A kind of preparation method and application of graphene oxide-Brianite composite

A graphene and composite technology, applied in chemical instruments and methods, water pollutants, other chemical processes, etc., can solve the problems of insufficient single output and long reaction process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] Aiming at the problems in the preparation of graphene composite materials in the prior art, the present application provides a preparation method of graphene oxide-brillonite composites, which has the advantages of safe preparation process, high single output and short preparation time . Specifically, the embodiment of the present invention discloses a preparation method of a graphene oxide-brillonite composite, comprising the following steps:

[0019] The zinc sulfate heptahydrate and the urea are reacted in water for the first time, and then the graphene oxide dispersion liquid is added, and the reaction is performed again to obtain the graphene oxide-brillonite composite.

[0020] In the above-mentioned preparation process, the present application firstly prepared bryantite, but bryantite was not directly prepared in one step, specifically, the primary reaction of zinc sulfate heptahydrate and urea in water, more specifically, the primary reaction It can be carried ...

Embodiment

[0026] Dissolve 1g of heptashui, zinc sulfate and 3g of urea in 100g of water. After the solution is completely dissolved, pour the solution into a three-necked flask, raise the temperature of the oil bath to 95 °C, and put the three-necked flask into the oil bath. Start the reaction, the three-necked flask needs to be connected to a serpentine condenser during the reaction, so that the water content in the solution remains unchanged as much as possible, which is beneficial to the stability of the product;

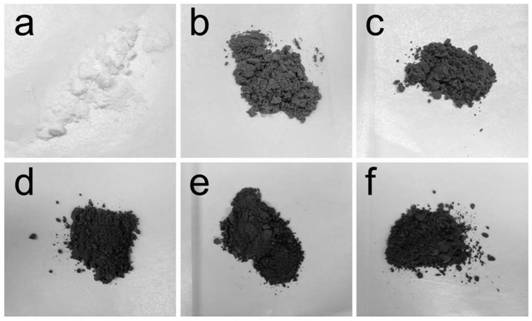

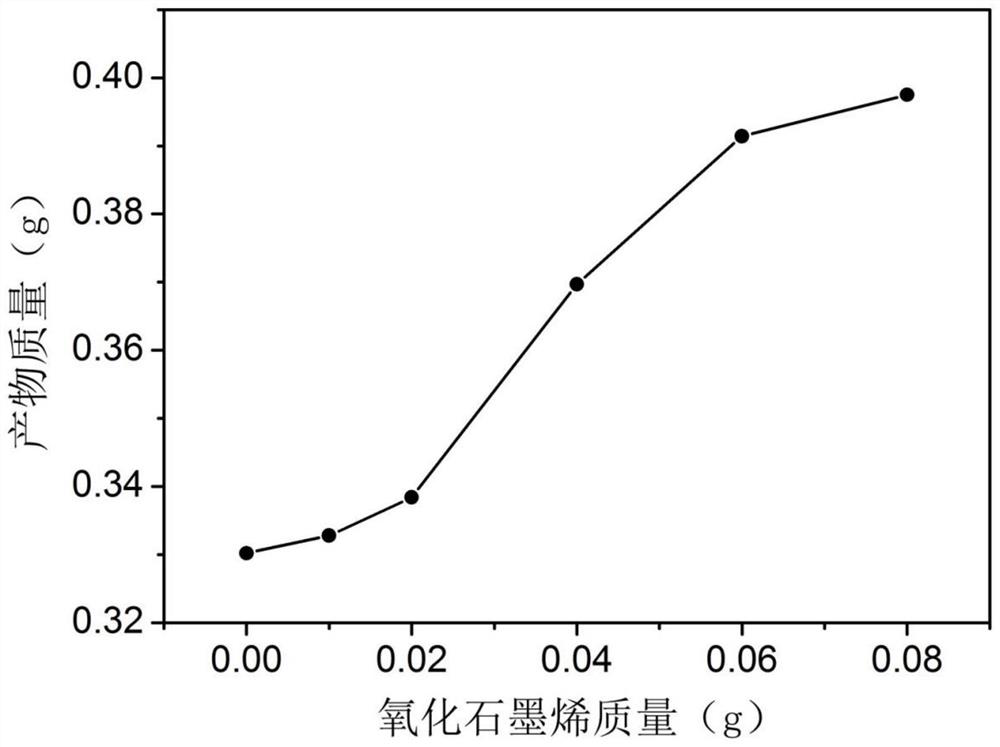

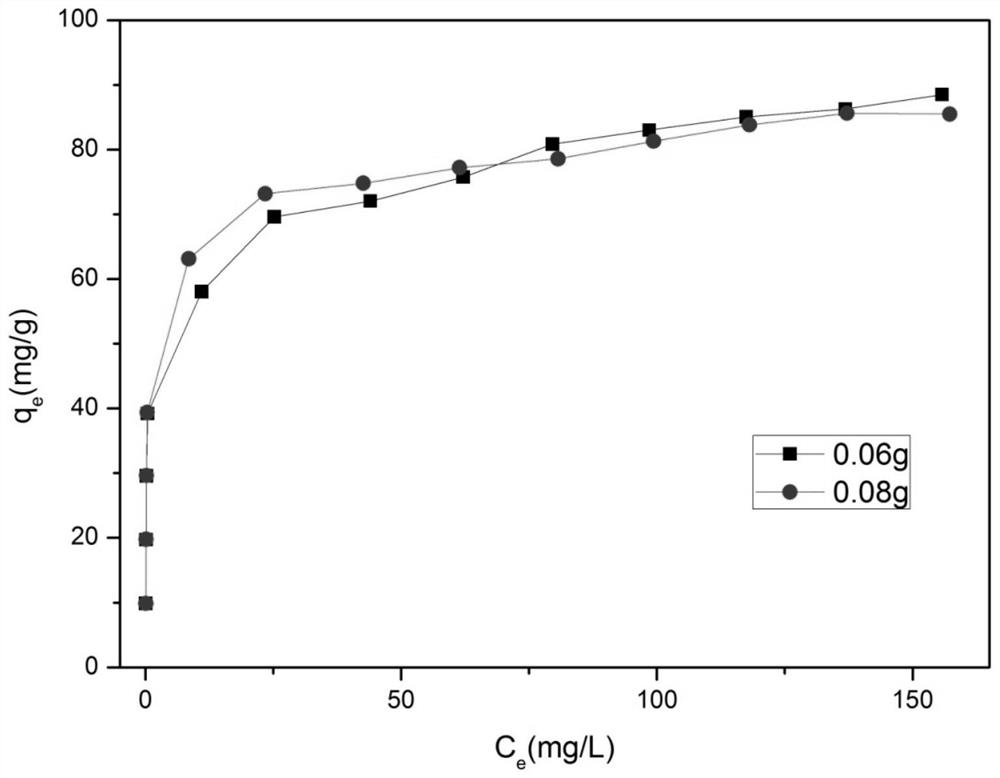

[0027] Prepare graphene oxide dispersion liquid while the above reaction is carried out, dissolve 0.01g~0.08g of graphene oxide in 20g of water, and ultrasonicate for more than 1 hour; after 5 hours of oil bath reaction, add graphene oxide to the three-necked flask The dispersion liquid was kept at 95°C and reacted for another 1 h, then the three-necked flask was taken out from the oil bath, cooled naturally, the precipitate was taken out, and the final product was obtained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com