P-type oxide semiconductor thin-film transistor and preparing method thereof

A technology for oxide semiconductors and thin film transistors, applied in the fields of semiconductor/solid-state device manufacturing, transistors, semiconductor devices, etc., can solve the problems of less reports of P-type oxide thin film transistors, and achieve suitable for large-scale industrial production, good electrical properties, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

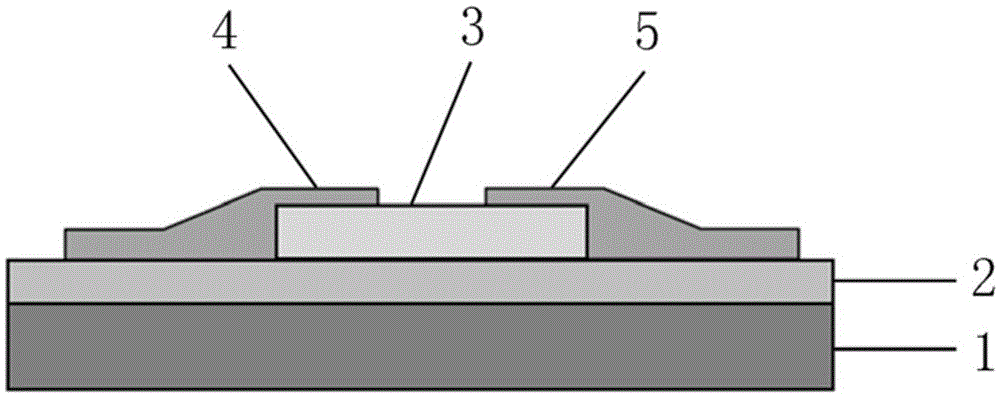

[0033] The P-type oxide semiconductor thin film transistor of this embodiment, such as figure 1 shown, including:

[0034] A substrate 1, the substrate 1 is a heavily doped silicon substrate (heavily doped N-type silicon wafer), and the heavily doped silicon substrate is used as a gate electrode at the same time;

[0035] an insulating layer 2, which is a silicon dioxide film, located on the gate electrode;

[0036] The active layer 3 is a P-type delafossite structure oxide film, located on the insulating layer 2;

[0037] The source electrode 4 and the drain electrode 5 are all Cu films, respectively located on the active layer 3;

[0038] Wherein, the material of the P-type delafossite structure oxide film is CuAlO 2 .

[0039] The thickness of the insulating layer is 300nm, the thickness of the active layer is 80nm, and the thickness of the source electrode and the drain electrode is 200nm.

[0040] The preparation method of the P-type oxide semiconductor thin film tra...

Embodiment 2

[0048] The structure diagram of the P-type oxide semiconductor thin film transistor of this embodiment is the same as that of Embodiment 1, specifically including:

[0049] A substrate, the substrate is a heavily doped silicon substrate (heavily doped N-type silicon wafer), and the heavily doped silicon substrate is used as a gate electrode at the same time;

[0050] an insulating layer, which is a transparent zirconium dioxide film, located on the gate electrode;

[0051] The active layer is a P-type delafossite structure oxide film and is located on the insulating layer;

[0052] The source electrode and the drain electrode are all Cu films, respectively located on the active layer;

[0053] Wherein, the material of the P-type delafossite structure oxide film is CuInO 2 .

[0054] The thickness of the insulating layer is 300nm, the thickness of the active layer is 120nm, and the thickness of the source electrode and the drain electrode is 200nm.

[0055] The preparation ...

Embodiment 3

[0062] The structure diagram of the P-type oxide semiconductor thin film transistor of this embodiment is the same as that of Embodiment 1, specifically including:

[0063] A substrate, the substrate is a heavily doped silicon substrate (heavily doped N-type silicon wafer), and the heavily doped silicon substrate is used as a gate electrode at the same time;

[0064] an insulating layer, which is a transparent aluminum oxide film, located on the gate electrode;

[0065] The active layer is a P-type delafossite structure oxide film and is located on the insulating layer;

[0066] The source electrode and the drain electrode are all Cu films, respectively located on the active layer;

[0067] Wherein, the material of the P-type delafossite structure oxide film is CuGaO 2 .

[0068] Wherein, the thickness of the insulating layer is 300nm, the thickness of the active layer is 120nm, and the thickness of the source electrode and the drain electrode is 200nm.

[0069] The prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com