Five-cavity full-automatic electron beam deposition system

An electron beam deposition, fully automatic technology, applied in ion implantation plating, metal material coating process, coating, etc., can solve the problems of long production time and high cost, so as to increase production, save pumping time and reduce cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the drawings.

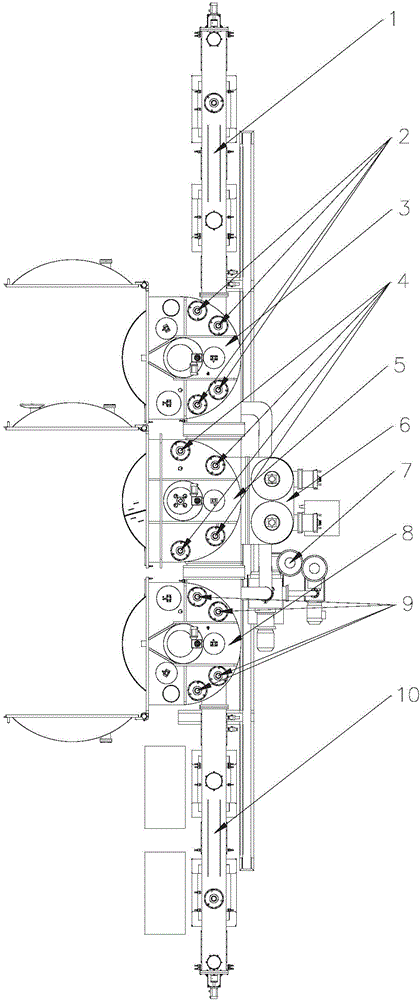

[0019] Such as figure 1 As shown, the present invention includes an air extraction system and five cavities. The five cavities include a transfer chamber I1, a loading chamber I3, a process chamber 5, a loading chamber II8, and a transfer chamber which are arranged sequentially from top to bottom and communicate with each other. Cavity II10, each cavity is connected with the air extraction system.

[0020] The pumping system includes a vacuum pumping system I2, a vacuum pumping system II4, a vacuum pumping system III6, a vacuum pumping system IV7, and a vacuum pumping system V9, wherein the vacuum pumping system I2 is arranged on the top of the loading chamber I3, And respectively communicate with the transfer cavity I1 and the loading cavity I3. A vacuum exhaust system II4 is placed on the top of the process chamber 5, and a vacuum exhaust system III6 is placed on the sidew...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com