A standardized pre-embedded component for structural concrete construction and its construction method

A concrete and pre-embedded technology, which is applied in the direction of basic structure engineering, building structure, and building material processing, can solve problems such as difficulty in ensuring welding quality and connection strength, affecting the quality of pre-embedded steel plates, and time-consuming and labor-intensive problems. Quality, low production cost, overcome the effect of low processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

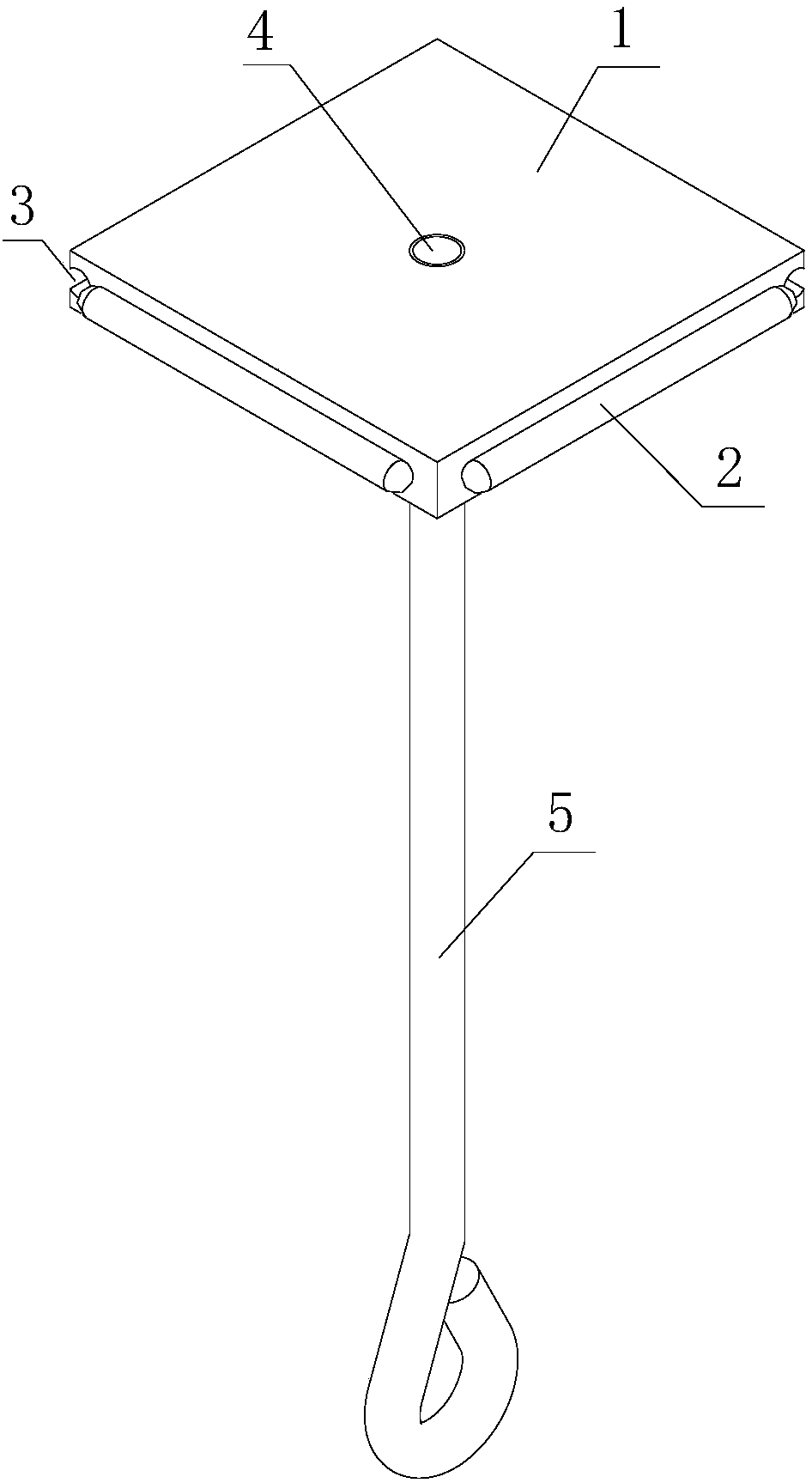

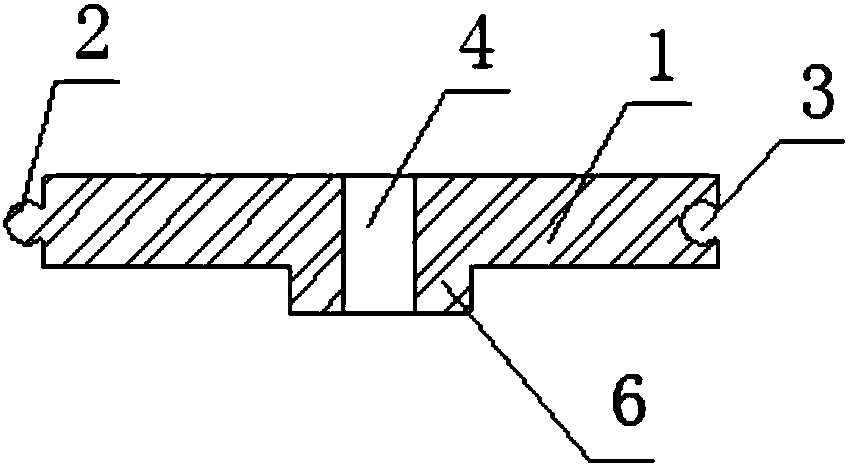

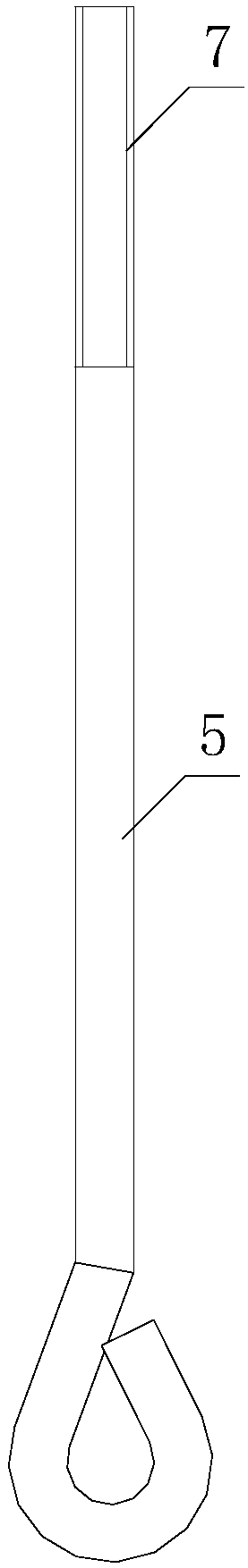

[0029] like Figure 1 to Figure 3 As shown, a standardized embedded assembly for structural concrete construction according to the present invention includes an embedded steel plate 1 and anchor bolts 5 connected to the embedded steel plate 1, and the adjacent two sides of the embedded steel plate 1 are set There are convex ribs 2, and the two sides corresponding to the embedded steel plate 1 and the convex ribs 2 are provided with card slots 3, and the embedded steel plate 1 is provided with bolt holes 4 for connecting anchor bolts 5, and the bolt holes 4 The lower part is provided with a reinforcing plate 6 . By adopting this technical scheme, the pre-embedded steel plate 1 can be manufactured in the factory, which overcomes the problems that the on-site production of the pre-embedde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com