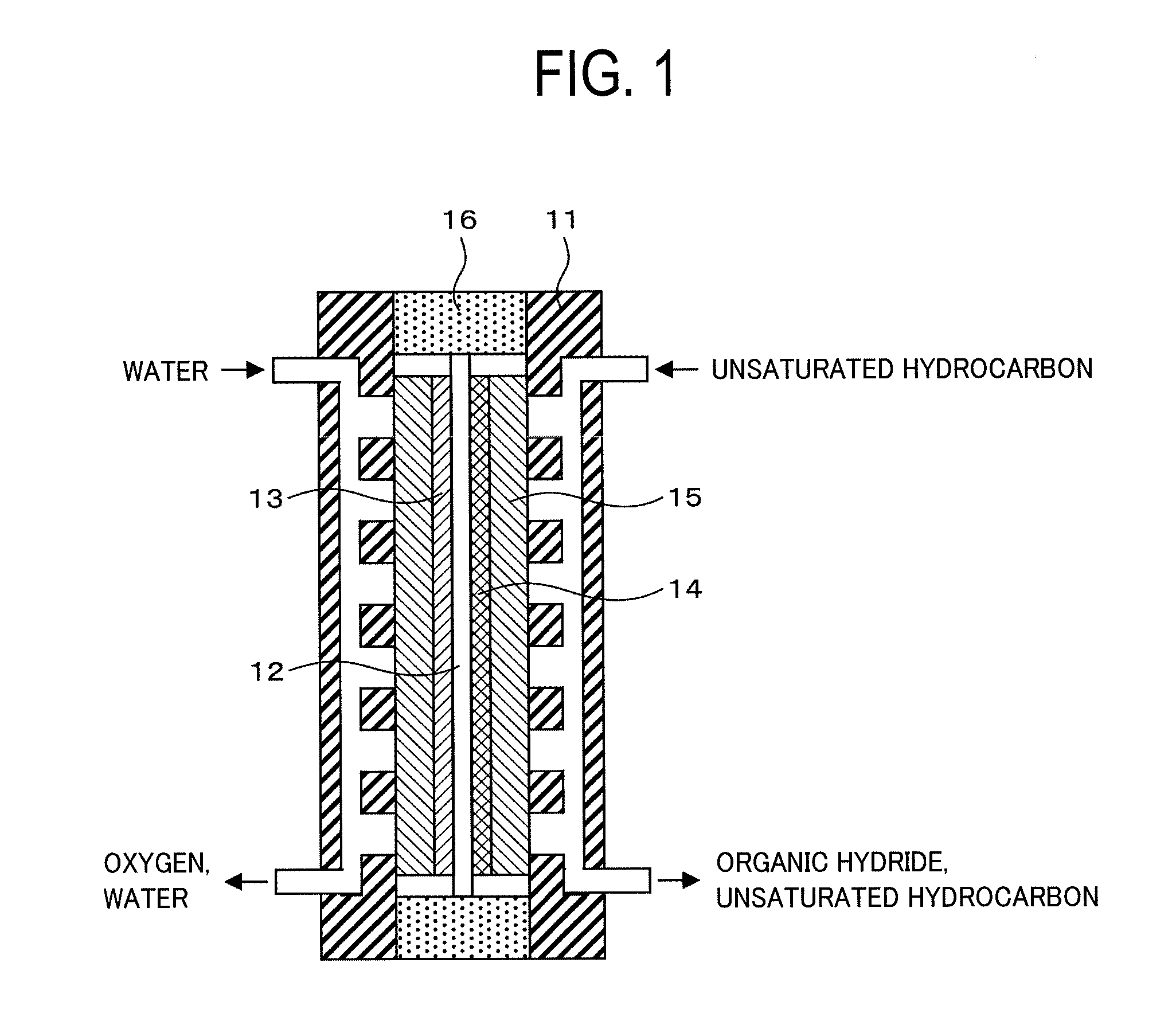

Membrane Electrode Assembly and Organic Hydride Manufacturing Device

InactiveUS20130087451A1Low wettabilityImprove energy efficiencyCellsOrganic diaphragmsPolymer electrolytesHigh energy

There is provided a membrane electrode assembly and an organic hydride manufacturing device capable of obtaining higher energy efficiency even if manufacturing organic hydride in one step with a single device. A membrane electrode assembly in which a cathode catalyst layer and an anode catalyst layer are placed to sandwich a solid polymer electrolyte membrane, wherein the cathode catalyst layer includes catalytic metal which causes hydrogenation of unsaturated hydrocarbons to organic hydrides, and a carrier of the catalytic metal, and the carrier provides on its surface a functional group which decreases wettability of the unsaturated hydrocarbons.

Owner:HITACHI LTD

Diamond electrode, method for producing same, and electrolytic cell

InactiveUS7951274B2Low production costEasy to produceCellsElectrode shape/formsDiamond electrodesSilicon

Owner:SUMITOMO ELECTRIC HARDMETAL CORP

Rhodium electrocatalyst and method of preparation

InactiveUS6358381B1Highly corrosive mediaCellsOrganic-compounds/hydrides/coordination-complexes catalystsElectrolysisOxygen

The invention relates to a novel rhodium sulfide catalyst for the reduction of oxygen in industrial electrolyzers. The catalyst is highly resistant towards corrosion and poisoning by organic species, thus resulting particularly suitable for use in aqueous hydrochloric acid electrolysis, when technical grade acid containing organic contaminants is employed.

Owner:DE NORA SPA

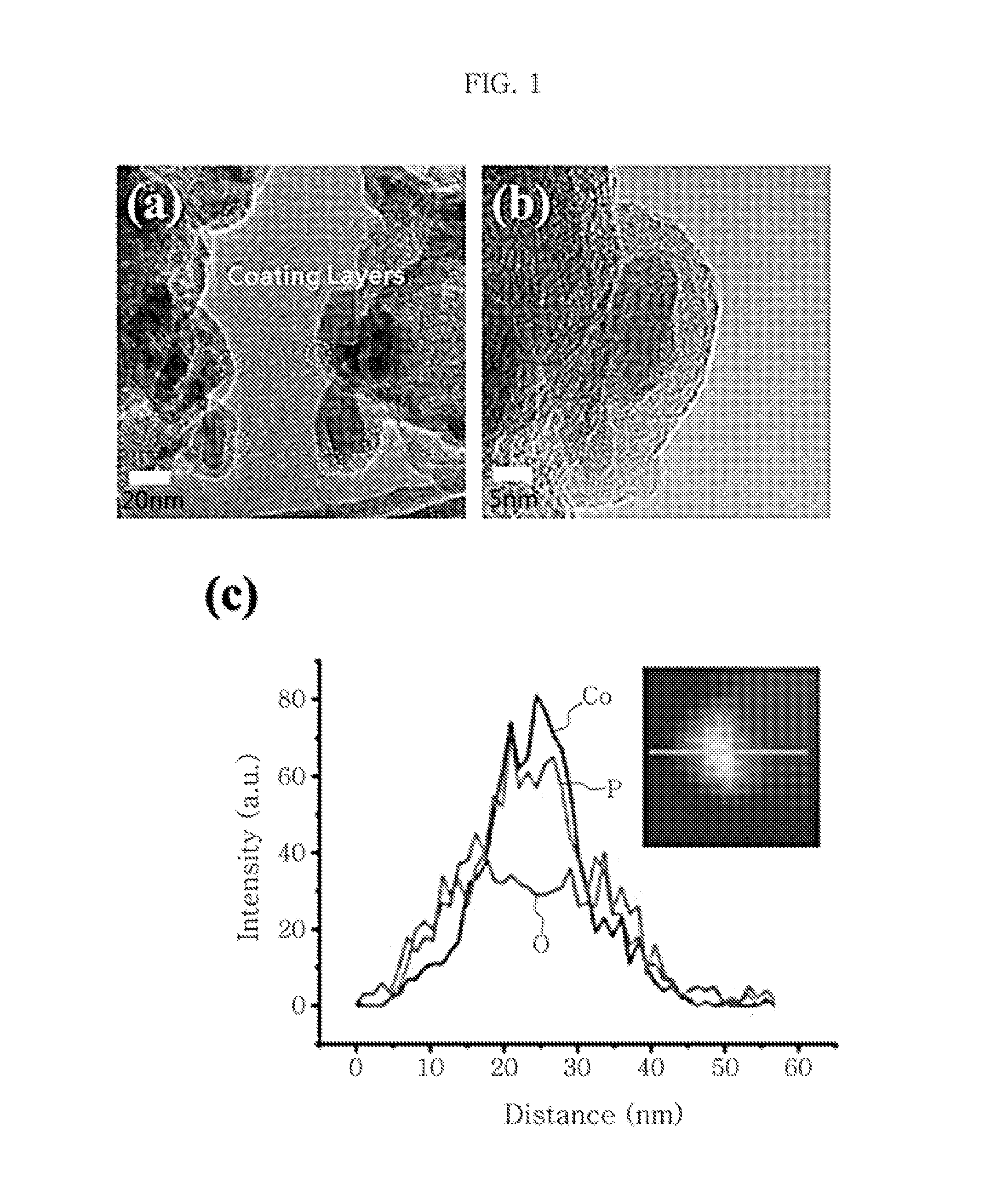

Non-precious metal based water electrolysis catalyst for oxygen evolution at anode and hydrogen evolution at cathode and preparation method of the same

ActiveUS20160199821A1Excellent oxygen evolution reaction activityHigh oxidation numberMaterial nanotechnologyCatalyst activation/preparationHydrogenElectrolysis

Disclosed is a non-precious metal based water electrolysis catalyst represented by CoX / C (X is at least one selected from the group consisting of P, O, B, S and N) for evolution of hydrogen and oxygen at a cathode and anode, respectively, at the same time, the catalyst including a cobalt-containing compound fixed to a carbon carrier.

Owner:KOREA INST OF SCI & TECH

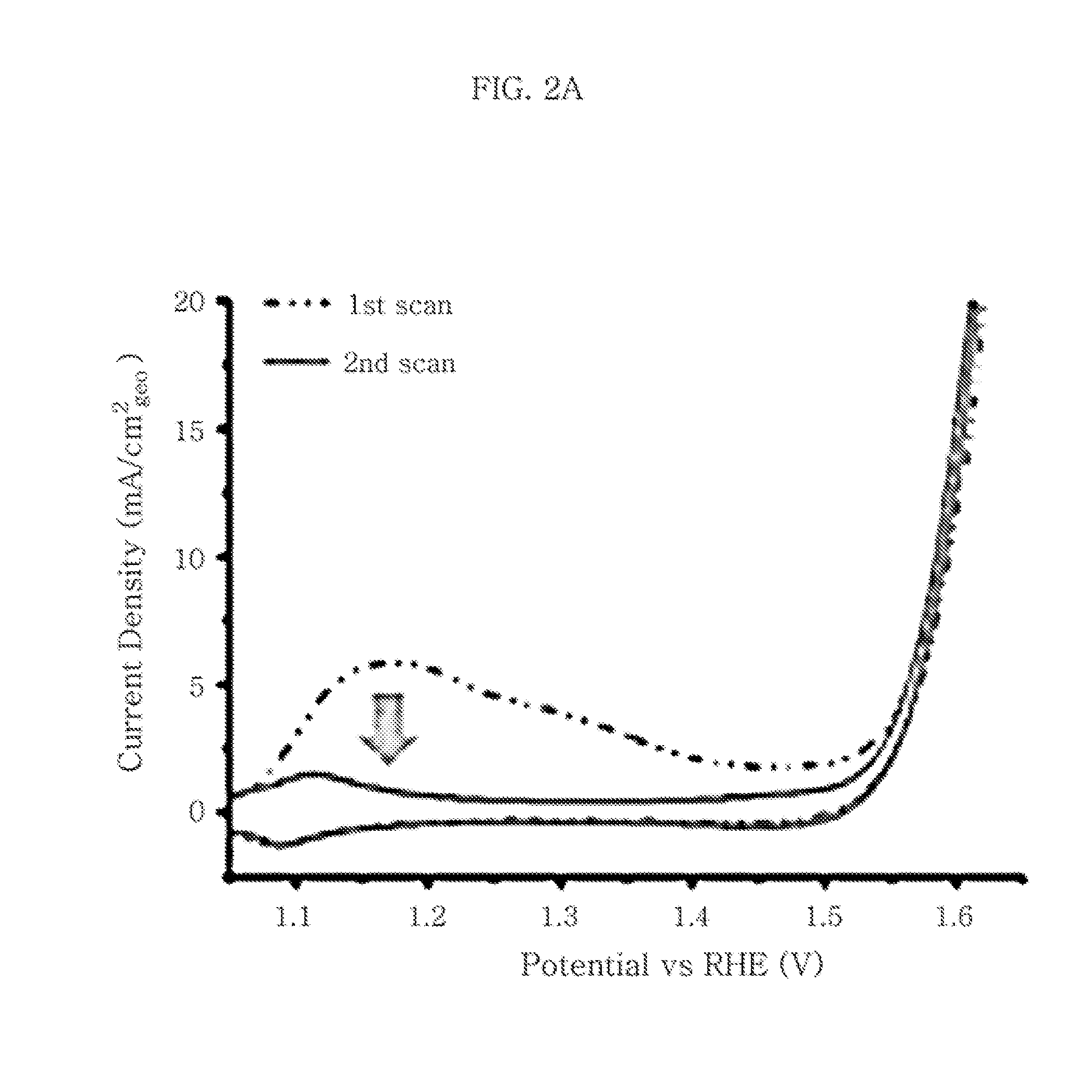

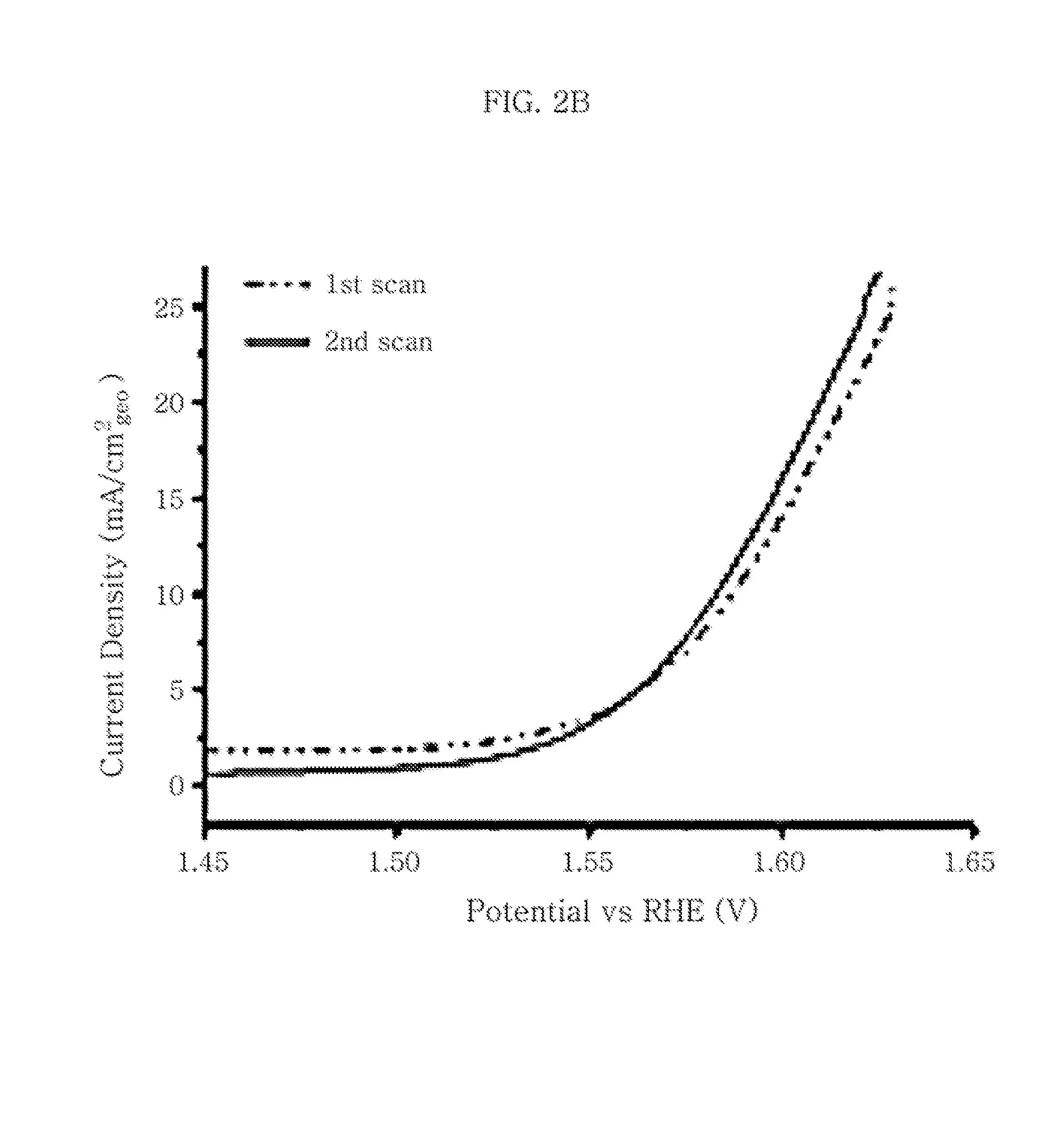

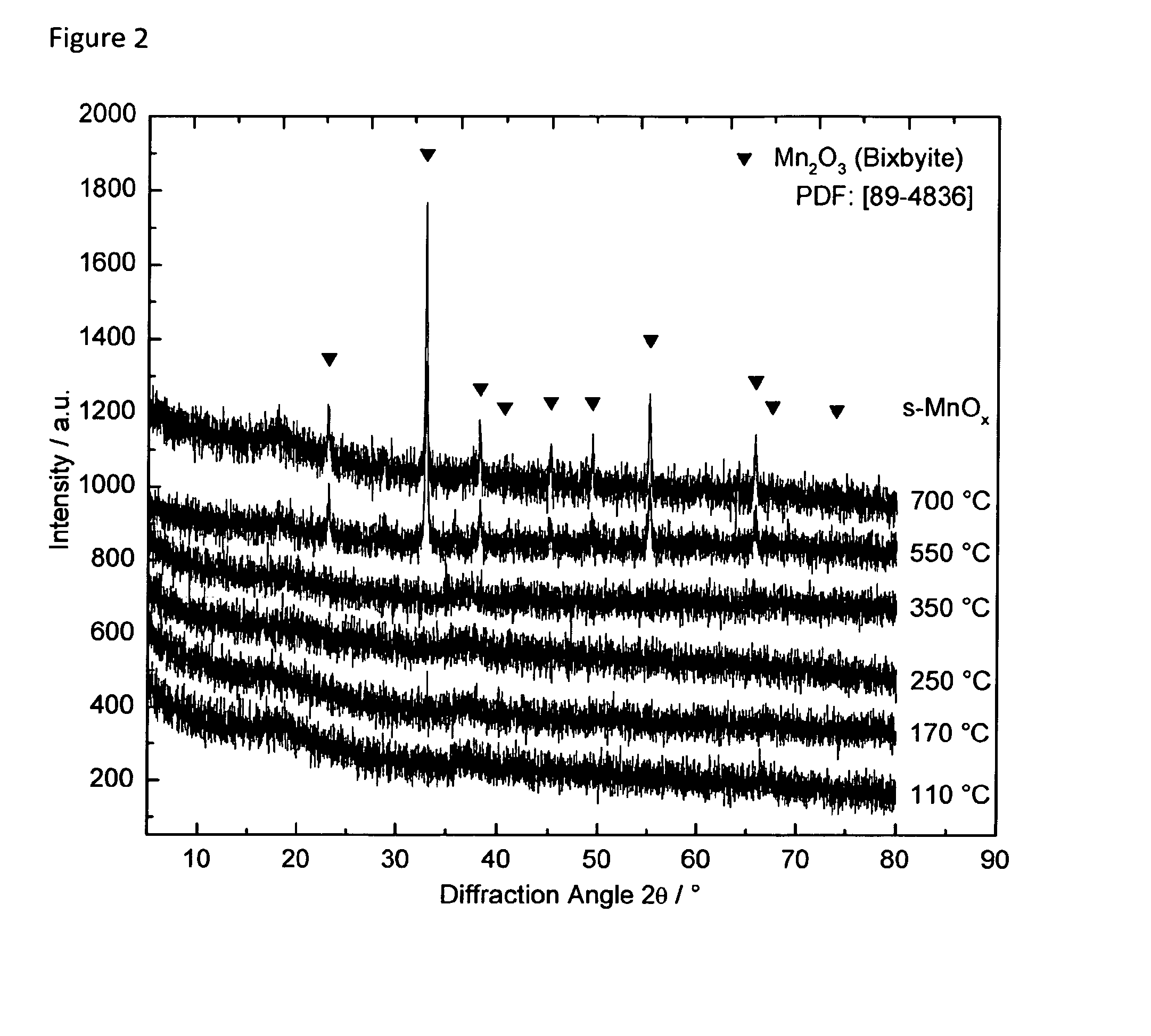

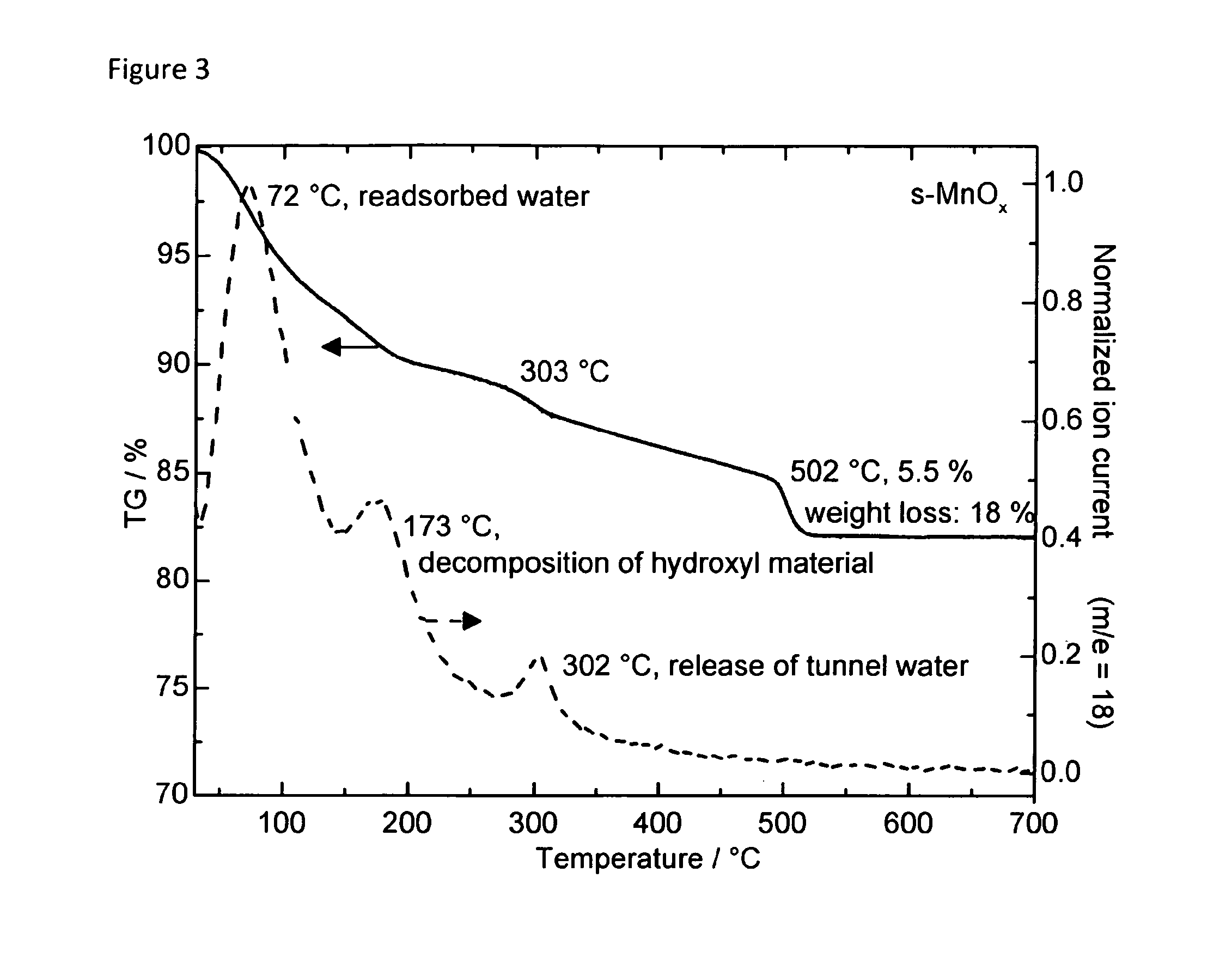

Electrolytic water splitting using a carbon-supported mnox-composite

InactiveUS20150068917A1High activityInexpensive and scalable techniqueMachining electrodesMaterial nanotechnologyWater useElectrolysis

The present invention relates to the electrolytic splitting of water using a carbon-supported manganese oxide (MnOx) composite. Specifically, the present electrolytic splitting of water is carried under neutral electrolyte conditions with a high electrolytic activity, while using an oxygen evolution reaction (OER)-electrode comprising the present carbon-supported MnOx composite. Next, the present invention relates to a process for producing such a carbon-supported MnOx composite as well as to a composite obtainable by the present process for producing the same and to an OER-electrode comprising the carbon-supported MnOx composite obtainable by the present process.

Owner:MAX PLANCK GESELLSCHAFT ZUR FOERDERUNG DER WISSENSCHAFTEN EV

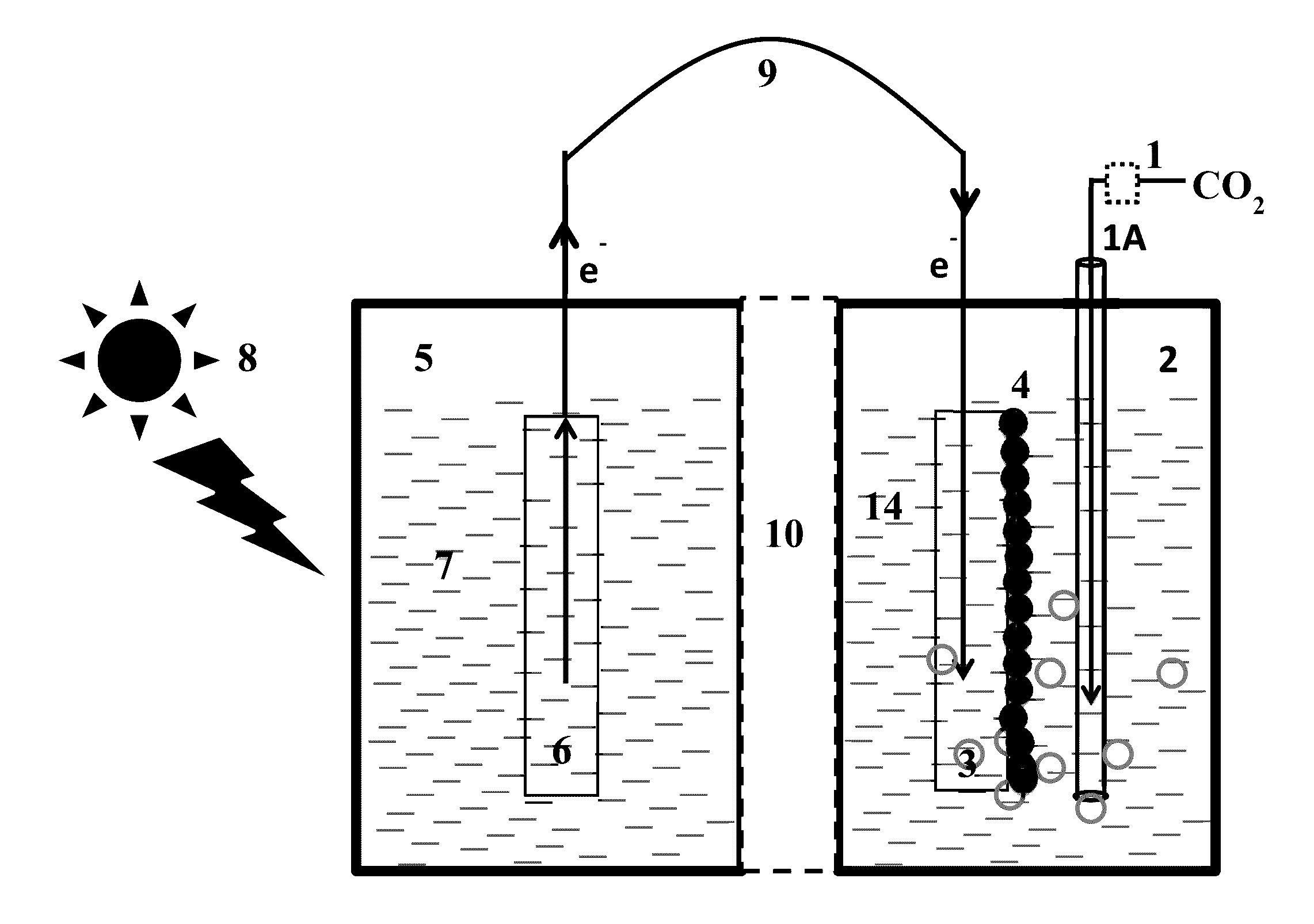

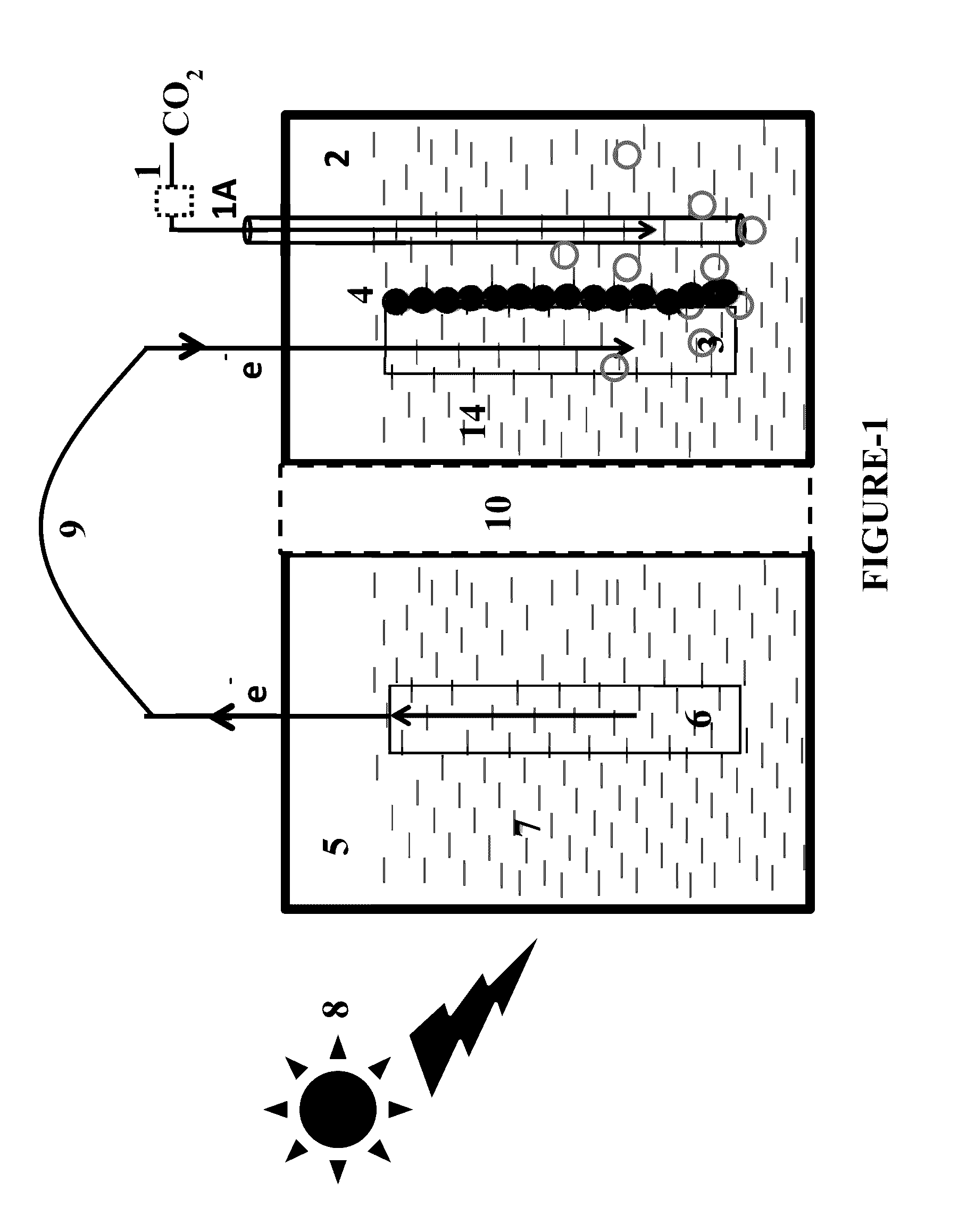

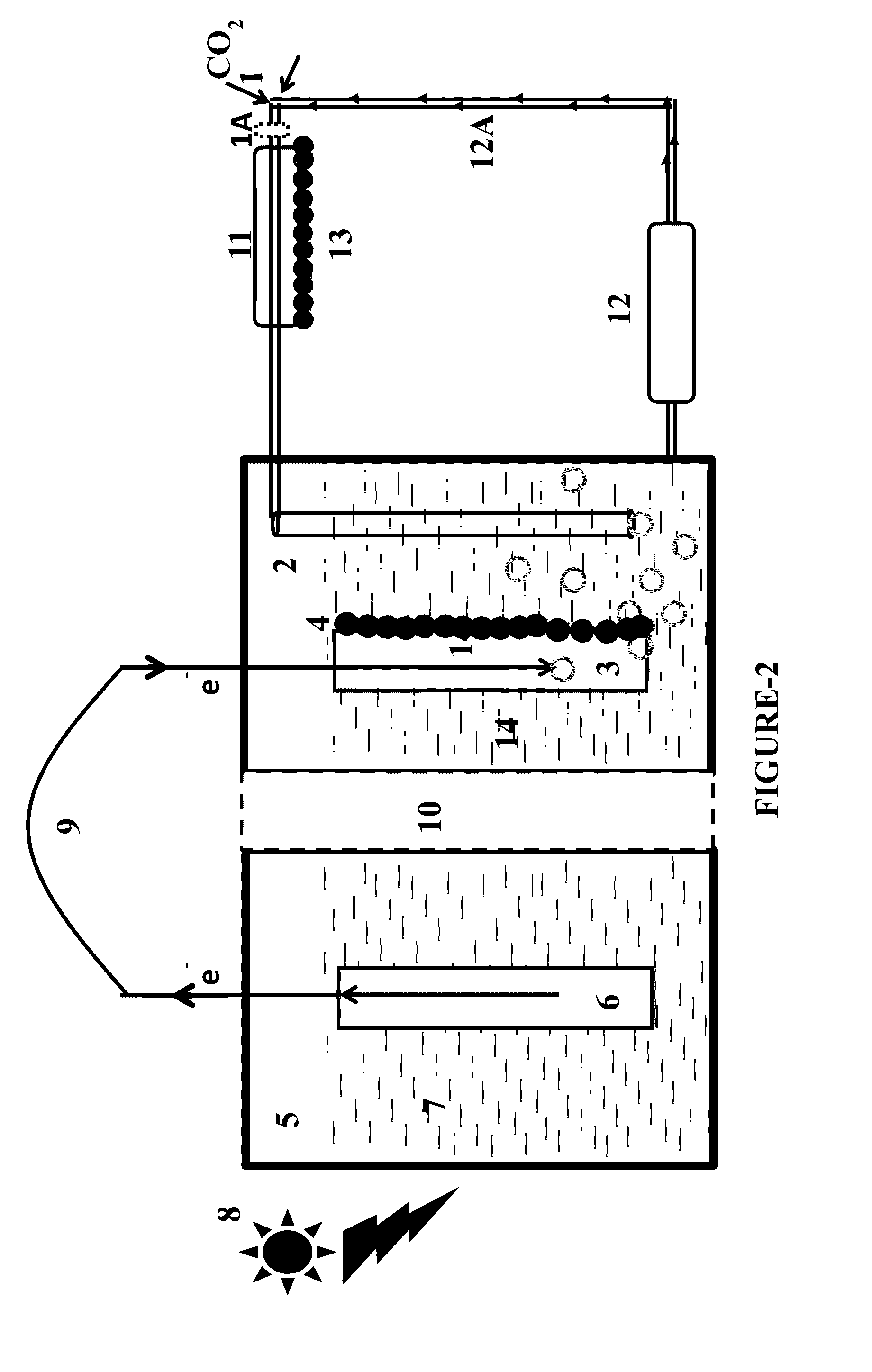

Device and method for conversion of carbon dioxide to organic compounds

The present invention relates to a device for bioassisted conversion of carbon dioxide to organic compounds that can be used a fuels and chemicals. The present invention also relates to a bioassisted process of converting carbon dioxide to organic compounds.

Owner:INDIAN OIL CORPORATION

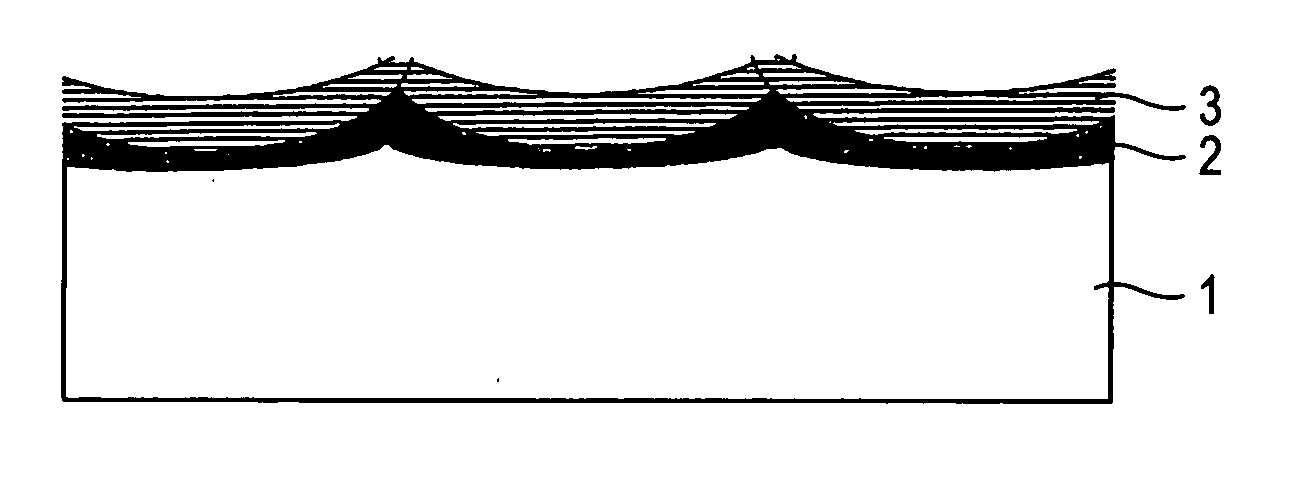

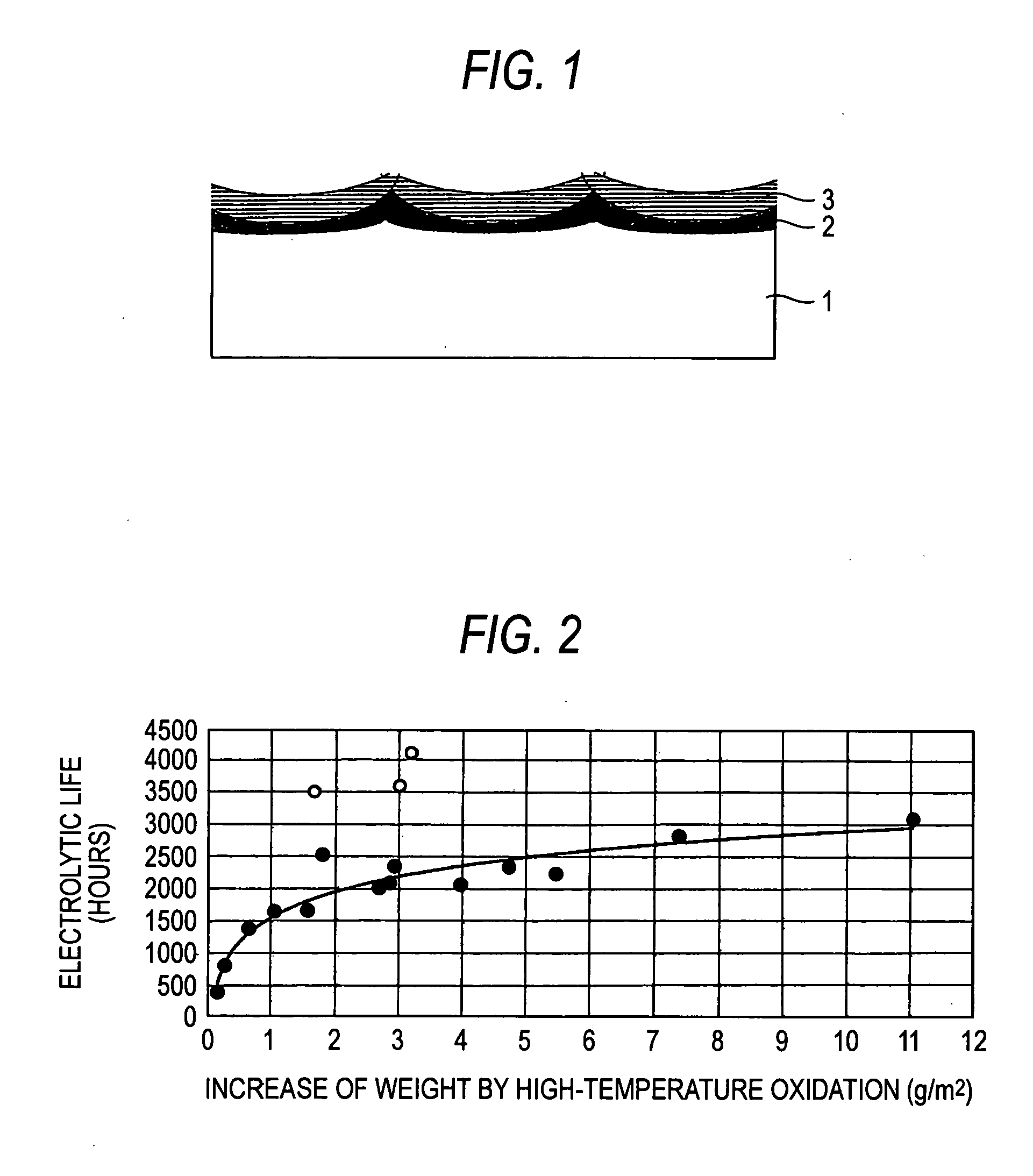

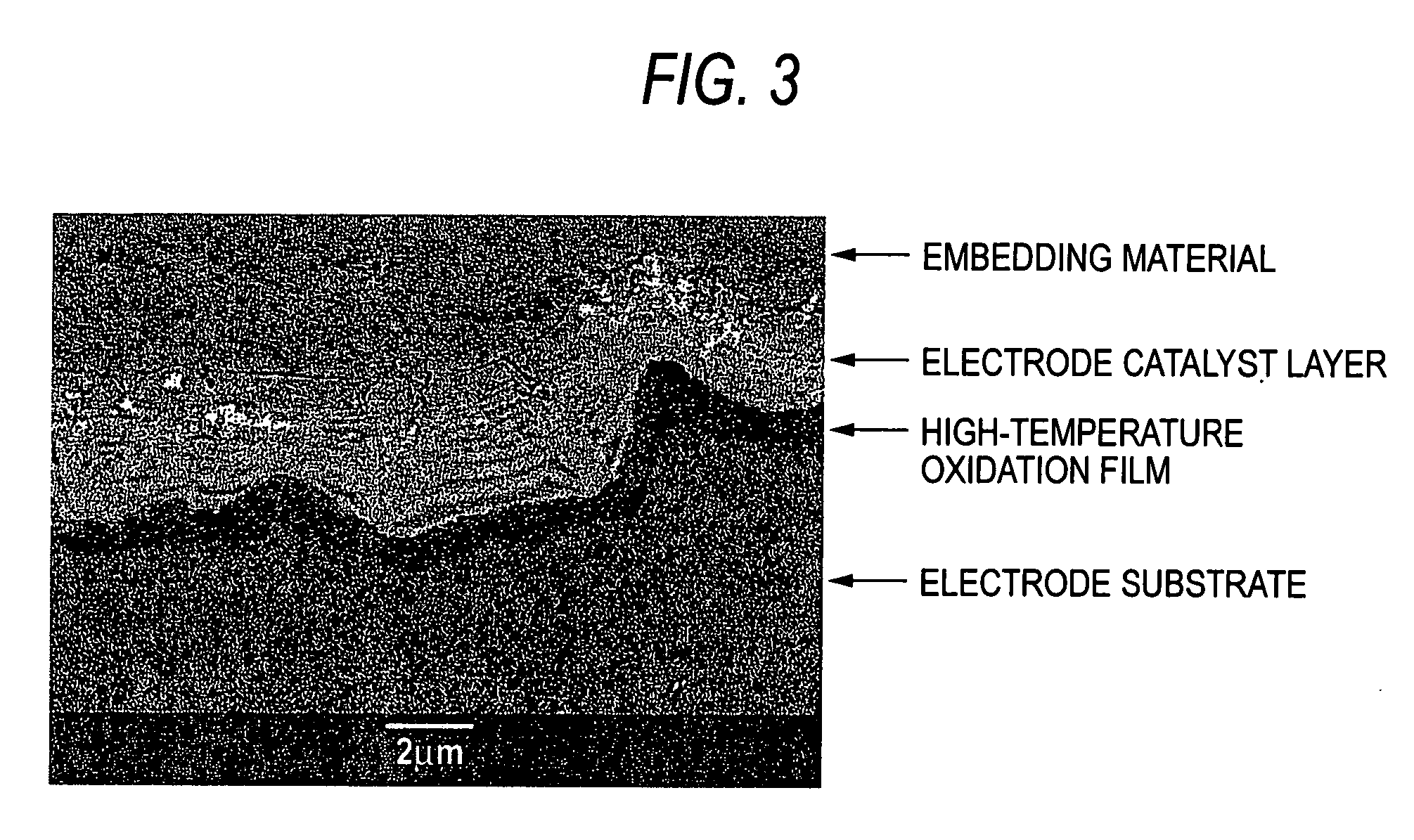

Electrolytic electrode and process of producing the same

An electrolytic electrode having an interlayer having more excellent peeling resistance and corrosion resistance and longer electrolytic life than conventional electrolytic electrodes and capable of flowing a large amount of current at the industrial level and a process of producing the same are provided. The electrolytic electrode includes a valve metal or valve metal alloy electrode substrate on the surface of which is formed a high-temperature oxidation film by oxidation, and which is coated with an electrode catalyst. The high-temperature oxidation film is integrated with the electrode substrate, whereby peeling resistance is enhanced. Further, by heating the high-temperature oxidation film together with the electrode catalyst, non-electron conductivity of the interlayer is modified, thereby making it possible to flow a large amount of current.

Owner:DE NORA PERMELEC LTD

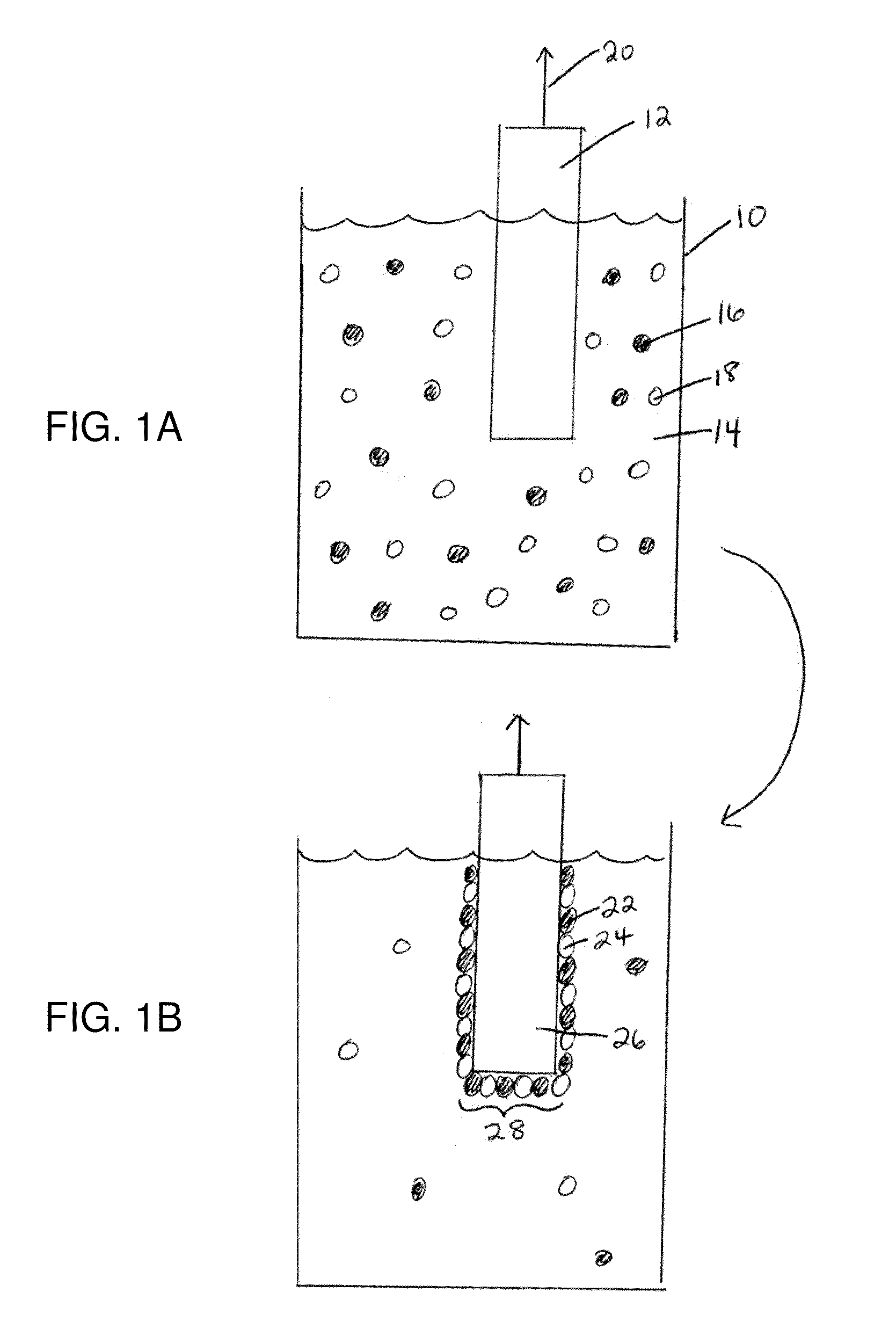

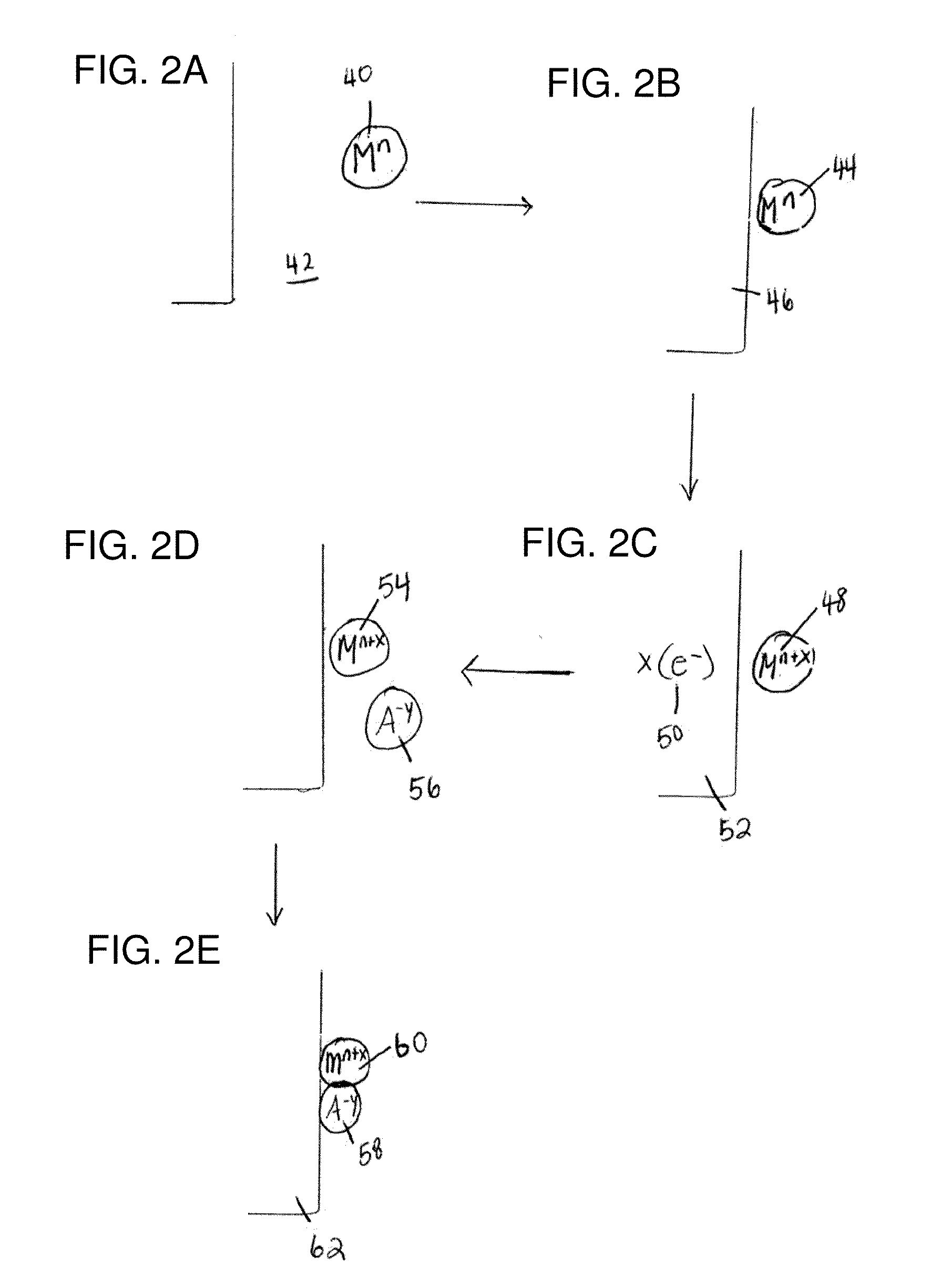

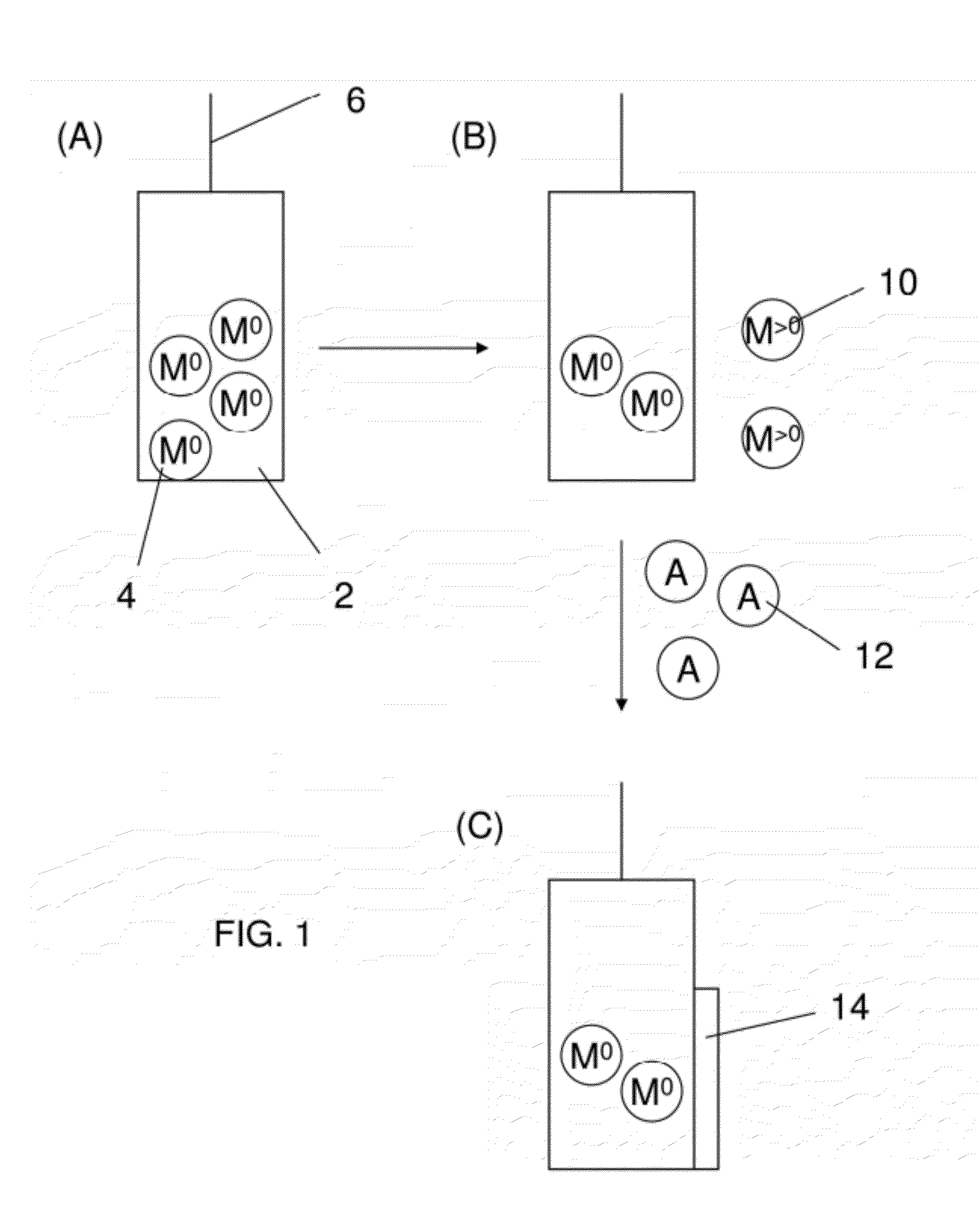

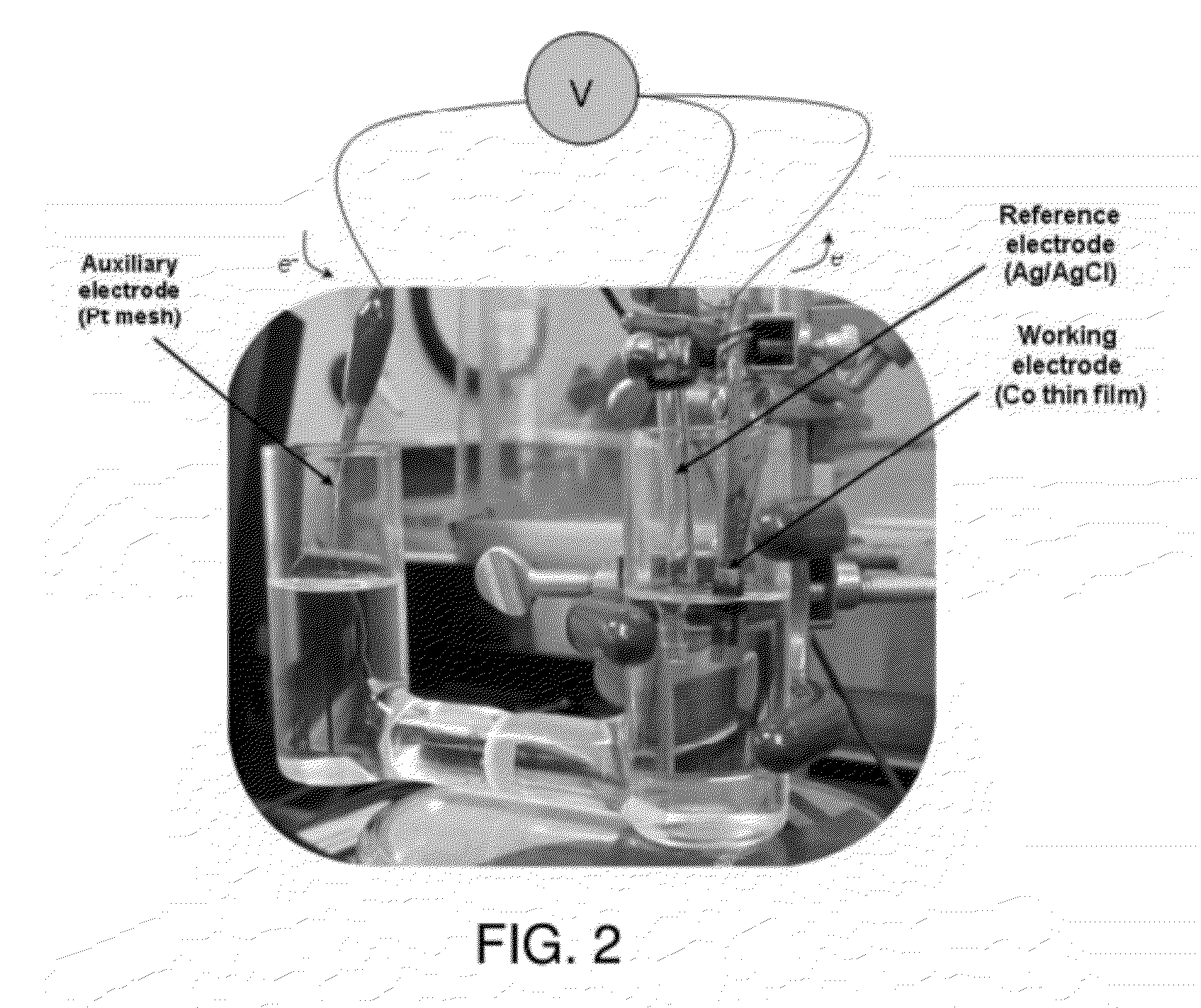

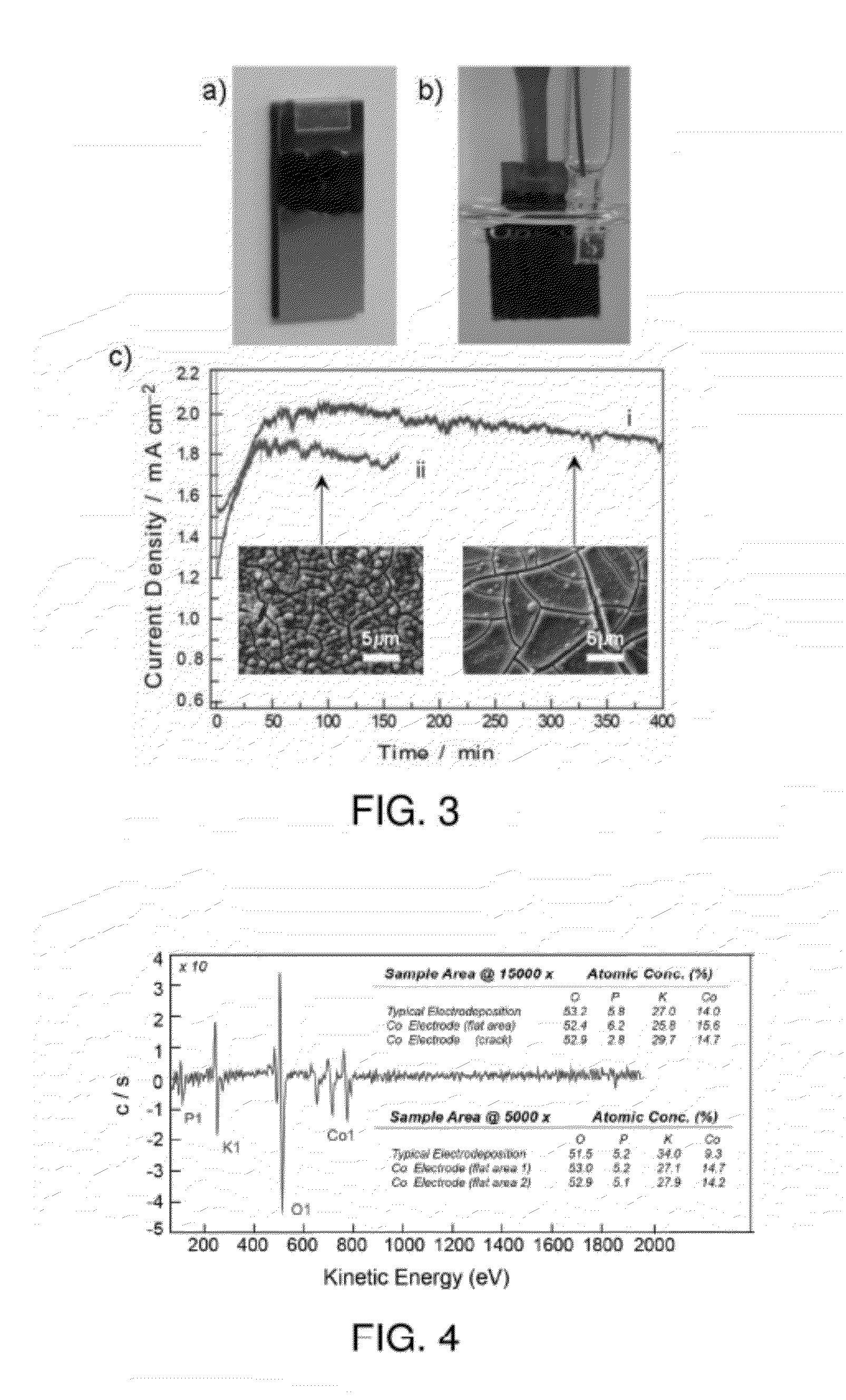

Methods for forming electrodes for water electrolysis and other electrochemical techniques

InactiveUS20120156577A1Photography auxillary processesElectrochemical processing of electrodesElectrolysed waterOxidation state

Methods of forming electrodes for electrolysis of water and other electrochemical techniques are provided. In some embodiments, the electrode comprising a current collector and a catalytic material. The method of forming the electrode may comprising immersing a current collector comprising a metallic species in an oxidation state of zero in a solution comprising anionic species, and causing a catalytic material to form on the current collector by application of a voltage to the current collector, wherein the catalytic material comprises metallic species in an oxidation state greater than zero and the anionic species.

Owner:MASSACHUSETTS INST OF TECH

Engineered electrode for electrobiocatalysis and process to construct the same

The present disclosure provides a ready-to-use bio-electrode stable for long term storage and a process of constructing the same. The process for construction of bio-electrode for electro-biocatalysis comprising of: selection of an electro-active bacteria; enrichment of said electro-active bacteria in a nutrient rich medium; separation of said electro-active bacterial cells from said nutrient rich medium; selection of an electrode material; surface modification of said electrode material; layering the surface modified electrode material with conductive material; layering the surface modified electrode material with an electro-active bacterial cells along with biofilm inducing agents and stabilizing agents; conditioning the electro-active bacterial cells layered electrode; incubating the electrode obtained with an immobilizing agent along with conductive material; and conditioning the electrode with micronutrients to obtain a bio-electrode.

Owner:INDIAN OIL CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com