A kind of preparation method of delafossite structure Agcro2 nanocrystalline material

A nanocrystalline material, delafossite technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the nano-effects that do not reach the nanoscale, large crystal size, and photoelectrochemical properties. Can be fully reflected and other issues, to achieve the effect of low price, low production cost, and easy control of process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

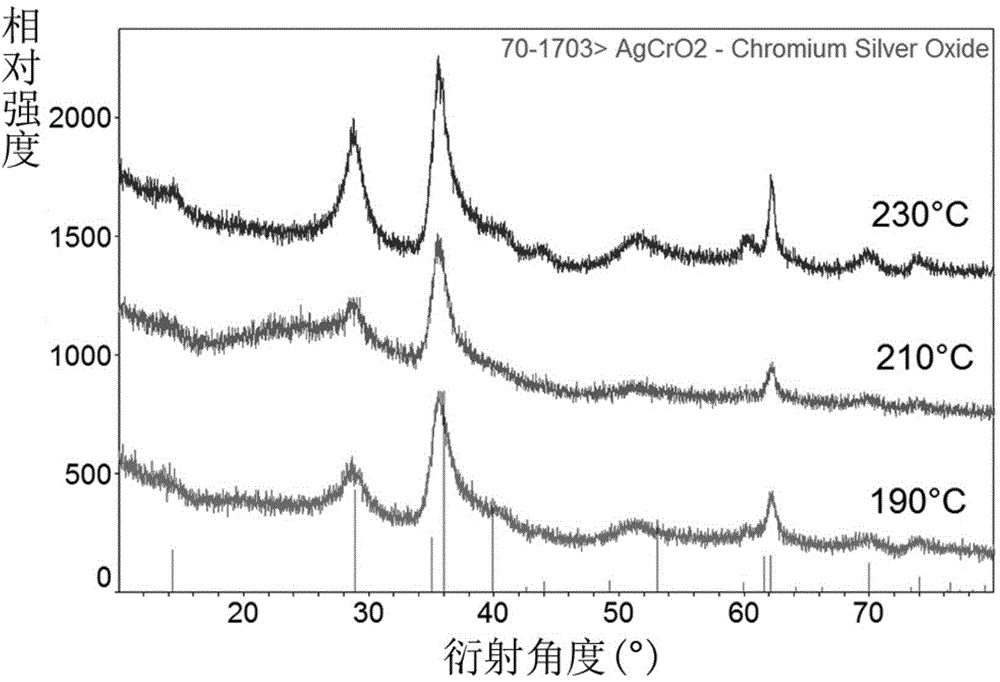

Embodiment 1

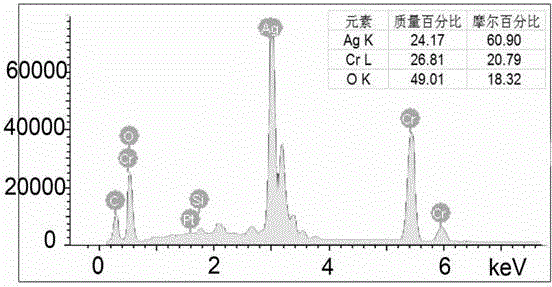

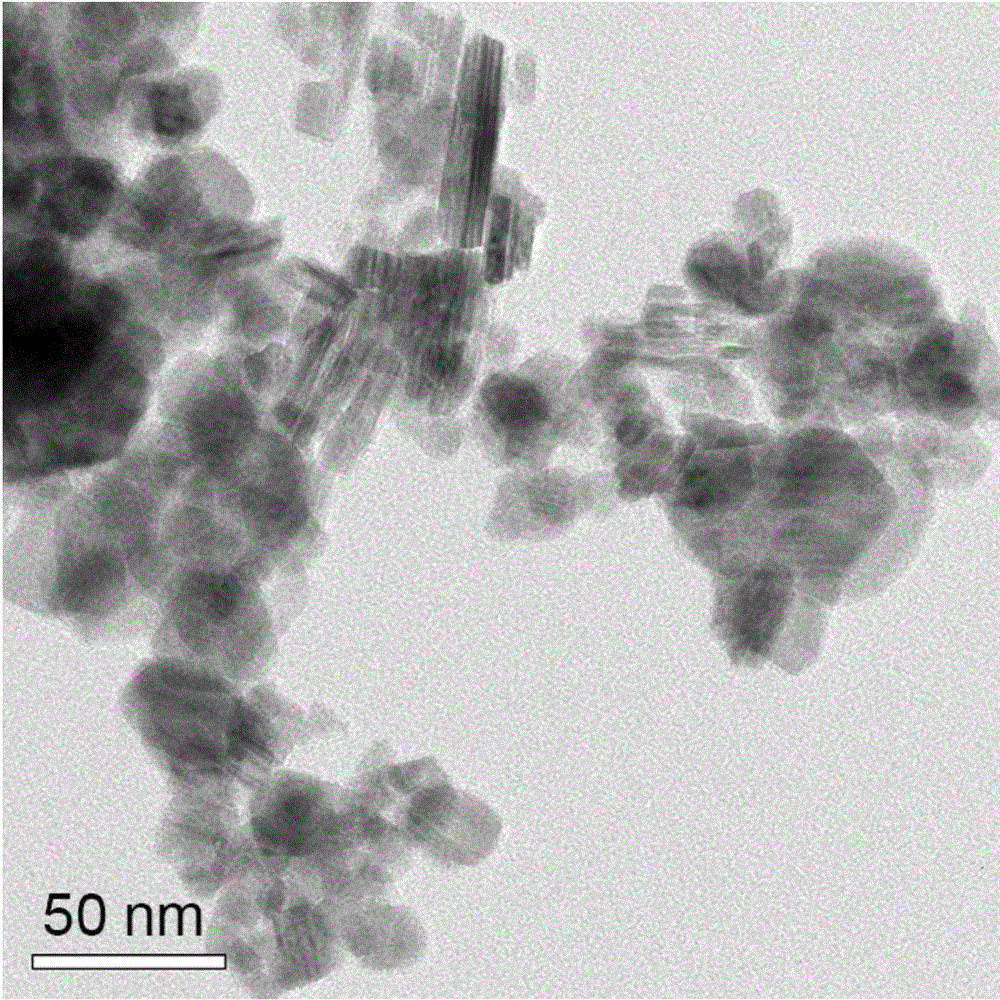

[0027] Weigh AgNO at room temperature according to the Ag:Cr molar ratio of 0.9-1.1:1 3 and Cr(NO 3 ) 3Finally, add deionized water and stir it with a magnetic stirrer for about 10-15 minutes. After it is completely dissolved, add 4 times the molar amount of NaOH that acts as a mineralizer, and continue stirring for about 10-15 minutes until it is completely dissolved and forms water. Thermally reactive precursor. Transfer the above reaction precursor to a hydrothermal reactor (usually polytetrafluoroethylene), and control the filling rate of the reaction solution to about 65%. After sealing the kettle body, place it in a programmed temperature-controlled oven for hydrothermal reaction, set the reaction temperature to 230°C, and the reaction time to 36-60 hours.

[0028] After the reaction, the kettle body was naturally cooled to room temperature, and the kettle body was opened to take out the reaction product. Use deionized water followed by dilute HNO 3 , dilute NH 3 ·...

Embodiment 2

[0030] Weigh the AgNO at room temperature according to the Ag:Cr molar ratio of 1:1 3 and Cr(NO 3 ) 3 Finally, add deionized water and stir it with a magnetic stirrer for about 10-15 minutes. After it is completely dissolved, add 4 times the molar amount of NaOH that acts as a mineralizer, and continue stirring for about 10-15 minutes until it is completely dissolved and forms water. Thermally reactive precursor.

[0031] Transfer the above reaction precursor to a hydrothermal reaction kettle (usually polytetrafluoroethylene), and control the filling rate of the reaction solution to about 65-75%. After sealing the kettle body, place it in a programmed temperature-controlled oven for hydrothermal reaction, set the reaction temperature to 210°C, and the reaction time to 36-60 hours.

[0032] After the reaction, the kettle body was naturally cooled to room temperature, and the kettle body was opened to take out the reaction product. Use deionized water followed by dilute HNO ...

Embodiment 3

[0034] Weigh the AgNO at room temperature according to the Ag:Cr molar ratio of 1:1 3 and Cr(NO 3 ) 3 Finally, add deionized water and stir it with a magnetic stirrer for about 10-15 minutes. After it is completely dissolved, add 3 times the molar amount of NaOH that acts as a mineralizer, and continue stirring for about 10-15 minutes until it is completely dissolved and forms water. Thermally reactive precursor.

[0035] Transfer the above reaction precursor to a hydrothermal reactor (usually polytetrafluoroethylene), and control the filling rate of the reaction solution to about 70%. After sealing the kettle body, place it in a programmed temperature-controlled oven for hydrothermal reaction, set the reaction temperature to 190°C, and the reaction time to 36-60 hours.

[0036] After the reaction, the kettle body was naturally cooled to room temperature, and the kettle body was opened to take out the reaction product. Use deionized water followed by dilute HNO 3 , dilute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com