A method for preparing silver cobaltate polycrystalline powder with high single-phase delafossite structure

A delafossite, single-phase technology, applied in chemical instruments and methods, cobalt compounds, inorganic chemistry, etc., can solve problems such as difficult synthesis of silver-based delafossite compounds, achieve good economic and social benefits, and operate The effect of convenience and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

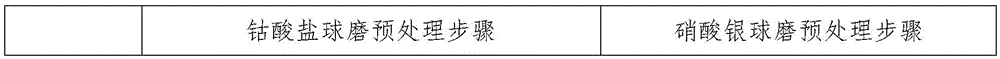

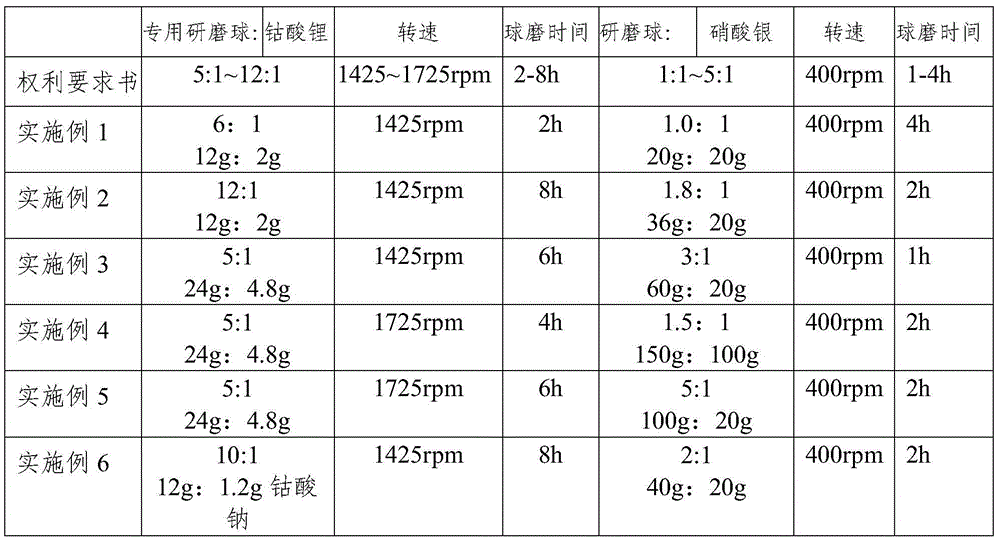

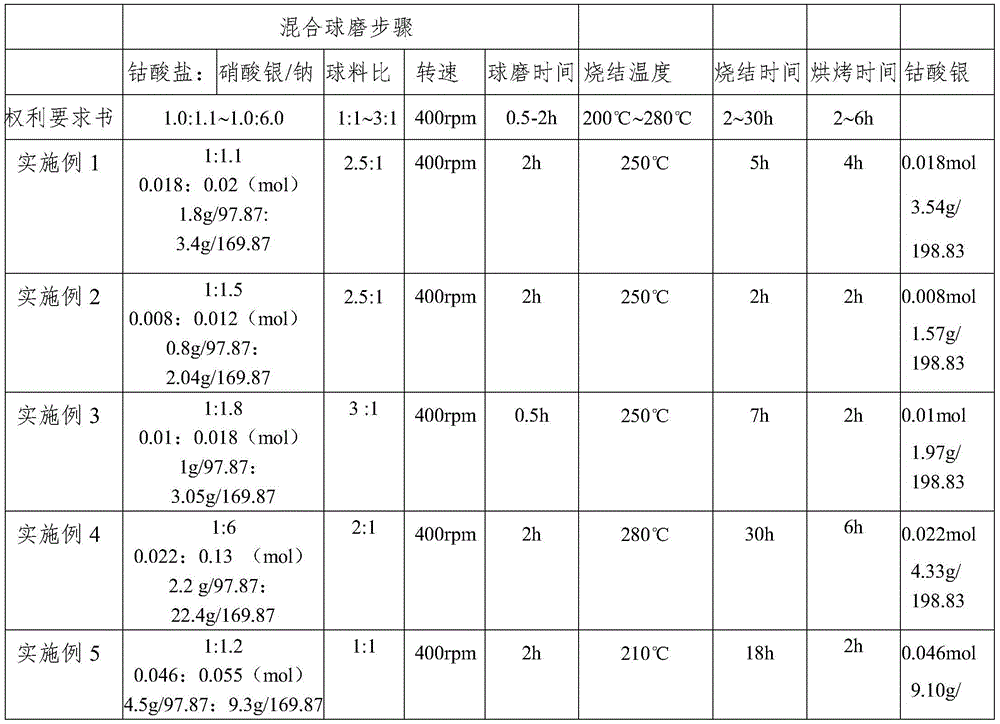

Embodiment 1

[0025] Weigh 12 g of special grinding balls for high-energy ball mills, weigh 2 g of lithium cobaltate raw materials according to the mass ratio of special grinding balls for high-energy ball mills to lithium cobaltate as 6:1, and place the grinding balls and lithium cobaltate in a ball mill tank Ball milling was performed on a high-energy ball mill with a rotating speed of 1425 rpm and a ball milling time of 2 hours to obtain a treated lithium cobalt oxide sample. Take by weighing 20g silver nitrate, according to the mass ratio of grinding ball and silver nitrate is 1: 1, select quality to be 20g grinding ball, put grinding ball and silver nitrate powder in ball mill tank and carry out ball milling on planetary ball mill, wherein rotating speed is 400rpm, the ball milling time is 4h, and the treated silver nitrate sample is obtained. Weigh 1.8g (separate after grinding, loss) (1.80 / 97.87=0.018mol) lithium cobaltate sample and 3.40g (3.40 / 169.87=0.02mol) according to the molar...

Embodiment 2

[0027] Weigh 12 g of special grinding balls for high-energy ball mills, weigh 1 g of lithium cobaltate raw material according to the mass ratio of special grinding balls for high-energy ball mills to lithium cobaltate as 12:1, and place the grinding balls and lithium cobaltate in a ball mill tank Ball milling was performed on a high-energy ball mill with a rotating speed of 1425 rpm and a ball milling time of 8 hours to obtain a treated lithium cobalt oxide sample. Take by weighing 20g silver nitrate, be 1.8: 1 to select quality as 36g grinding ball by the mass ratio of grinding ball and silver nitrate, put grinding ball and silver nitrate powder in the ball mill tank and carry out ball milling on planetary ball mill, wherein rotating speed is 400rpm, the ball milling time is 2h, and the treated silver nitrate sample is obtained. Weigh 0.8g (0.8 / 97.87=0.008mol) of lithium cobaltate sample and 2.04g (2.04 / 169.87=0.012mol) of silver nitrate sample according to the molar ratio of...

Embodiment 3

[0029] Weigh 24g of the special grinding balls for the high-energy ball mill, weigh 4.8g of lithium cobaltate raw material according to the mass ratio of the special grinding balls for the high-energy ball mill to lithium cobaltate as 5:1, and place the grinding balls and lithium cobaltate in the ball mill jar In the process, ball milling was performed on a high-energy ball mill with a rotating speed of 1425 rpm and a ball milling time of 6 hours to obtain a treated lithium cobaltate sample. Take by weighing 20g silver nitrate, according to the mass ratio of grinding ball and silver nitrate, be 3: 1 to select quality and be 60g grinding ball, put grinding ball and silver nitrate powder in ball mill jar and carry out ball milling on planetary ball mill, wherein rotating speed is 400rpm, the ball milling time is 1h, and the treated silver nitrate sample is obtained. Weigh 1g (1 / 97.87=0.01mol) lithium cobaltate sample and 3.05g (3.05 / 169.87=0.018mol) silver nitrate sample accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com