Patents

Literature

53results about How to "High single output" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anatase titanium dioxide nano-rods and preparation method thereof

ActiveCN103387261AGood dispersionHas a steric hindrance effectNanotechnologyTitanium dioxideSolventElectron

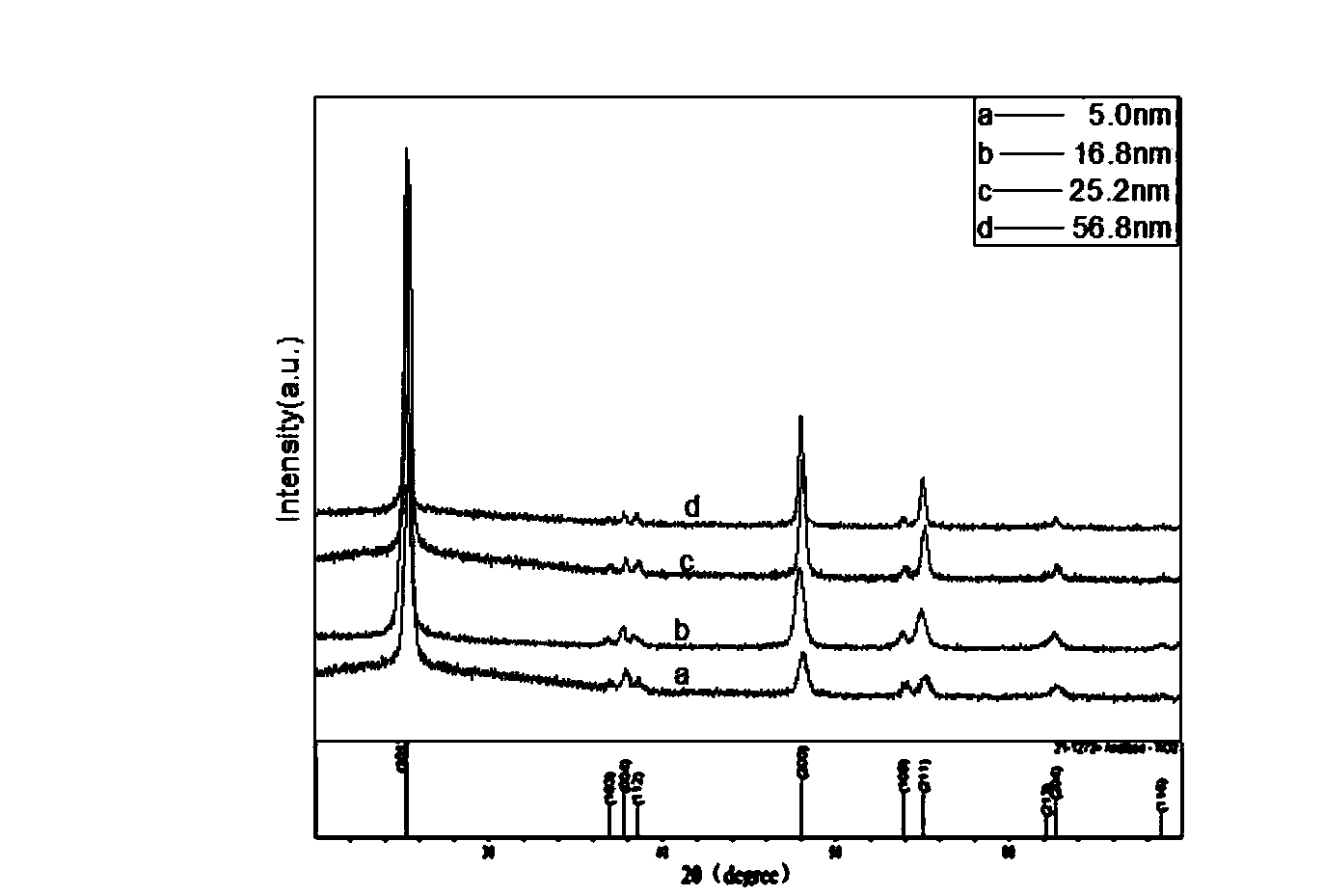

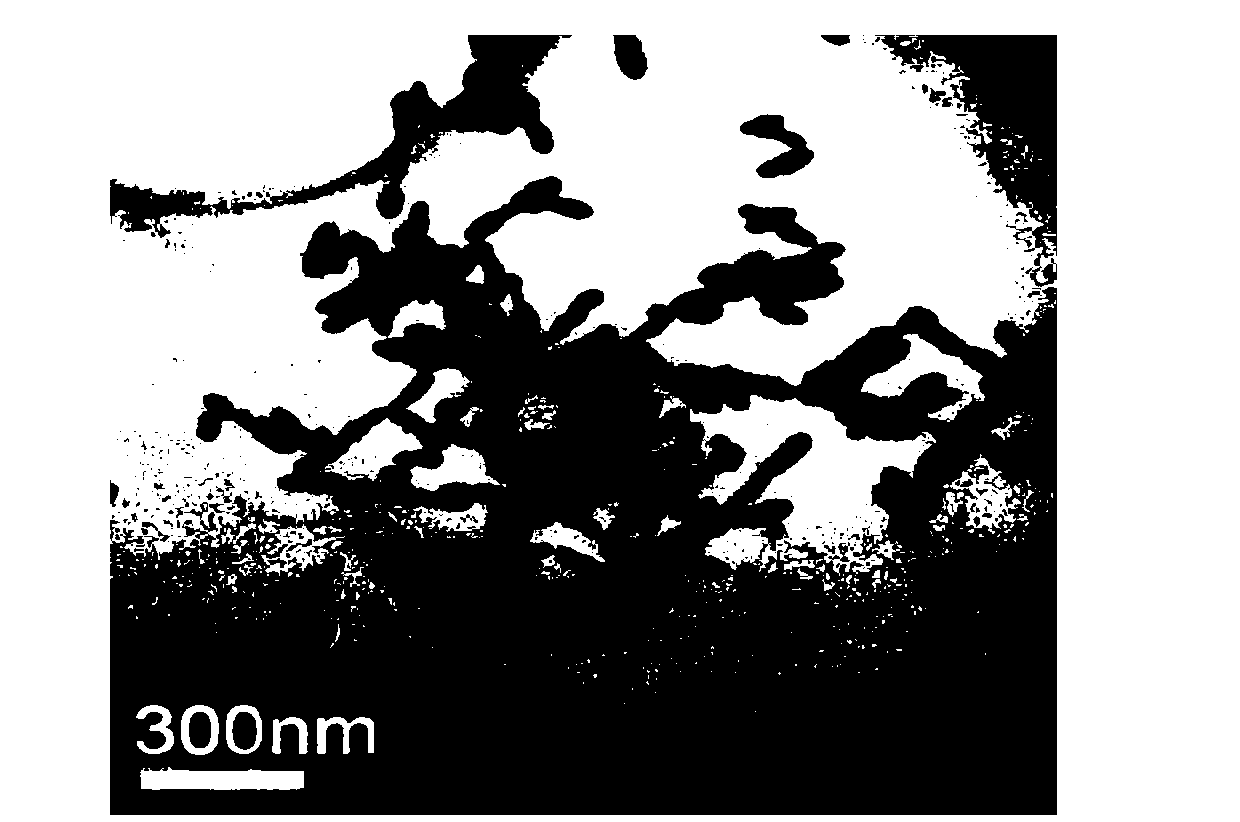

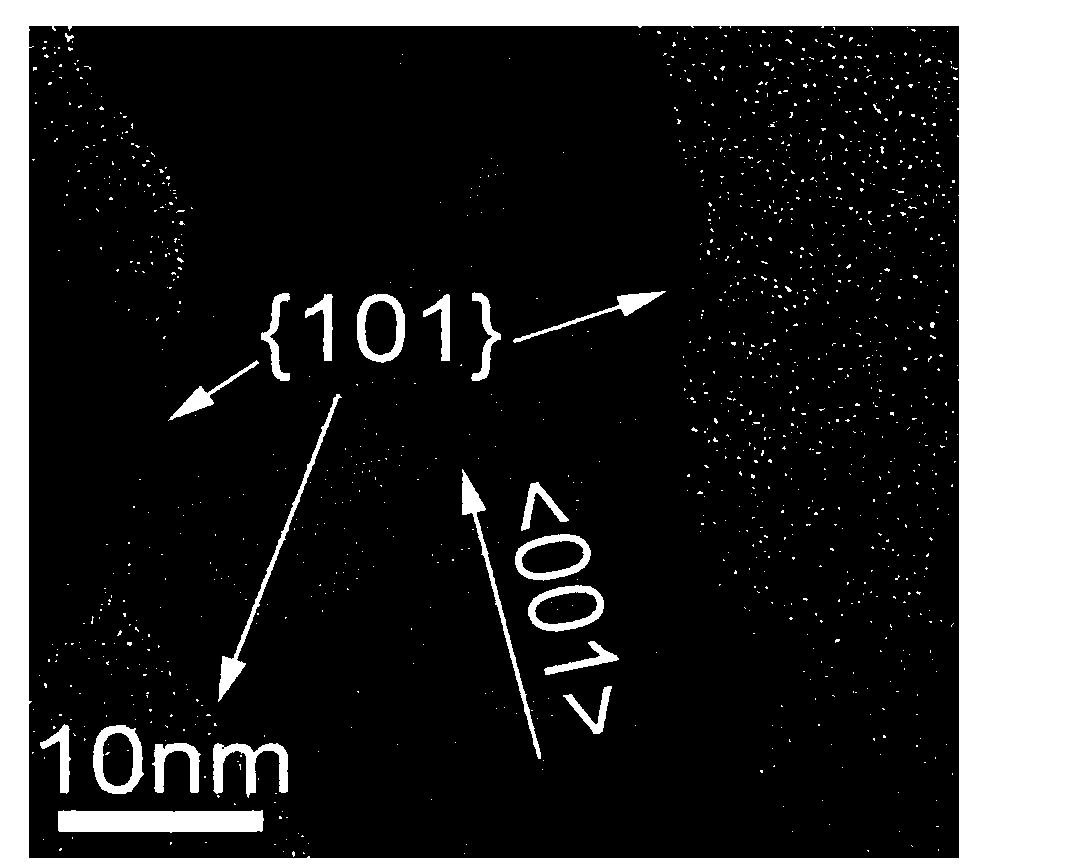

The invention discloses anatase titanium dioxide nano-rods and a preparation method thereof. According to the invention, titanium alkoxide is adopted as a titanium source, an organic alkali is adopted as a glue solution, ethylene glycol-water or ethylene glycol-water-ethanol is adopted as a solvent; low-temperature glue solution is carried out, and then high-temperature hydrothermal reaction is carried out; and crystal growth is controlled in a manner of oriented bonding, such that the morphology of a final product is controlled in a special nano-rod shape. The oriented bonding direction is a (001) direction, and a crystal exposed surface is a {101} surface. With different reaction conditions, the diameters of the nano-rods are adjustable within a range of 5-60nm, and the lengths of the nano-rods are adjustable within a range of 50-400nm. According to the nano-rod growth process, a plurality of anatase grains are subjected to local bonding fusion according to a certain optimized direction through crystal lattice match sharing common crystal surfaces, such that the nano-rods with certain length-to-diameter ratio, good dispersion, and huge specific surface area is formed. With an electrode material prepared by using the nano-rods, higher electron collection efficiency can be easily obtained, and high photoelectric performance is provided.

Owner:HUAZHONG UNIV OF SCI & TECH

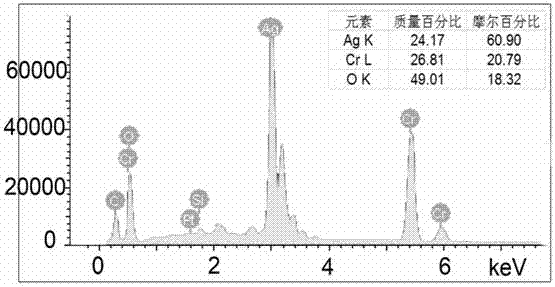

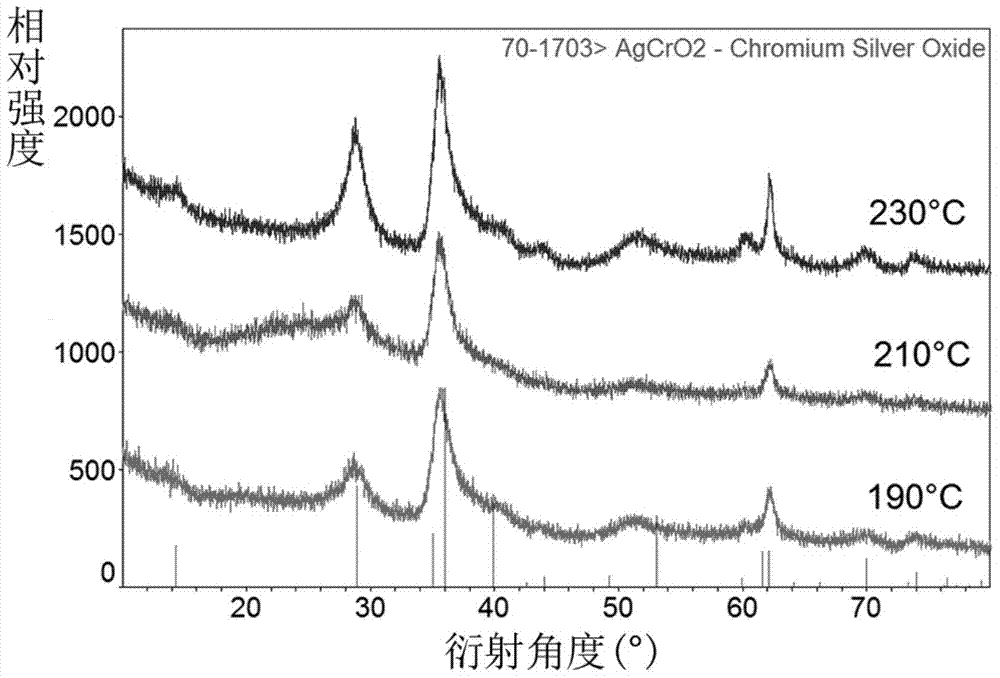

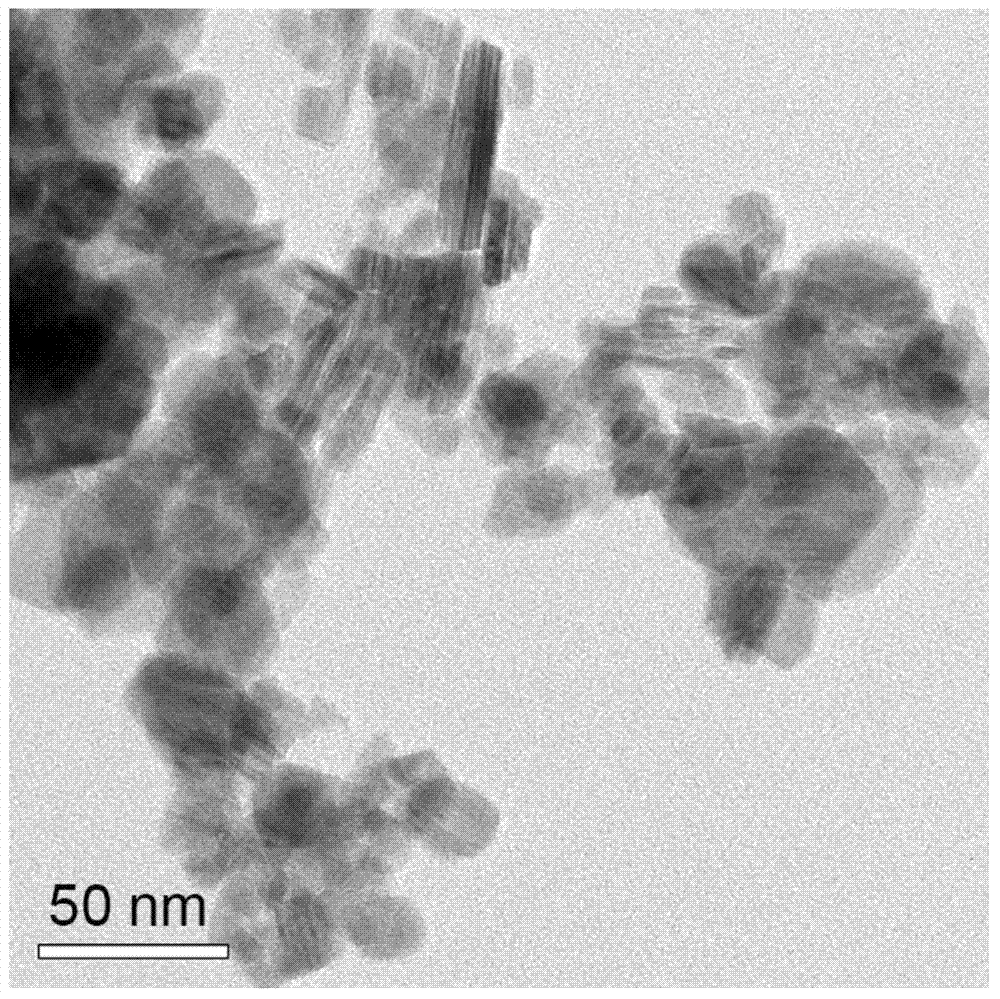

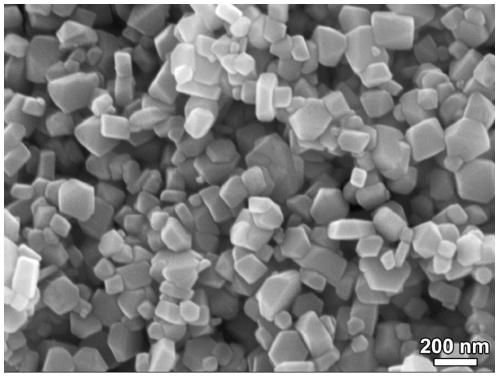

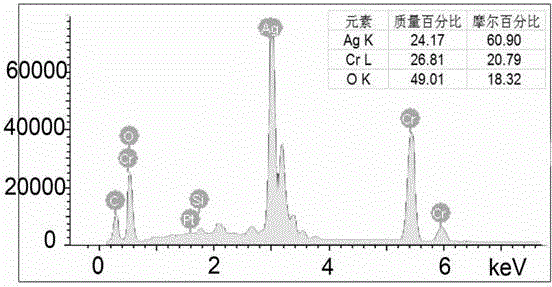

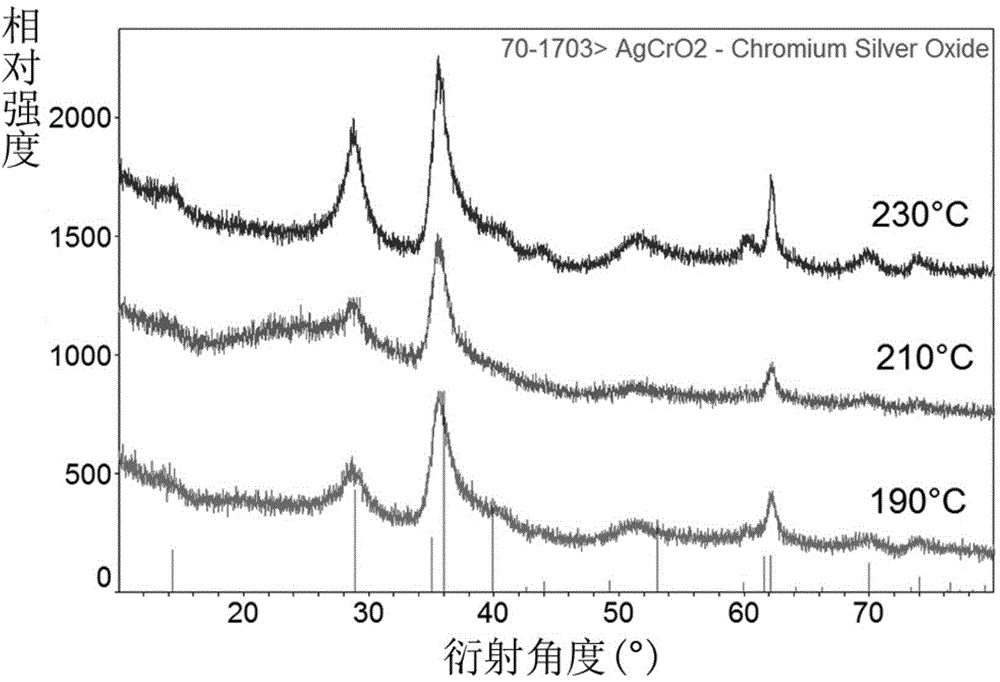

Preparation method for delafossite-structure AgCrO2 nanocrystalline material

ActiveCN103880081AHigh yieldLow costMaterial nanotechnologyLight-sensitive devicesDelafossiteSynthesis methods

The invention discloses a preparation method for a delafossite-structure AgCrO2 nanocrystalline material, in particular to a low-temperature hydro-thermal synthesis method for rapidly preparing a delafossite-structure AgCrO2 nanocrystalline material. The preparation method comprises the following steps: regulating a reaction precursor constituent, a reaction temperature and the filling rate parameter of reaction solution in a hydro-thermal reaction kettle, reacting at 190-230 DEG C for 36-60 hours, carrying out centrifugal cleaning treatment on the reaction product for multiple times, and drying at 60 DEG C in a vacuum drying oven for 24-48 hours, thereby finally obtaining the AgCrO2 nanocrystalline material with the size of 10-20 nm. The method is simple to operate, easy in control over process parameters, pollution-free, high in yield, and capable of being widely used in photoelectric function devices such as transparent conductive oxides.

Owner:WUHAN UNIV OF TECH

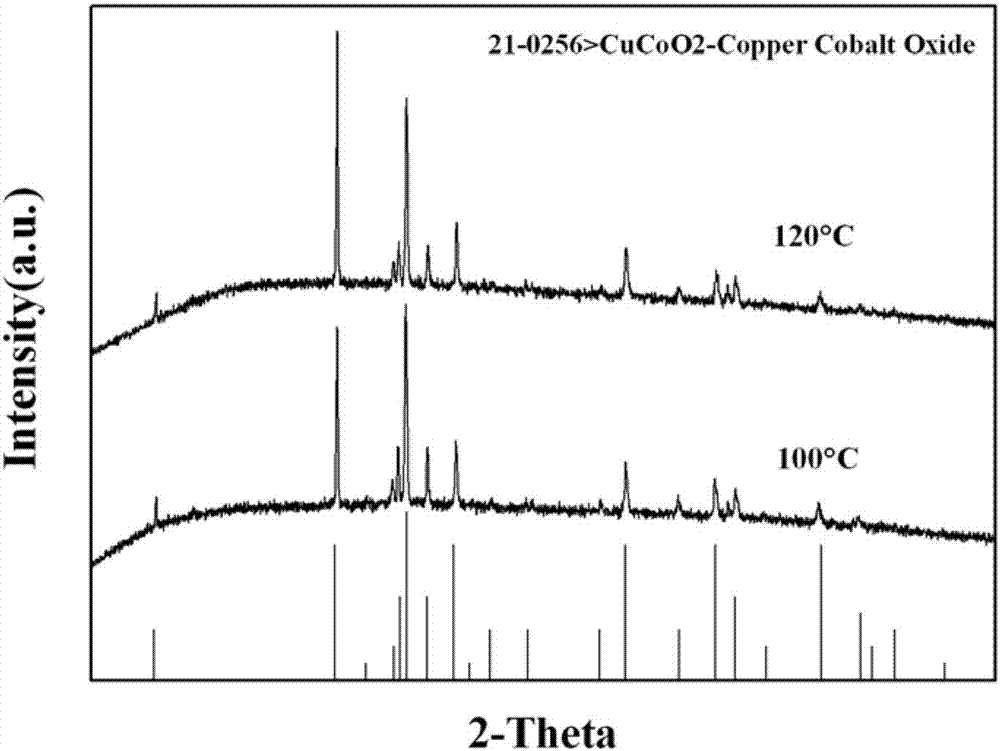

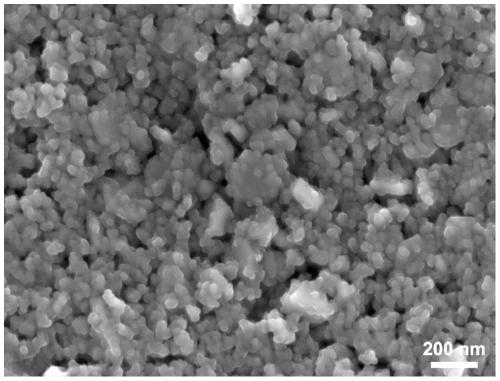

A delafossite-structured CuCoO2 crystal material and a low-temperature preparation method thereof

ActiveCN107098401ASimple preparation processGood experimental repeatabilityCobalt compoundsDelafossiteReaction temperature

The invention relates to the field of preparation of delafossite-structured crystal materials, particularly relates to preparation of a CuCoO2 crystal material at a low temperature by utilizing a hydrothermal process, and more particularly relates to a low-temperature preparation method of the delafossite-structured CuCoO2 crystal material. The method is characterized in that a low-temperature hydrothermal reaction is utilized, reaction precursor components, the reaction temperature and the filling coefficient of a filling liquid in a hydrothermal reactor are regulated, and after Co(NO3)<2>.6H2O and Cu(NO3)<2>.3H2O are reacted at 100-120 DEG C for 12-36 h, a reaction product is subjected to centrifugal cleaning treatment and drying to obtain the crystal material the particle size of which is 1-4 microns. The method when compared with other CuCoO2 crystal material preparing methods has advantages of an ultralow temperature, a high yield, a low cost and low pollution.

Owner:WUHAN UNIV OF TECH

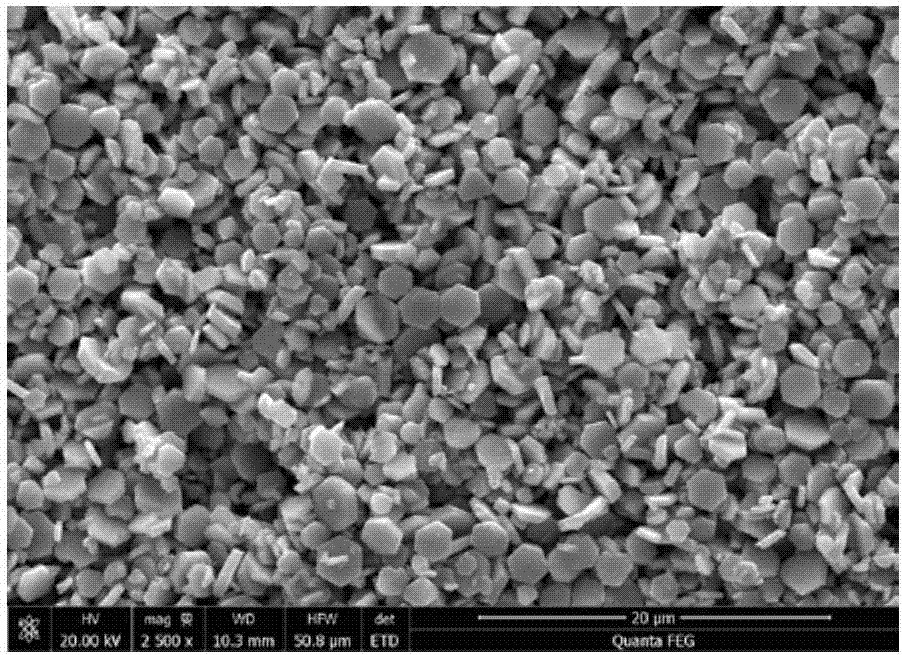

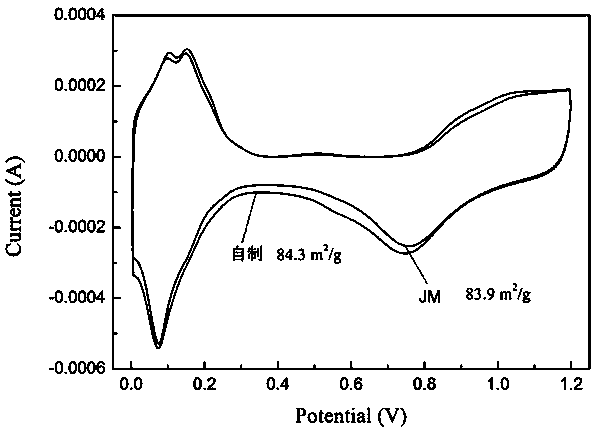

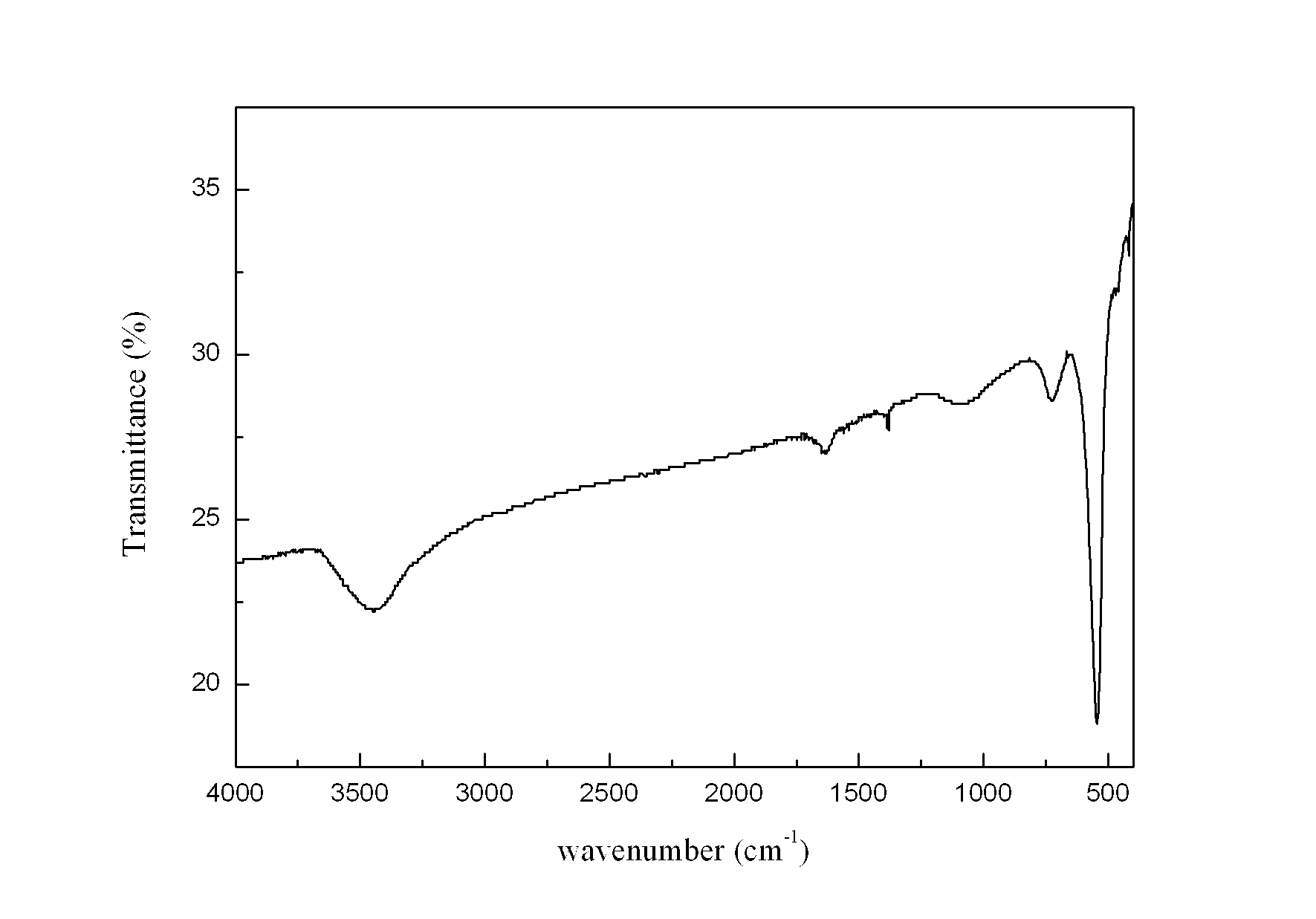

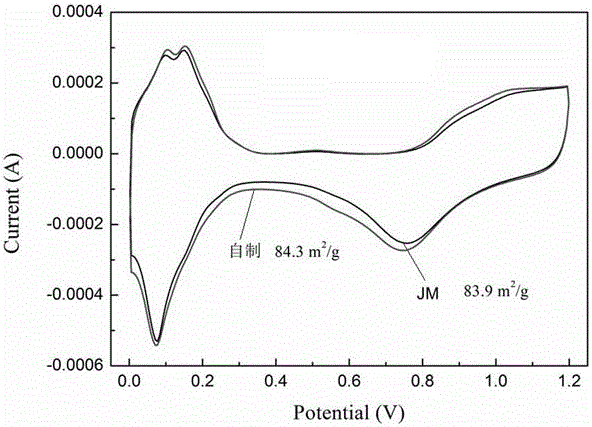

Pt/C catalyst of fuel cell and preparation technology thereof

ActiveCN103730668ALarge electrochemical active areaSimple processCell electrodesMetal/metal-oxides/metal-hydroxide catalystsPtru catalystFuel cells

The invention discloses a Pt / C catalyst of a fuel cell. The Pt / C catalyst is characterized in that the mass fraction of Pt in the Pt / C catalyst is 60%, and the Pt / C catalyst comprises the following raw material components in parts by weight: 1-2 parts of a carbon black carrier, 100-200 parts of deionized water, 200-350 parts of a reducibility polyhydric alcoholic solution with 15-30g / L chloroplatinic acid hexahydrate, 30-100 parts of reducibility polyhydric alcohol, and 10-40 parts of 1M aqueous alkali. Compared with the prior art, the catalyst prepared by the preparation technology provided by the invention has the advantages that the electrochemical active area is large, the technology is simple, and the single-pass output is high.

Owner:KUSN INNOVATION INST OF NANJING UNIV

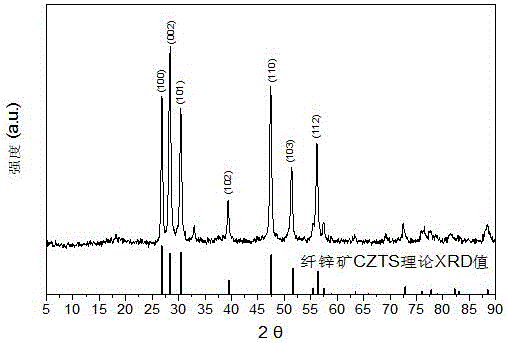

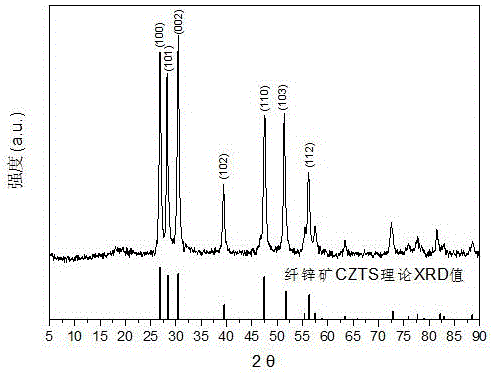

Large-scale preparation method for wurtzite Cu2ZnSnS4 nanocrystal

ActiveCN106395886ALow costImprove product qualityTin compoundsNanotechnologyNew energy1-dodecanethiol

The invention discloses a large-scale preparation method for a wurtzite Cu2ZnSnS4 nanocrystal, belonging to the field of photoelectric material new-energy technology. The method comprises the following steps: weighing a monovalent copper salt, a zinc salt and a tin salt, adding the monovalent copper salt, the zinc salt and the tin salt into a three-neck flask, adding oleylamine as a solvent and successively carrying out heating and cooling to room temperature; adding 1-dodecanethiol and carbon disulfide as sulfur sources, carrying out a reaction under heating and then carrying out cooling to room temperature; carrying out centrifugation and discarding supernatant; carrying out cleaning with a mixed solution of hexane, methanol and ethanol a plurality of times and collecting a precipitate; and drying the precipitate so as to obtain the wurtzite Cu2ZnSnS4 nanocrystal. The method provided by the invention is simple, great in output and high in yield and can produce plural grams of the wurtzite Cu2ZnSnS4 nanocrystal at a time; the output of the method at a time is one magnitude order higher than the output of conventional methods; and the prepared nanocrystal has an easily regulable atomic ratio, and an ideal wurtzite Cu2ZnSnS4 nanocrystal can be obtained by simply changing the ratio of a precursor.

Owner:KUNMING UNIV OF SCI & TECH

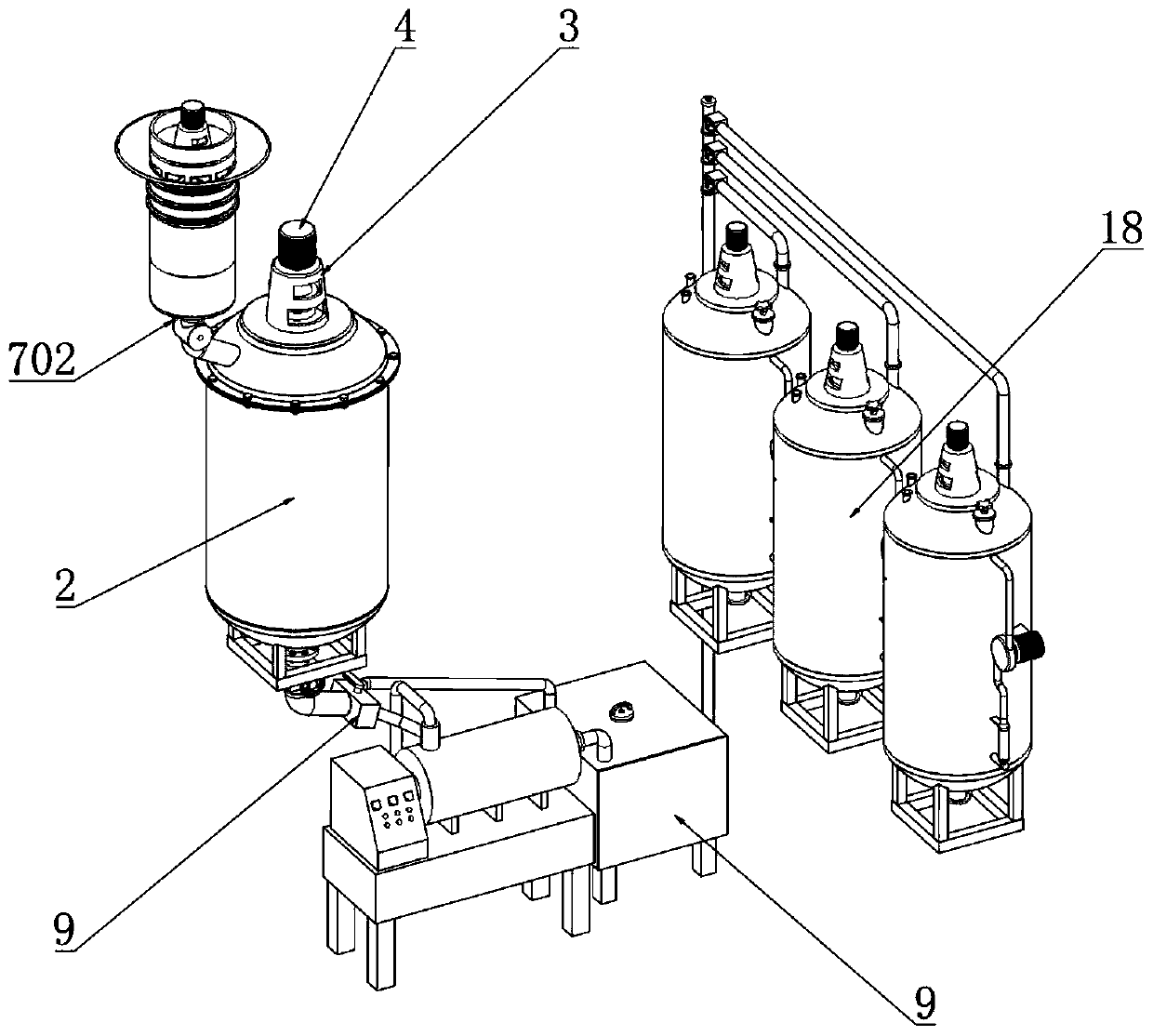

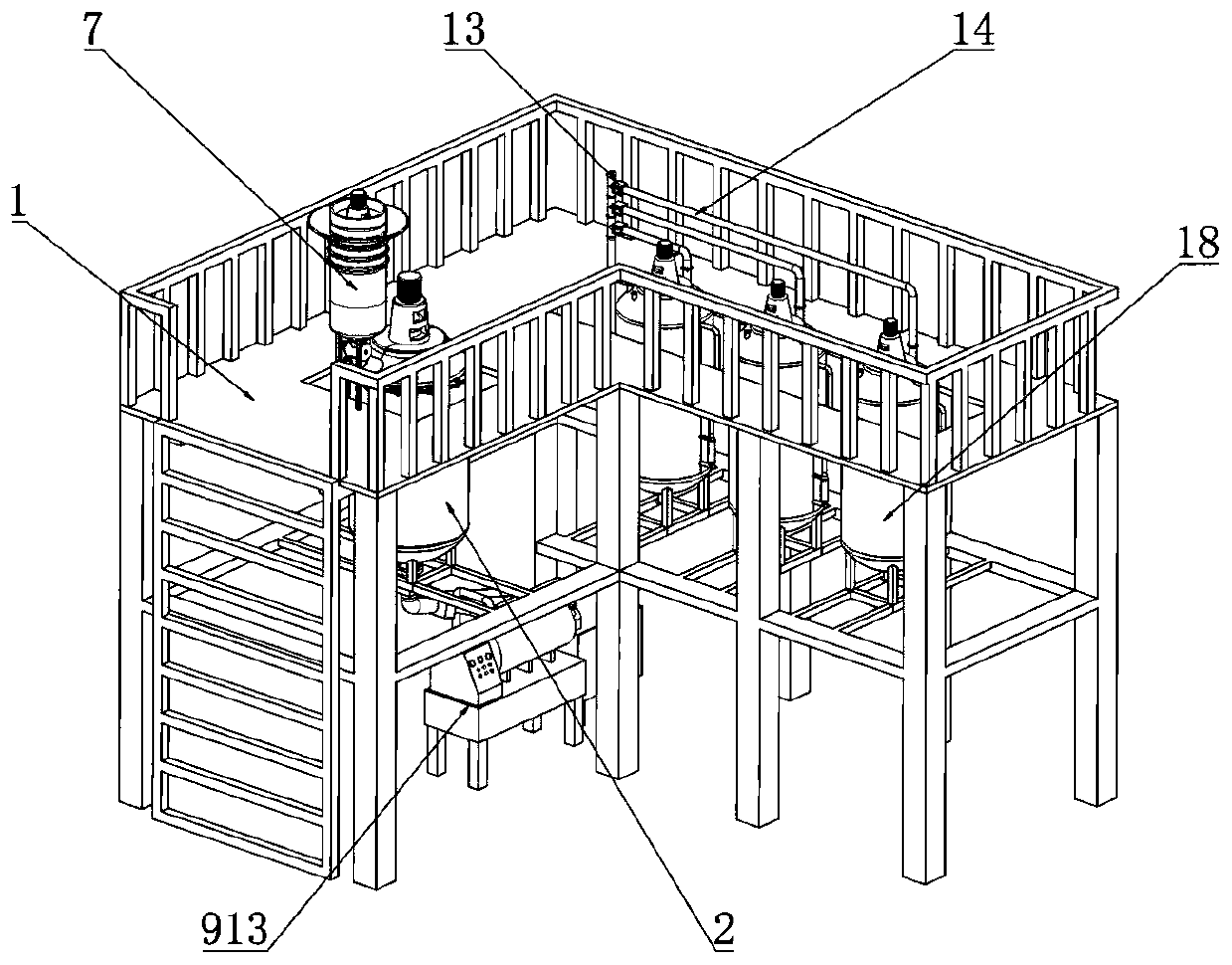

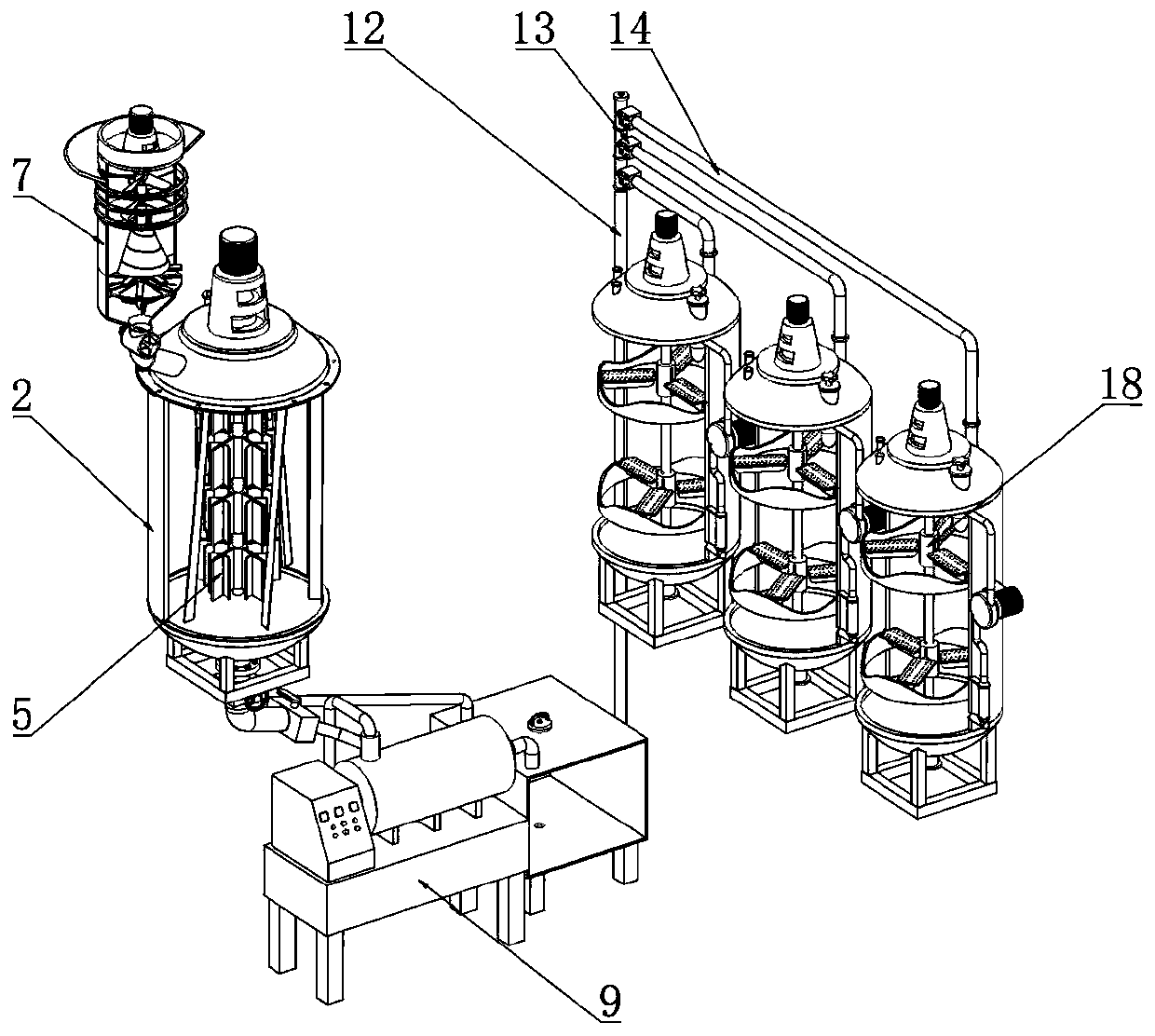

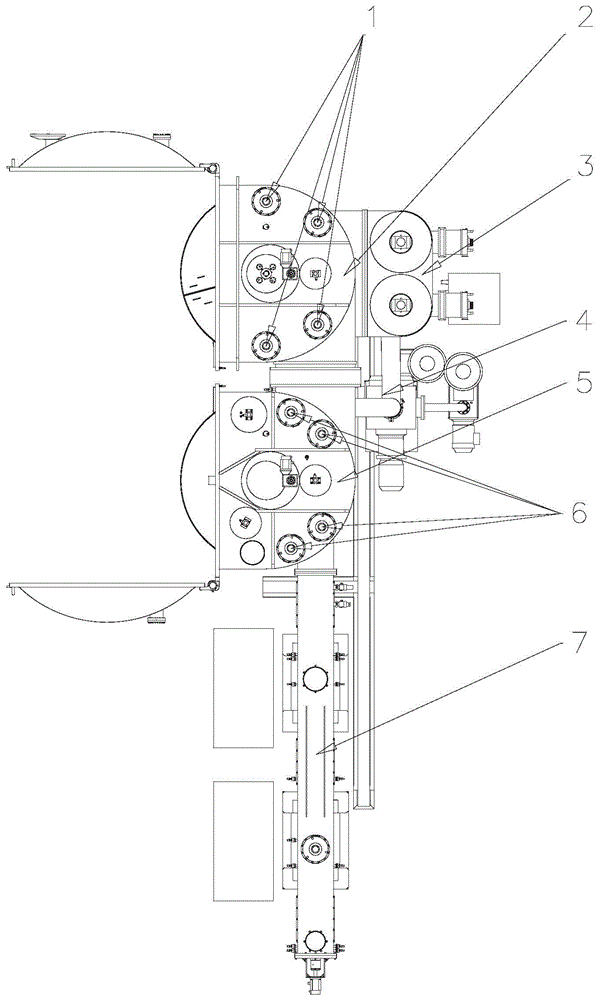

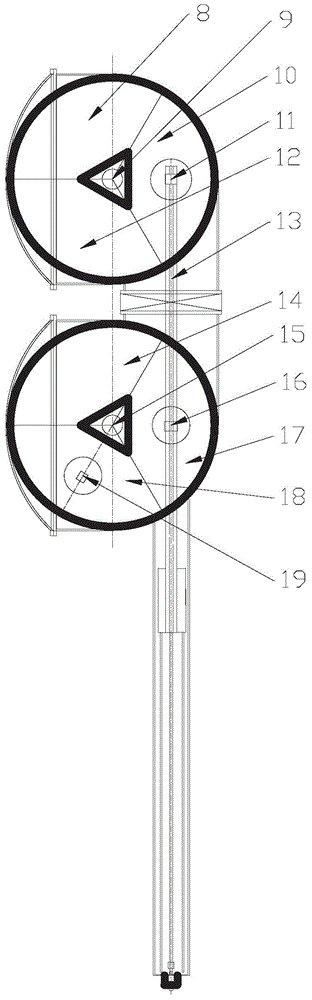

Manufacturing device for producing weather-resistant environment-friendly anticorrosive coating

ActiveCN111569760AScientific and reasonable structureEasy to useTransportation and packagingMixer accessoriesWeather resistanceElectric machine

The invention discloses a manufacturing device for producing a weather-resistant environment-friendly anticorrosive coating. The manufacturing device comprises a mounting support, wherein a dispersingbarrel is fixedly connected to one end of the top of the mounting support; a fixed mounting rack is fixedly connected to the middle part of the top end of the dispersing barrel; a dispersing motor isfixedly connected to the middle part of the top end of the fixed mounting rack; the input end of the dispersing motor is electrically connected with the output end of a mains supply; and an efficientdispersing and discharging mechanism is arranged on the inner side of the dispersing barrel. According to the invention, powdery raw materials are added into the dispersing barrel through a materialadding port; under the action of a driving gear and a rotating gear ring, the rotating gear ring, a connecting inclined rod, a mounting ring and a dispersing rotating shaft are driven to rotate in opposite directions, and therefore, stirring vertical plates, stirring arc plates and a mounting ring on the dispersing rotating shaft rotate in opposite directions in the dispersing barrel at the same time; and thus, efficient stirring in the dispersing barrel is achieved, the mixing rate of raw materials in the dispersing barrel is increased, the mixing time of anticorrosive paint is shortened, andthe processing efficiency of the anticorrosive paint is improved.

Owner:丹阳市美尔鑫化工有限公司

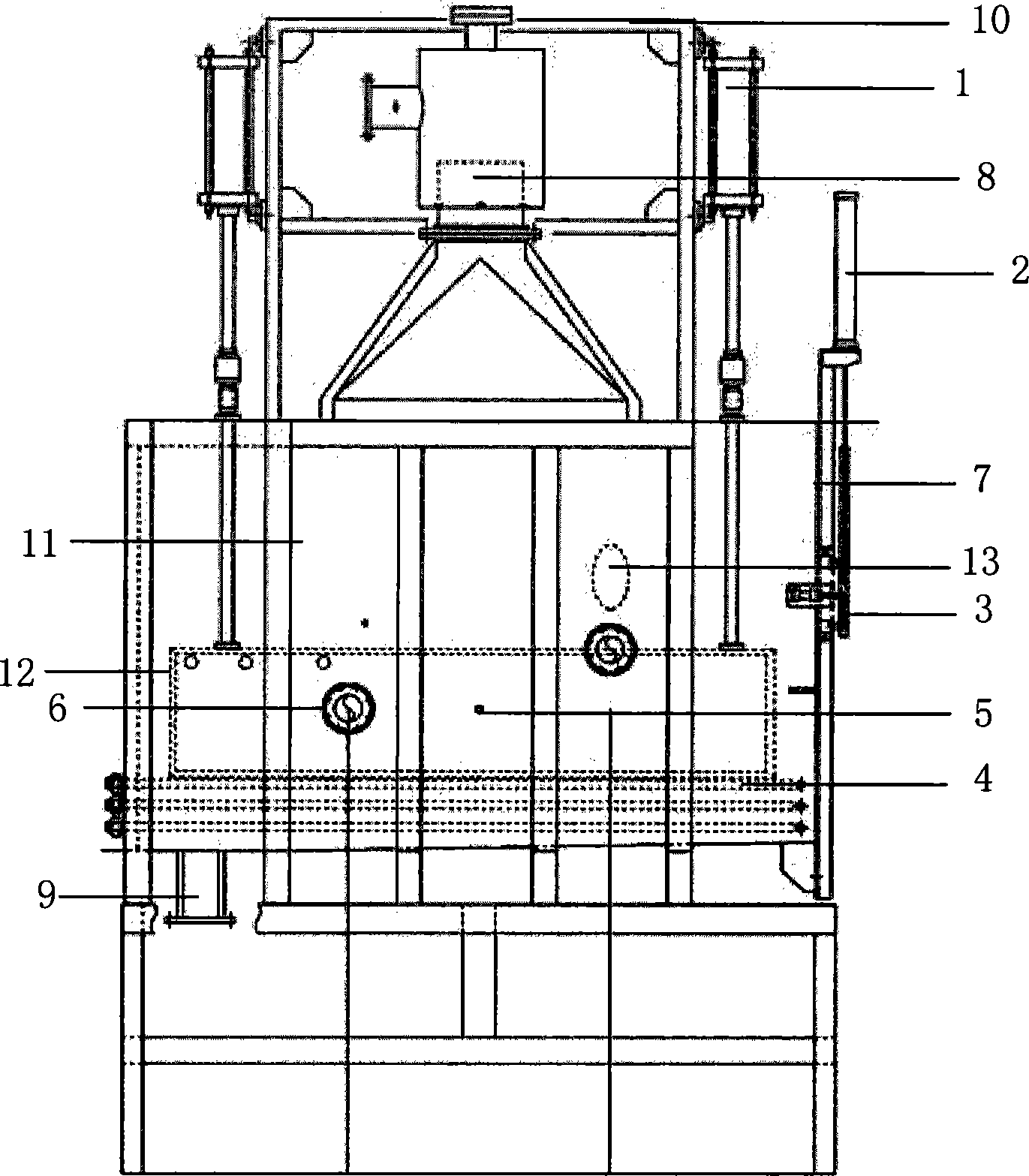

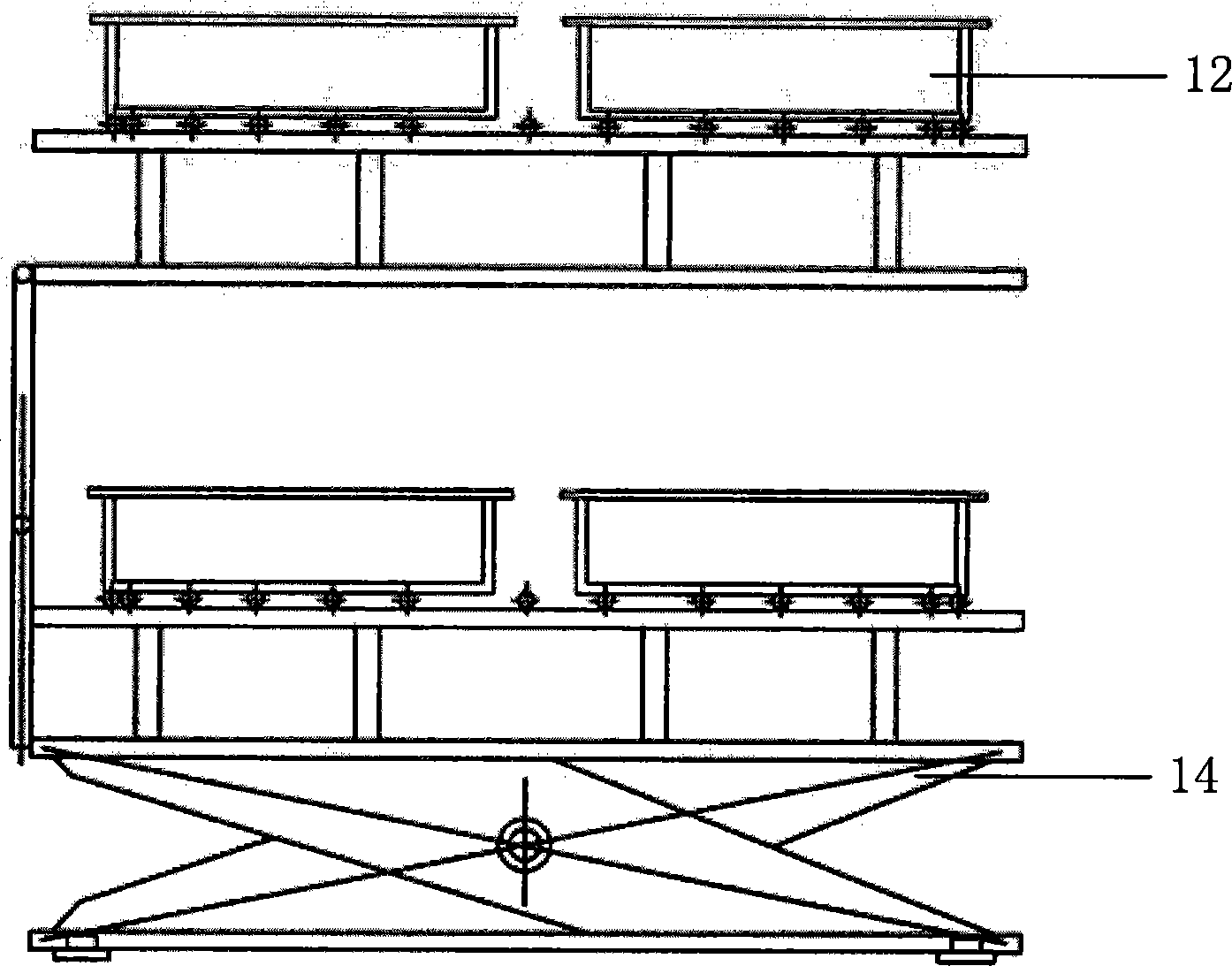

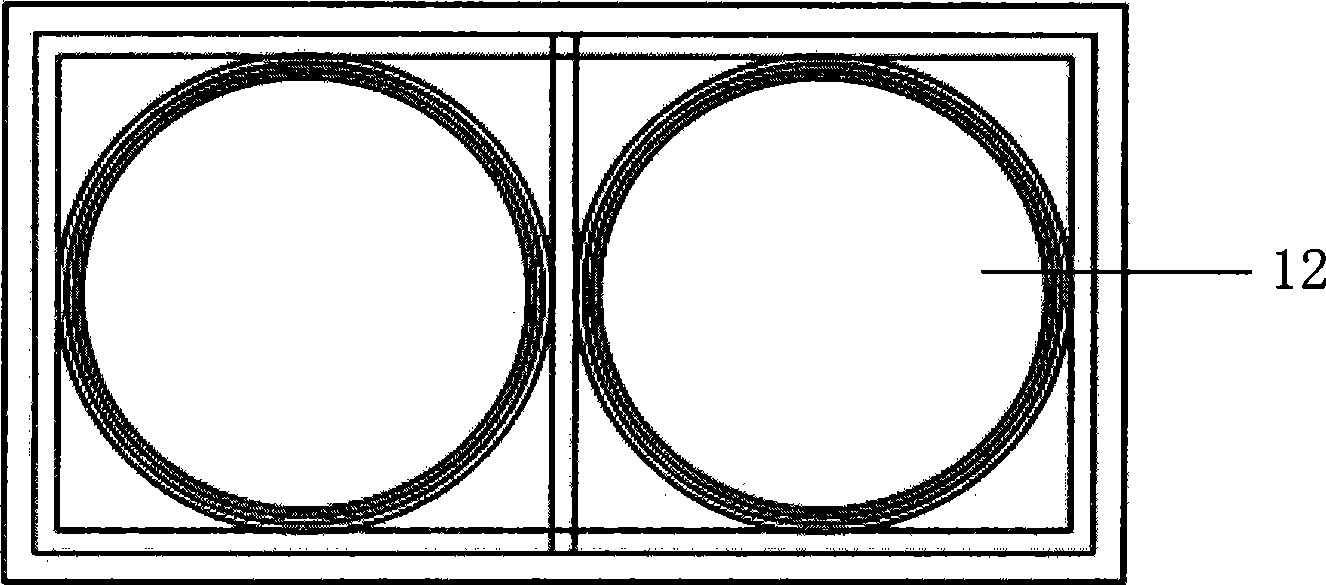

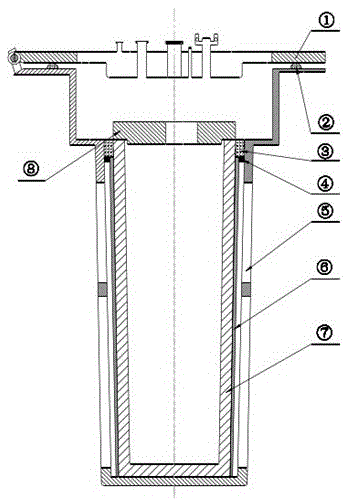

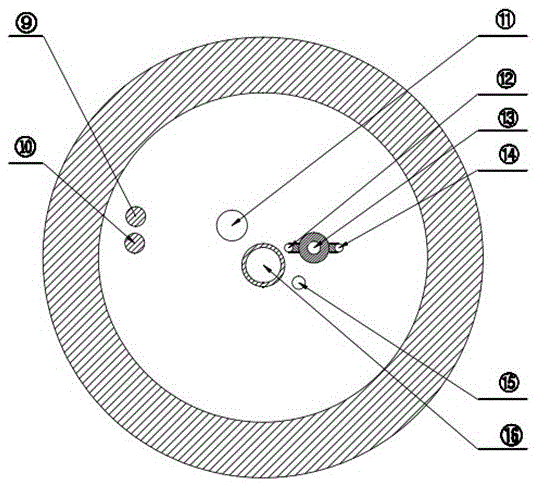

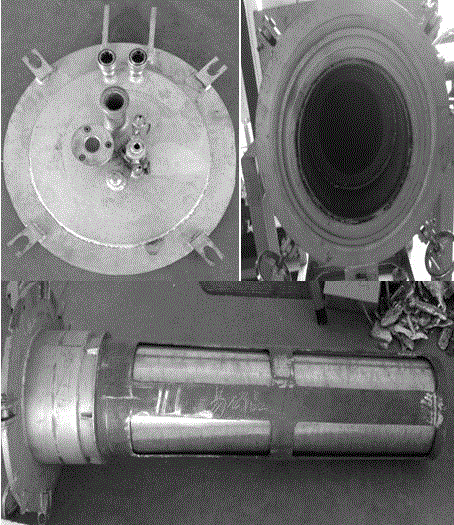

Low-temperature deep frying device and method for deep frying food

ActiveCN104170903ARealize automatic oil fillingReal-time detection of temperatureOil/fat bakingDeep fryingEngineering

The invention provides a low-temperature deep frying device and a method for deep frying food to be deep fried. The low-temperature deep frying device comprises a deep frying groove, a material inlet / outlet door, an oil inlet / outlet, a heating tube arranged in the deep drying groove, a vacuum device for making the interior of the deep frying groove reach a vacuum state, a deep frying main air cylinder for adjusting the deep frying position, a material inlet / outlet door air cylinder a for driving the material inlet / outlet door to descend or ascend, a material inlet / outlet door air cylinder b for driving the material inlet / outlet door to be opened or closed, an oil level meter for detecting the height of the oil level, a temperature gauge for detecting the oil temperature, and an electromagnetic valve used for receiving an oil temperature signal and controlling the deep frying main air cylinder, the material inlet / outlet door air cylinder a and the material inlet / outlet door air cylinder b, wherein the material inlet / outlet door and the oil inlet / outlet are communicated with the deep frying groove. According to the low-temperature deep frying device, the amount of oil injected into the deep frying groove and the temperature of the oil in the deep frying groove can be known through the oil level meter and the temperature gauge; through the deep frying main air cylinder, the position of a material inlet basket can be adjusted so that articles, to be deep fried, in the material inlet basket can make full contact with the oil.

Owner:BEIJING KAIDA HENGYE AGRI TECH DEV

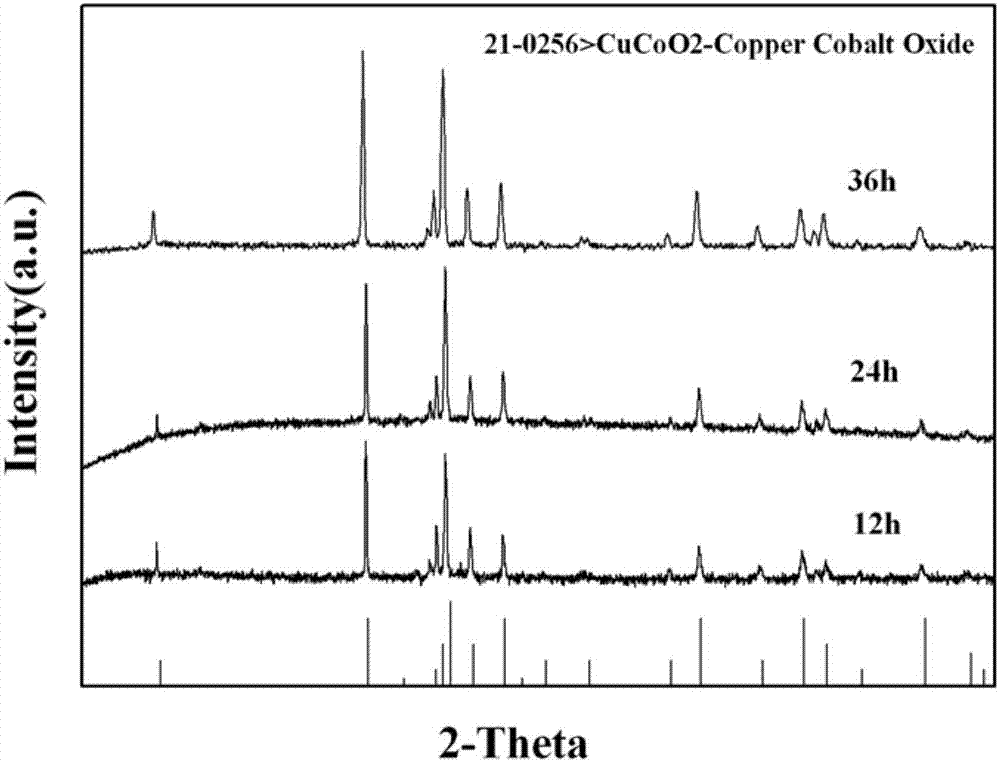

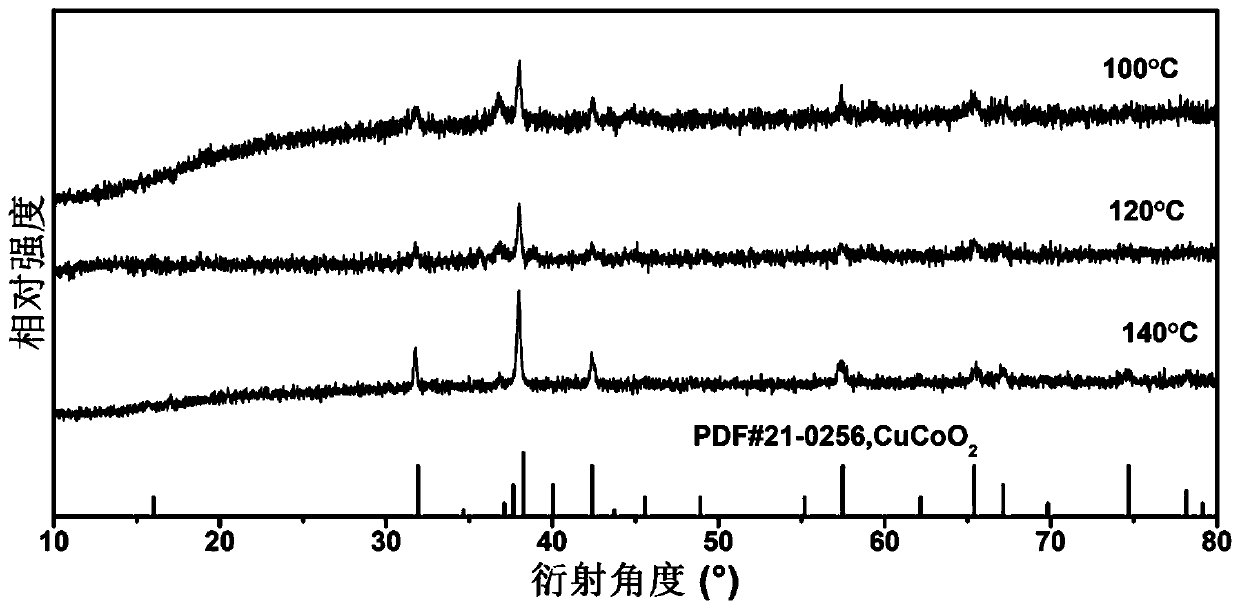

Method for preparing CuCoO2 nanocrystal material based on MOFs material at low temperature

ActiveCN109748327ALow costReduce yieldMaterial nanotechnologyCobalt compoundsMetal-organic frameworkStructure based

The invention relates to a method for synthesizing a nano-sized CuCoO2 crystal material according to a hydrothermal method at relatively low temperature. A method for preparing a CuCoO2 nanocrystal material adopting a delafossite structure based on an MOFs material at low temperature is characterized by comprising the following steps: preparing a reaction precursor by using a metal organic framework material (Metal Organic Frameworks, the MOFs material) as a starting reactant, putting the reaction precursor into a hydrothermal reaction kettle, performing a hydrothermal reaction at 100-140 DEGC for 24-48 hours, then centrifugally cleaning a reaction product to obtain a precipitate, and drying the precipitate to obtain the CuCoO2 nanocrystal material adopting the delafossite structure and having the size of the 50-200 nm. The operation is simple, technological parameters are easy to control, and the method is pollution-free and high in yield and has the characteristics of low temperature and rapidness; the CuCoO2 nanocrystal material can be widely applied to various novel photoelectric functional devices.

Owner:WUHAN UNIV OF TECH

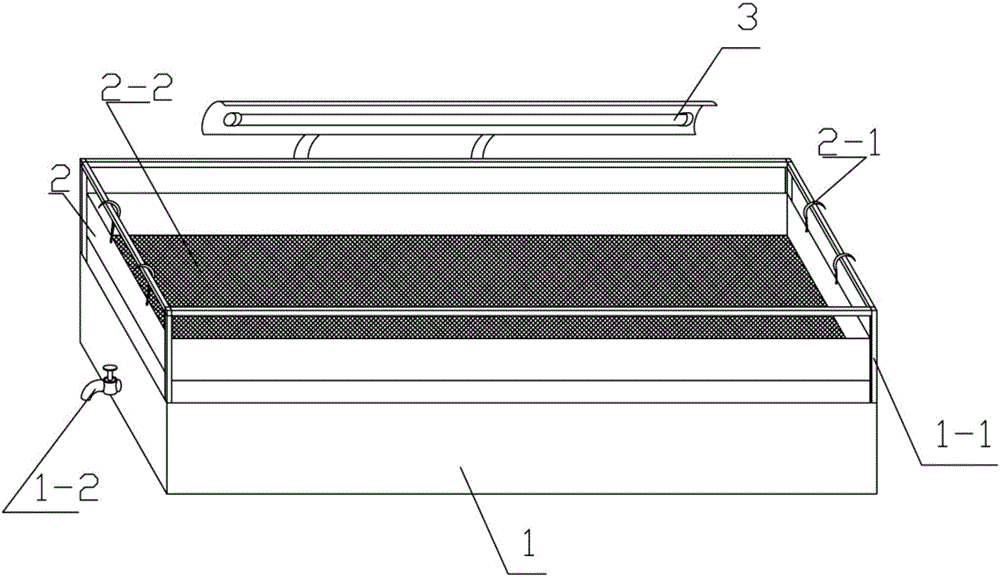

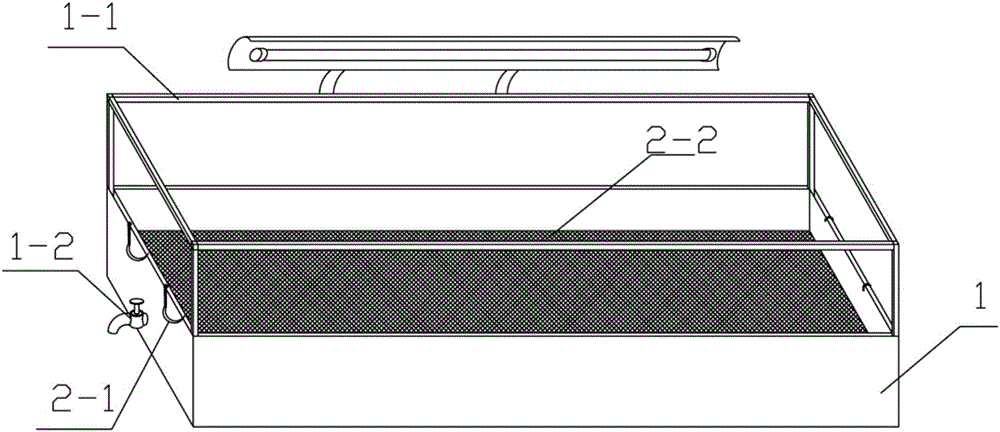

Method for feeding hirudo nipponia adults and sustainably extracting hirudin and special equipment

InactiveCN106188277AHigh single outputSave resourcesAnimal husbandryLeech-based protease inhibitorsSaline waterEconomic benefits

The invention provides a method for feeding hirudo nipponia adults and sustainably extracting hirudin. The method specifically comprises the following steps: 1) satiating hirudo nipponia with induced liquids, and cleaning and cleaning again with saline of which the concentration is 0.6 to 0.8%; 2) adding vomiting liquids according to a weight ratio of the hirudo nipponia to the vomiting liquids of 1: 1; 3) carrying out ultraviolet-irradiation induction on the hirudo nipponia for 2 to 3 times, wherein the induction is carried out for 10 to 15 minutes for each time and at an interval of 10 to 15 minutes for next time; 6) after the irradiation induction is finished, spraying the saline of which the concentration is 0.6 to 0.8% to clean the hirudo nipponia, and collecting cleaning liquids as hirudin extracting solutions. The invention provides the method for sustainably providing the hirudin to save sources of the hirudo nipponia. Furthermore, the extraction vomitive agents provided by the invention can increase the single-yield of the hirudin, so that the method for feeding the hirudo nipponia adults and sustainably extracting the hirudin has significant economic benefits.

Owner:重庆志微生物技术有限公司

Manufacturing method of high-reliability and high-thermal-conductivity diamond reinforced metal matrix composite material

ActiveCN112981164AImprove thermal conductivityImprove reliabilityTransportation and packagingMetal-working apparatusHeat conductingCarbide

The invention discloses a manufacturing method of a high-reliability and high-thermal-conductivity diamond reinforced metal matrix composite material, and relates to a manufacturing method of a composite material. The method aims to solve the problems that an existing diamond reinforced metal matrix composite material is low in thermal conductivity, and the reliability is reduced. The method comprises the steps of carrying out cold pressing on diamond powder with a coating to obtain a diamond blank, carrying out spark plasma sintering under the vacuum or inert atmosphere protection to obtain a diamond preformed body, placing the diamond preformed body and a mold on the platform surface of a press, pouring a molten metal matrix to the top of the diamond preformed body in the mold, and carrying out pressure infiltration. According to the method, the coating on the diamond surface is sintered by spark plasma sintering to form a continuous heat conducting passage, so that the heat conducting property of the material is improved. The coating easily reacts with the diamond to generate carbide metal and is stable, so that the reliability of the manufactured composite material is improved. The method is suitable for manufacturing the diamond reinforced metal matrix composite material.

Owner:HARBIN INST OF TECH

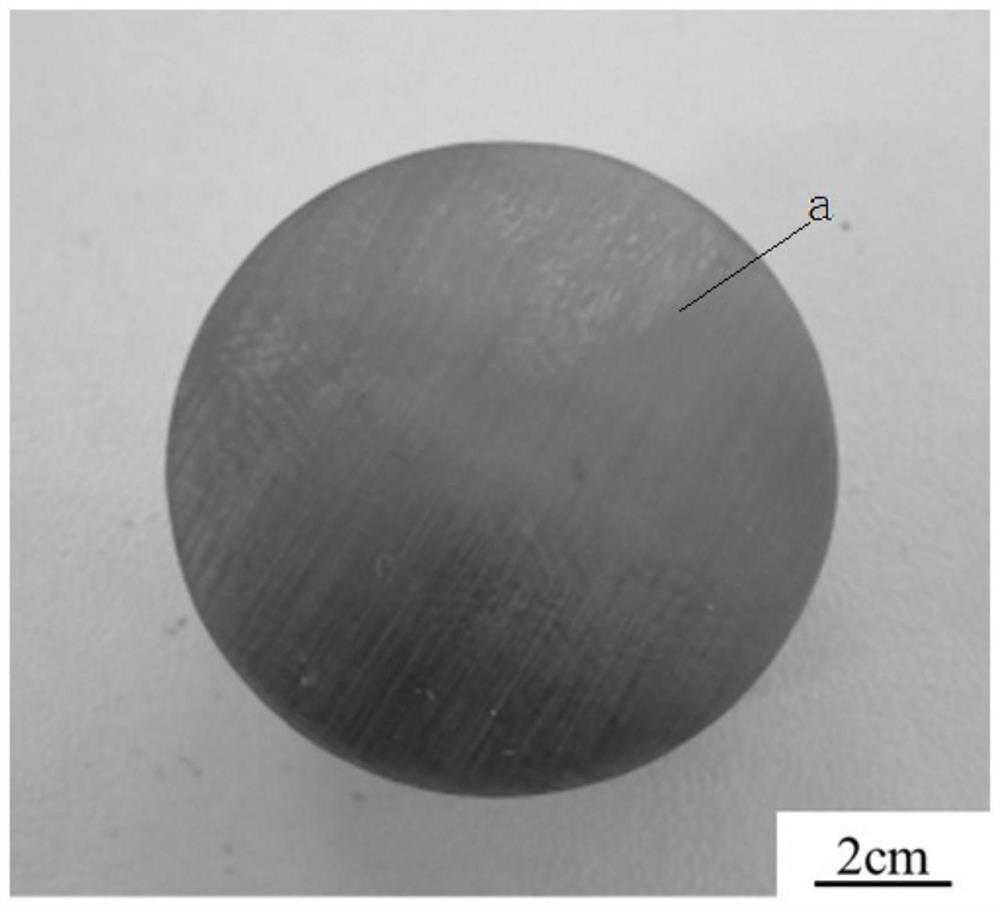

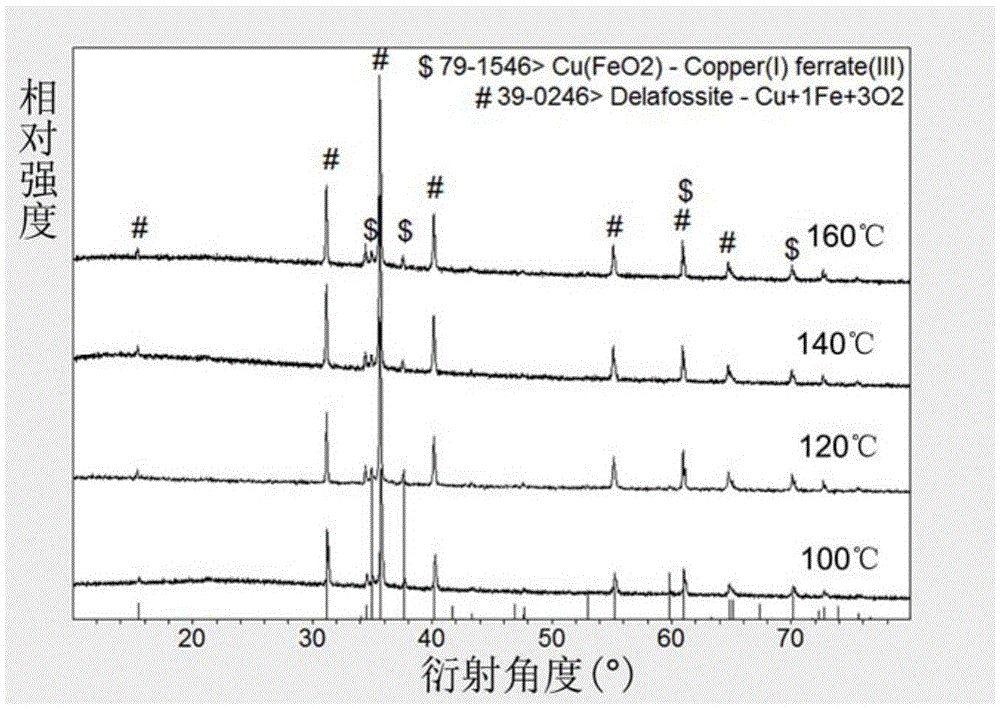

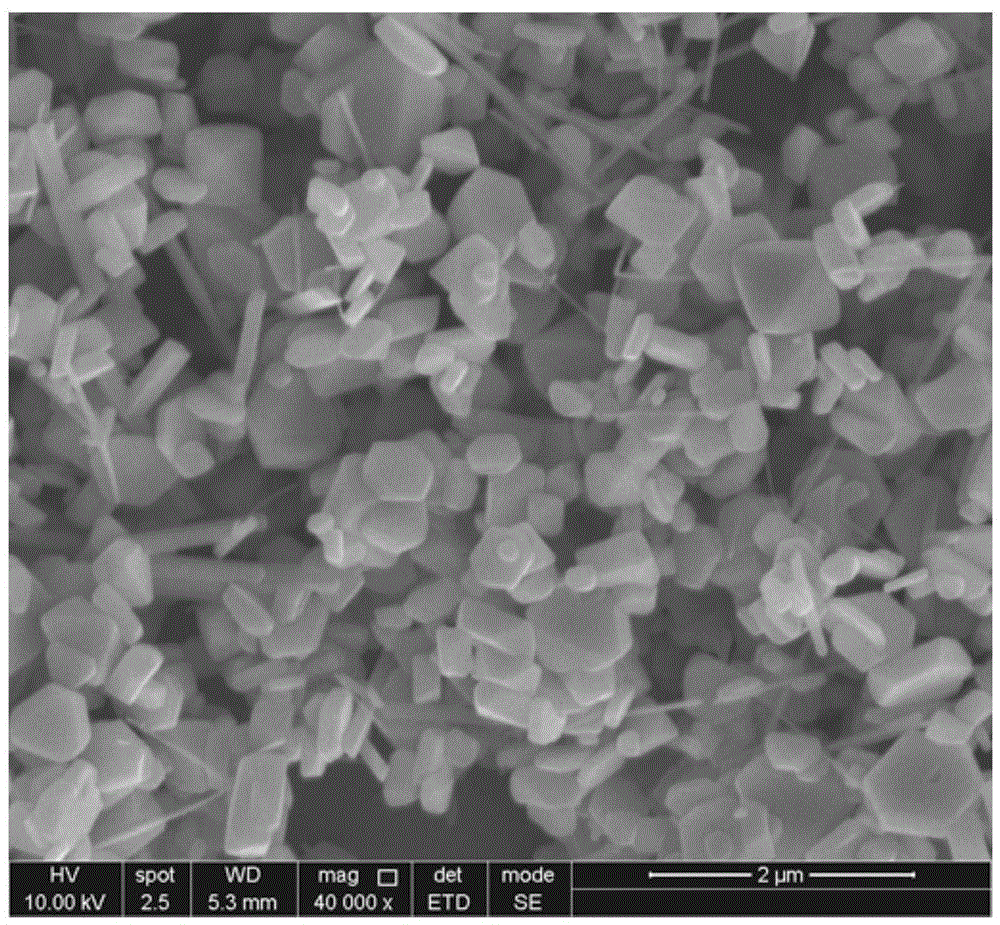

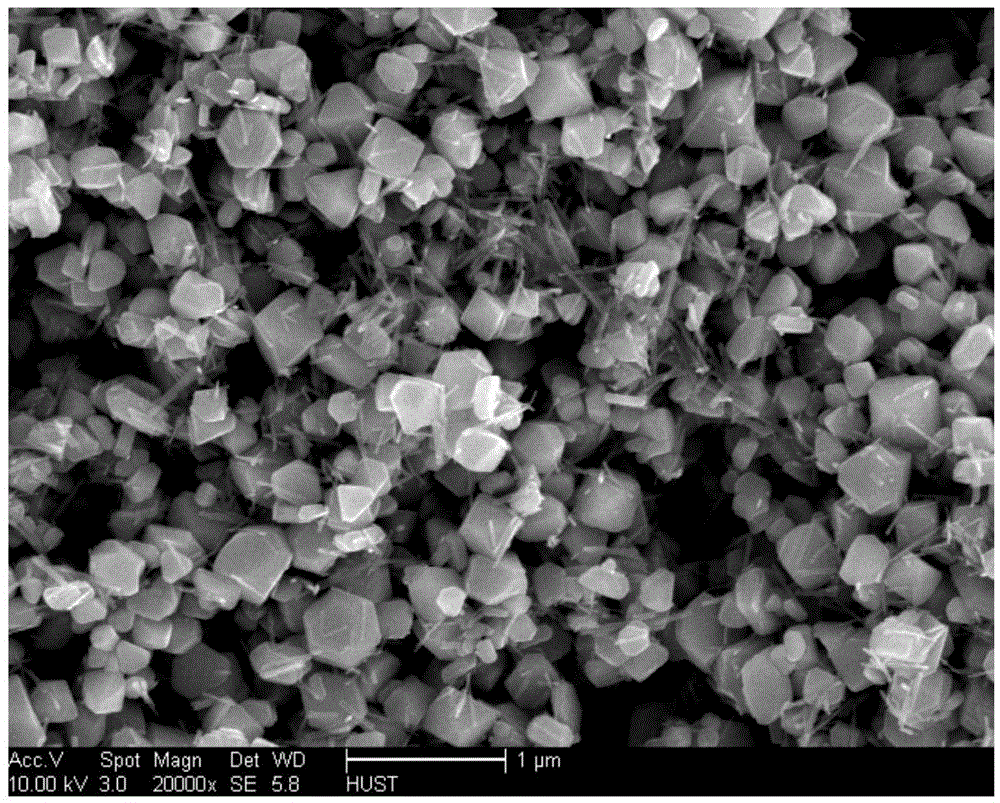

A kind of low-temperature preparation method of delafossite structure cufeo2 crystal material

ActiveCN104058461BSimple preparation processProcess parameters are easy to controlMaterial nanotechnologyIron compoundsDelafossiteReaction temperature

The invention discloses a low-temperature preparation method for a CuFeO2 crystal material of a delafossite structure, in particular to a low-temperature hydrothermal synthesis method for rapidly preparing the CuFeO2 nanocrystalline material of the delafossite structure. The method comprises the steps that parameters including reaction precursor components, the reaction temperature and the filling rate of a reaction solution in a hydrothermal reaction kettle are regulated and controlled through a low-temperature hydrothermal reaction, reactants including Cu(NO3)2 and FeCl2 react for 12 hours to 48 hours at the temperature ranging from 100 DEG C to 160 DEG C, and then, after a reaction product is processed through centrifugal cleaning and dried, the nanoscale CuFeO2 crystal material is obtained. The low-temperature preparation method for the CuFeO2 crystal material of the delafossite structure is easy to operate, the technological parameters are easy to control, no pollution is caused, the yield is high, and the method can be widely used for photoelectricity functional devices such as transparent conducting oxide.

Owner:WUHAN UNIV OF TECH

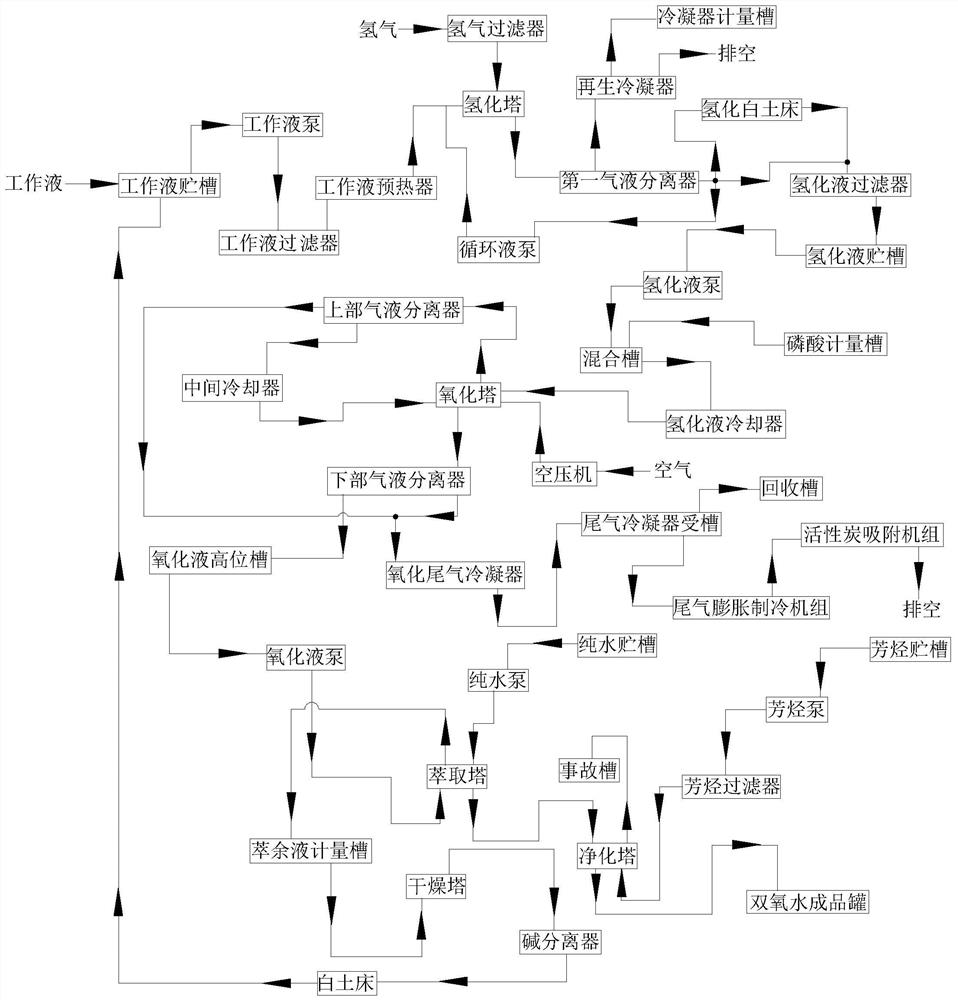

A kind of anthraquinone method prepares the working liquid of hydrogen peroxide and its application

ActiveCN109911859BImprove solubilityImprove oxidation efficiencyPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesSolubilityAnthraquinones

The present invention adopts an anthraquinone method to prepare a working solution of hydrogen peroxide, which includes a solute 2-ethylanthraquinone and a solvent system for dissolving 2-ethylanthraquinone. The solvent system includes solvent heavy aromatic hydrocarbons and trioctyl phosphate. , o-methylcyclohexyl acetate, the volume ratio of the heavy aromatic hydrocarbon, trioctyl phosphate, o-methylcyclohexyl acetate is 78:23:8. The working fluid designed by the present invention can replace part of trioctyl phosphate with o-methylcyclohexyl acetate, which can effectively improve the solubility of anthraquinone in the working fluid solvent system, thereby improving the oxidation efficiency and hydrogenation efficiency, and can effectively improve the preparation of hydrogen peroxide. The single output of the process can effectively reduce production costs.

Owner:HUAQIANG CHEM GRP

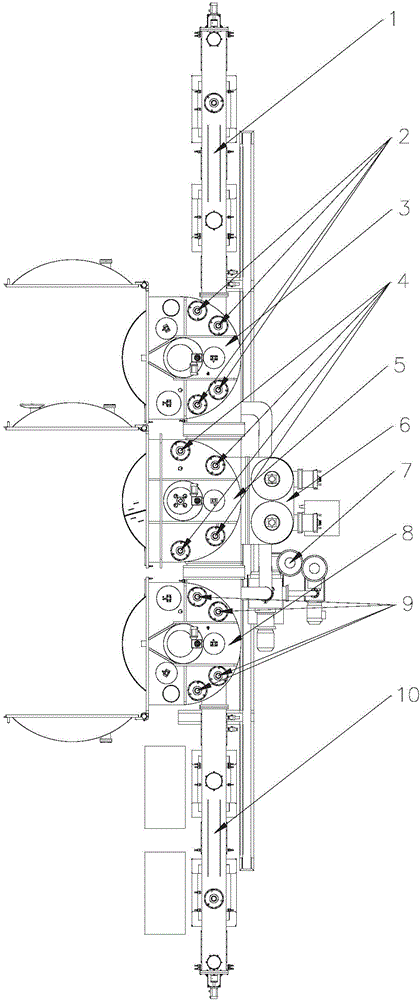

Metal fiber production technology

The invention relates to a metal fiber production technology. The metal fiber production technology has simple processes, can be operated simply and has a low cost. The metal fiber production technology comprises putting multiple stainless steel bars into the cavity of a casting mold, wherein the stainless steel bars are arranged in parallel along a casting mold extension direction, putting the casting mold in a high-temperature vacuum environment, filling the cavity with melt pure iron, taking out the cooled first casting part from the casting mold, orderly carrying out turning, cogging and rolling on the first casting part to obtain a first wire rod, cutting the first wire rod into multiple wire rods with the same length along the cross section of the first wire rod, repeating the above processes on the first wire rod to obtain a second wire rod, orderly carrying out multi-channel drawing and annealing treatment on the second wire rod to obtain a composite filament, carrying out electrolysis in an acid solution based on the composite filament as an anode, washing the metal wires by distilled water and carrying out rinsing to obtain the metal fibers according with standards.

Owner:DEANWINNER CHINA METAL TECH

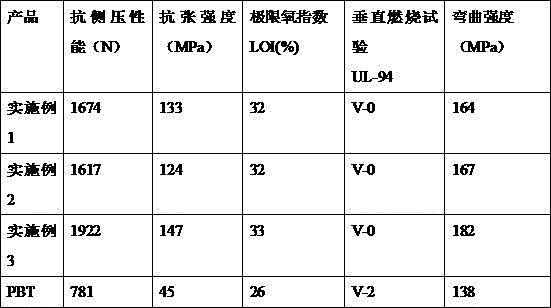

Optical fiber outer sheath material and preparation method thereof

ActiveCN106189111AEasy to processMake up for the defect of low rigidityPolytetramethylene terephthalateAntioxidant

The invention discloses an optical fiber outer sheath material and a preparation method thereof. The optical fiber outer sheath material is prepared from the following raw materials in parts by weight: 40-55 parts of polytrimethylene terephthalate, 5-10 parts of modified lignin, 25-35 parts of polybutylene terephthalate, 2-3 parts of ultraviolet-resistant material, 2-3 parts of compatilizer, 1-2 parts of antioxidant, 3-5 parts of coupling agent, 2-3 parts of nano composite hydroxide-inorganic filler powder and 0.1-0.2 part of dispersing agent. The optical fiber outer sheath material has the advantages of higher impact resistance, high tensile strength, high elastic modulus and favorable flame retardancy.

Owner:NANJING WASIN FUJIKURA OPTICAL COMM LTD

Five-cavity full-automatic electron beam deposition system

InactiveCN104630718AReduce pumping timeIncrease productionVacuum evaporation coatingSputtering coatingEngineeringMechanical engineering

The invention relates to the technical field of preparing various thin films on glass, plastic and ceramic matrixes and particularly relates to a five-cavity full-automatic electron beam deposition system. The system comprises a suction system and five cavities which comprise a transmission cavity I, a loading cavity I, a process cavity, a loading cavity II and a transmission cavity II sequentially communicated, wherein the cavities are connected with the suction system; vacuum locking systems are arranged between the loading cavity I and the process cavity and between the loading cavity II and the process cavity; sample carrying plates are arranged in the loading cavity I, the process cavity and the loading cavity II. According to the system provided by the invention, the suction time after exchanging the sample carrying plate every time in the process cavity is shortened while the output is high, so that the process flow of the process cavity and pick-and-place of the sample carrying plate in the loading cavities I and II are carried out at the same time. Moreover, other parts except a process cavity door and doors of the loading cavities I and II in the clean room can be placed in a common environment, so that the cost is relatively low.

Owner:SHENYANG SCI INSTR RES CENT CHINESE ACAD OF SCI

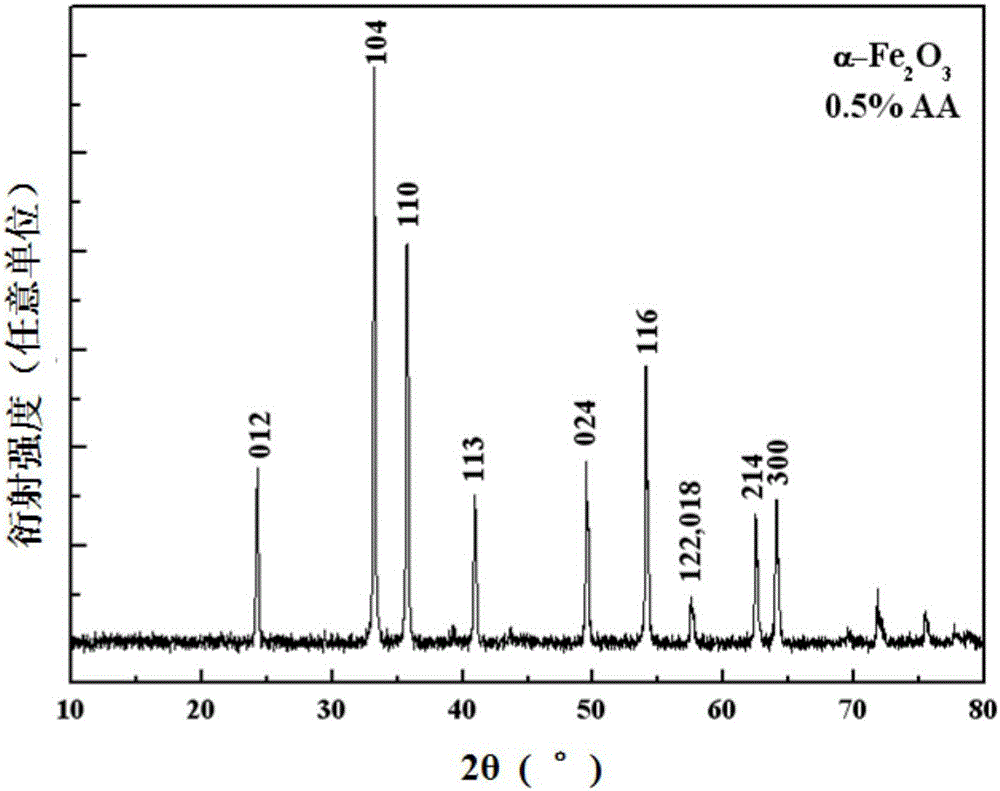

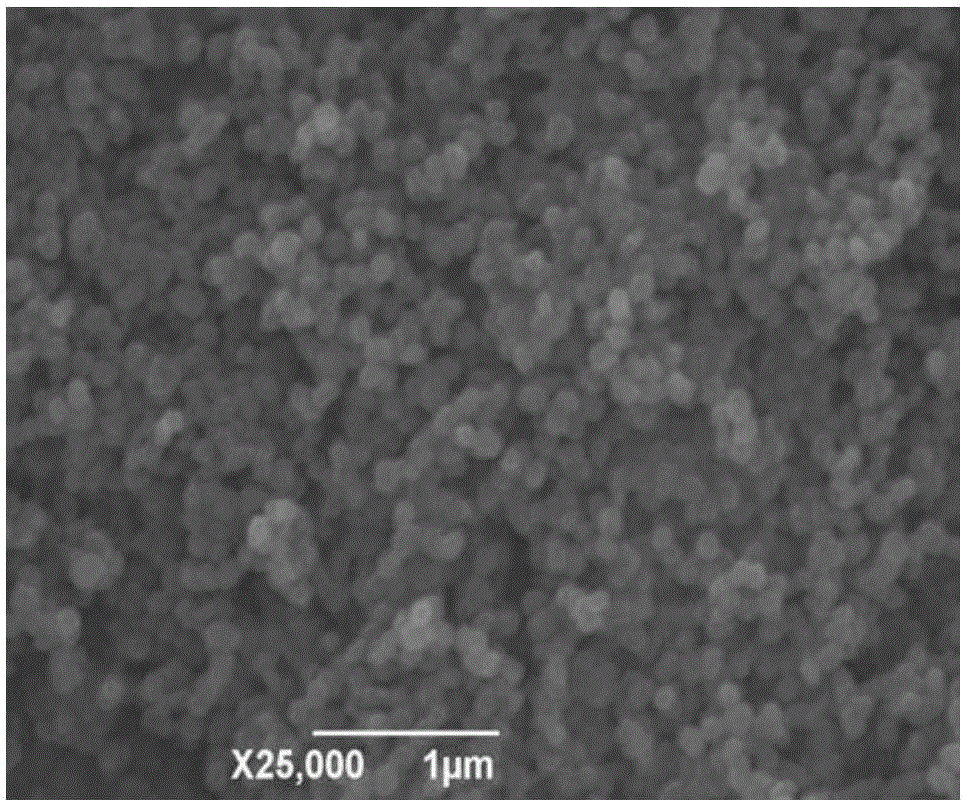

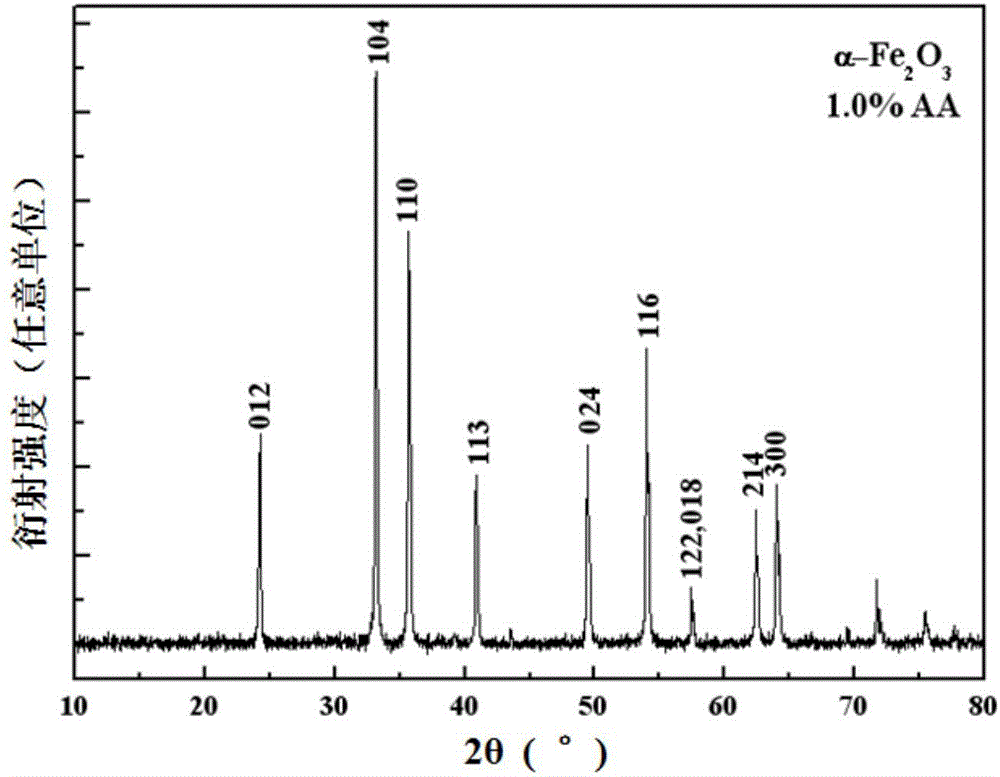

Preparation method for morphology-controllable hematite for degrading environmental pollutants

InactiveCN106745313APromote degradationImprove degradation rateFerric oxidesCrystallinityReducing agent

The invention discloses a preparation method for morphology-controllable hematite for degrading environmental pollutants. The method comprises the following steps: 1) dropwise adding 1-6mol / L alkali liquor into a ferric salt solution with Fe<3+> concentration of 0.1-1mol / L till the solution is neutral; 2) adding reductive-form ascorbic acid into the obtained product at the mole ratio of reductive-form ascorbic acid to Fe<3+> of (0.5-2):100 and adjusting pH value till being neutral; 4) performing high-temperature ageing on the acquired product, cooling and then centrifugally separating solid precipitate. The invention provides the method for chemically precipitating and quickly compounding a large number of pure hematite spheroid with excellent crystalline degree, uniform size distribution, monodispersity and controllable morphology at one time in the presence of reducing agent ascorbic acid. The hematite has an excellent degrading performance for the environmental pollutants and especially has an excellent effect for degrading toxic organic wastewater, such as degradation rate for methylene blue reaching up to 96.50%.

Owner:HUAZHONG AGRI UNIV

Full automatic electronic deposition system

InactiveCN104630719AReduce pumping timeSmall sizeVacuum evaporation coatingSputtering coatingVacuum pumpingAutomatic transmission

The invention belongs to the technical field of plating of various films on glass, plastic and ceramic substrates, and particularly relates to a full automatic electronic beam deposition system. The full automatic electronic beam deposition system comprises a technological cavity, a loading cavity, a transmission cavity, a vacuum pumping system and a full automatic transmission mechanism, wherein the technological cavity, the loading cavity and the transmission cavity are sequentially communicated; the technological cavity, the loading cavity and the transmission cavity are all connected with the vacuum pumping system, and the full automatic transmission mechanism automatically takes sample substrates out of and put in the technological cavity and the loading cavity. The full automatic electronic deposition system has a high yield, reduces the air pumping time of the technological cavity after a sample loading plate is changed each time. The full automatic electronic deposition system simultaneously carries out the technological process of the technological cavity and the process of taking the sample loading plate out of and putting in the loading cavity; and except for a technological cavity door and a loading cavity door arranged inside a clean room, the other parts can be put in common environments, so that the cost is lowered.

Owner:SHENYANG SCI INSTR RES CENT CHINESE ACAD OF SCI

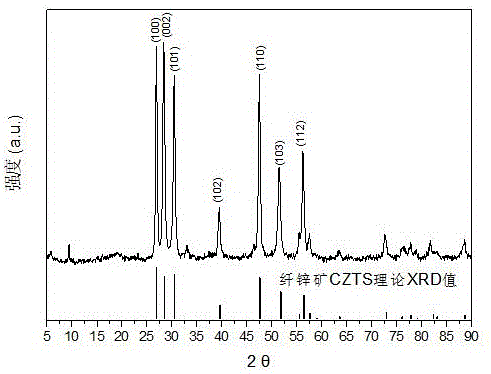

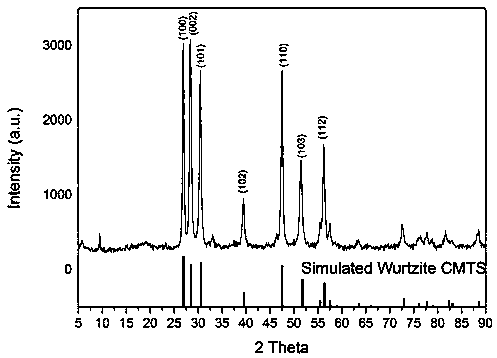

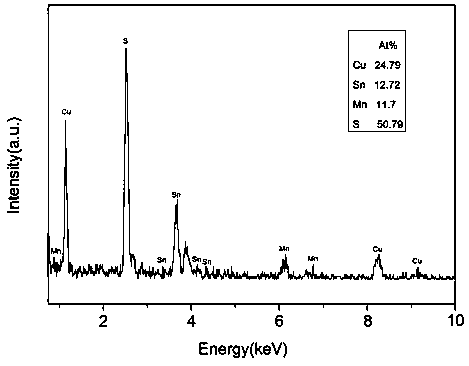

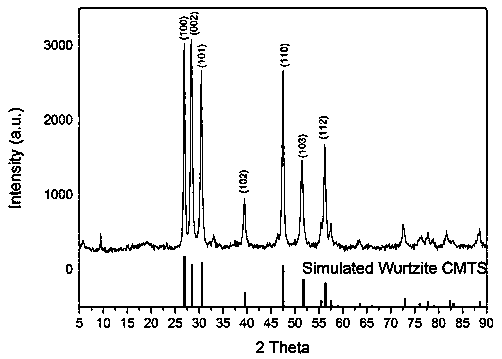

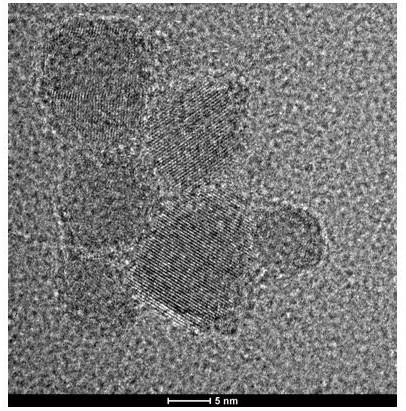

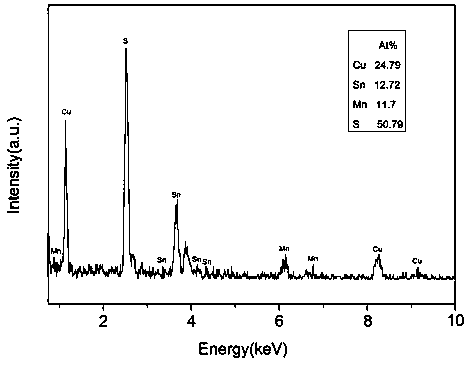

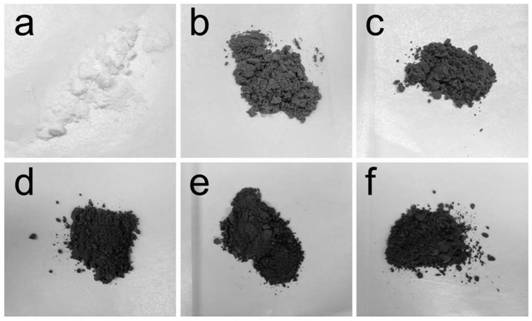

Preparation method of wurtzite CMTS nano-crystal

The invention relates to a preparation method of a wurtzite CMTS nano-crystal and belongs to the new energy source technical field of photovoltaic materials and devices. The preparation method comprises the following steps: adding a copper source, a manganese source, a tin source and sodium dodecyl benzoate into an organic solvent and dissolving; then raising the temperature to 100 to 120 DEG C ata constant speed to obtain a precursor solution; sequentially adding n-dodecyl mercaptan and carbon disulfide into the precursor solution and uniformly mixing; raising the temperature to 140 to 180 DEG C at a constant speed and reacting for 15 to 60min; then raising the temperature to 250 to 300 DEG C at a constant speed and reacting for 30 to 60min to obtain a reaction system; cooling to room temperature; centrifuging to separate a solid and liquid; washing the solid for 3 to 5 times by adopting an organic washing solution and drying to obtain the wurtzite Cu2MnSnS4 nano-crystal. The wurtzite Cu2MnSnS4 nano-crystal prepared by the invention has the advantages of great production and high yield; the atom ratio of the nano-crystal is easy to regulate and control and the average grain diameter of the wurtzite Cu2MnSnS4 nano-crystal is a nano-grade.

Owner:KUNMING UNIV OF SCI & TECH

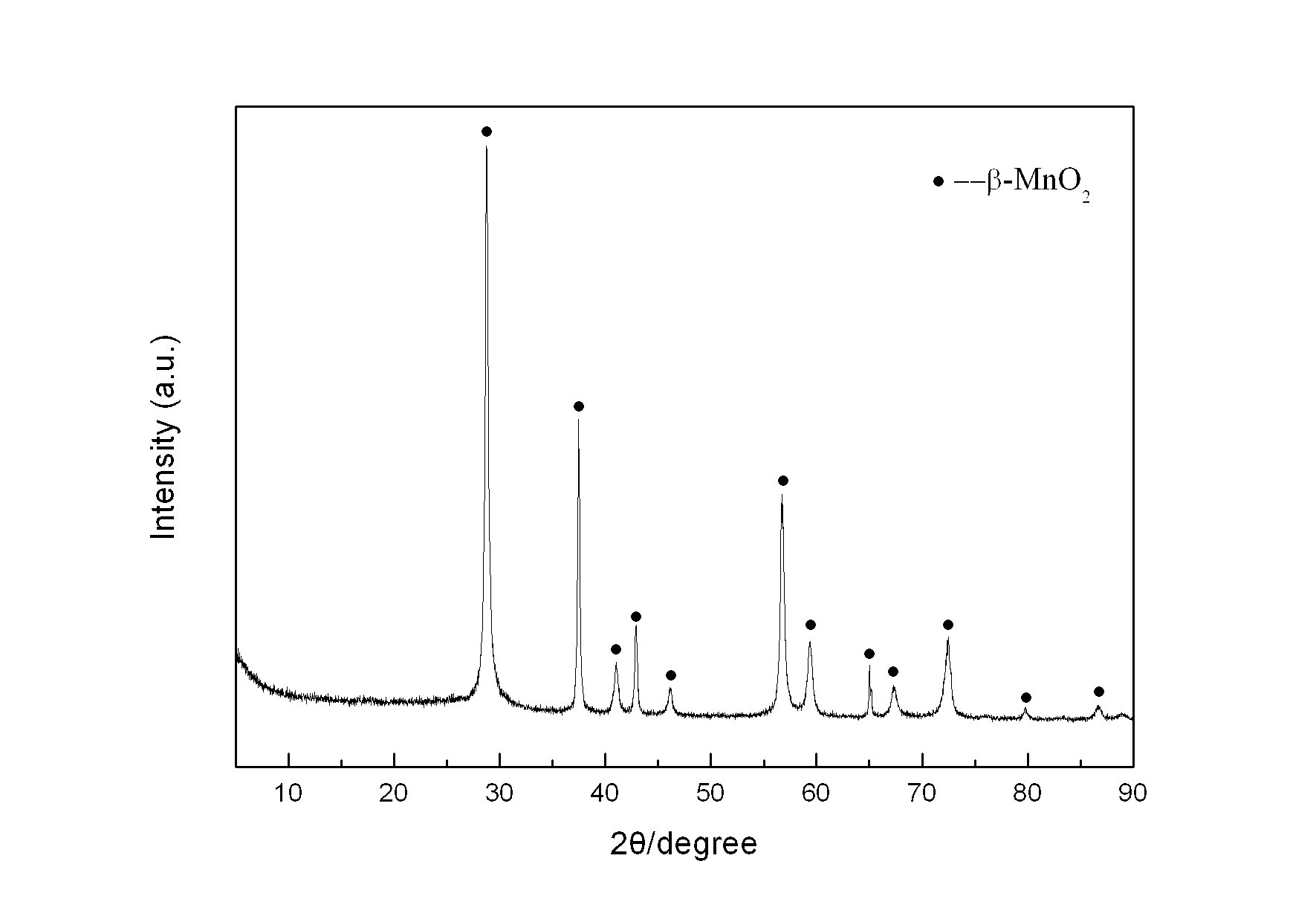

Preparation method of 1*1-type manganese oxide octahedral molecular sieves

InactiveCN102730760AShort production processReduce pollutionMolecular-sieve and base-exchange compoundsManganese oxides/hydroxidesPyrolusiteSource material

The invention discloses a preparation method of 1*1-type manganese oxide octahedral molecular sieve (pyrolusite, beta-MnO2) nano-rods, and especially relates to a preparation method which is used for synthesizing single-phase 1*1-type manganese oxide octahedral molecular sieve nano-rods having good crystallinity under the conditions of non-pressurized heating reflux so that a large amount of the 1*1-type manganese oxide octahedral molecular sieve nano-rods are synthesized by one step. The preparation method provided by the invention is characterized in that a mixed solution containing one or more salts of single divalent manganese, permanganates and strong acids undergoes a reflux reaction to produce the 1*1-type manganese oxide octahedral molecular sieve nano-rods under the control of a concentration, a temperature and time. The preparation method allows mild reaction conditions, can be operated simply, can be controlled easily, has low energy consumption, produces low pollution and has a high single yield. The 1*1-type manganese oxide octahedral molecular sieve nano-rods obtained by the preparation method can be used for catalysts, magnetic materials and chemical power source materials.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

A kind of pt/c catalyst for fuel cell and its preparation process

ActiveCN103730668BLarge electrochemical active areaSimple processCell electrodesMetal/metal-oxides/metal-hydroxide catalystsFuel cellsPtru catalyst

Owner:KUSN INNOVATION INST OF NANJING UNIV

A method of silk screen printing monochrome gradient effect pattern

ActiveCN110116564BAdaptableWide range of printing applicationsPattern printingOther printing apparatusScreen printingYarn

The invention provides a method for silk-screening monochrome gradient effect patterns. The method includes arranging mesh plates of areas where gradient effect patterns are silk-screened into patternholes that are gradually changed from large to small or from small to large, wherein mesh yarn in the mesh plates are selected from silk screens of 90 T - 120 T; arranging UV light curing adhesive layers including the pattern holes on the double surfaces of the mesh yarn; silk-screening a gradient effect pattern ink layer formed by monochrome on a printed object, the angle of a scraper during silk-screening being 60-70 DEG, the speed of printing being 10-15 times / min, and the thickness of the ink layer of the silk-screening being more than 15 microns; covering the ink layer with underpaintingink after the gradient effect pattern ink layer is fixed, wherein the thickness of the covered underpainting ink layer is more than 3 microns; and obtaining a target product after the underpainting ink layer is fixed. The method can be realized by using existing common silkscreen equipment, so that the method is convenient in operation, simple in printing and plate making, low in cost and strongin adaptability, and can realize monochrome gradient silkscreen effects.

Owner:LENS TECH CHANGSHA

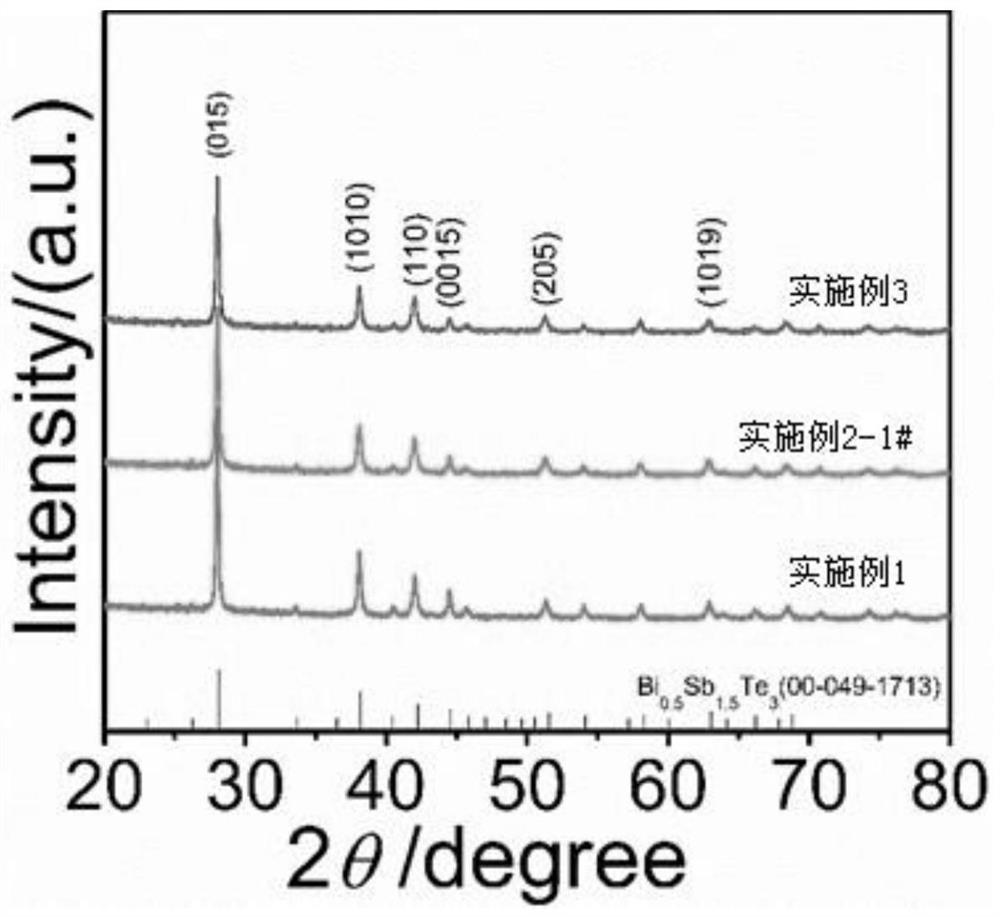

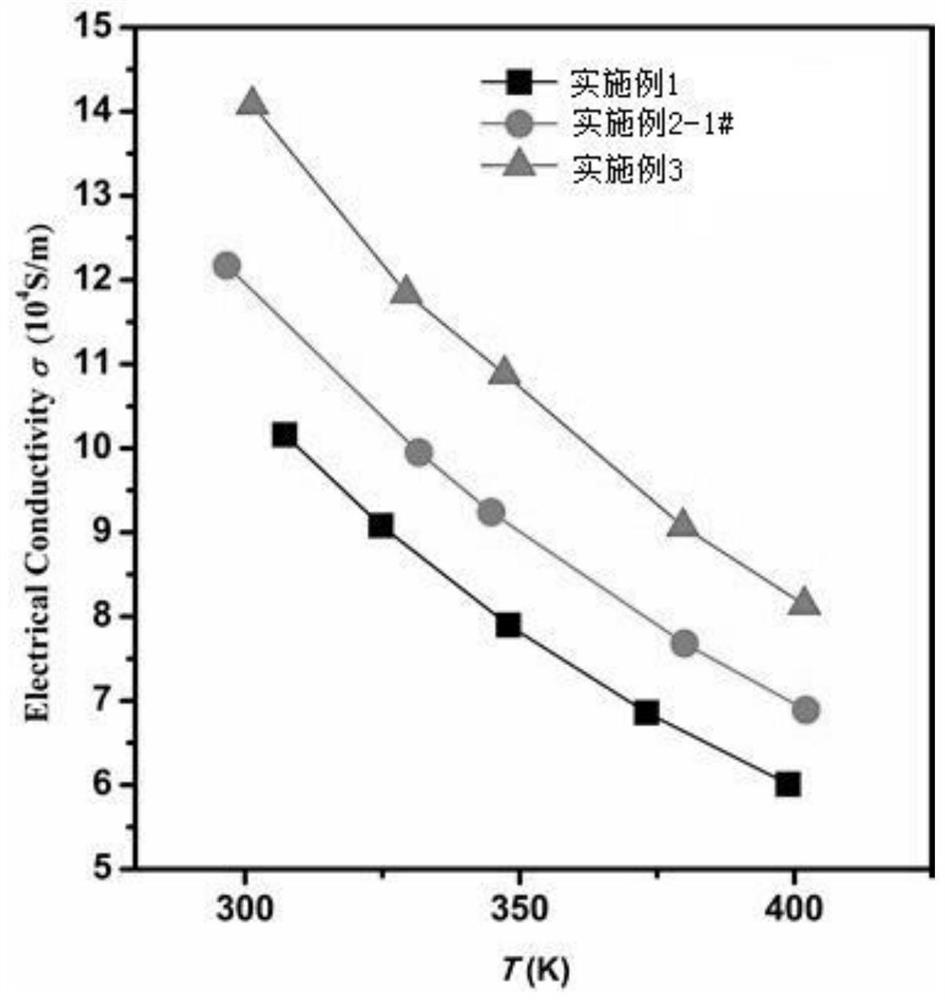

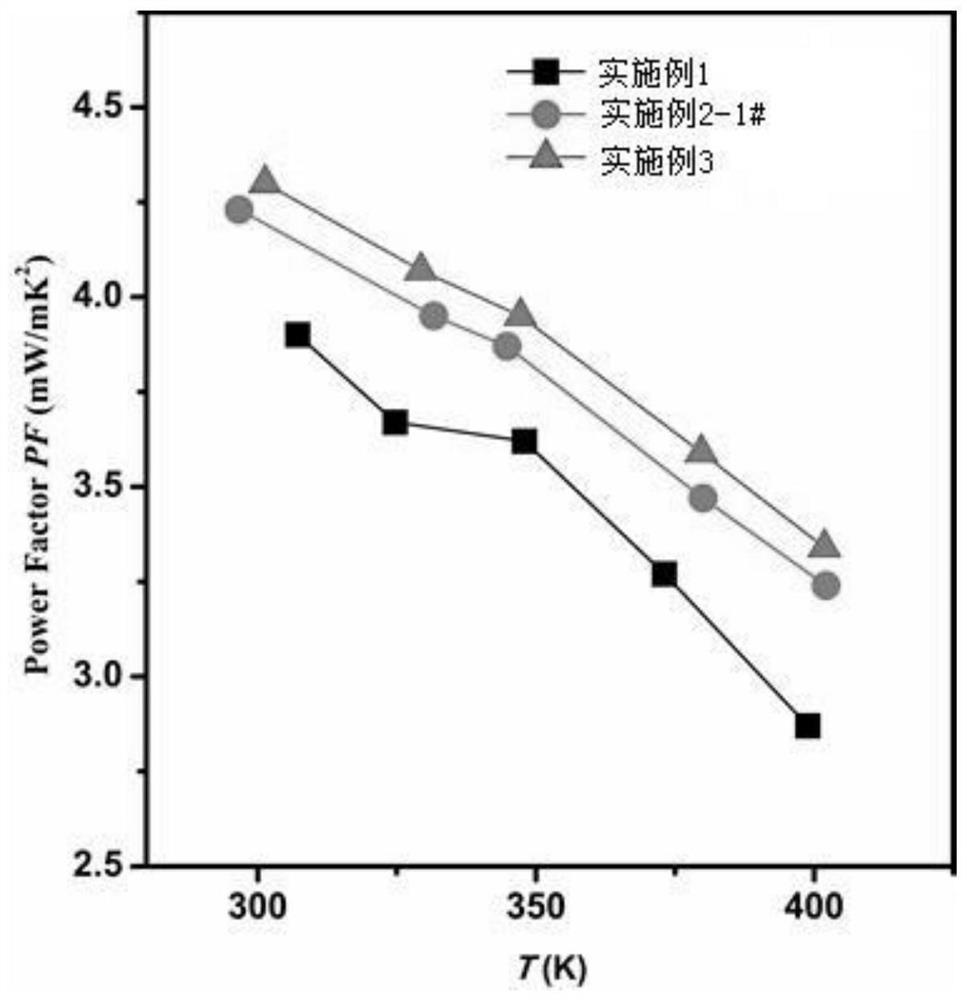

Method for preparing ZnTe doped p-type polycrystalline Bi2Te3 thermoelectric material

ActiveCN111864041ALow thermal conductivityGood repeatabilityPolycrystalline material growthThermoelectric device manufacture/treatmentCrystallographyChemical composition

The invention discloses a method for preparing a ZnTe-doped p-type polycrystalline Bi2Te3 thermoelectric material, which comprises the following steps of: (1) weighing high-purity elementary substances Bi, Sb, Te and Zn as raw materials according to the stoichiometric ratio of each element in the chemical composition of the ZnTe-doped p-type polycrystalline Bi2Te3 thermoelectric material; (2) sealing the raw materials weighed in the step (1) in vacuum, melting, and cooling to obtain an ingot body; (3) carrying out melt spinning on the ingot body obtained in the step (2) in a protective atmosphere, collecting the obtained thin strip, carrying out vacuum sealing, and annealing; and (4) grinding the thin strip obtained by annealing in the step (3), and performing spark plasma activated sintering to obtain the ZnTe doped high-performance p-type polycrystalline Bi2Te3 thermoelectric material. The method is high in repeatability, and the prepared p-type polycrystalline Bi2Te3 thermoelectricmaterial is excellent in thermoelectric performance and good in stability.

Owner:WUHAN UNIV OF TECH

Preparation method of silicon carbide powder and silicon carbide powder

The invention relates to a preparation method of silicon carbide powder and the silicon carbide powder. The preparation method comprises the steps of: S1, mixing silicon powder and graphite powder forthe first time, then performing vacuum smelting gas atomization treatment to form spherical and / or sub-spherical powder, and keeping the smelting temperature at 1,500DEG C-1,600DEG C; and S2, puttingthe powder obtained in the S1 into a graphite crucible, putting the graphite crucible into a reaction chamber, and carrying out a heating synthesis reaction to obtain the silicon carbide powder. Through vacuum smelting gas atomization treatment, the mixing uniformity of the raw materials is improved, and the mixing time of the raw materials is shortened; and the graphite powder is coated with themolten silicon through vacuum smelting gas atomization treatment, so that compact spherical and / or sub-spherical powder is formed, more raw materials can be filled in a limited reaction chamber, thesingle-time yield of the silicon carbide powder is increased, and the production cost is reduced.

Owner:BYD CO LTD

Bottom dropping method of three-ton smelting furnace

The invention discloses a bottom dropping method of a three-ton smelting furnace. The method comprises the following steps of: A, proportioning; B, building the furnace, (1) before bedding of the furnace, examining whether induction coil cement falls, repairing the fallen part and necessarily drying after repair, (2) ramming a furnace bottom, (3) ramming a furnace body and (4) ramming a furnace collar; and C, roasting the furnace, wherein the furnace roasting time is 10-18 hours. The smelting furnace produced by the invention is solid and stable and has high resistance and superior integral quality, the erosion to the furnace wall by slag is reduced, the capacity of the charge is large, one-time yield is high, and the production difficulty and the production cost are reduced.

Owner:滁州航佑电气有限公司

Transmission system used in five-chamber automatic electron beam deposition system

ActiveCN104630737ASmall sizeReduce pumping timeVacuum evaporation coatingSputtering coatingAutomatic transmissionElectron beam deposition

The invention relates to the technical field of preparation of various films on glass, plastic and ceramic matrixes, and concretely relates to a transmission system used in a five-chamber automatic electron beam deposition system. The transmission system used in five-cavity automatic electron beam deposition system comprises an automatic transmission mechanism, an elevating cylinder, a sample support plate and a sample rack, the five chambers comprise a transmission chamber I, a loading chamber I, a technology chamber, a loading chamber II and a transmission chamber II which are connected in order, wherein an elevating cylinder, a sample support plate and a sample rack are arranged in the loading chamber I, the technology chamber and the loading chamber II, the sample rack is connected to a motor and is driven to rotate through the motor, the sample support plate is arranged on the sample rack, the elevating cylinder is capable of lifting or descending of the sample support plate, and the automatic transmission mechanism carries the sample support plate to move among chambers. According to the invention, the output is high, the air exhaust time in the technology chamber after the sample support plate is replaced can be saved, and process and pick-and-place of the sample support plate can be carried out simultaneously.

Owner:SHENYANG SCI INSTR RES CENT CHINESE ACAD OF SCI

A kind of preparation method of wurtzite cmts nanocrystal

The invention relates to a preparation method of a wurtzite CMTS nano-crystal and belongs to the new energy source technical field of photovoltaic materials and devices. The preparation method comprises the following steps: adding a copper source, a manganese source, a tin source and sodium dodecyl benzoate into an organic solvent and dissolving; then raising the temperature to 100 to 120 DEG C ata constant speed to obtain a precursor solution; sequentially adding n-dodecyl mercaptan and carbon disulfide into the precursor solution and uniformly mixing; raising the temperature to 140 to 180 DEG C at a constant speed and reacting for 15 to 60min; then raising the temperature to 250 to 300 DEG C at a constant speed and reacting for 30 to 60min to obtain a reaction system; cooling to room temperature; centrifuging to separate a solid and liquid; washing the solid for 3 to 5 times by adopting an organic washing solution and drying to obtain the wurtzite Cu2MnSnS4 nano-crystal. The wurtzite Cu2MnSnS4 nano-crystal prepared by the invention has the advantages of great production and high yield; the atom ratio of the nano-crystal is easy to regulate and control and the average grain diameter of the wurtzite Cu2MnSnS4 nano-crystal is a nano-grade.

Owner:KUNMING UNIV OF SCI & TECH

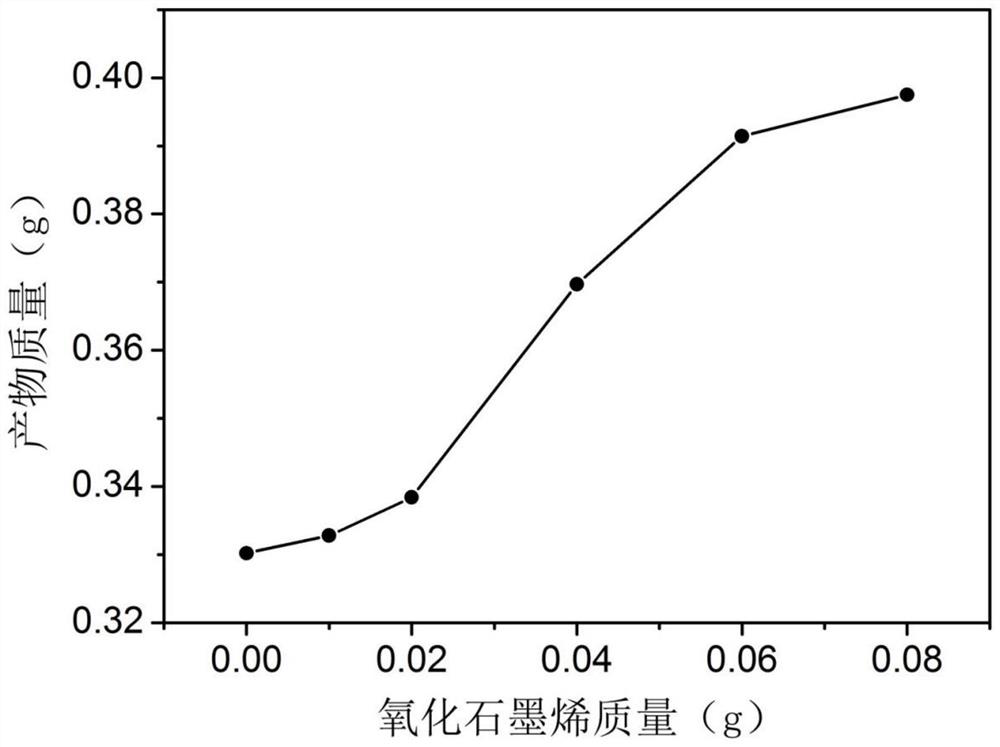

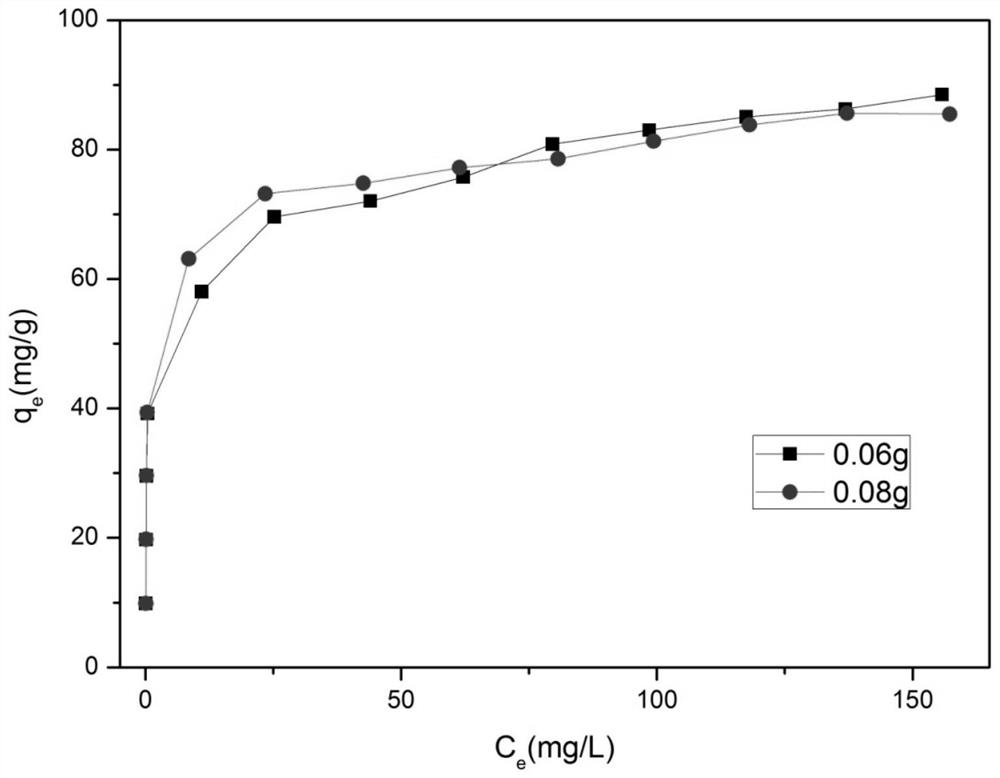

A kind of preparation method and application of graphene oxide-Brianite composite

ActiveCN111760553BImprove securityHigh single outputOther chemical processesWater contaminantsSulfate zincPhysical chemistry

The invention provides a preparation method of a graphene oxide-Brianite composite, comprising the following steps: reacting zinc sulfate heptahydrate and urea in water for the first time, adding graphene oxide dispersion liquid, and reacting again to obtain graphite oxide ene-brianite complex. This application provides a preparation method of graphene oxide-Brianite composite. The preparation raw materials of this preparation method are all non-hazardous chemicals, the preparation process is safer, and the preparation time is short. Generally, it can be completed in 7-8 hours. And the yield of graphene oxide-brianite prepared in one time is high.

Owner:苏州昆道新材料科技有限公司

A kind of preparation method of delafossite structure Agcro2 nanocrystalline material

ActiveCN103880081BHigh yieldLow costMaterial nanotechnologyLight-sensitive devicesSynthesis methodsReaction temperature

The invention discloses a preparation method for a delafossite-structure AgCrO2 nanocrystalline material, in particular to a low-temperature hydro-thermal synthesis method for rapidly preparing a delafossite-structure AgCrO2 nanocrystalline material. The preparation method comprises the following steps: regulating a reaction precursor constituent, a reaction temperature and the filling rate parameter of reaction solution in a hydro-thermal reaction kettle, reacting at 190-230 DEG C for 36-60 hours, carrying out centrifugal cleaning treatment on the reaction product for multiple times, and drying at 60 DEG C in a vacuum drying oven for 24-48 hours, thereby finally obtaining the AgCrO2 nanocrystalline material with the size of 10-20 nm. The method is simple to operate, easy in control over process parameters, pollution-free, high in yield, and capable of being widely used in photoelectric function devices such as transparent conductive oxides.

Owner:WUHAN UNIV OF TECH

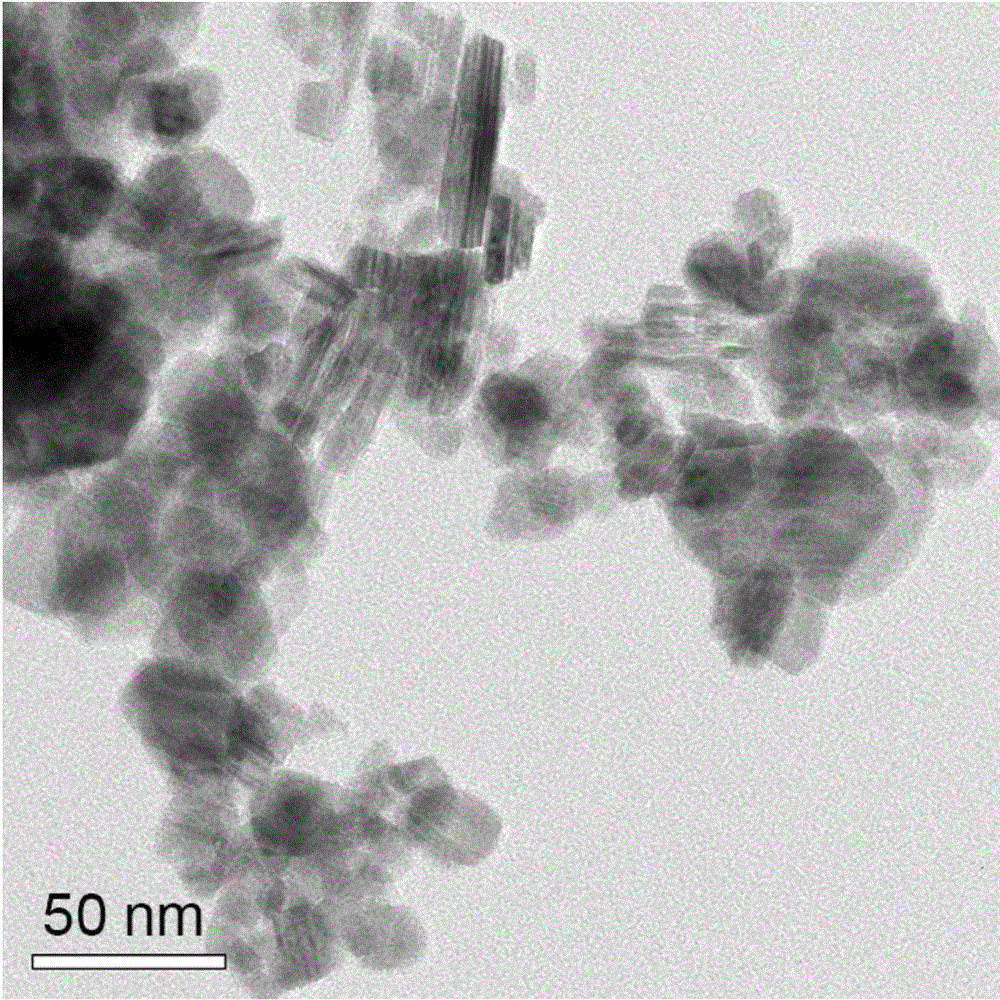

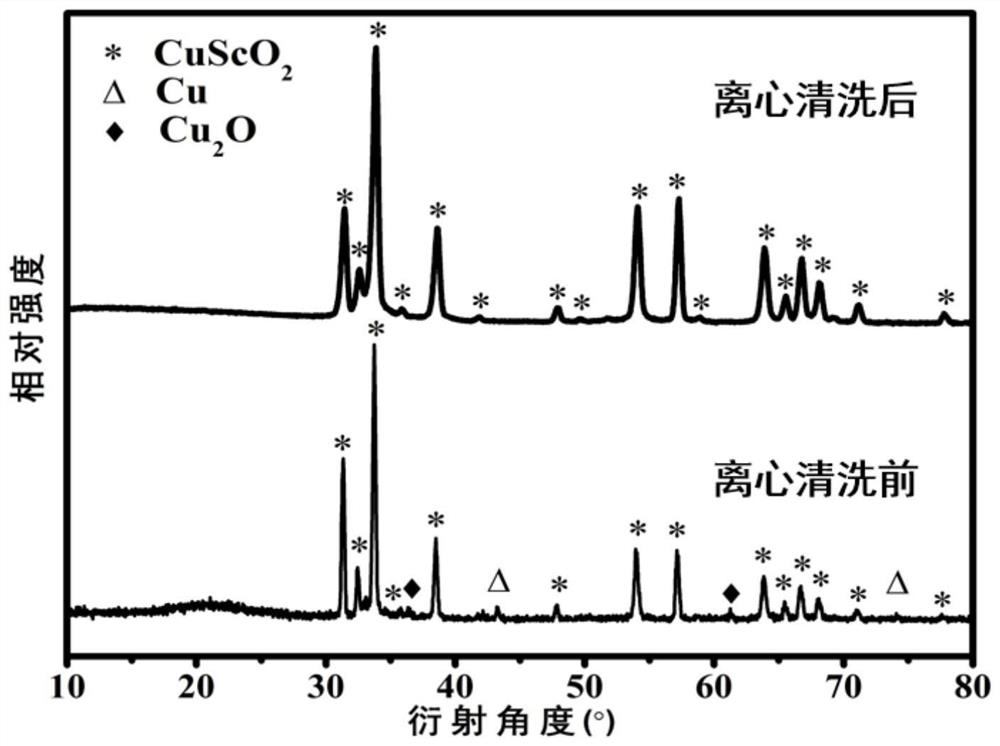

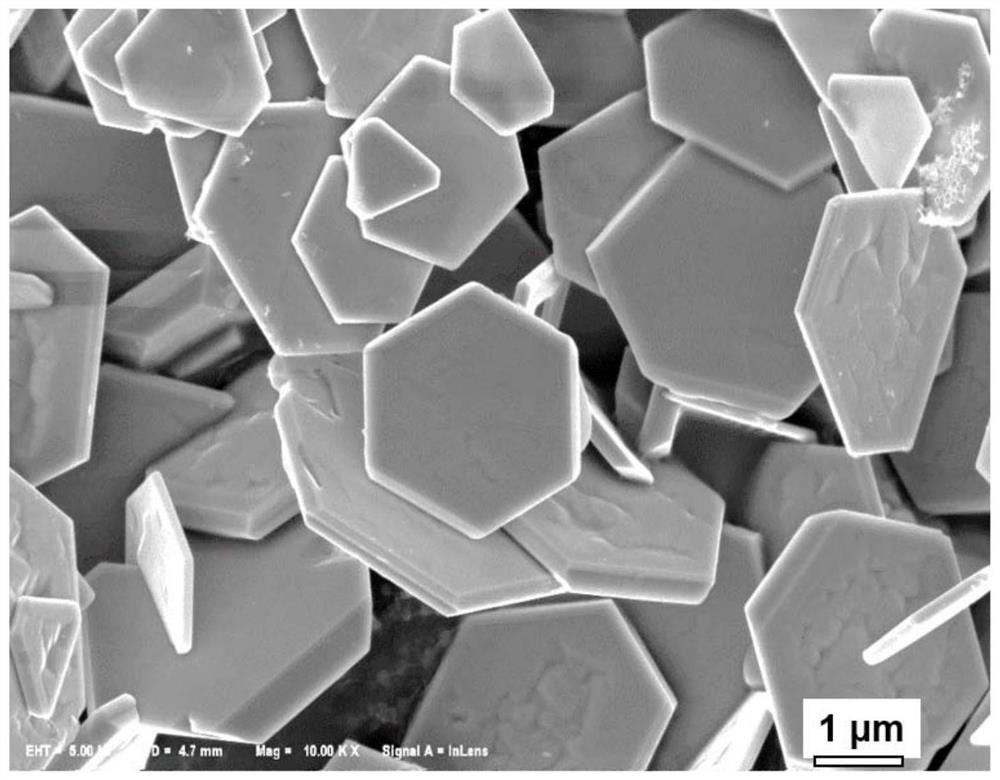

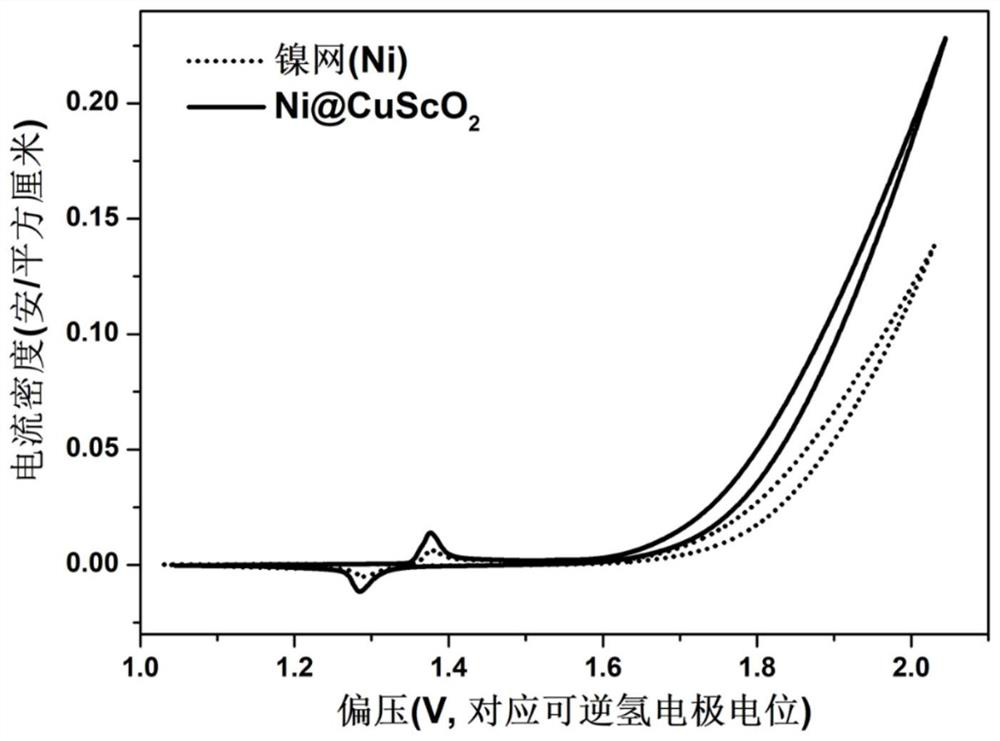

A p-type delafossite structure cusco 2 Crystal material and its preparation method and use

ActiveCN110980791BReduce the cost of large-scale productionWide variety of sourcesLight-sensitive devicesHeterogenous catalyst chemical elementsPtru catalystDissolution

The invention discloses a p-type delafossite structure CuScO 2 Crystal material and its preparation method and application, the method comprises: step 1, preparation of reaction precursor: with Cu 2+ Source reactants and Sc 3+ The source reactant is used as the raw material, deionized water is used as the reaction liquid, and the reducing agent and mineralizing agent are added and stirred until completely dissolved to prepare the reaction precursor; step 2, the reaction precursor is subjected to hydrothermal treatment at 210-240°C After reacting for 12 to 48 hours, the reaction product was centrifuged to obtain a precipitate, and the precipitate was dried to obtain the p-type delafossite structure CuScO 2 crystal material. The present invention utilizes the single reaction of hydrothermal method to prepare gram-level CuScO 2 Crystal material, no need to adjust the pH value of the precursor reactant; and the present invention explores CuScO for the first time 2 As a catalyst material in electrolytic water oxygen evolution, it shows good electrolytic water oxygen evolution activity and stability under alkaline conditions.

Owner:WUHAN UNIV OF TECH

A furnace device and method for preparing ultra-high-purity aluminum

ActiveCN104263969BExtended service lifeReduce bearing deformationWorking capacityElectromagnetic stirring

The invention belongs to the technical field of metal purification, and relates to a furnace pipe device and a method for preparing ultra-high purity aluminum. The furnace pipe device is characterized by sequentially comprising a furnace pipe outer frame, a thin-wall seal sleeve and a graphite crucible from outside to inside, wherein a hinge furnace lid is arranged at the upper part of the furnace pipe; a water inlet hole, a water outlet hole, an observation hole, an air exhaust hole, an air inlet hole, an exhaust vent, a temperature measuring hole and a pressure measuring hole are formed in the furnace lid; a rubber seal strip is arranged between the furnace lid and the furnace pipe outer frame; and the furnace lid is connected and fastened with the furnace pipe through buckles and bolts. The furnace pipe device disclosed by the invention is capable of melting aluminum one time; the crystal is 65Kg; the height of a crystal aluminum ingot can reach 90cm; the single production can be increased by 2.5 times in comparison with that of a conventional high-purity aluminum production technology; an argon protection environment is only kept in the furnace pipe; the furnace pipe device has no environmental requirements on heating and electromagnetic stirring devices, and is strong in continuous working ability; compared with a conventional production technology, the furnace pipe device and the method have the advantages that the power consumption is reduced by 2 / 3; and the energy consumption cost is saved by 3 / 5.

Owner:江苏金海铝业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com