Engineered electrode for electrobiocatalysis and process to construct the same

a biocatalysis and electrode technology, applied in the field of bioelectrochemical systems, can solve the problems of biofilm stability on the electrode, less attractive appearance, and system like microbial electro-synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0110]The disclosure will now be illustrated with working examples, which is intended to illustrate the working of disclosure and not intended to take restrictively to imply any limitations on the scope of the present disclosure. Unless defined otherwise, all technical and scientific terms used herein have the same meaning as commonly understood to one of ordinary skill in the art to which this disclosure belongs. Although methods and materials similar or equivalent to those described herein can be used in the practice of the disclosed methods and compositions, the exemplary methods, devices and materials are described herein. It is to be understood that this disclosure is not limited to particular methods, and experimental conditions described, as such methods and conditions may vary.

example1

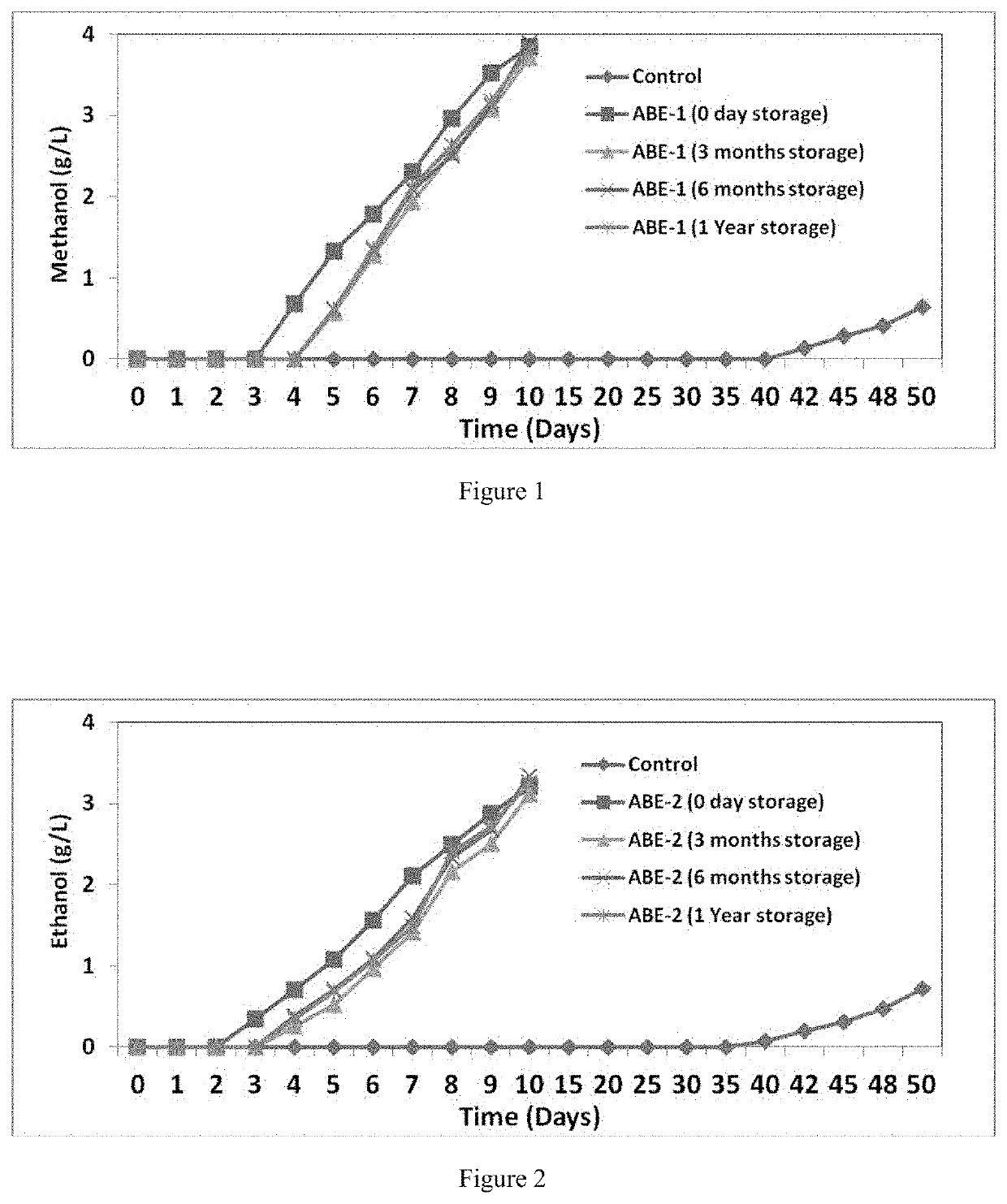

e Biosynthesis of Methanol Using Artificially Constructed Bio-Electrode

[0111]Bacterial Culture

[0112]Three different microbial cultures, viz., Pseudomonas aeruginosa MTCC 25019, Shewanella sp. MTCC 25020, Seudomonas stutzeri MTCC 25027 were grown separately at 30° C. in a medium containing the following mineral salts (per litre): 2.5 g of NaHCO3, 0.25 g of NH4Cl, 0.06 g of NaH2PO4H2O, 0.1 g of KCl, 0.024 g of C6H5FeO7 (ferric citrate), yeast extract 0.5%; peptone 0.25% 10 ml of a vitamin mix and 10 ml of a trace mineral solution. Anaerobic conditions were achieved by flushing the media with N2:CO2 (80:20) to remove oxygen and to keep the pH of the bicarbonate buffer at pH 6.8. In log phase microbial culture was centrifuged (8000 rpm) and washed in phosphate buffer. Then the equal (wet) weight of the microbes were mixed and added into fresh media, allowed for growth and centrifuged again to separate the selective mixed microbial consortia.

[0113]Bio-Electrode Construction[0114]a) First...

example 2

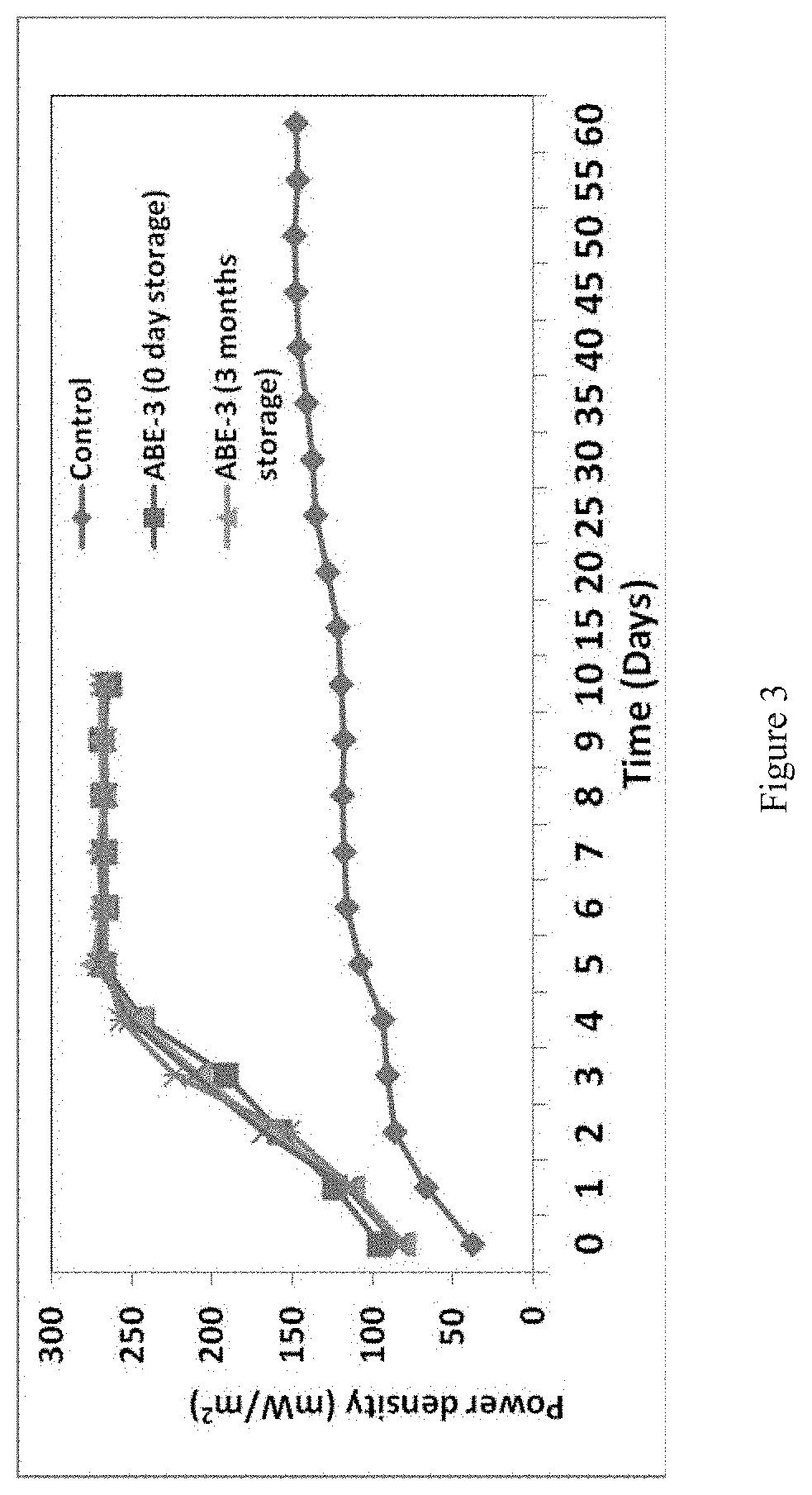

Biosynthesis of Ethanol Using Artificially Constructed Bioelectrode

[0121]Bacterial Culture

[0122]Three different microbial cultures, viz., Clostridium ljungdahlii DSM 13528, Sporomusa silvacetica DSM 10669, Cupriavidus nectar DSM 529, Sporomosa ovate DSM 2662 were grown separately at 30° C. in a medium containing the following mineral salts (per litre): 2.5 g of NaHCO3, 0.25 g of NH4Cl, 0.06 g of NaH2PO4H2O, 0.1 g of KCl, 0.024 g of C6H5FeO7 (ferric citrate), 10 ml of a vitamin mix and 10 ml of a trace mineral solution. Anaerobic conditions were achieved by flushing the media with N2:CO2 (80:20) to remove oxygen and to keep the pH of the bicarbonate buffer at pH 6.8. Each microbial culture was centrifuged (8000 rpm) and washed in phosphate buffer. Then the equal (wet) weight of the microbes were mixed and added into fresh media, allowed for growth and centrifuged again to separate the selective mixed microbial consortia.

[0123]Bio-Electrode Construction[0124]a) First, the carbon felt ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| OD | aaaaa | aaaaa |

| pH | aaaaa | aaaaa |

| conductive | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com