Patents

Literature

44results about How to "Perfect alarm function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

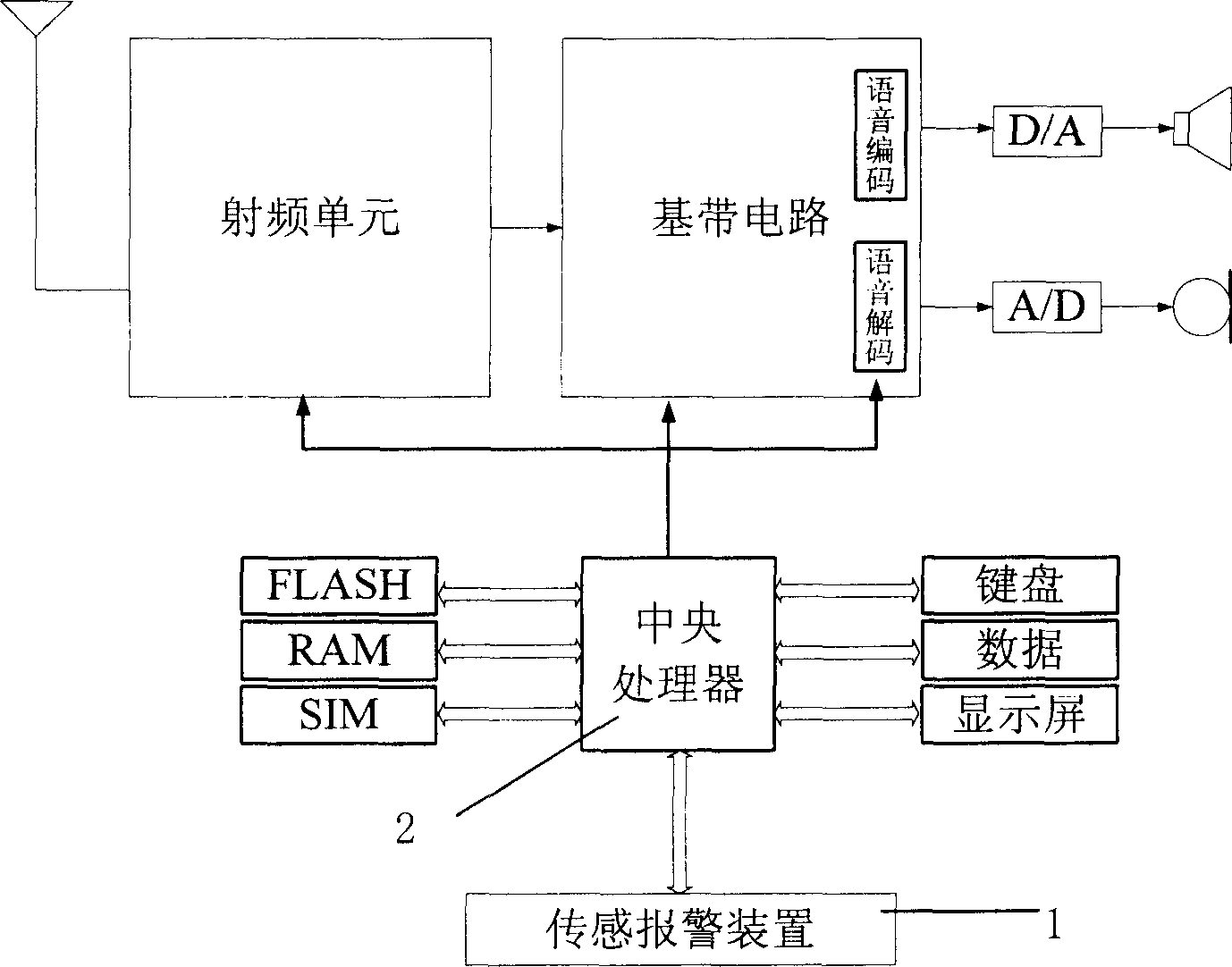

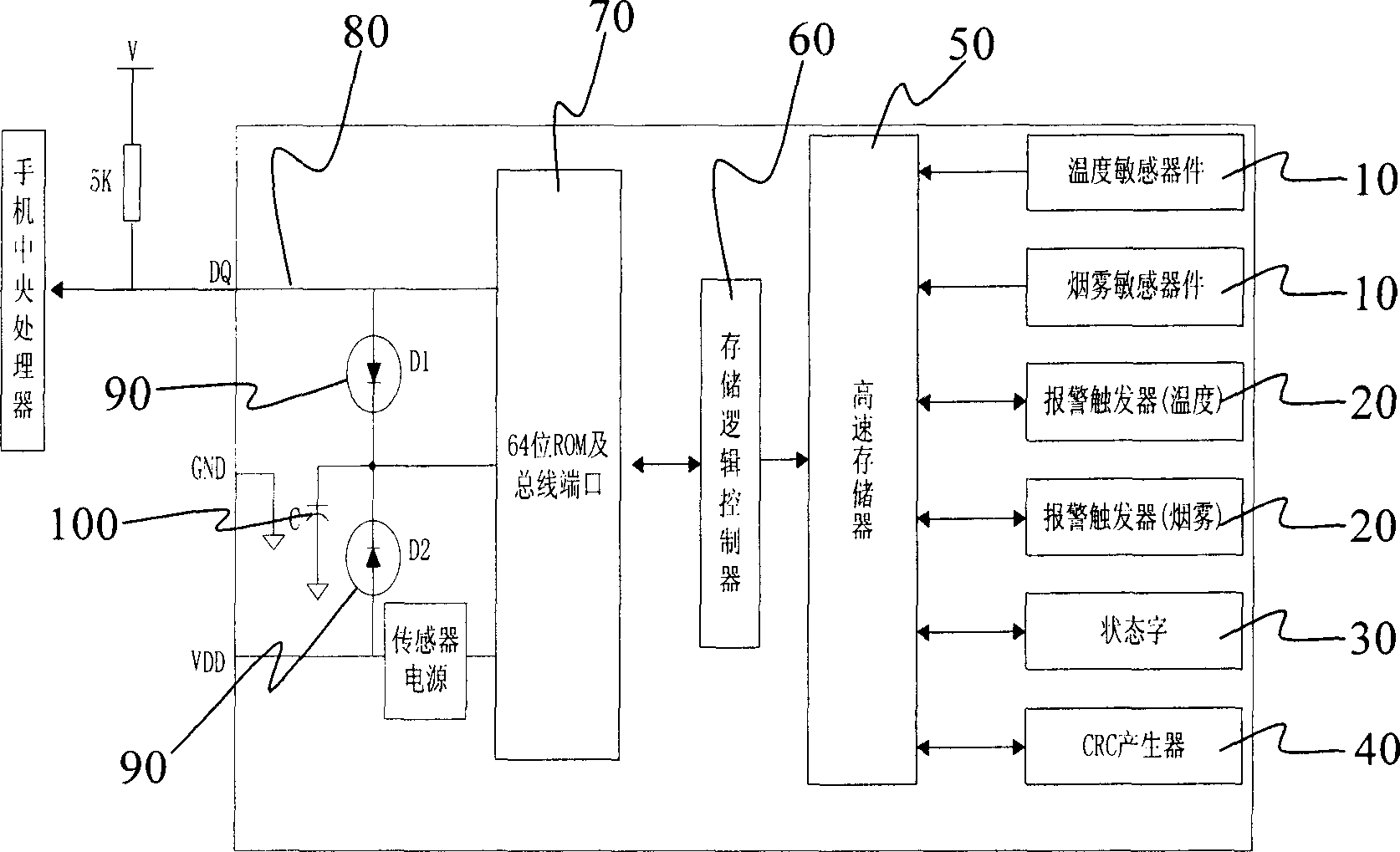

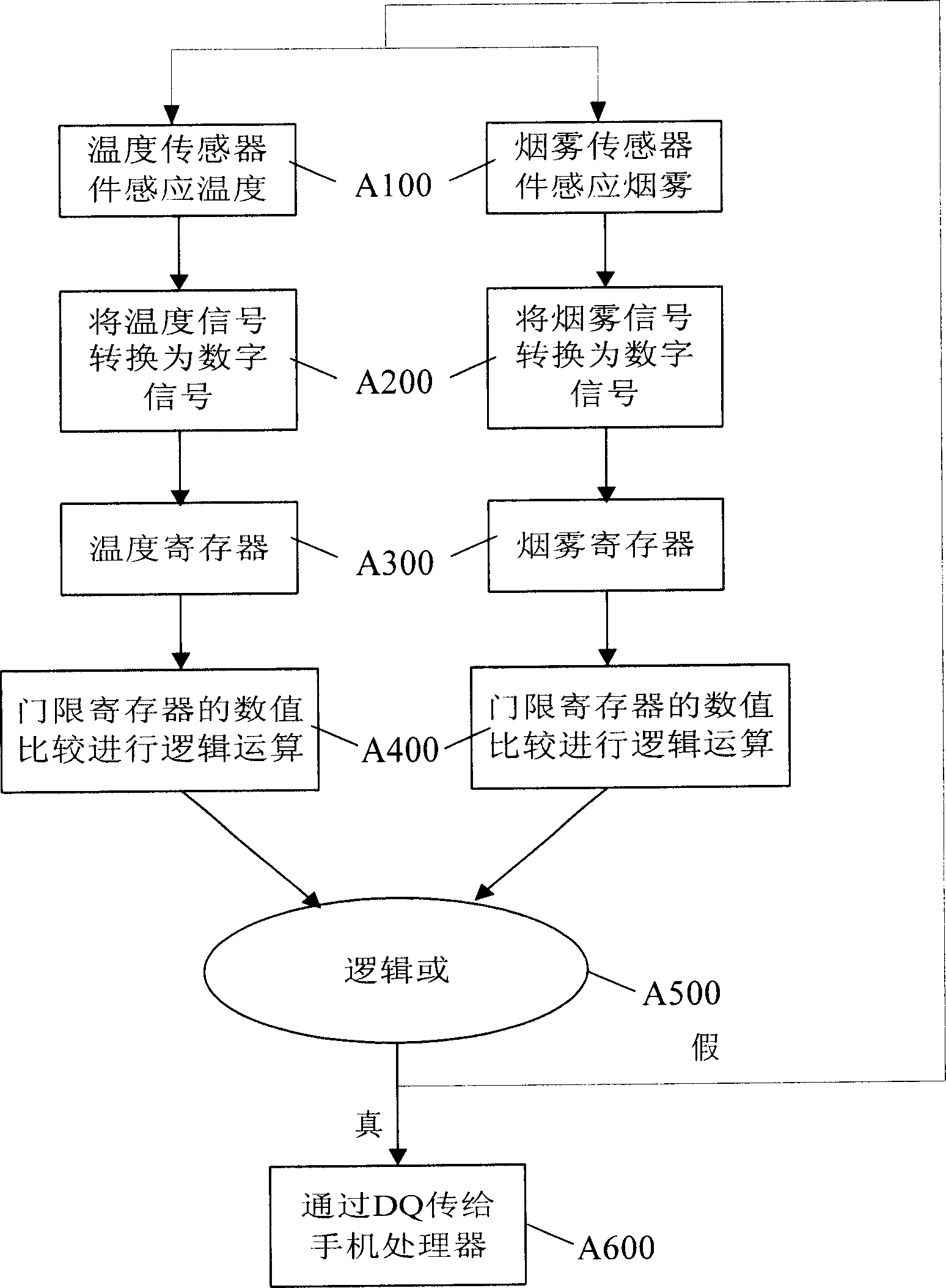

Mobile telephone with alarm function and its alarm method

InactiveCN1805469APerfect alarm functionProtect lifeAlarmsTelephone set constructionsGeolocationSpeech sound

The invention relates to an alarming mobile telephone and relative alarming method. Said alarming mobile telephone comprises an alarm helper set module for setting the helper; an alarm transmission period set module for setting the alarm transmission period; an alarm content record module for recording the alarm content in voice; and an alarm transmission module for transmitting said alarm content and the information of geological position to the said helper. And said invention can combine the sensor alarm. When detecting the external information content is over the preset valve, said invention can send alarm information with accurate geological position to special user. The invention is based on present mobile telephone to combine the positioning system to add accurate geological position information, which can effectively protect people.

Owner:LG ELECTRONICS (CHINA) R&D CENT CO LTD

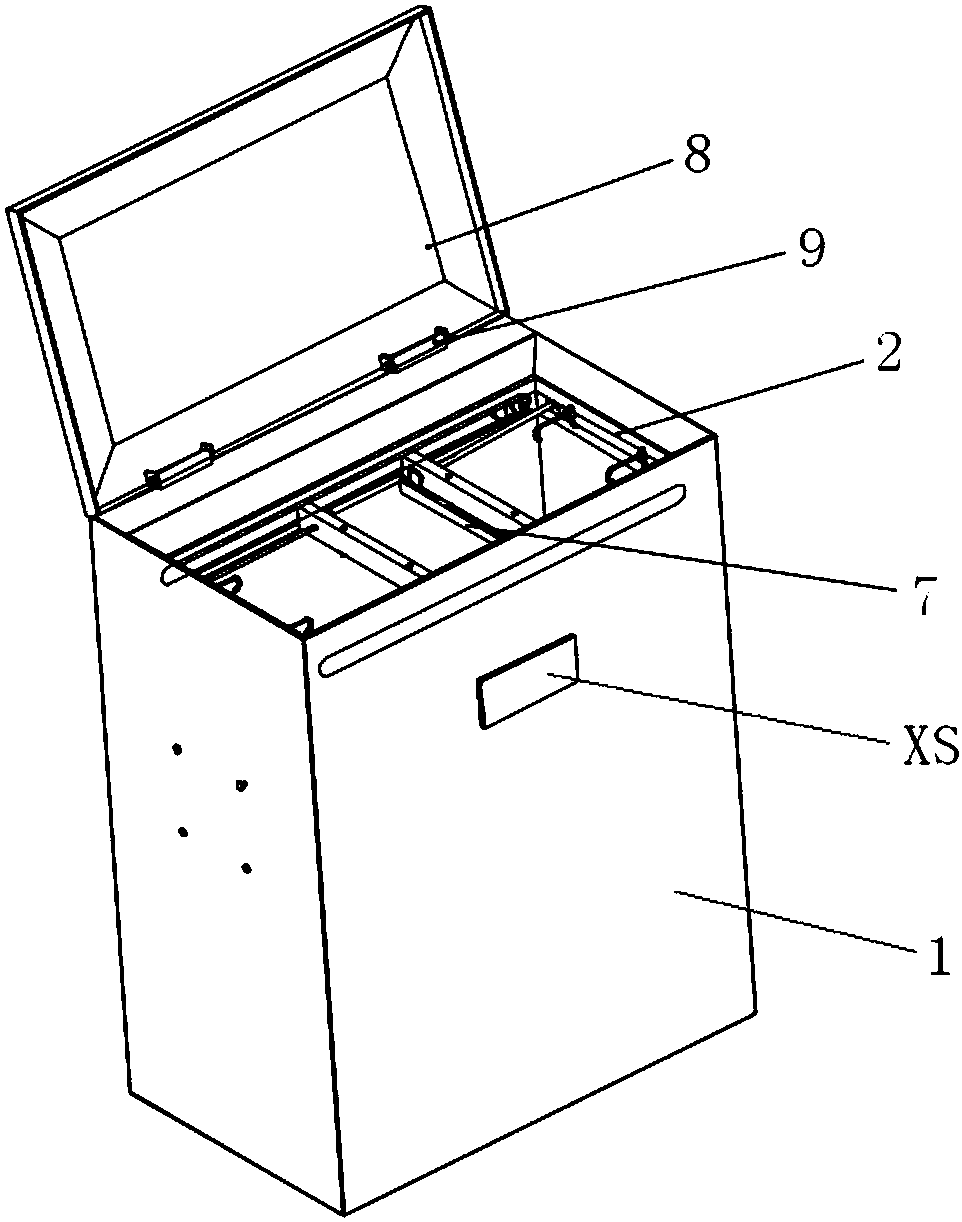

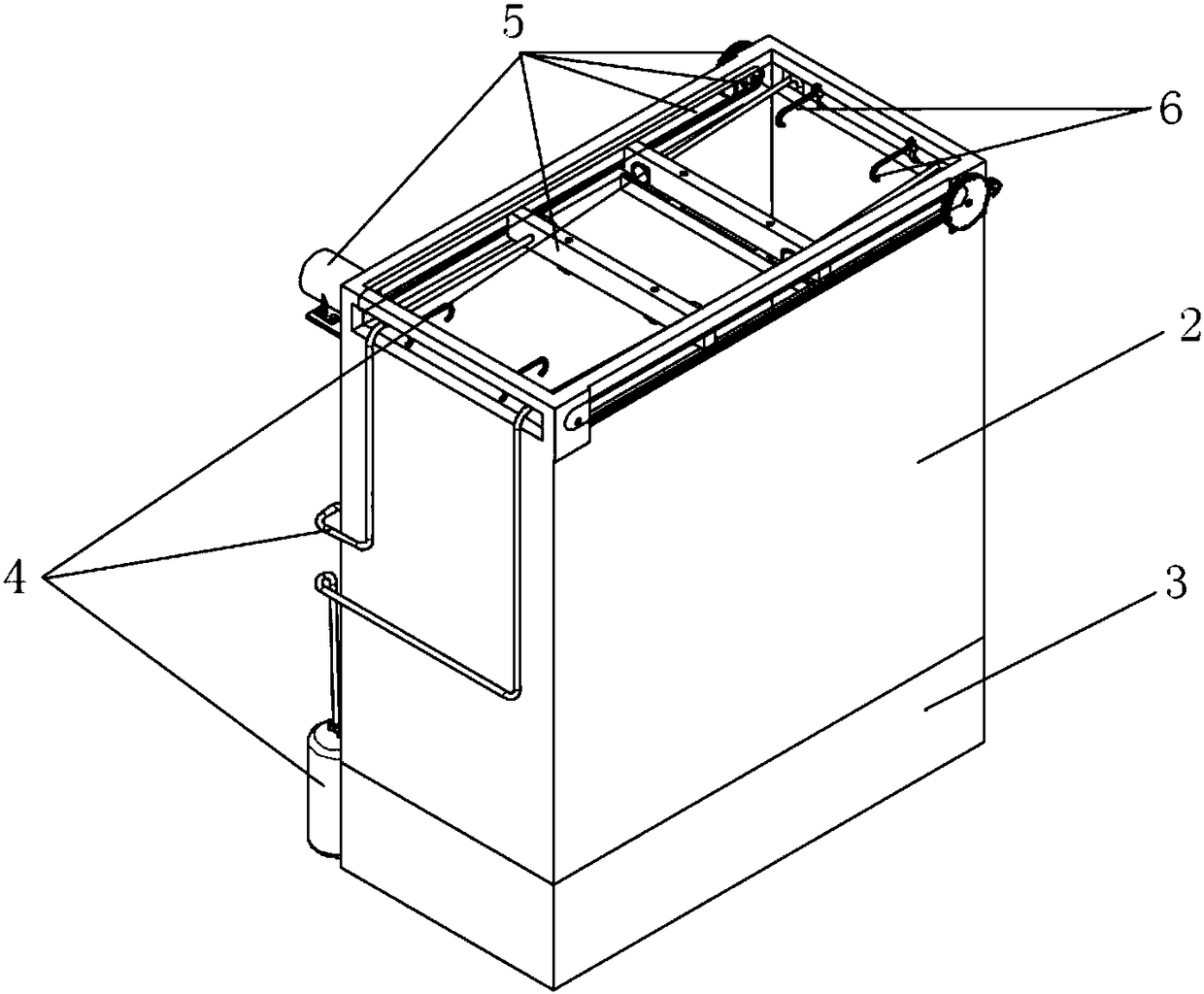

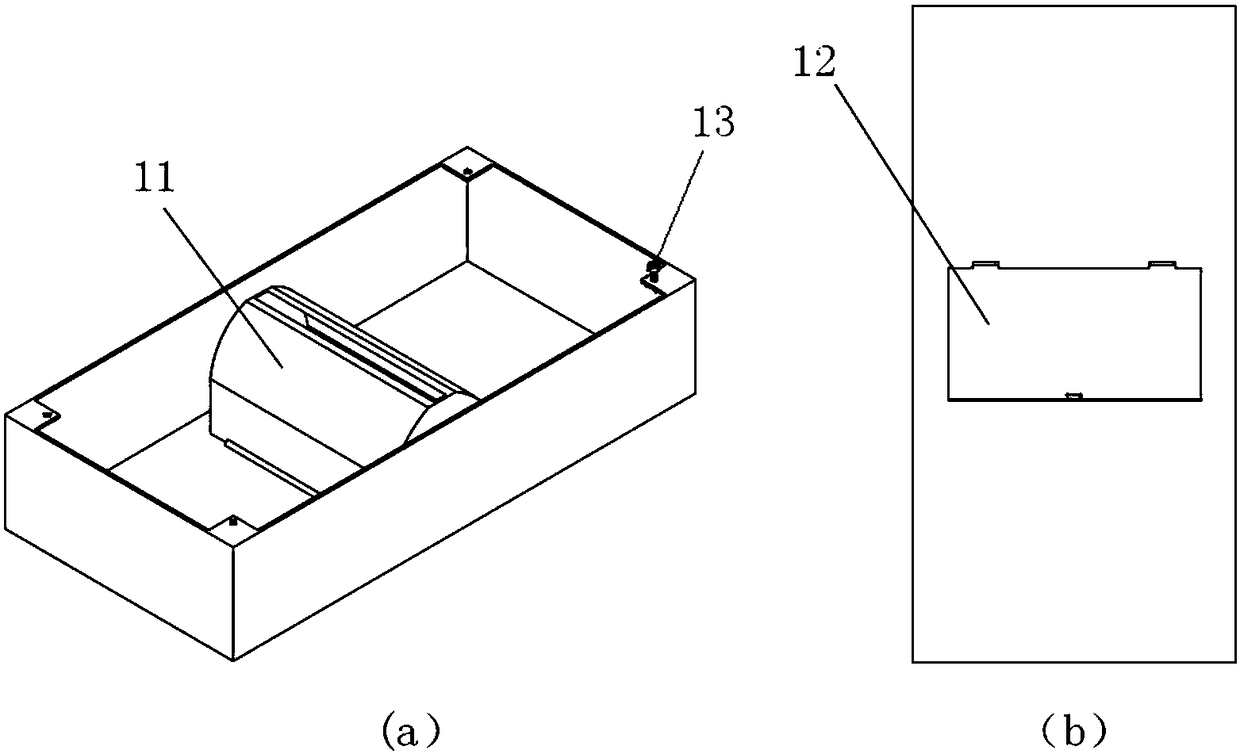

Multifunctional intelligent garbage can

The invention discloses a multifunctional intelligent garbage can. The multifunctional intelligent garbage can comprises an outer can, an inner can, a garbage bag opening and closing device and an intelligent controller, wherein the inner can is sleeved with the outer can, the garbage bag opening and closing device comprises a grabbing device and an opening and closing mechanism, the opening and closing mechanism comprises two parallel push rods and a push rod driving mechanism, the two ends of each push rod correspond to the upper edges of the front and rear walls of the inner can respectively, the grabbing device comprises vacuum pumps and multiple suckers, and the suckers are distributed and installed on the opposite surfaces of the two push rods and connected with the vacuum pumps through flexible air pipes. According to the multifunctional intelligent garbage can, a garbage can body is internally provided with the garbage bag opening and closing device controlled by the intelligent controller, so that automation of garbage bag opening and closing is achieved, not only are replacement and sealing of garbage bags convenient and fast, but also there is no need for a user to touchgarbage directly, and thus the life quality of the user is greatly improved; the garbage can is low in production cost and suitable for application and popularization.

Owner:TANGSHAN COLLEGE

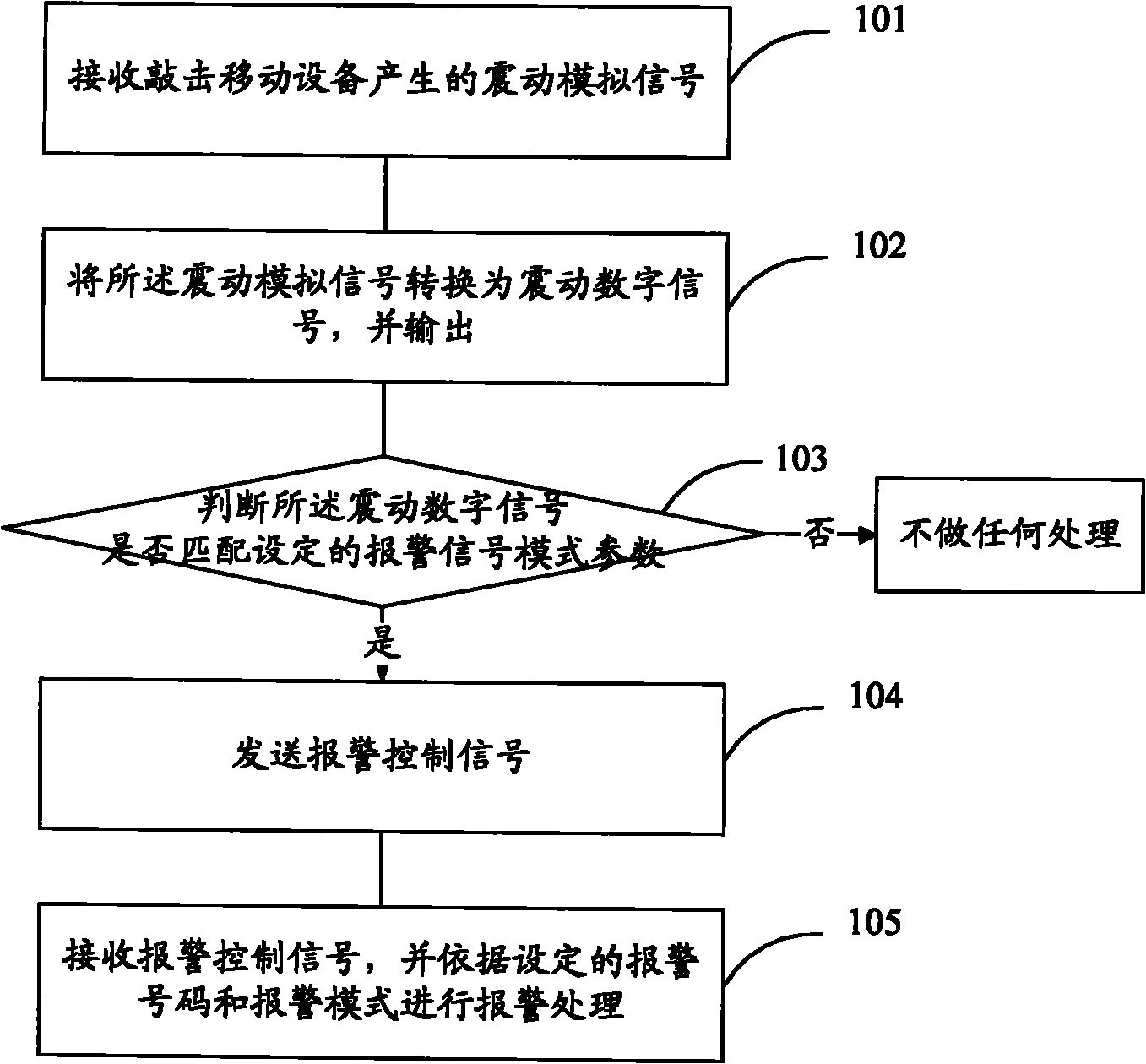

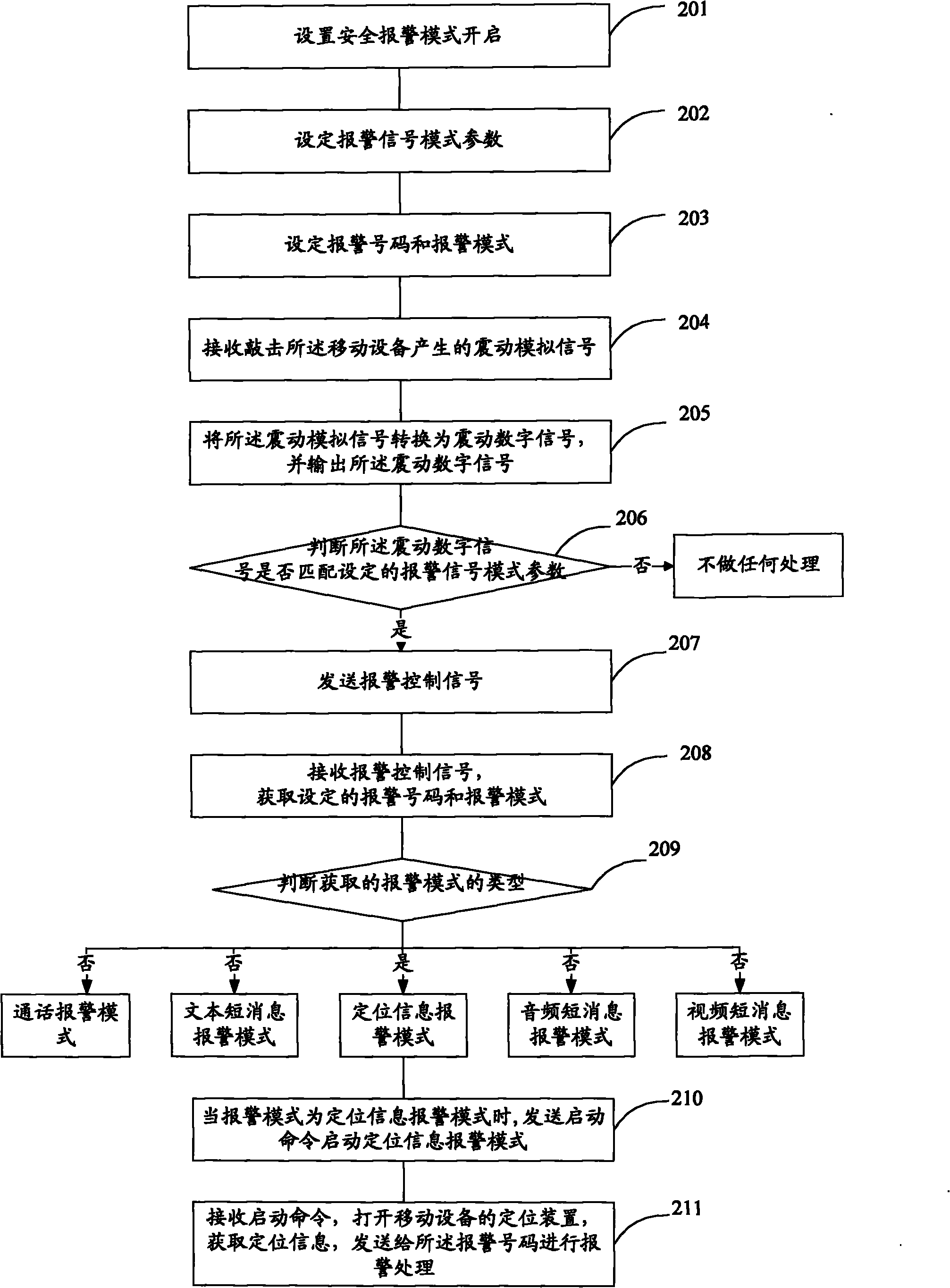

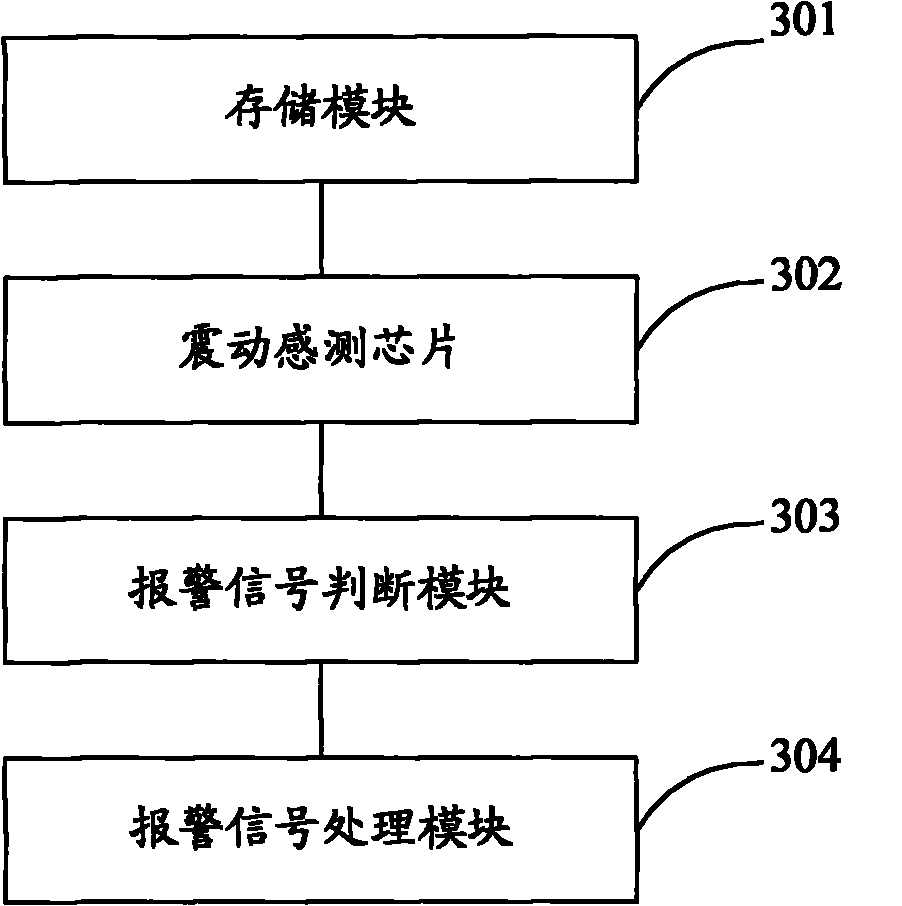

Safety alarm device and method for mobile equipment

InactiveCN101877751APerfect alarm functionAvoid sightSubstation equipmentMessaging/mailboxes/announcementsControl signalEngineering

The invention provides a safety alarm device and a safety alarm method for mobile equipment. The safety alarm device for the mobile equipment comprises a storage module, a vibration sensing chip, an alarm signal judgment module and an alarm signal processing module, wherein the storage module is used for storing a set alarm signal pattern parameter, alarm number and alarm mode; the vibration sensing chip is used for receiving a vibration analog signal generated by knocking the mobile equipment, converting the vibration analog signal into a vibration digital signal and outputting the vibration digital signal; the alarm signal judgment module is used for receiving the vibration digital signal output by the vibration sensing chip and outputting an alarm control signal when the vibration digital signal is matched with the alarm signal pattern parameter stored by the storage module; and the alarm signal processing module is used for performing alarm processing according to the alarm number and the alarm mode which are stored in the storage module when receiving the alarm control signal output by the alarm signal judgment module. When accidental injury occurs, the safety alarm device can quickly and snugly give an alarm so as to effectively guarantee the personal safety of warners.

Owner:YINGHUADA (SHANGHAI) ELECTRONIC CO LTD

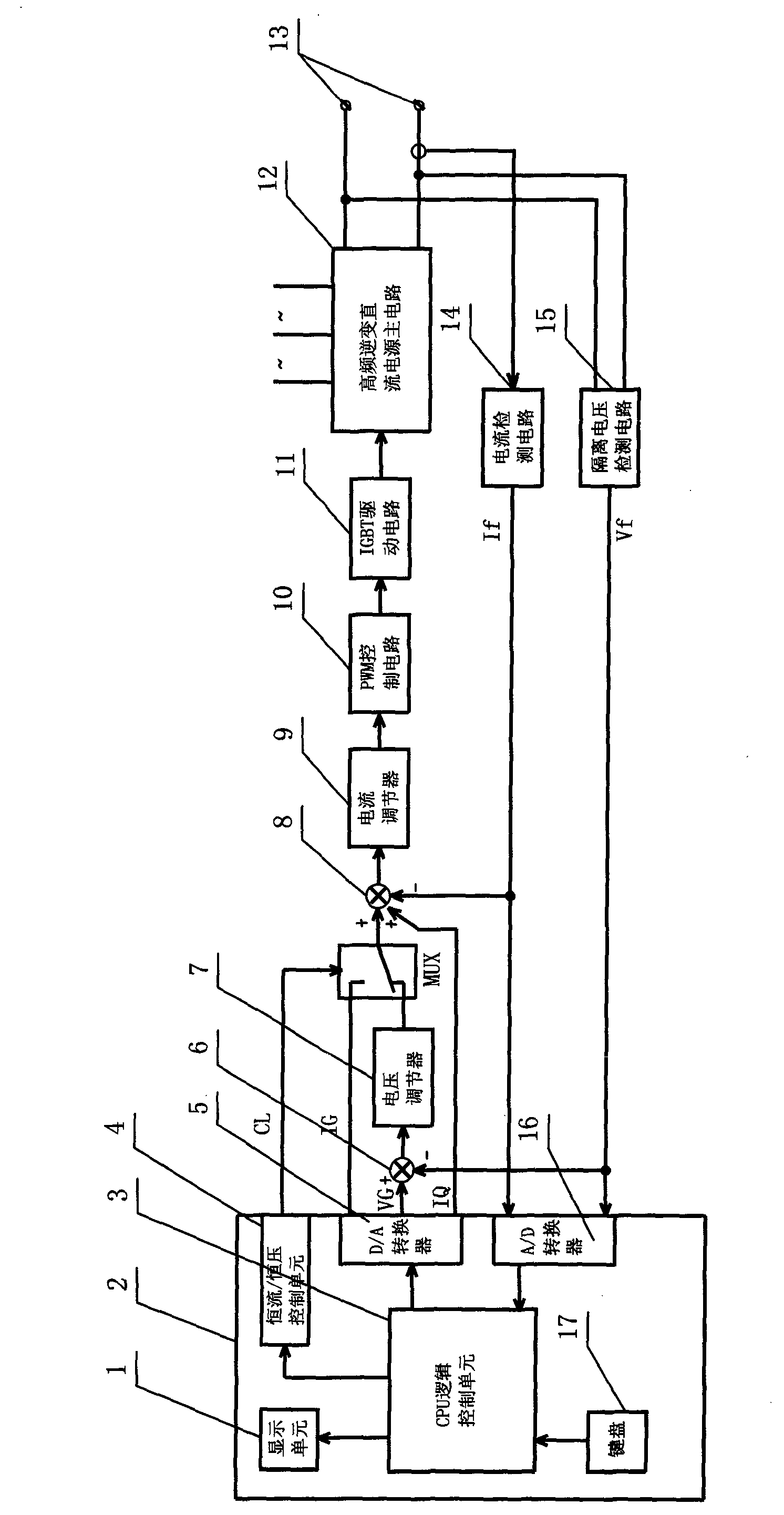

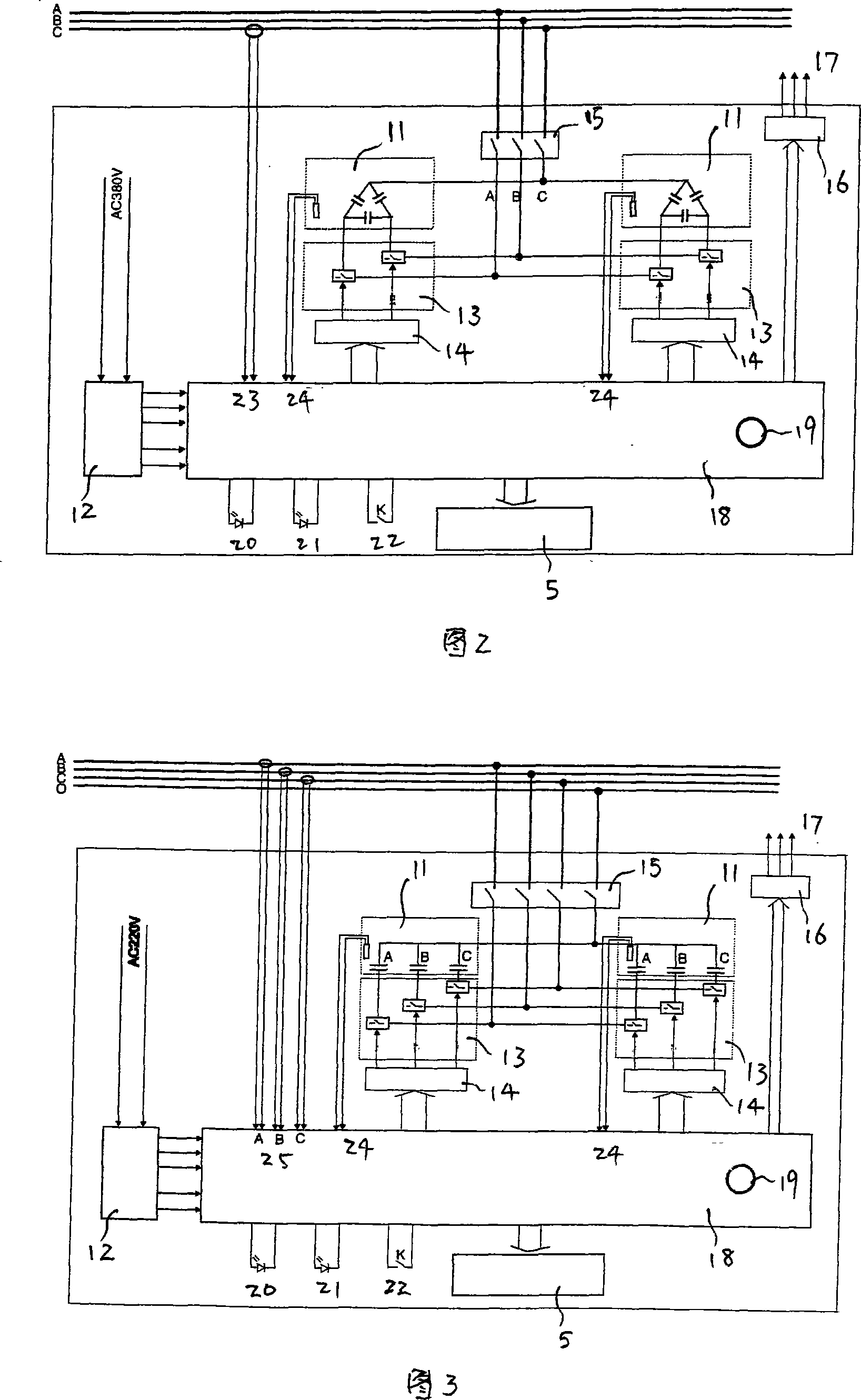

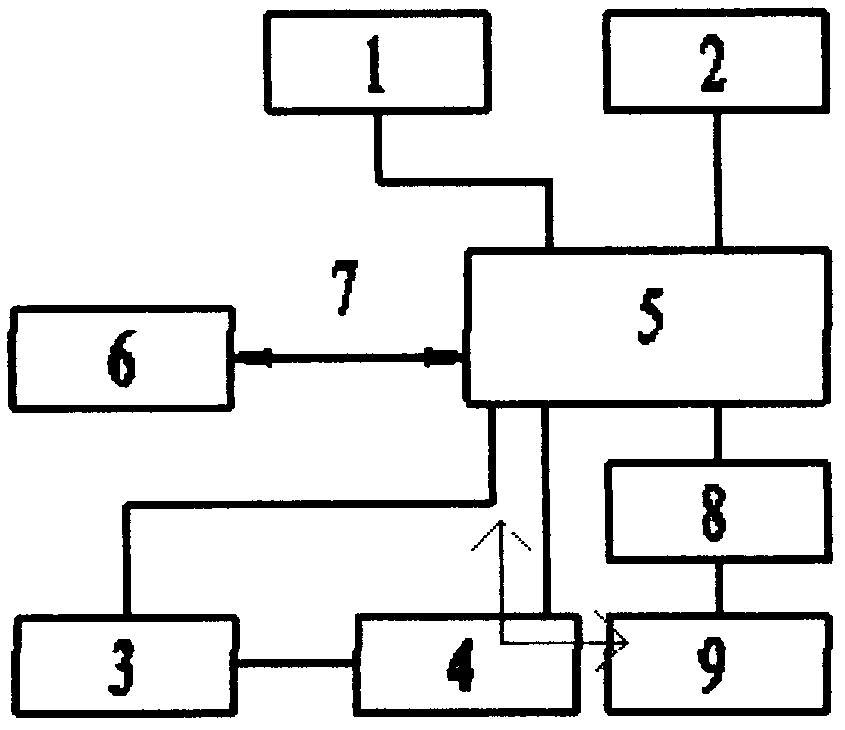

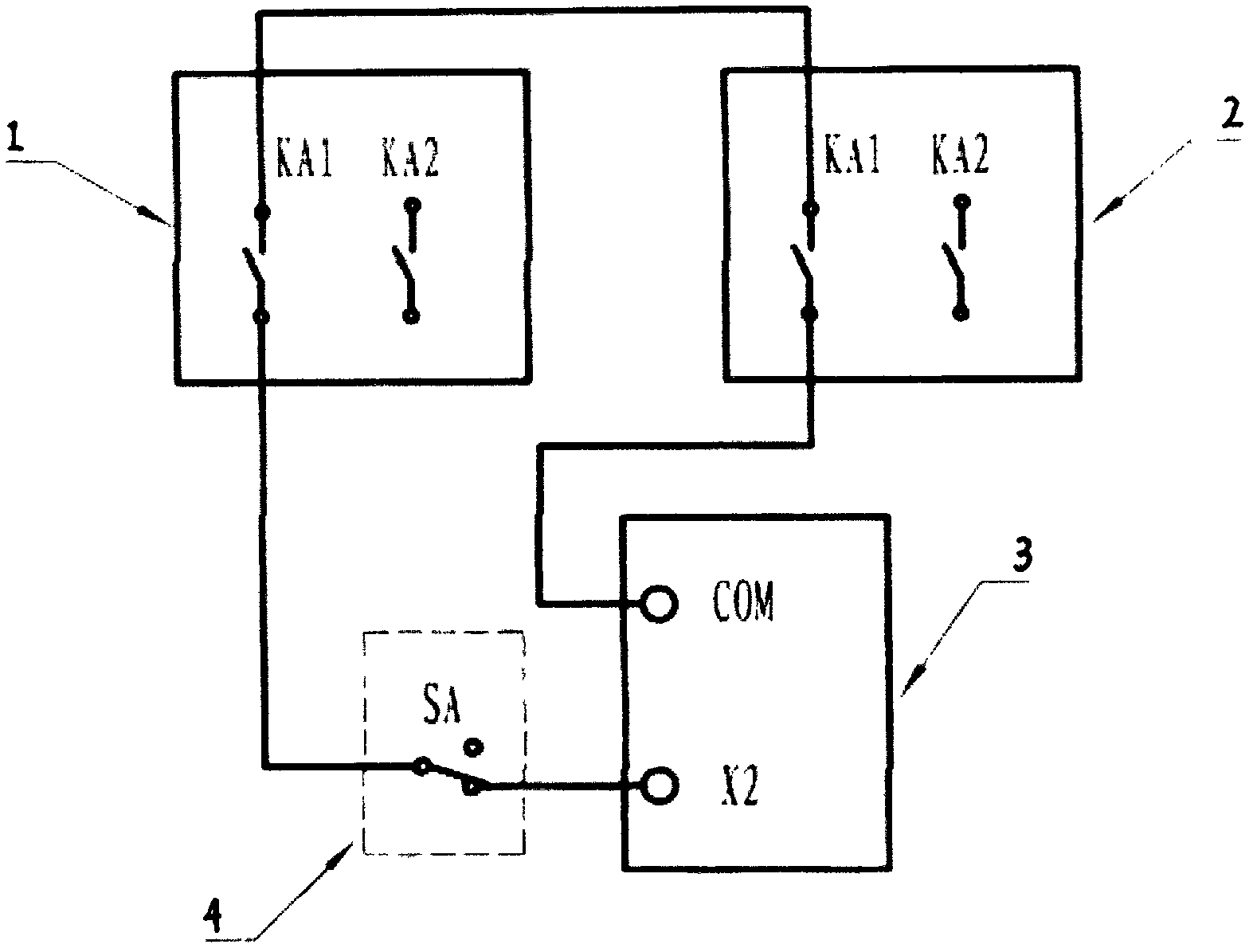

Multifunctional high-frequency inversion direct-current electric welding machine realizing circuit

InactiveCN103817402AAchieve multi-functionRealize intelligenceArc welding apparatusSoft switchingConstant current

The invention relates to an electric welding machine circuit, in particular to a multifunctional high-frequency inversion direct-current electric welding machine realizing circuit which comprises an electric welding machine control unit, a voltage regulator, a current regulator, a PWM (pulse-width modulation) control circuit, an IGBT (insulated gate bipolar transistor) driving circuit, a high-frequency inversion direct-current power source main circuit, an electric welding machine output electrode, a current detection circuit and an isolation voltage detection circuit. The electric welding machine control unit is a control center taking a CPU (central processing unit) logic control unit as a core, and the CPU logic control unit is connected with a display unit, a constant-current or constant-voltage control unit, a D / A converter and an A / D converter respectively. High-frequency technology, soft switching technology and digital control technology are adopted to realize constant-voltage characteristic and constant-current characteristic of an electric welding machine. The electric welding machine has three functions including TIG (argon tungsten-arc welding), MMA (manual metal arc) and MIG (metal-inert gas) welding, production cost is lowered, requirements on multifunctional intelligentization and high-quality welding are met, and the electric welding machine has a friendly display interface and is convenient to operate and use.

Owner:YANCHENG DLD WELDING SCI & TECH

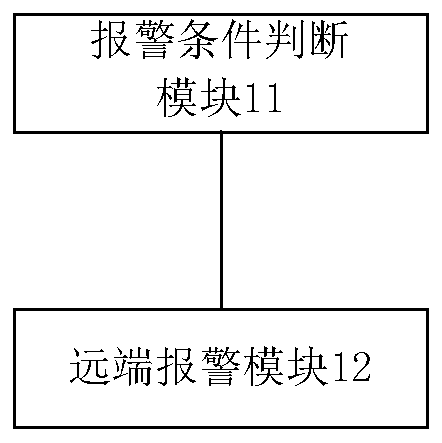

Intelligent alarm terminal

PendingCN110910607APerfect alarm functionExpand the scope of the sceneAlarmsElderly AdultEmbedded system

Owner:李健

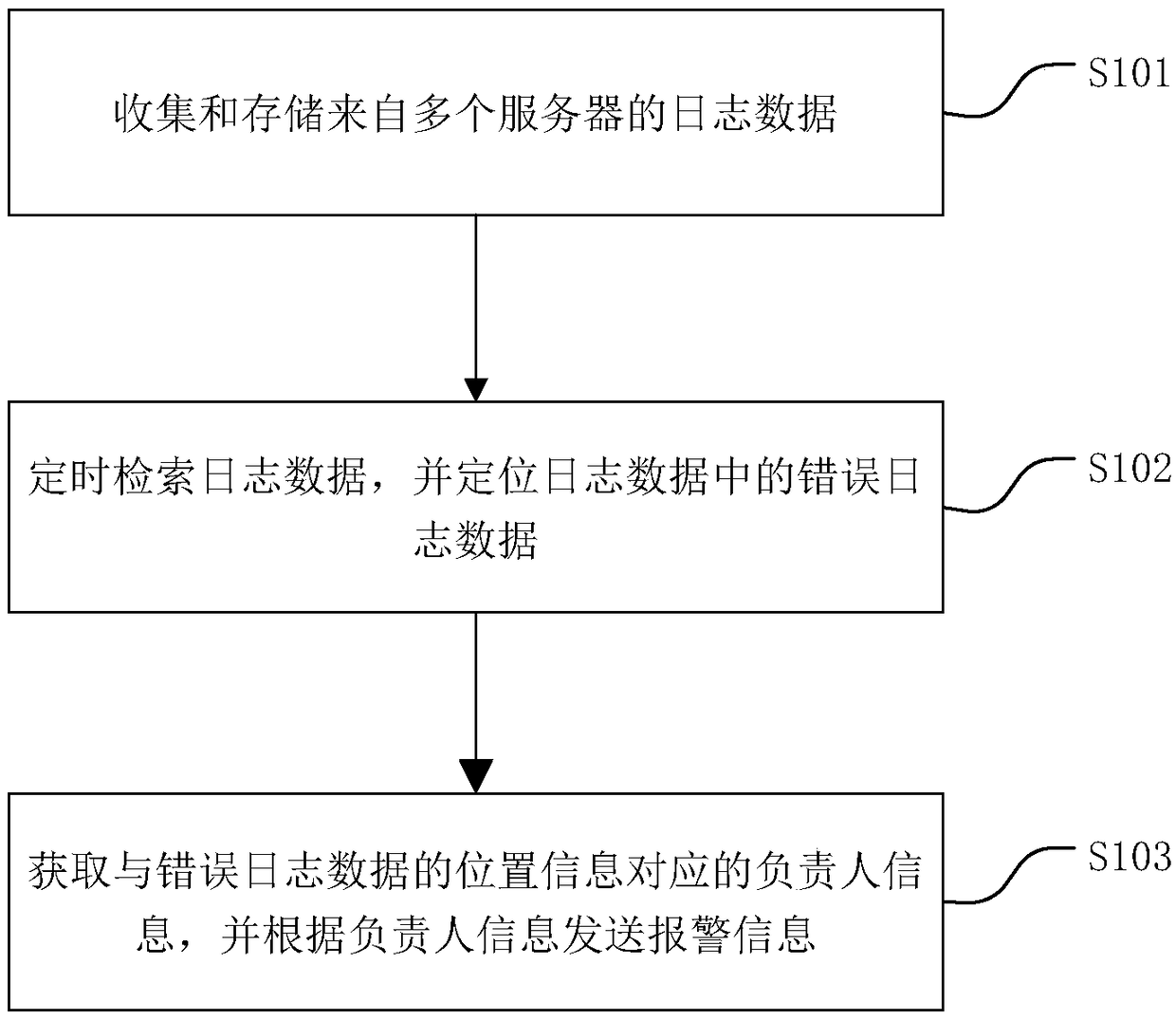

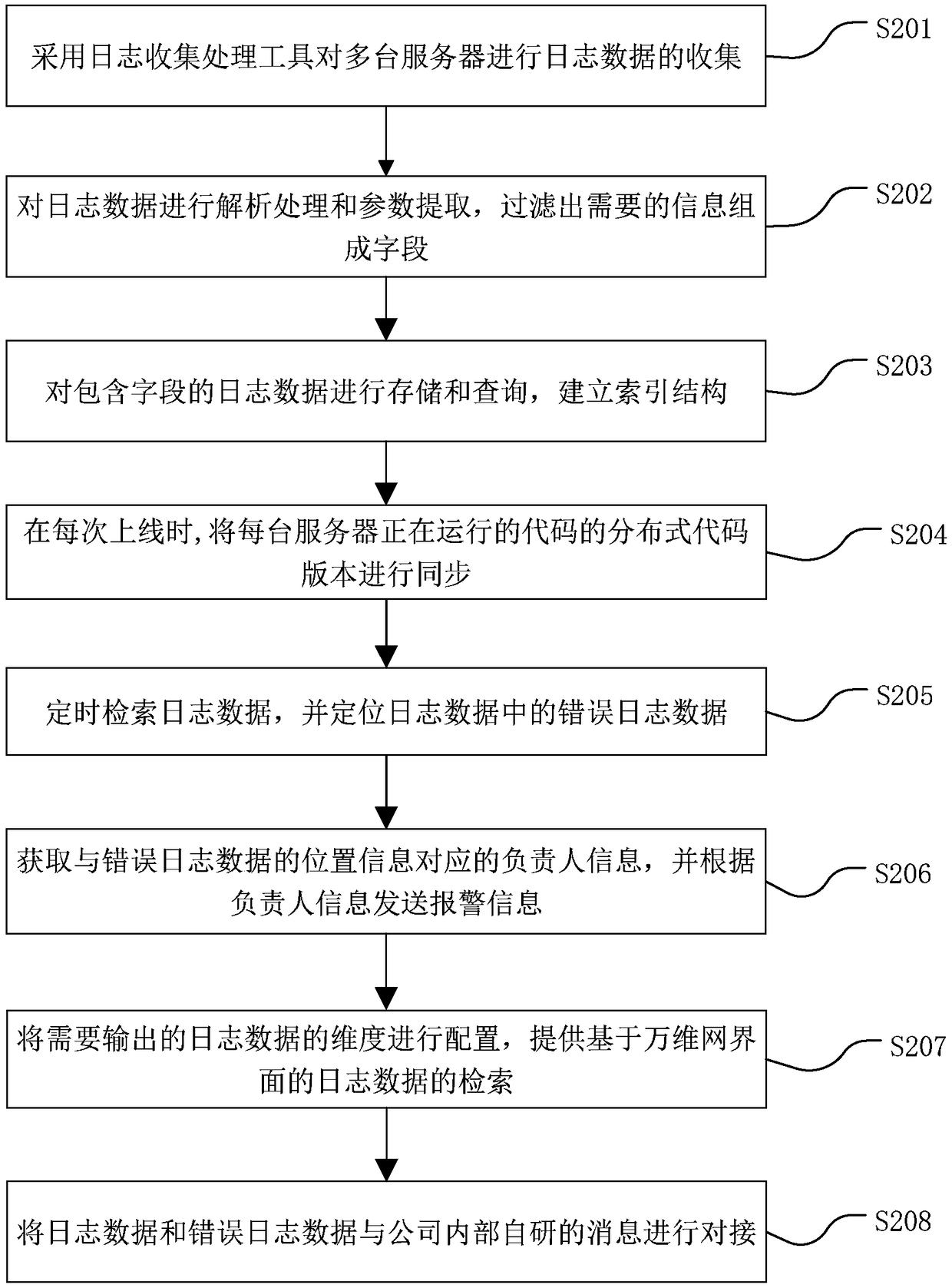

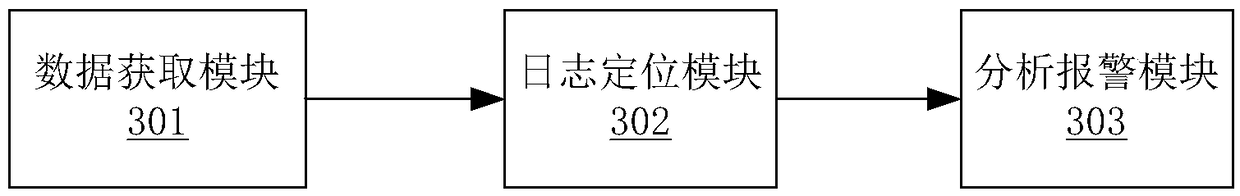

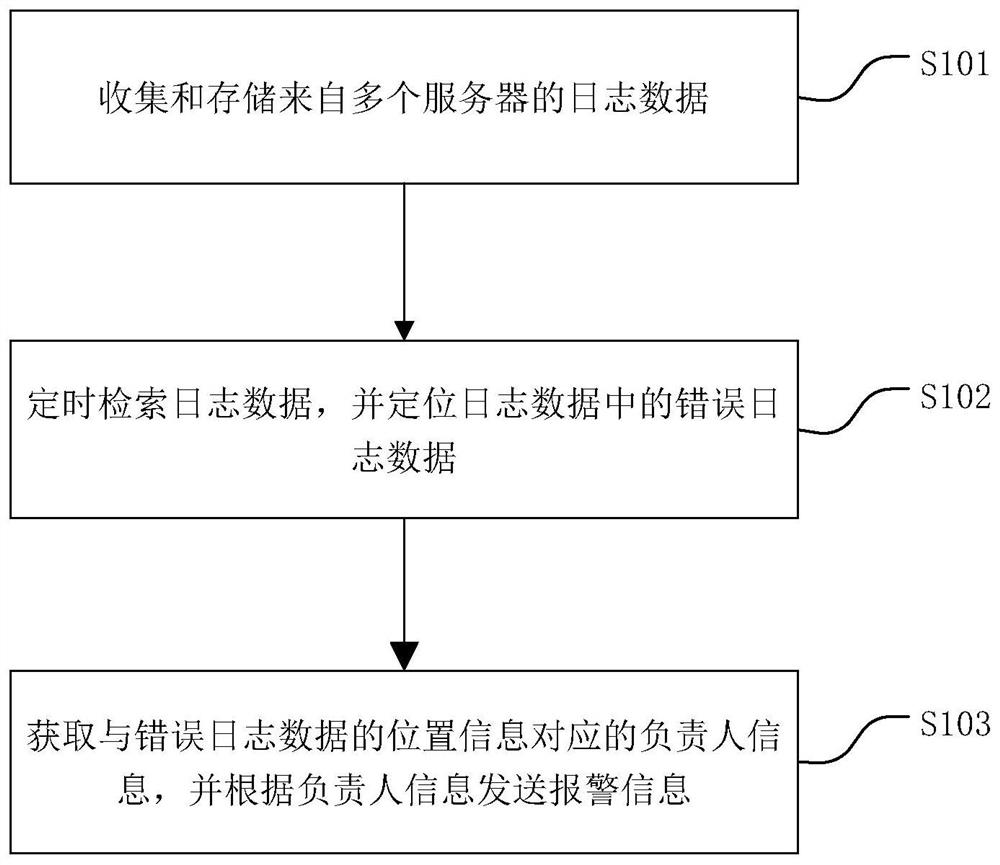

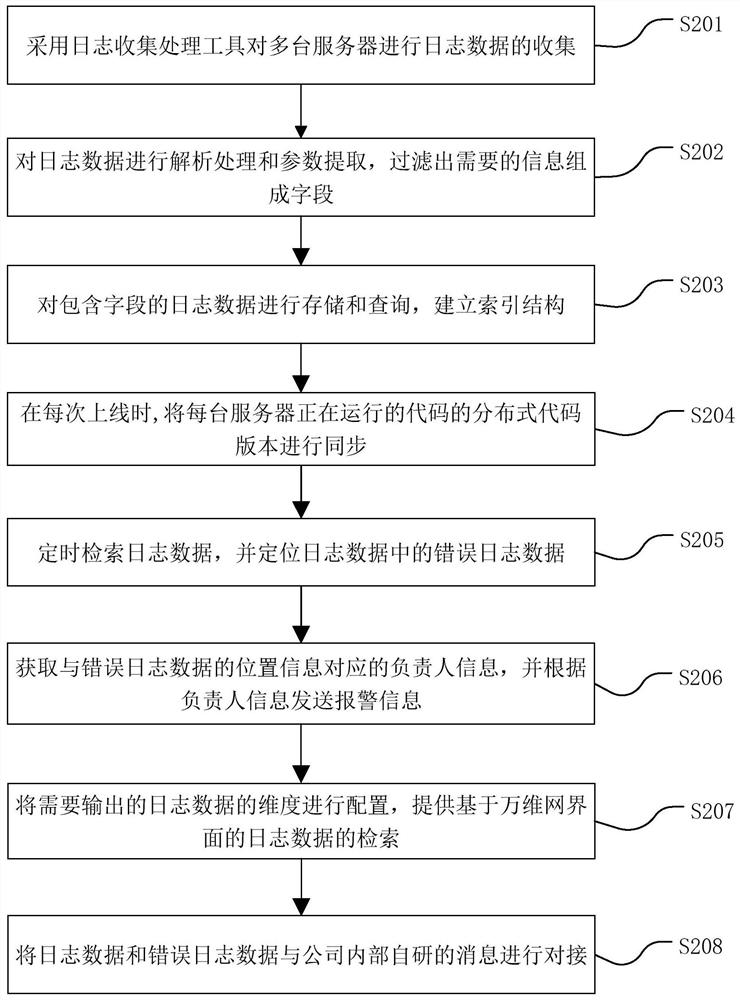

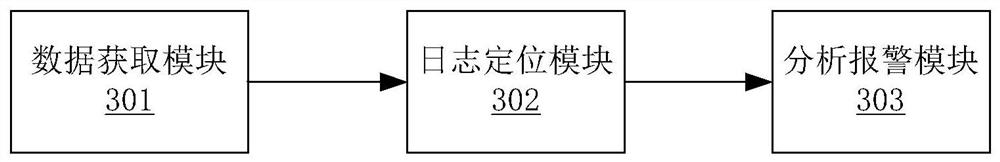

Log searching method, log searching device and computer readable storage medium

ActiveCN109492073APerfect alarm functionEasy to manageText database queryingCollections dataText messaging

The invention relates to a log searching method, a log searching device and a computer readable storage medium. The log searching method comprises the following steps: collecting and storing log datafrom a plurality of servers; retrieving the log data at regular time, and positioning error log data in the log data; and obtaining responsible person information corresponding to the position information of the error log data, and sending alarm information according to the responsible person information. Method for searching through log, log data collection is realized; the method comprises the following steps: obtaining a fault log, storing the fault log, positioning and analyzing the generation position of the fault log data through a distributed code version management tool, finding corresponding responsible person information, and sending alarm information through modes of mails, short messages, telephones and the like, so as to quickly respond to an ongoing server fault and realize real-time monitoring and alarm of the fault log.

Owner:BEIJING DAJIA INTERNET INFORMATION TECH CO LTD

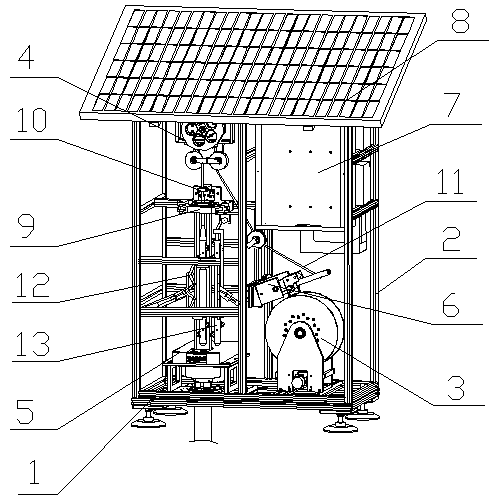

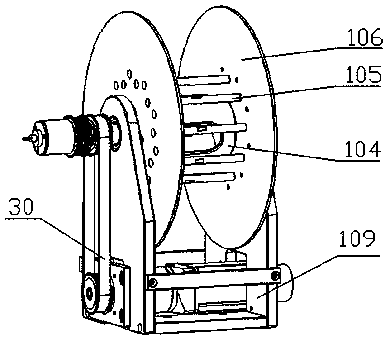

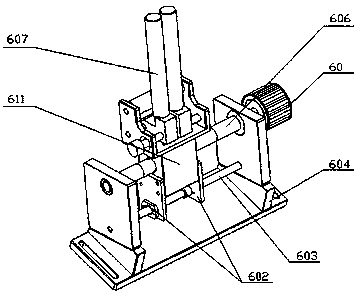

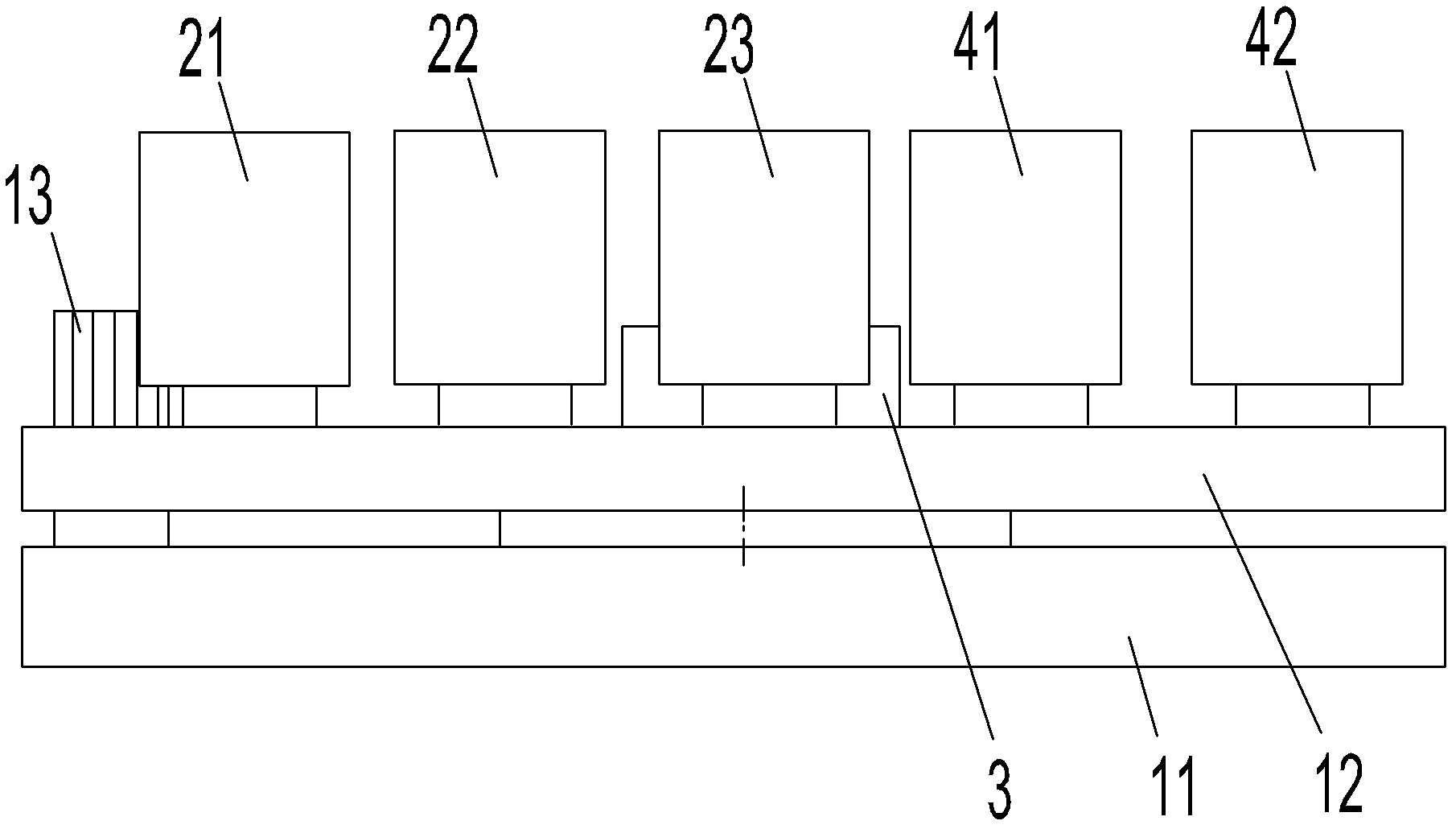

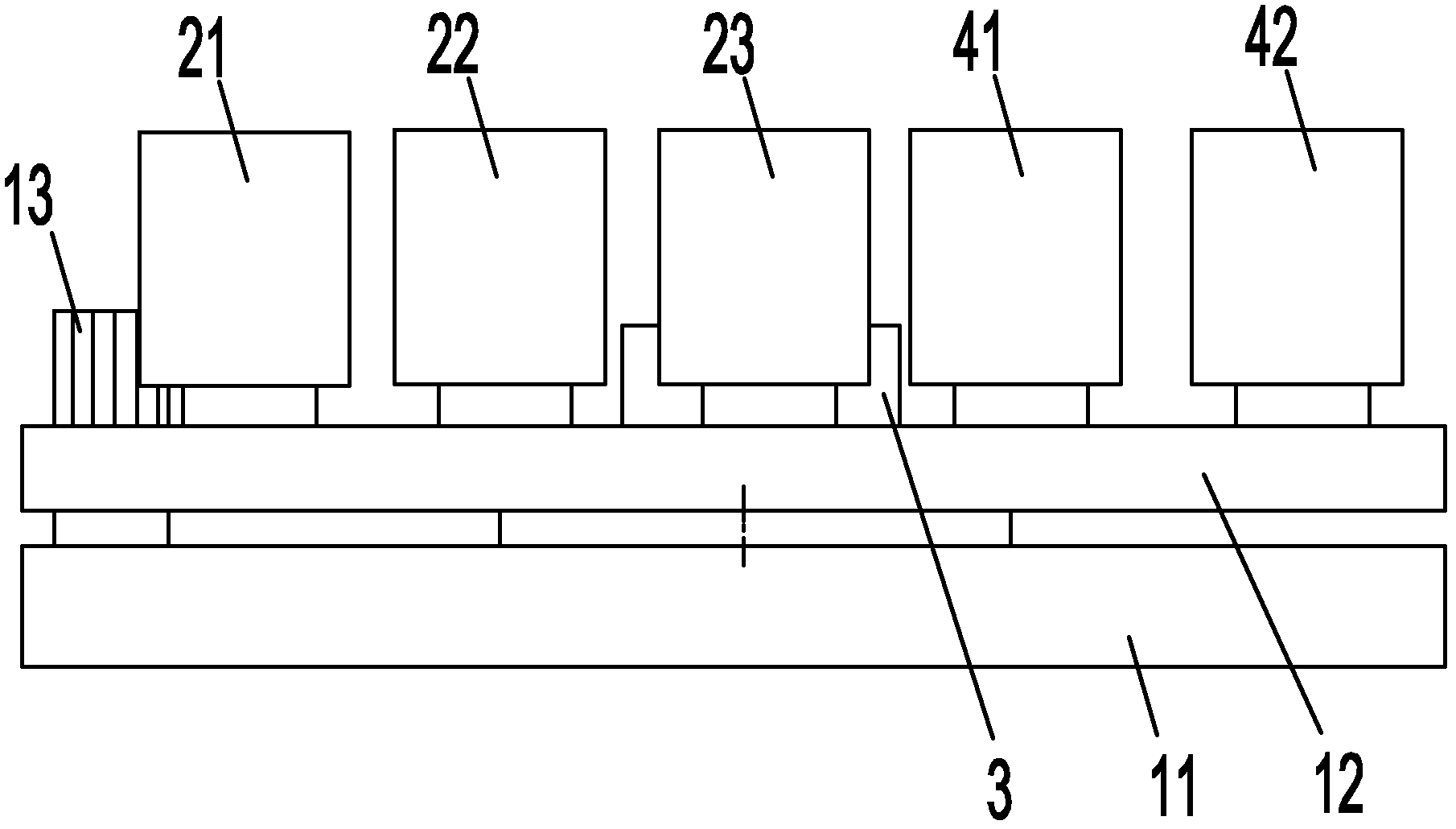

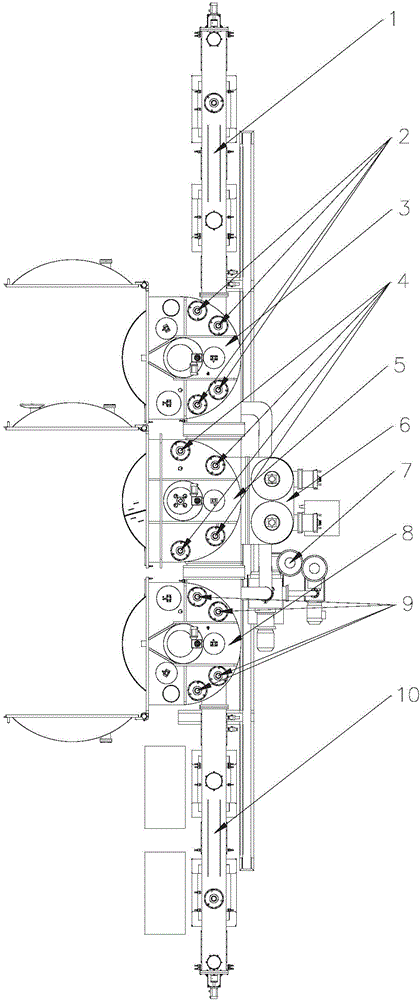

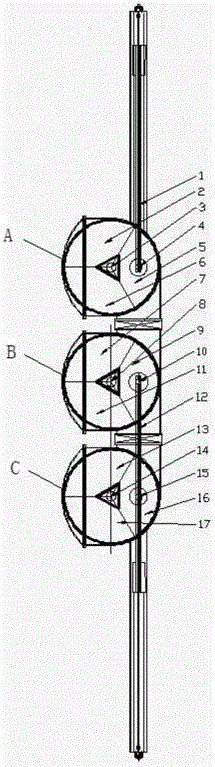

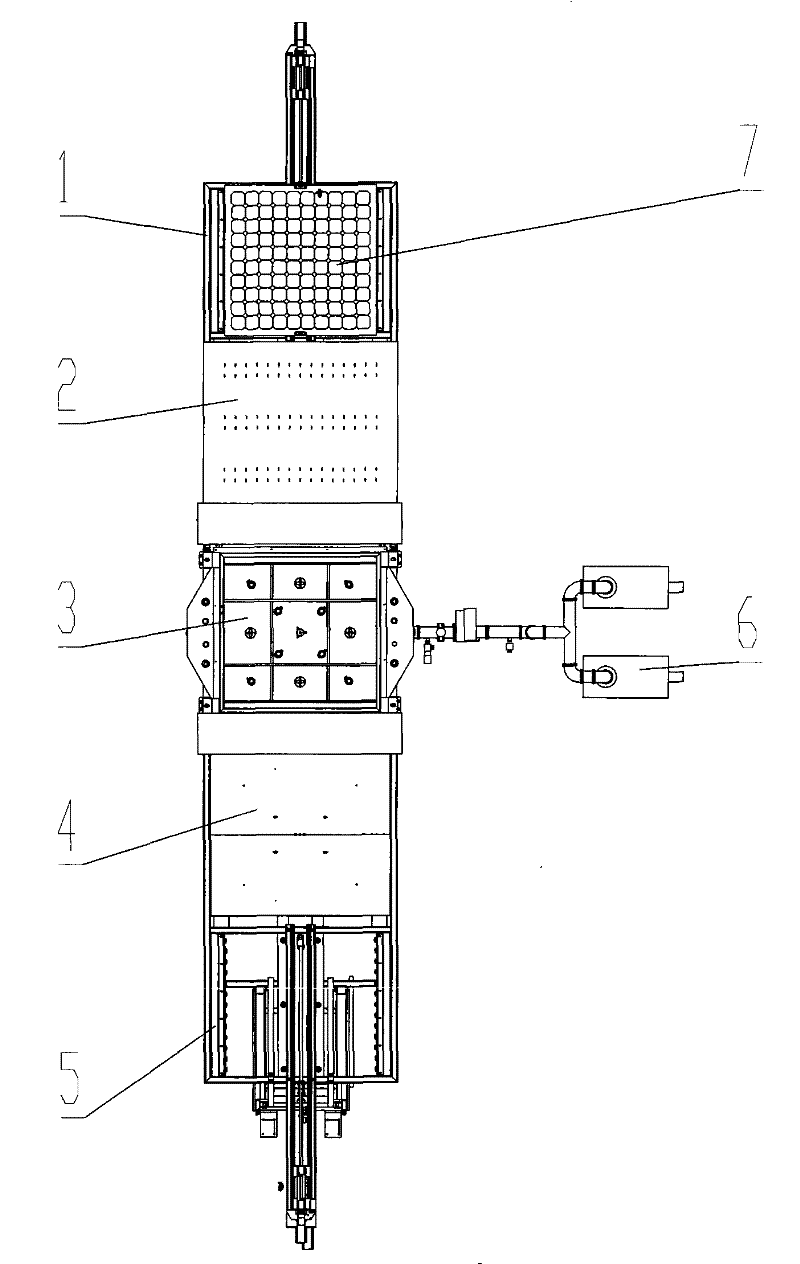

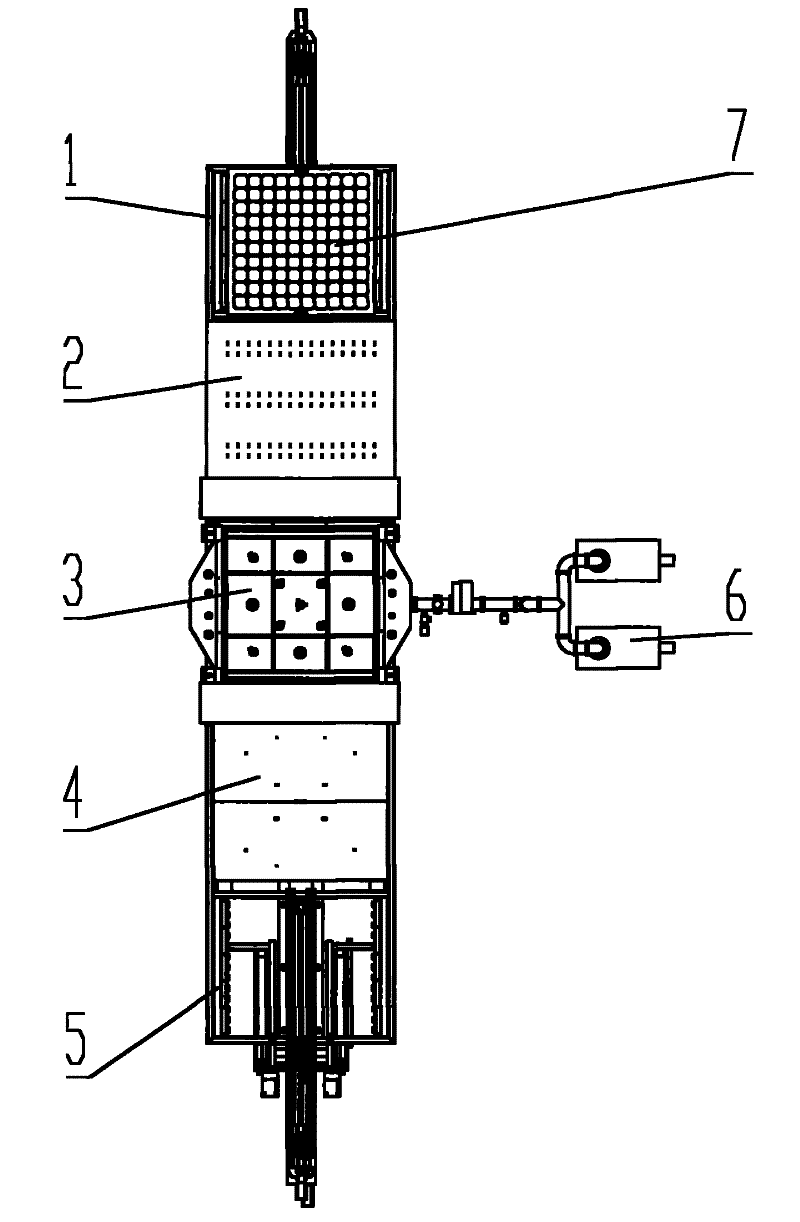

Intelligent inclination measuring system and monitoring method thereof

ActiveCN110359440AImprove human-computer interactionRegression is accurateIn situ soil foundationData acquisitionDeformation monitoring

The invention provides an intelligent inclination measuring system and a monitoring thereof method. The intelligent inclination measuring system comprises an automatic inclination measuring machine, adata acquisition terminal, a cloud monitoring management system and a power supply system. The automatic inclination measuring machine comprises a machine frame, an unwinding device, a cable arranging device, a meter counting device, a reversing device, a correcting device, an in-place detecting device, an electric control system, a gripping device and a trial winding device; the intelligent inclination measuring system is simple in structure and convenient to maintain, assemble and disassemble, and does not have a safety hazard; an inclination measuring pipe is detected by simulating automatic trial winding of an inclination measuring device; the damage of an inclination measuring sensor, inaccurate data and the like are avoided; the operating state of equipment can be monitored in realtime by arranging a tension sensor; automatic measurement is realized in the overall process; measuring point data are automatically acquired through the data acquisition terminal and are transmittedto the cloud monitoring management system in real time; event information in the operating process of the equipment is displayed through the cloud monitoring management system; the intelligent inclination measuring system processes and gives an alarm when an abnormity appears; the measurement precision is high; and the equipment is stable and reliable, and can be applied to deformation monitoringon a sliding surface in a soil body of a landslide mass, dangerous rock, high side slope and the like.

Owner:广州日昇岩土科技有限公司

Bridge anticollision early warning rotary table

InactiveCN102426805AEasy to installPerfect alarm functionMarine craft traffic controlEngineeringAlarm device

The invention discloses a bridge anticollision early warning rotary table comprising a rotatable support component and a control component as well as an intelligent detector and an intelligent alarm device which are arranged on the support component, wherein the intelligent detector comprises a shape detecting component used for acquiring vessel shape data and a position detecting component used for acquiring vessel position data. The bridge anticollision early warning rotary table disclosed by the invention has the beneficial effects of good integrity, high automation degree, low cost and the like.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD +2

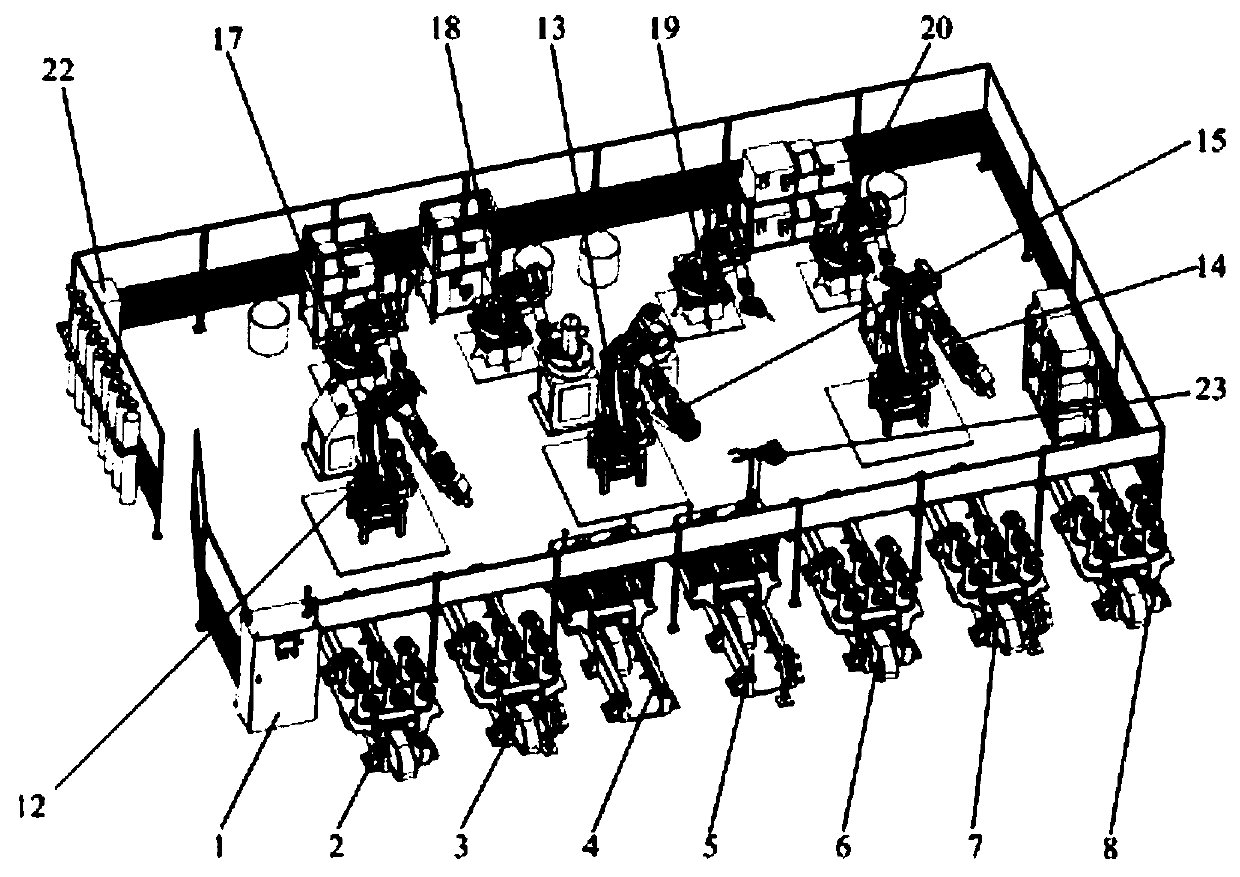

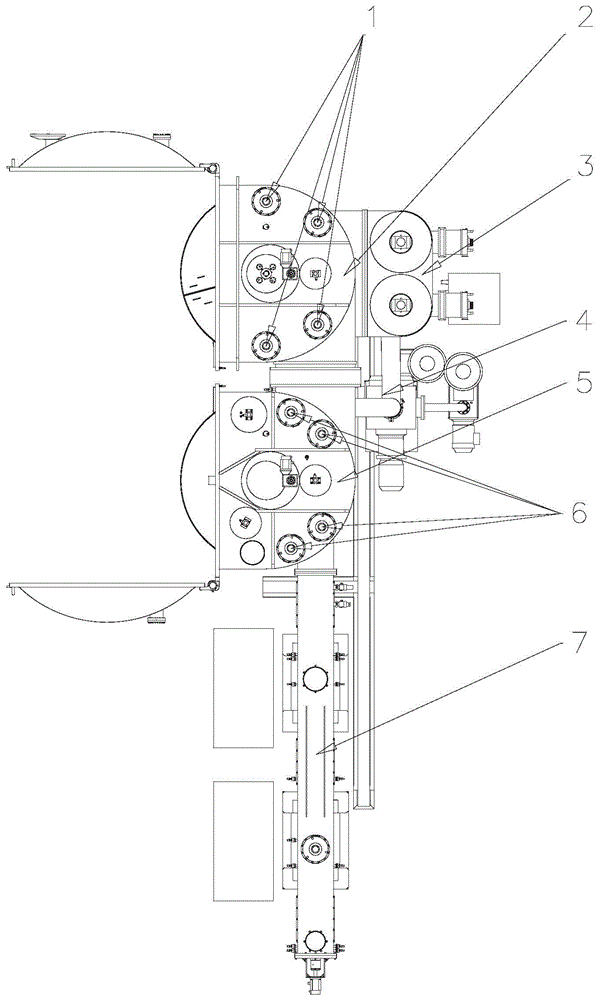

Automatic welding production line system for industrial filter

ActiveCN110757035AShort timeSimplify the flow of welding processWelding/cutting auxillary devicesAuxillary welding devicesProcess engineeringManufacturing line

The invention discloses an automatic welding production line system for an industrial filter. The automatic welding production line system comprises a first blank conveying table, a first flange conveying table, a semi-finished product discharging conveying table, a first finished product discharging conveying table, a first carrying robot, a second carrying robot, a third carrying robot, a firstwelding robot, a second welding robot, a third welding robot, a fourth welding robot and an industrial visual system, wherein the first blank conveying table, the first flange conveying table, the semi-finished product discharging conveying table and the first finished product discharging conveying table are arranged side by side; the first carrying robot is arranged between the first blank conveying table and the first welding robot; the second carrying robot is arranged between the first flange conveying table and the second welding robot; and the third carrying robot is arranged between thefirst finished product discharging conveying table and the fourth welding robot. The system is high in workpiece positioning precision and low in welding time consumption, and the workload is greatlyreduced.

Owner:716TH RES INST OF CHINA SHIPBUILDING INDAL CORP +2

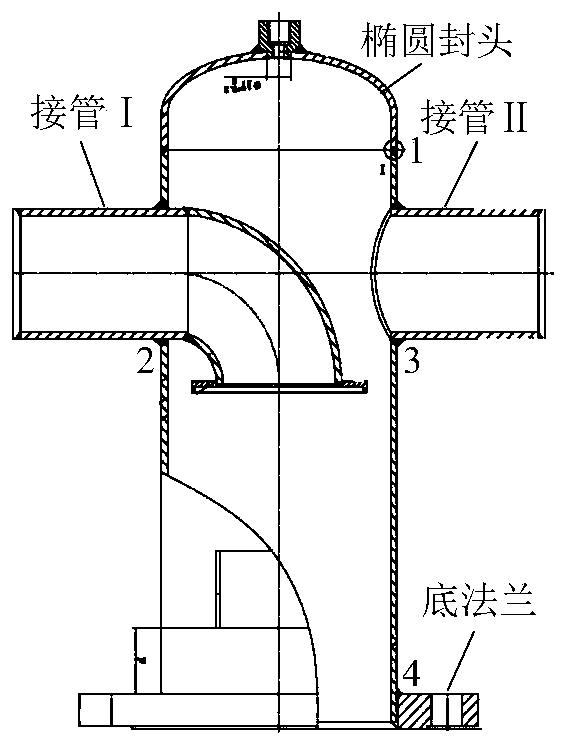

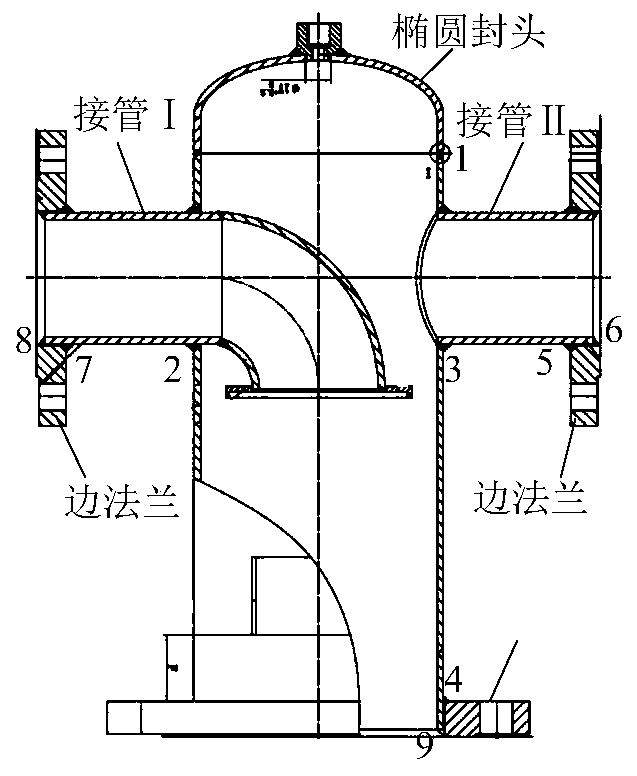

Rock and gas multi-process coupling test device for unconventional natural gas

InactiveCN108318666AGuaranteed measurement accuracySolve the accuracy problemEarth material testingDifferential pressureEngineering

The application provides a rock and gas multi-process coupling test device for unconventional natural gas, the device is characterized by comprising a first clamping mechanism, a second clamping mechanism and a differential pressure sensor, wherein pipelines at both ends of the first clamping mechanism and the second clamping mechanism are provided with first electromagnetic valves; pipelines at both ends of the differential pressure sensor are provided with manual valves; the differential pressure sensor 3 is connected in parallel with a second electromagnetic valve. The aim of designing anddeveloping the device is that the system can carry out a true triaxial experiment on shale carbonaceous, the system finds out a relationship of permeability of a coalbed methane reservoir in the developing process and an effective stress element and can reasonably determine a development mode of coalbed methane.

Owner:JIANGSU TUOCHUANG SCI INSTR CO LTD

Full-automatic online labeling machine and labeling method

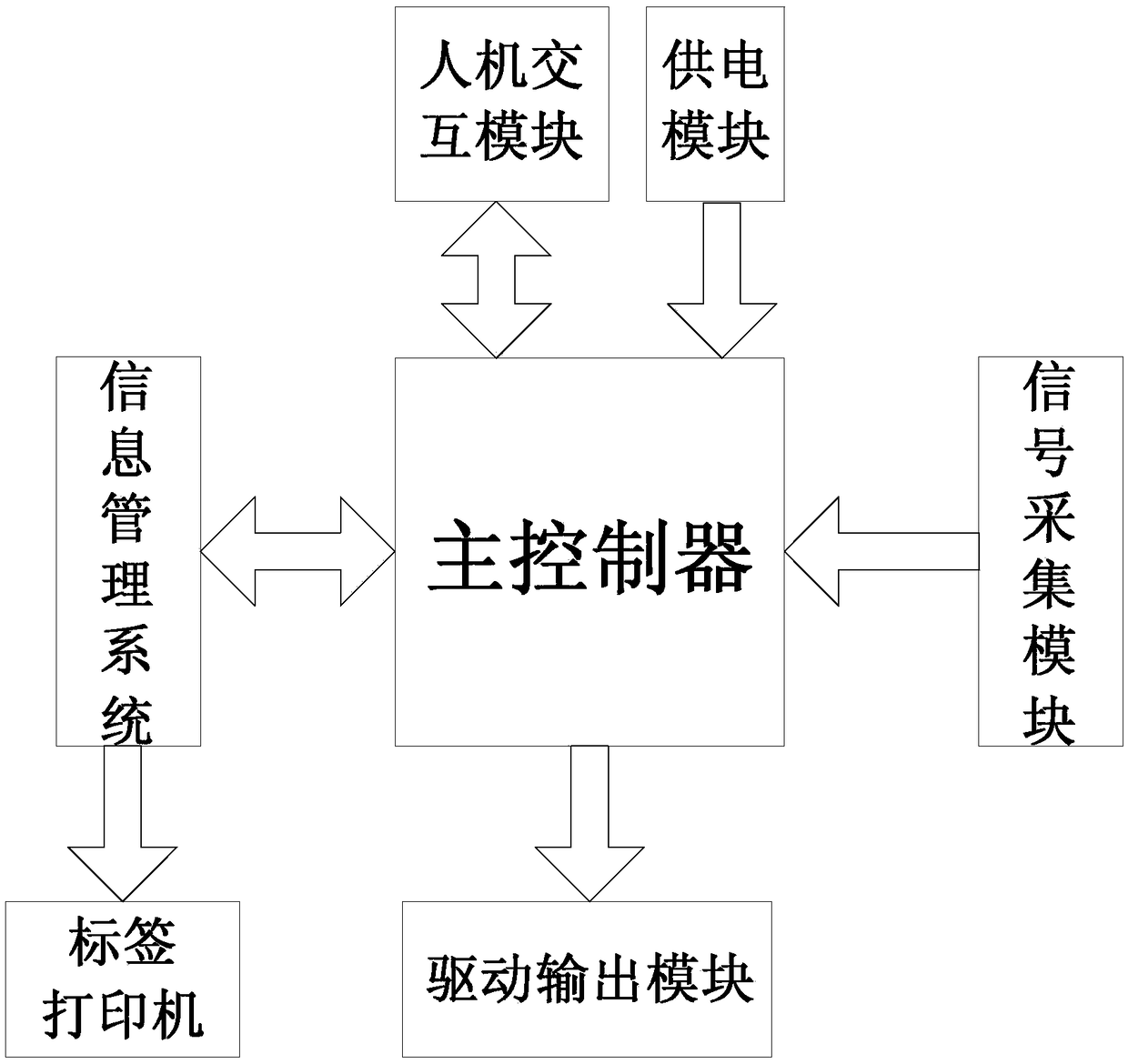

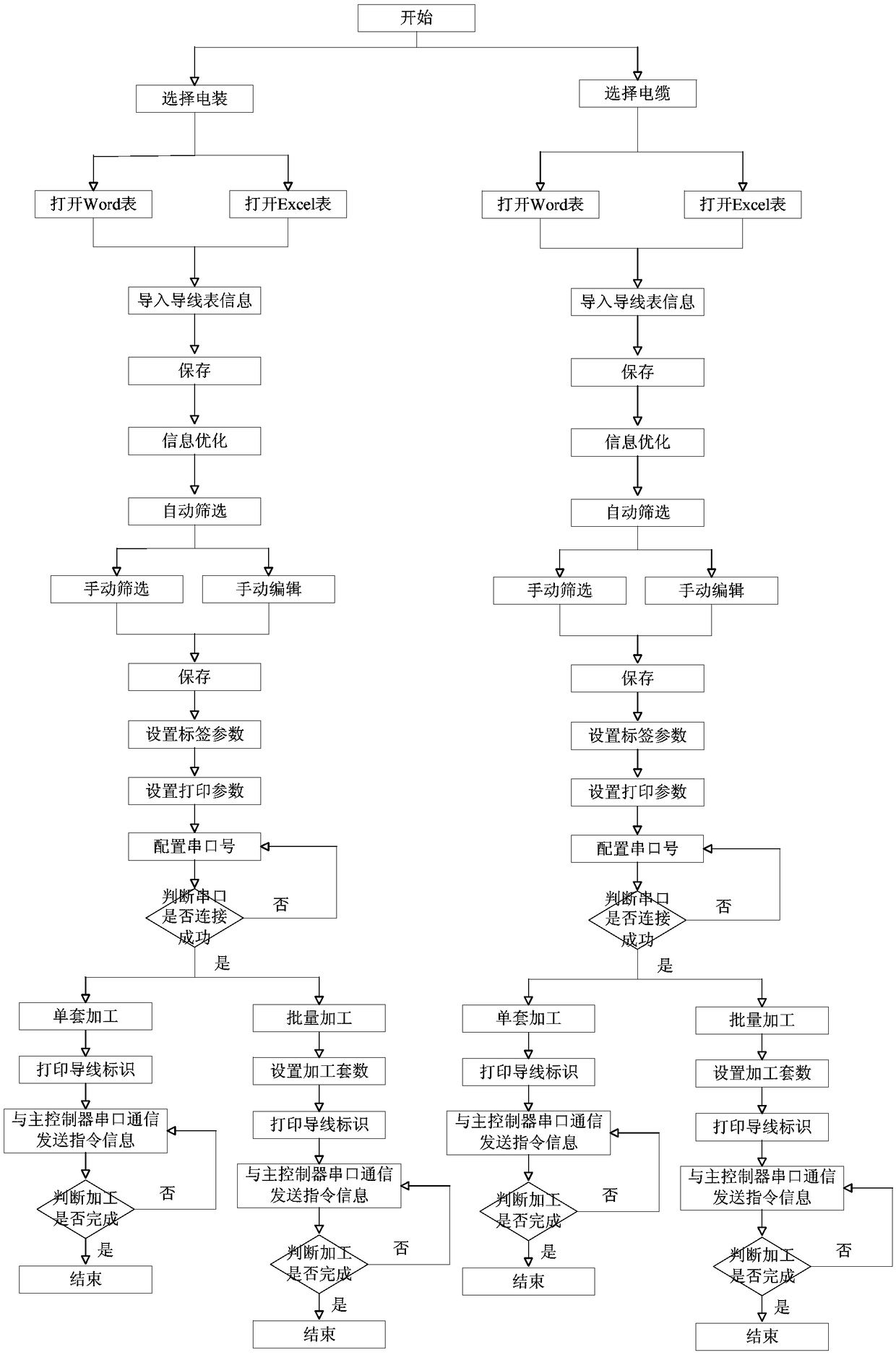

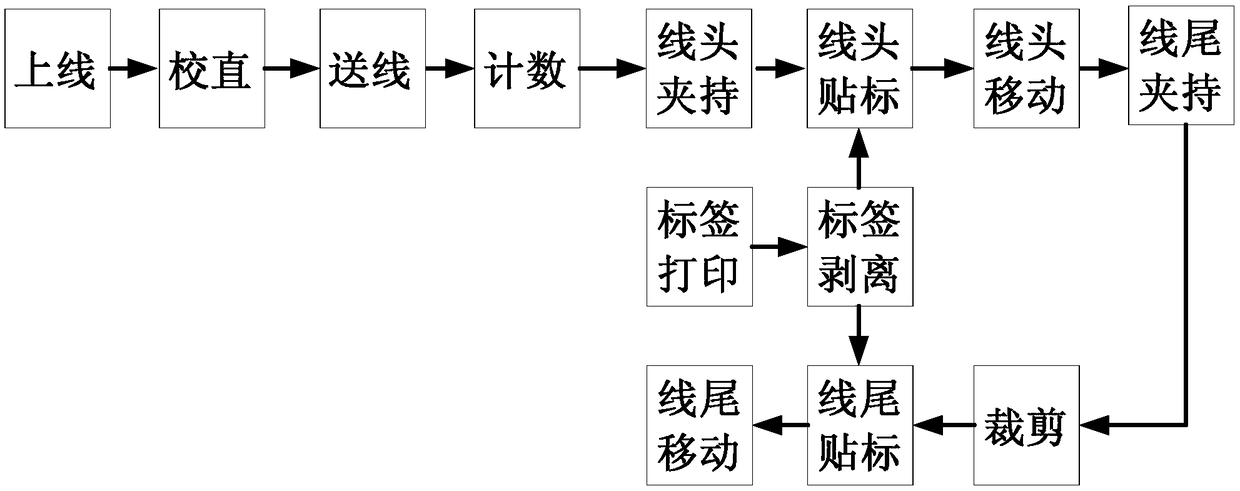

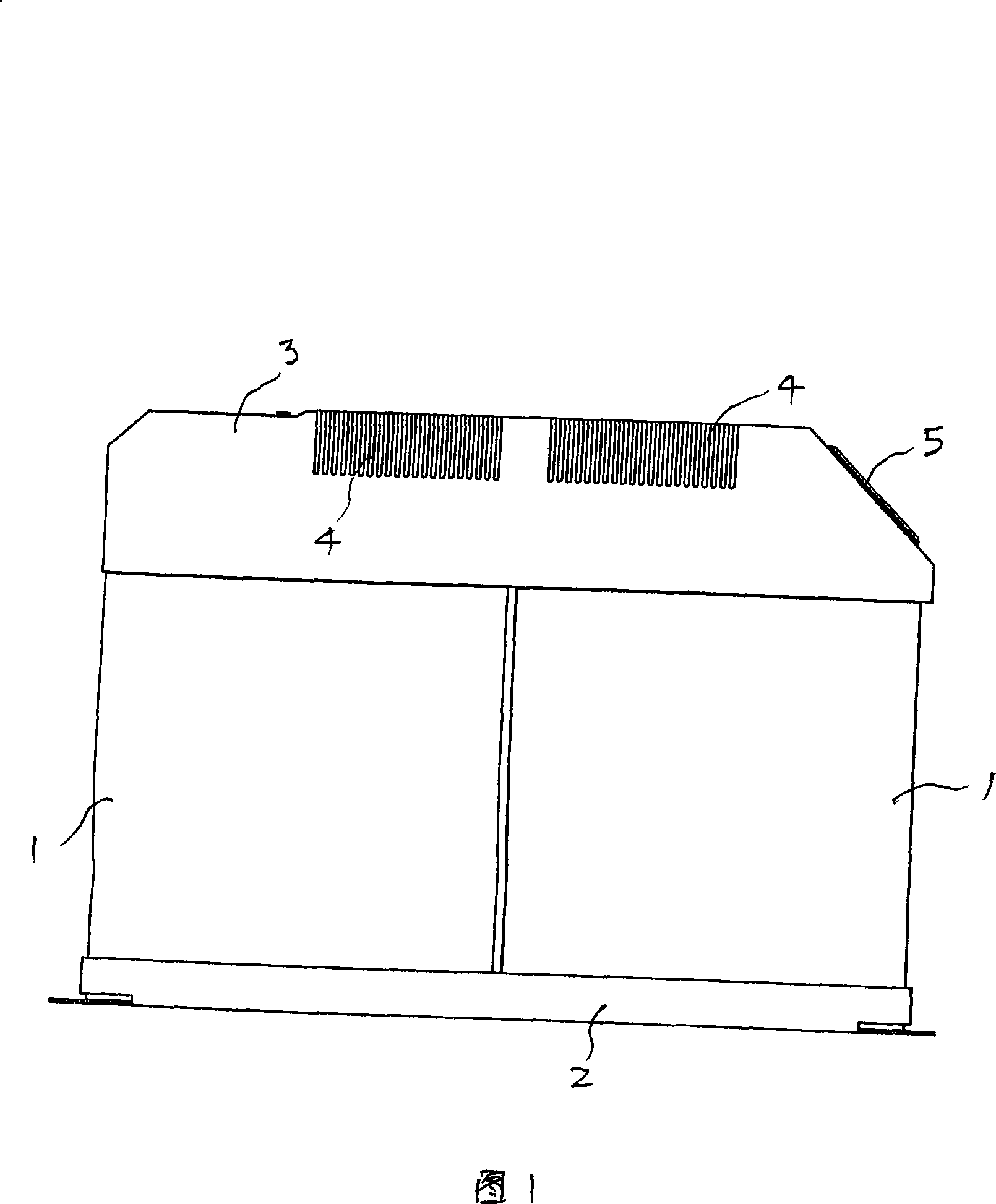

ActiveCN108820426AEasy to operateRealize semi-automatic processingLabelling machinesMaster controllerHuman–computer interaction

The invention provides a full-automatic online labeling machine and a labeling method. The labeling machine comprises a master controller, an information management system, a signal acquisition module, a driving output module, a man-machine interaction module, a power supply module and a label printing machine. Aiming at the disadvantages of like products at present, the full-automatic online labeling machine has the characteristics of high automation degree, wide application range, high efficiency, small volume, capability of setting parameters and the like, and can realize printing, labelingand online integrated function; electric fitting and cable type lead wire tables are imported and two forms of lead wire tables including Word and Excel are edited, screened and saved; the equipmenthas high reliability and has the functions of information prompting and abnormal alarming; a machining process of automatic equipment is simplified and the production efficiency is improved; the equipment is convenient to transport, simple and convenient to operate and convenient to maintain; if a user selects to machine in batches, the number of batch machining sets can be set, and the flexibility and convenience of utilizing the equipment are increased.

Owner:BEIJING AEROSPACE GUANGHUA ELECTRONIC TECH CO LTD

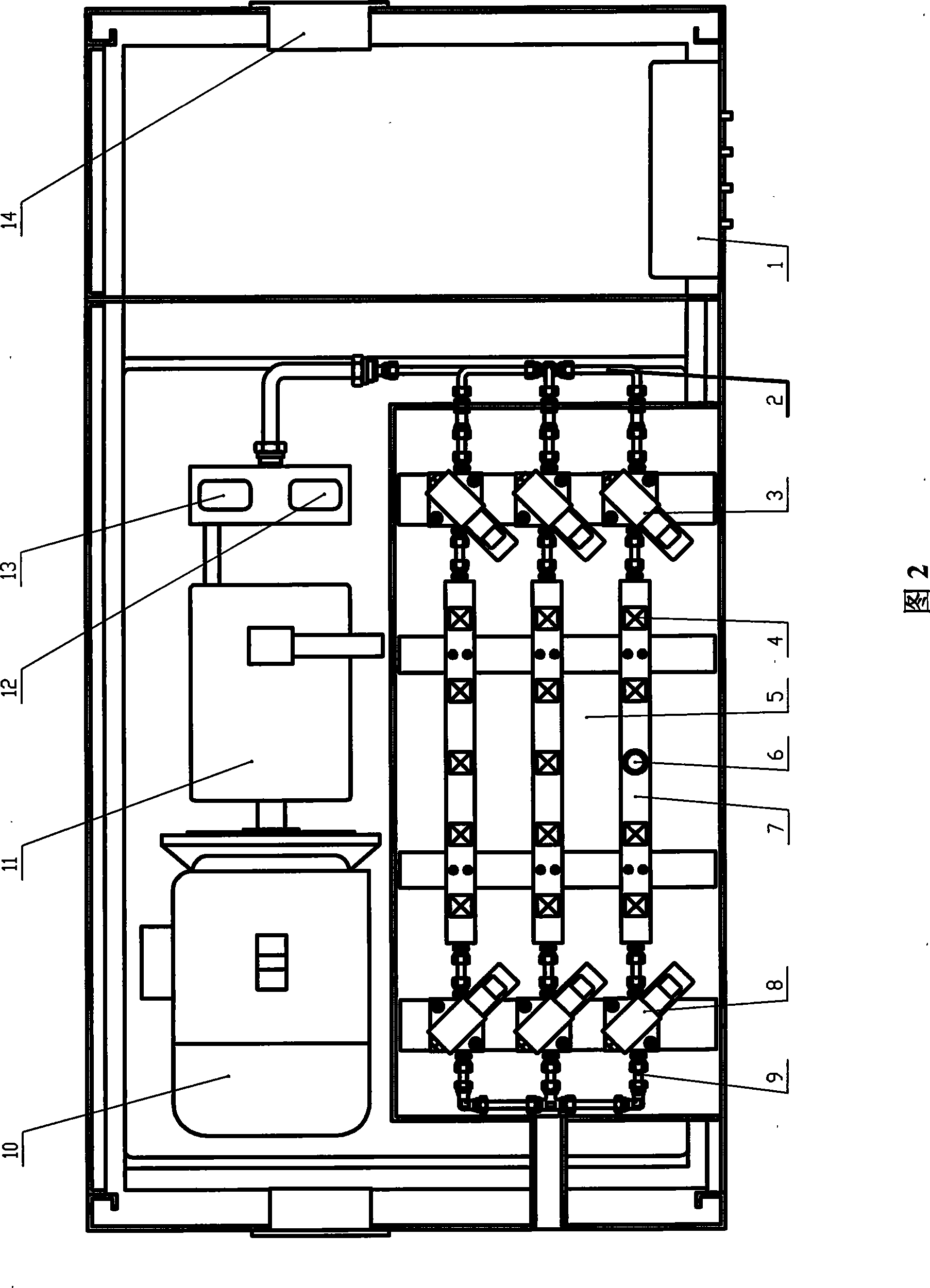

Integrated intelligent powerless compensation device

InactiveCN101145694AWork reliablyEasy to useReactive power adjustment/elimination/compensationReactive power compensationManufacturing cost reductionCompensation effect

The invention discloses an integrated intelligent reactive compensation device, which is characterized in that the device has a supporting board, two power capacitor groups are arranged on the supporting board, a circuit breaker is arranged on the top cover of the capacitor bank, a wiring upright post is correspondingly connected with a switch device on a circuit board, and the capacitor bank is also provided with an upper cover, and an element and a circuit interface are provided on the upper cover. The device comprises no capacitor and current transformer, so as to reduce manufacturing cost under the prerequisite of assuring the detection accuracy. The invention has the advantages of real-time detection and control, complete and intuitive displayed items, wide capacity transformation ratio and accurate compensation, complete protection and warning functions, high degree of intellectualization, good compensation effect, small volume, modularized and compact structure, convenience for power grid and user capacity-increasing reconstruction, zero-cross switching, high reliability, and remarkably improved service life of product. Multiple compensation devices can be combined for operation to meet the requirement of large arranged capacity. A plurality of compensation device can be on-line operated, therefore, meeting the demands of large installed capacity.

Owner:田锡公

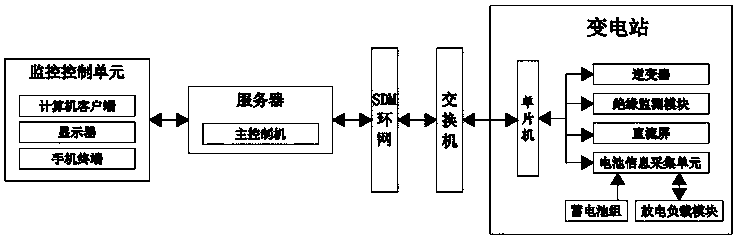

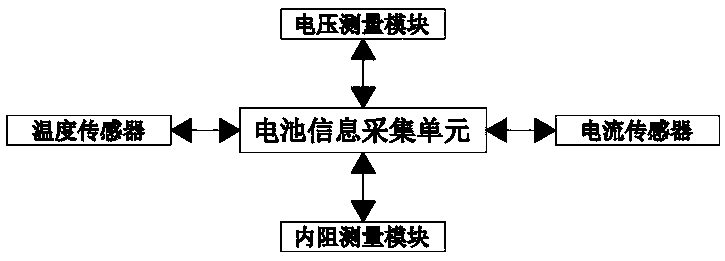

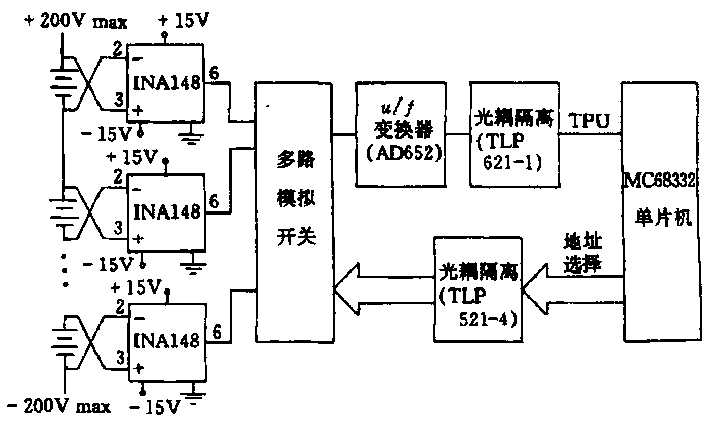

Online monitoring system for running state of transformer substation DC system

InactiveCN111007419ADetect health hazards in timePerfect alarm functionElectrical testingInternal resistanceTransformer

The invention discloses an online monitoring system for the running state of a transformer substation DC system, and relates to the technical field of substations. The system comprises a transformer substation, a switch, an SDM ring network, a server and a monitoring control unit. The transformer substation is electrically connected with the bidirectional input end of the switch through a local area network. The bidirectional output end of the switch is electrically connected with the bidirectional input end of the server through the SDM ring network. The voltage, the current and the environment temperature of a storage battery pack are monitored in real time according to the state of the storage battery pack; the voltage and the internal resistance of each single storage battery are monitored; cross comprehensive analysis is carried out on the voltage, internal resistance data and variation trend of a single storage battery in combination with a charge-discharge curve; health hidden troubles of the storage battery pack can be timely discovered and alarm prompt information can be given so that timely maintenance is facilitated, remote realization and real-time control can be realized, equipment of the transformer station DC system is enabled to be in a great working state, and objectives of safe production and working efficiency improvement can be achieved.

Owner:STATE GRID CORP OF CHINA +1

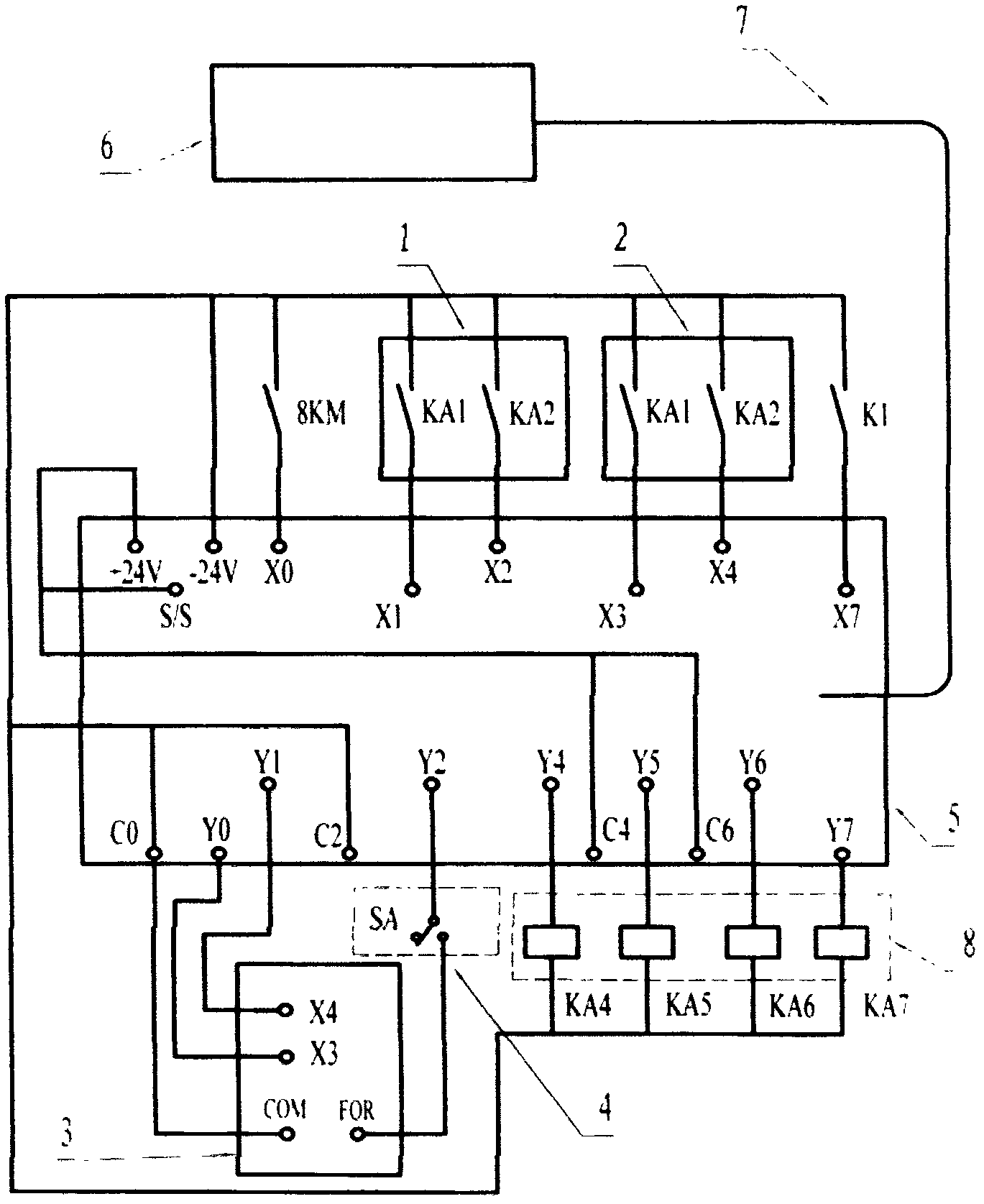

Automatic feeding controller of milling system

InactiveCN102580840AControl speedControl the feeding amountGrain treatmentsText displayControl system

The invention which relates to an automatic feeding controller of a milling system provides an automatic feeding controller based on the programming control of PLC (programmable controller). A technical scheme of the invention is that the automatic feeding controller of the milling system comprises the PLC, a text display, a communication cable, a host intelligent ammeter, a fan intelligent ammeter, a feeding spiral frequency converter, an expanded relay, an alarm and a frequency converter manual control switch. The controller which can accurately control the feeding amount of the whole milling production system, automatically cope with and process various abnormal states of the whole milling production system, effectively reduce waste and defective products and improve the production efficiency is suitable for milling automation control systems of powder processing enterprises.

Owner:广西贺州市科隆粉体有限公司

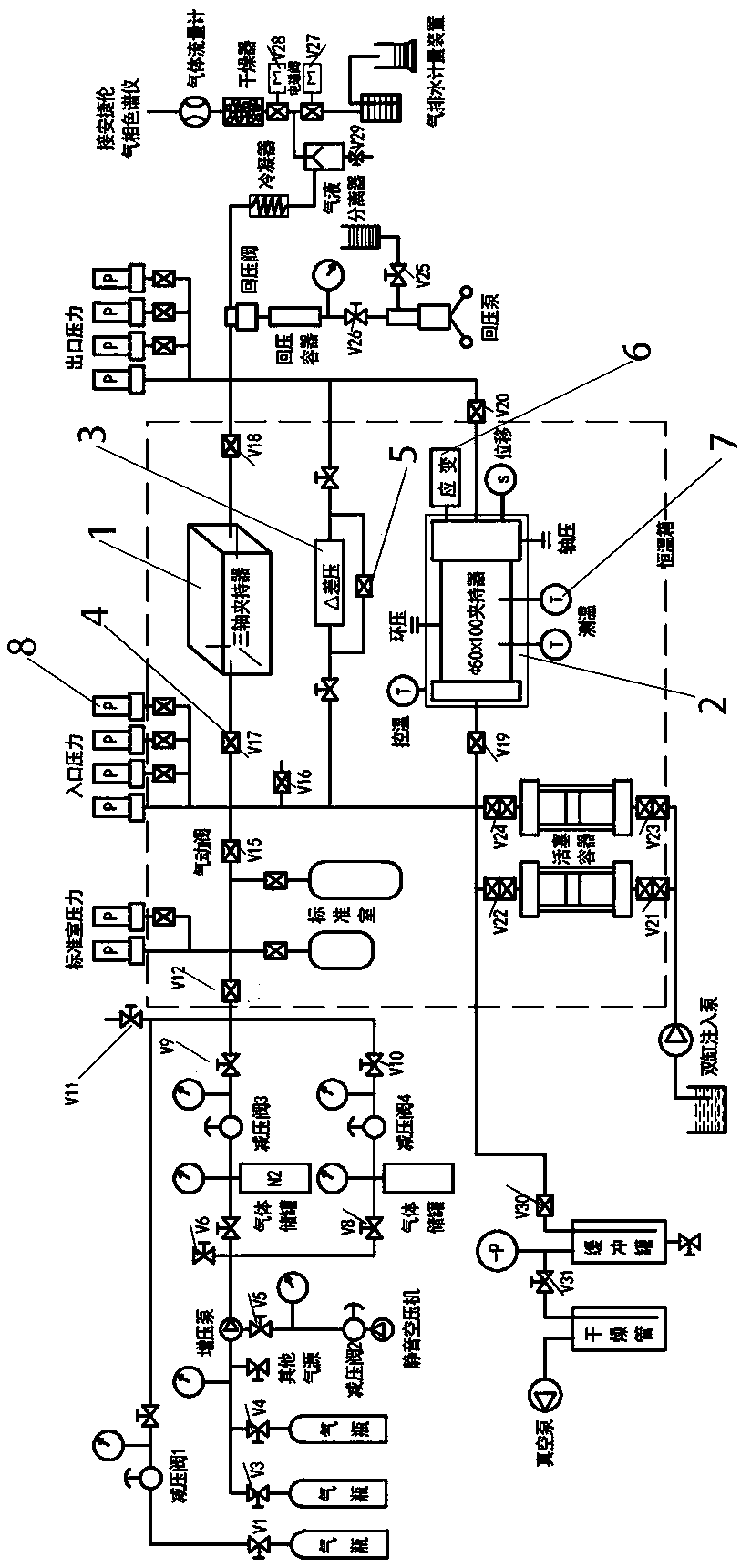

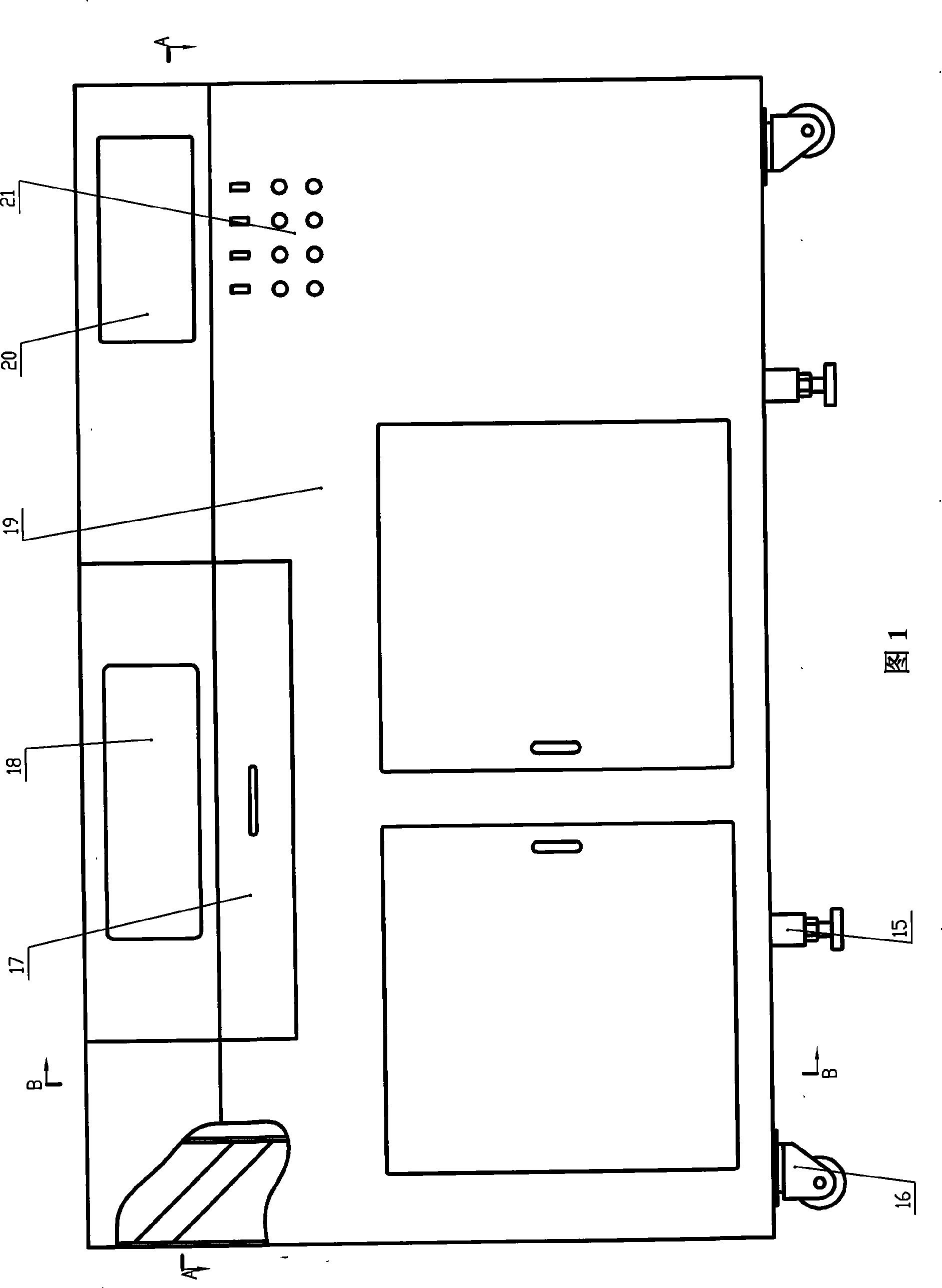

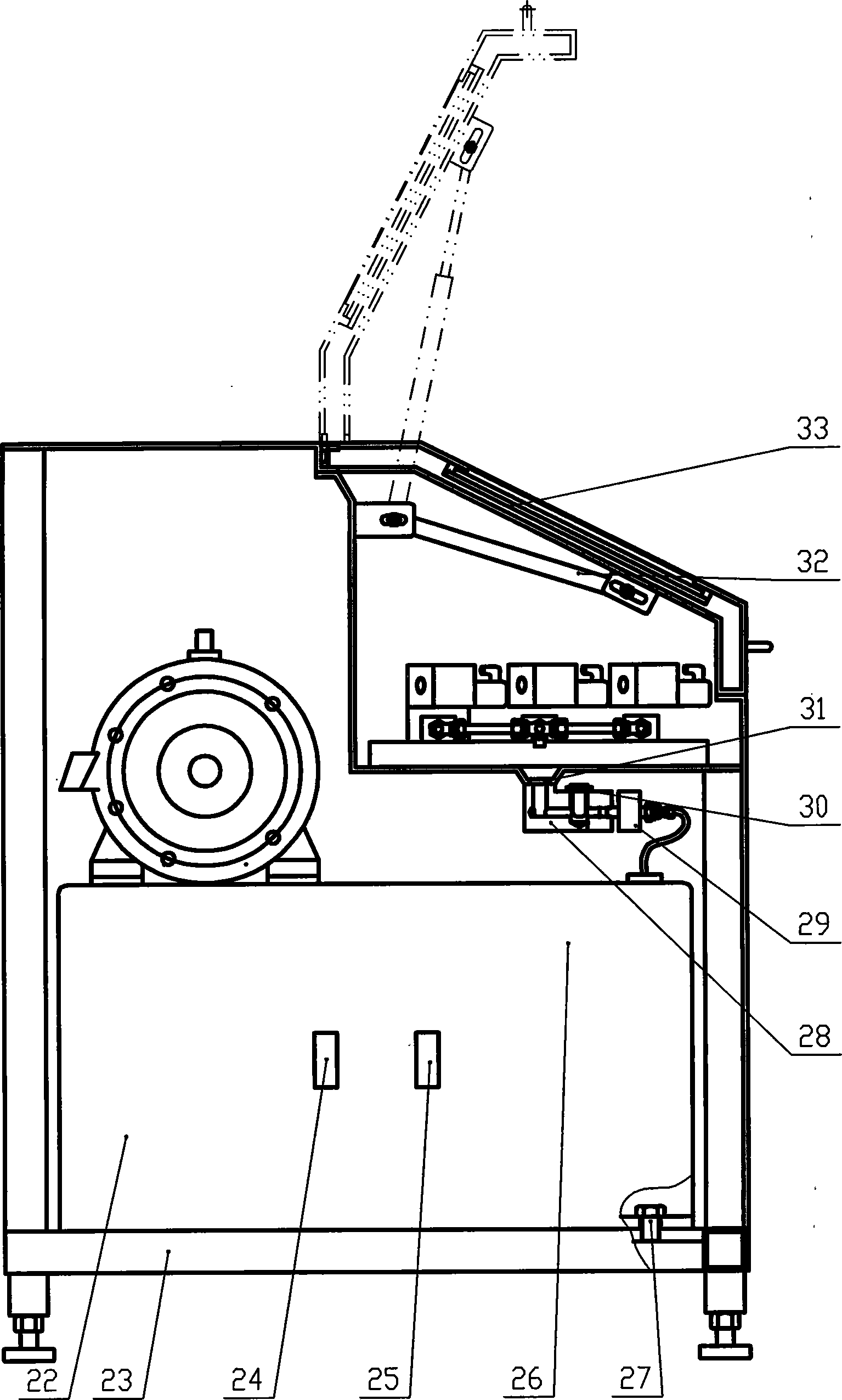

High-efficiency high-pressure sensor test machine

A high-efficiency high-pressure sensor testing machine comprises a bottom plate provided with a truckle, which has the technical point that: a cabinet and a pressure generating system is connected on the bottom plate, wherein the system comprises an oil tank fixedly arranged on the bottom plate, a motor and a variable pump are sequentially arranged on the upper part of the oil tank, the pressure outlet of the system is connected with a pipeline through an electromagnetic pressure regulator and a servo overflow valve, after being paralleled to be three-way, the pipeline is led to a testing area which is kept closed; an installation clamp is arranged in the testing area through conversion connection of a nested connector, each installation clamp is provided with two to eight installation positions, each of which is provided with a standard pressure sensor and a plurality of tested pressure sensor; a pressurized valve is serially connected to a pressure inlet end of the installation clamp, a cutoff valve is serially connected to a pressure outlet end of the installation clamp, and three-way pressure pipelines are paralleled to one way after the cutoff valve, and connected to a leakage discharge outlet at the lower part of the testing area; a panel computer and an electrical operation area are embedded into the upper part of the cabinet.

Owner:SHENYANG ACAD OF INSTR SCI

Five-cavity full-automatic electron beam deposition system

InactiveCN104630718AReduce pumping timeIncrease productionVacuum evaporation coatingSputtering coatingEngineeringMechanical engineering

The invention relates to the technical field of preparing various thin films on glass, plastic and ceramic matrixes and particularly relates to a five-cavity full-automatic electron beam deposition system. The system comprises a suction system and five cavities which comprise a transmission cavity I, a loading cavity I, a process cavity, a loading cavity II and a transmission cavity II sequentially communicated, wherein the cavities are connected with the suction system; vacuum locking systems are arranged between the loading cavity I and the process cavity and between the loading cavity II and the process cavity; sample carrying plates are arranged in the loading cavity I, the process cavity and the loading cavity II. According to the system provided by the invention, the suction time after exchanging the sample carrying plate every time in the process cavity is shortened while the output is high, so that the process flow of the process cavity and pick-and-place of the sample carrying plate in the loading cavities I and II are carried out at the same time. Moreover, other parts except a process cavity door and doors of the loading cavities I and II in the clean room can be placed in a common environment, so that the cost is relatively low.

Owner:SHENYANG SCI INSTR RES CENT CHINESE ACAD OF SCI

Full automatic electronic deposition system

InactiveCN104630719AReduce pumping timeSmall sizeVacuum evaporation coatingSputtering coatingVacuum pumpingAutomatic transmission

The invention belongs to the technical field of plating of various films on glass, plastic and ceramic substrates, and particularly relates to a full automatic electronic beam deposition system. The full automatic electronic beam deposition system comprises a technological cavity, a loading cavity, a transmission cavity, a vacuum pumping system and a full automatic transmission mechanism, wherein the technological cavity, the loading cavity and the transmission cavity are sequentially communicated; the technological cavity, the loading cavity and the transmission cavity are all connected with the vacuum pumping system, and the full automatic transmission mechanism automatically takes sample substrates out of and put in the technological cavity and the loading cavity. The full automatic electronic deposition system has a high yield, reduces the air pumping time of the technological cavity after a sample loading plate is changed each time. The full automatic electronic deposition system simultaneously carries out the technological process of the technological cavity and the process of taking the sample loading plate out of and putting in the loading cavity; and except for a technological cavity door and a loading cavity door arranged inside a clean room, the other parts can be put in common environments, so that the cost is lowered.

Owner:SHENYANG SCI INSTR RES CENT CHINESE ACAD OF SCI

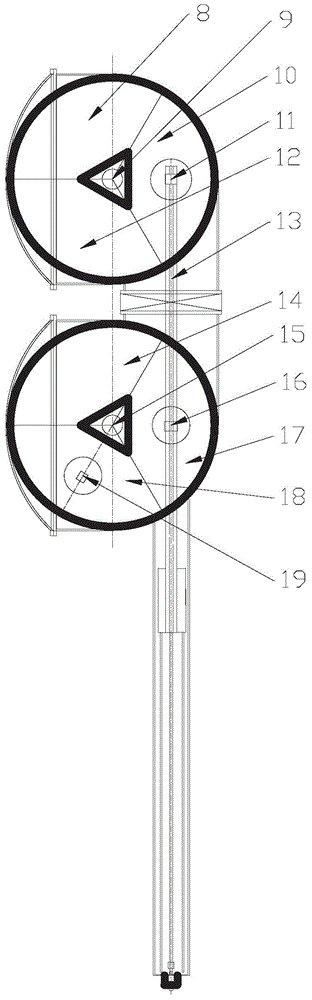

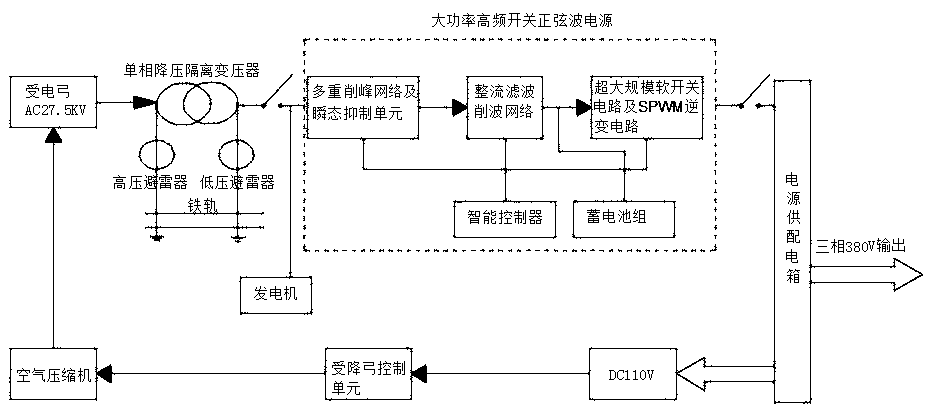

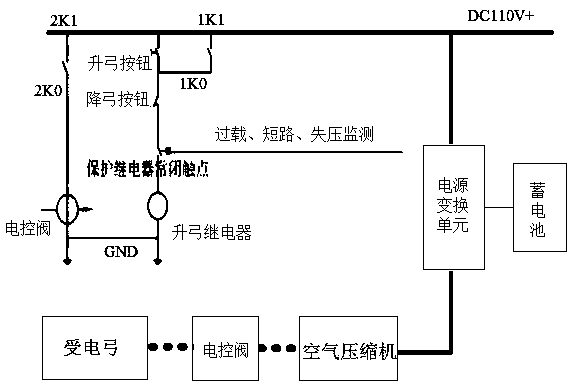

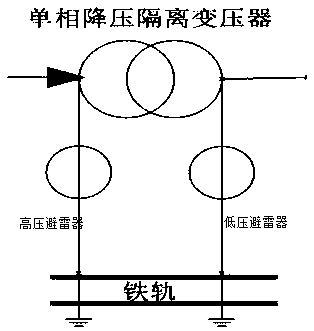

Comprehensive operation system for railway operation train set in alpine region

PendingCN110745008ARealize local oxygen supplyLow costSpeed controllerPropulsion using ac induction motorsContact networkHarmonics

The invention discloses a comprehensive operation system for a railway operation train set in an alpine region. The comprehensive operation system for the railway operation train set in the alpine region includes a power supply unit, the power supply unit includes a pantograph and a power control device, and the power control device includes a multiple peak clipping network and transient suppression unit, a rectification filtering clipping network, an ultra-large-scale soft-switching PWM pulse-width modulation circuit and an SPWM inverter circuit, single-phase AC850V is filtered by the multiple peak clipping network and transient suppression unit to remove high-frequency peaks and multiple harmonic sand then enters the rectification filtering clipping network to convert an alternating current power supply to a direct current power supply, and finally the direct current power supply is inverted to a three-phase AC380 / 220V alternating current power supply through the ultra-large-scale soft-switching PWM pulse-width modulation circuit and the SPWM inverter circuit. According to the comprehensive operation system for the railway operation train set in the alpine region, 27.5KV single-phase high voltage under a contact network is converted into a stable and high-quality three-phase four-wire AC380V, and a general-purpose diesel generator set currently used in mobile field operationtrain sets is replaced.

Owner:SICHUAN YOULIYUAN ELECTRIC TECH CO LTD

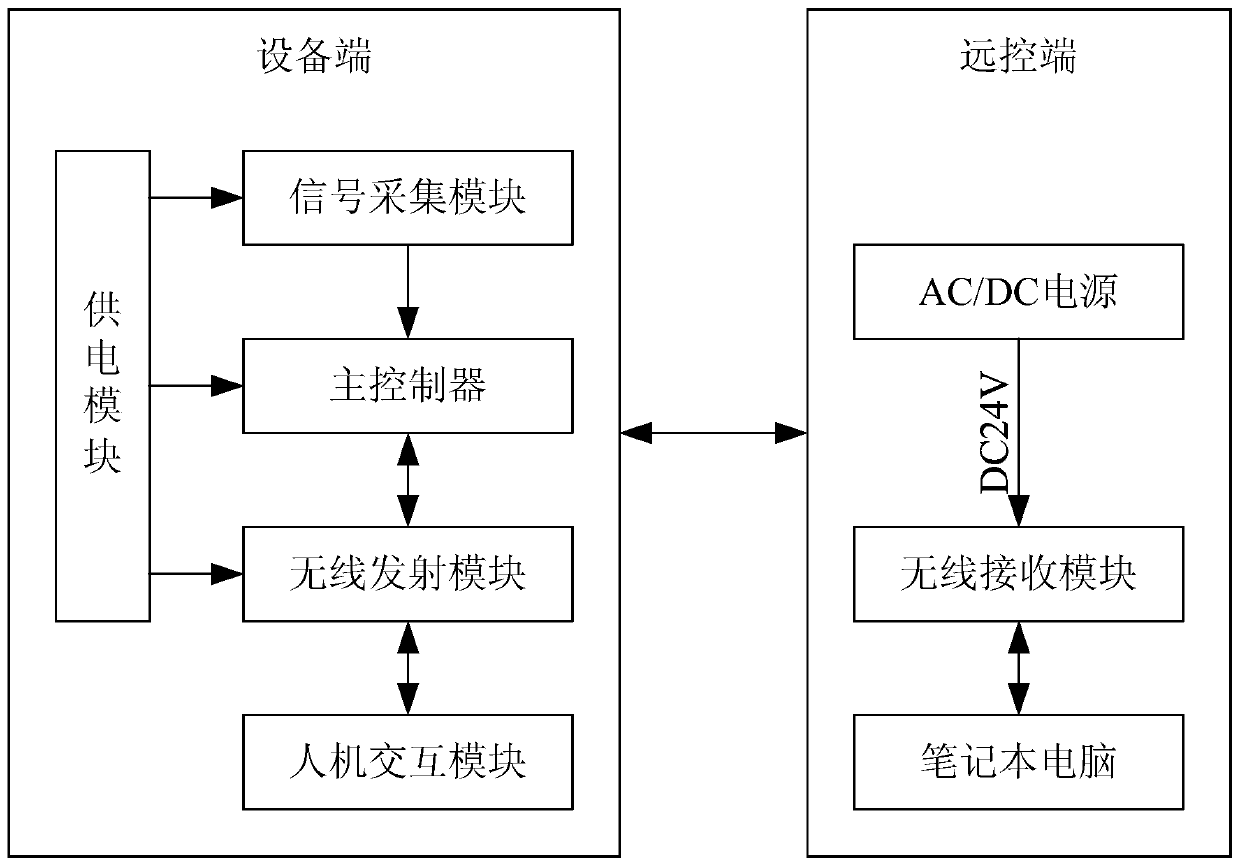

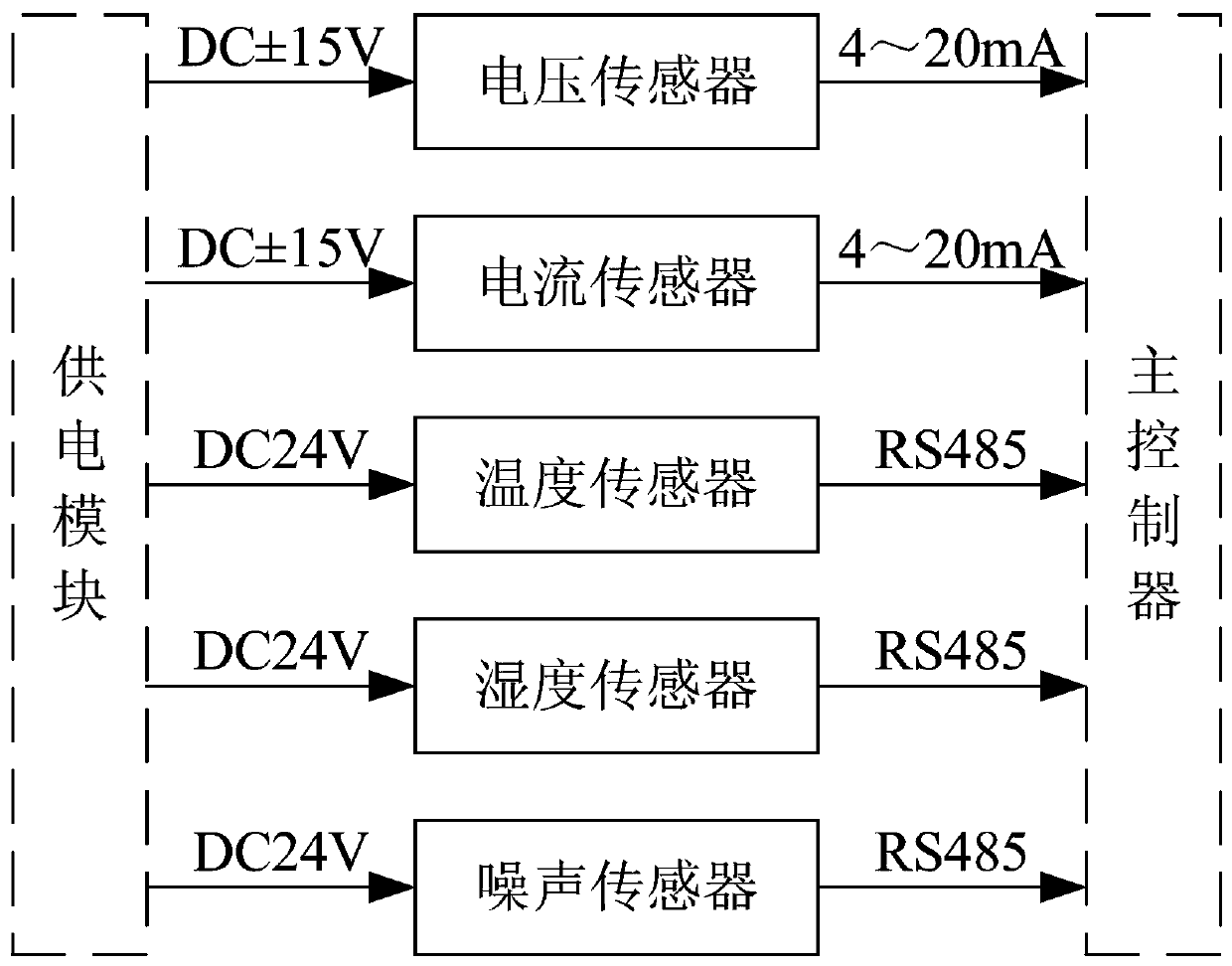

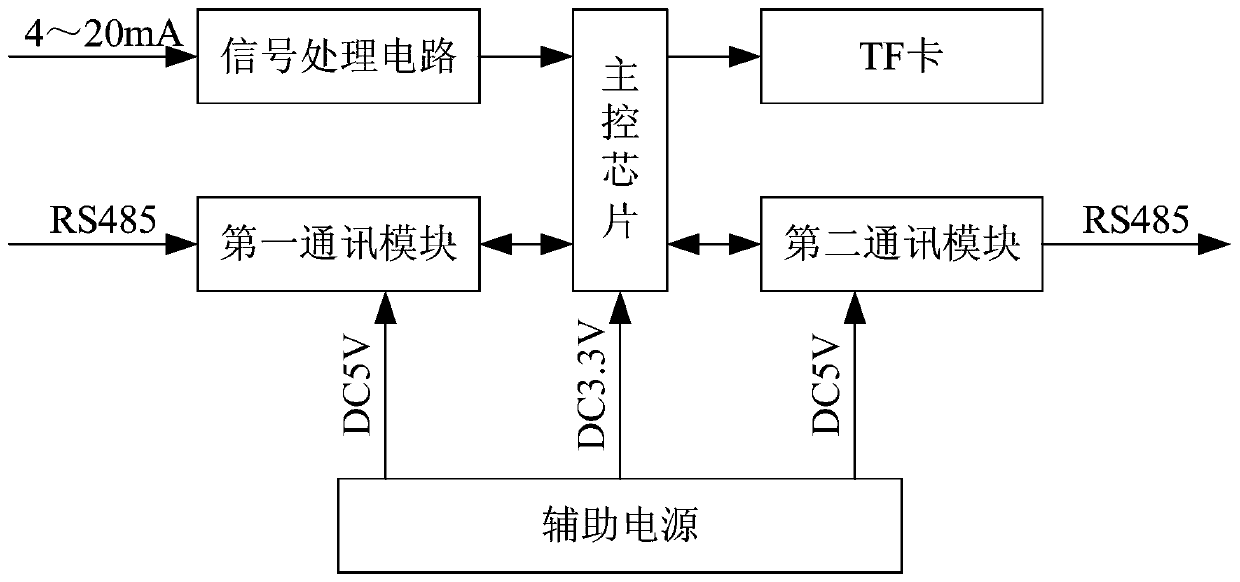

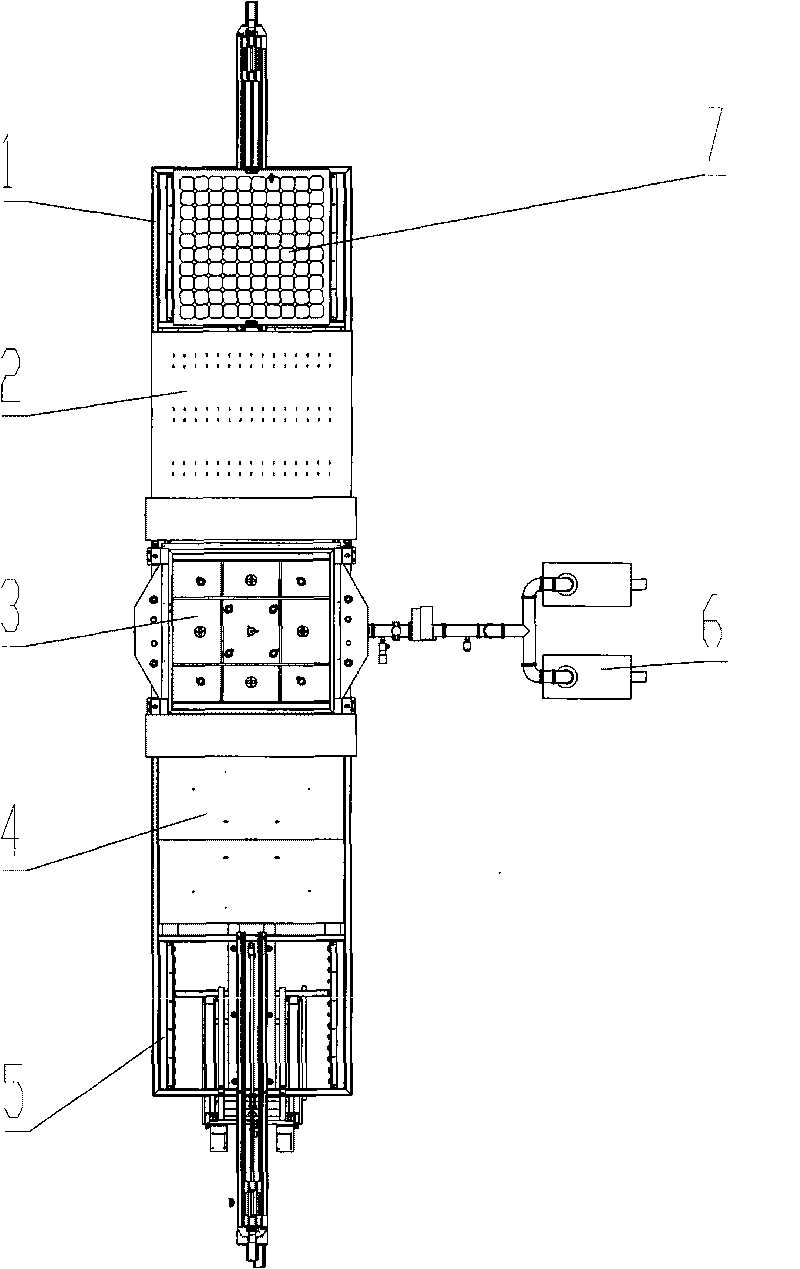

Fault current limiter monitoring equipment

ActiveCN110034550ARealize monitoringReal-time monitoring of working voltageProgramme controlMeasurement devicesNoise monitoringFault current limiter

The invention discloses fault current limiter monitoring equipment. The fault current limiter monitoring equipment comprises an equipment end and a remote control end, wherein the equipment end comprises a master controller, a signal acquisition module, a wireless emission module, a power supply module and a human-computer interaction module, and the remote control end comprises an AC / DC power module a wireless receiving module and a laptop computer. Aiming at the defect of current fault limiter monitoring equipment, the fault current limiter monitoring equipment has the characteristics of high automation, comprehensive information monitoring, high efficiency, wireless far-end monitoring and the like, voltage, current, temperature, humidity and noise monitoring and far-end data viewing ofa fault current limiter can be achieved, various warning signals are provided, on-line and real-time monitoring is achieved, the fault rate of the fault current limiter is reduced, and the running reliability of a power grid is provided.

Owner:BEIJING AEROSPACE GUANGHUA ELECTRONIC TECH CO LTD +1

Fully-automatic large-scale flat-plate type PECVD crystal silicon photovoltaic anti-reflection film preparation device

ActiveCN101748392ARealize automatic controlGood price performanceChemical vapor deposition coatingVacuum pumpingAtmospheric air

The invention relates to a film preparation device, in particular to a fully automatic large-scale flat-plate type PECVD crystal silicon photovoltaic anti-reflection film preparation device with a single chamber working under the vacuum, which solves the problems of longer single production time and low output existing in a PECVD device with a tubular structure in the prior art as well as the problems that a multi-chamber flat type PECVD device is required to work under the vacuum and the like. The preparation device is mainly provided with a loading platform, a preheating platform, a PECVD chamber, a cooling platform, an unloading platform and a vacuum pumping system, wherein the loading platform, the preheating platform, the PECVD chamber, the cooling platform and the unloading platform are arranged on a rack in sequence; the preheating platform and the cooling platform are respectively connected with a protective gas pipeline; and the PECVD chamber is connected with the vacuum pumping system through the pipeline. The invention only provides the vacuum environment for the PECVD chamber, and other parts work under the atmosphere or the protective gas. The invention can always achieve the technical indexes of the tubular PECVD and the multi-chamber flat type PECVD under the situation that the single chamber only works under the vacuum.

Owner:SHENYANG SCI INSTR RES CENT CHINESE ACAD OF SCI

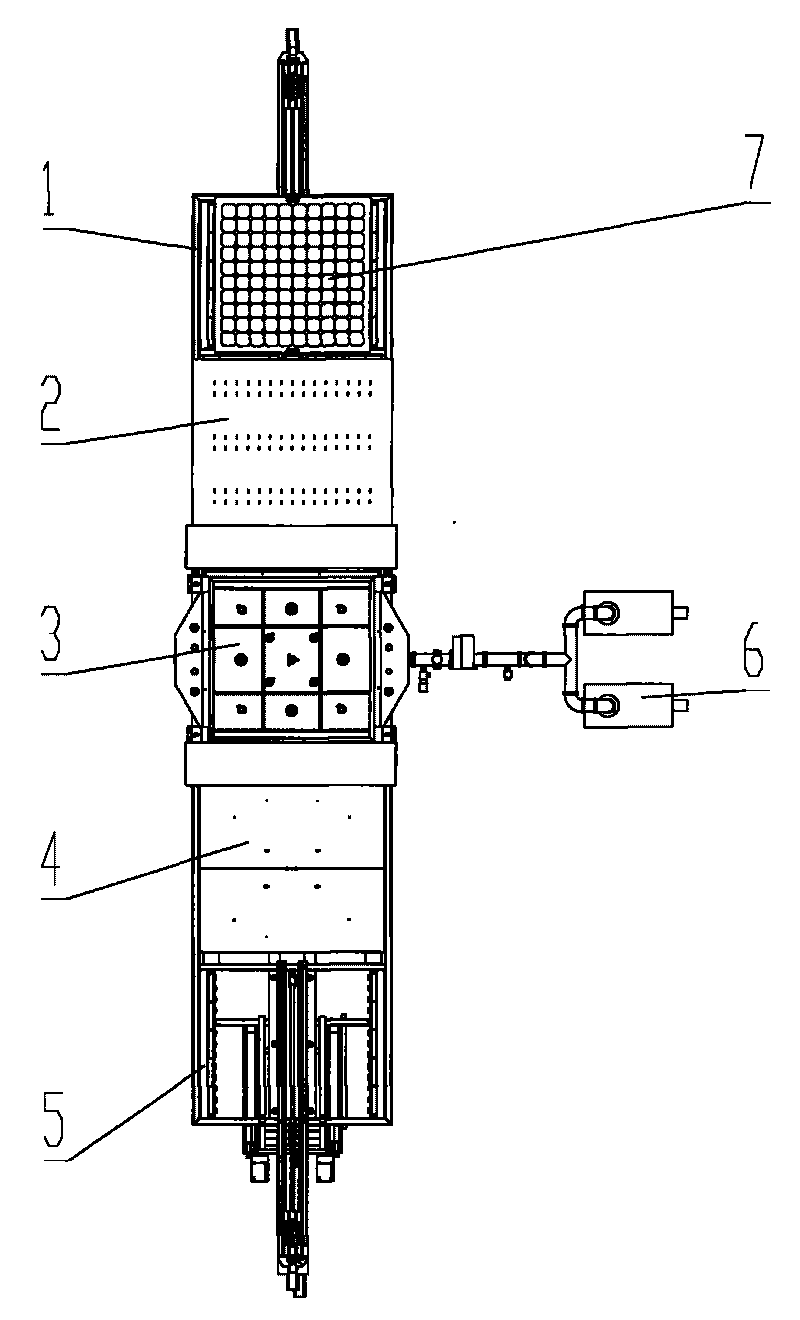

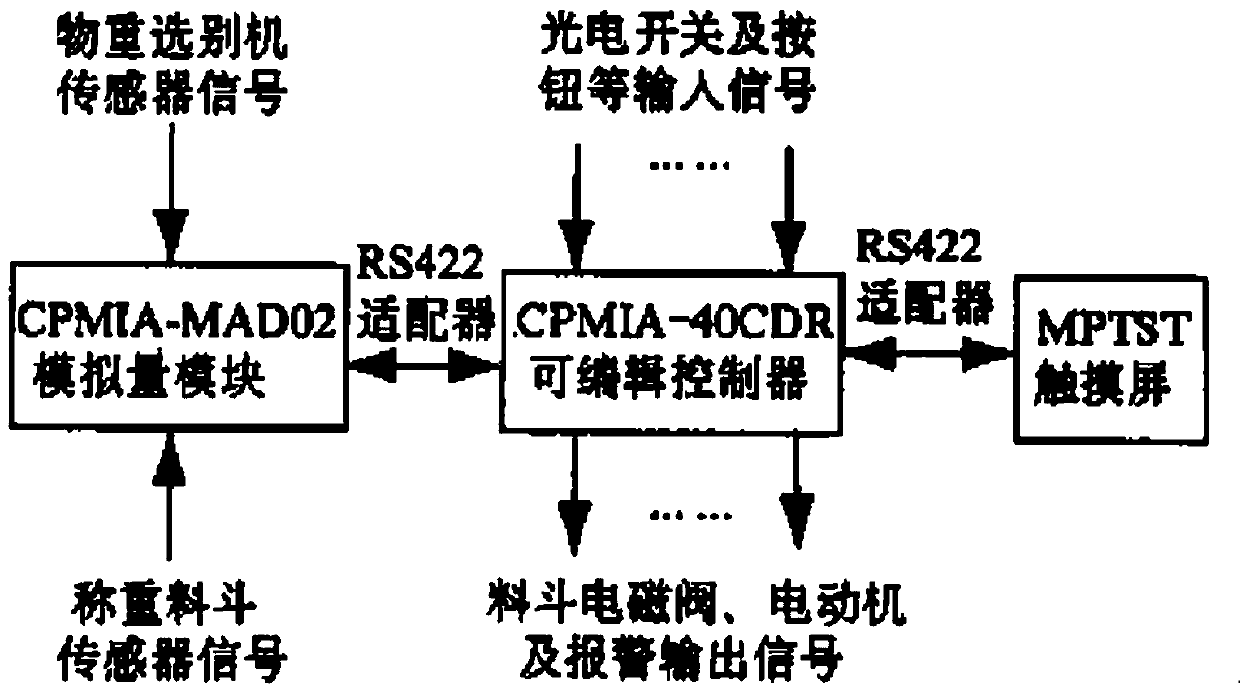

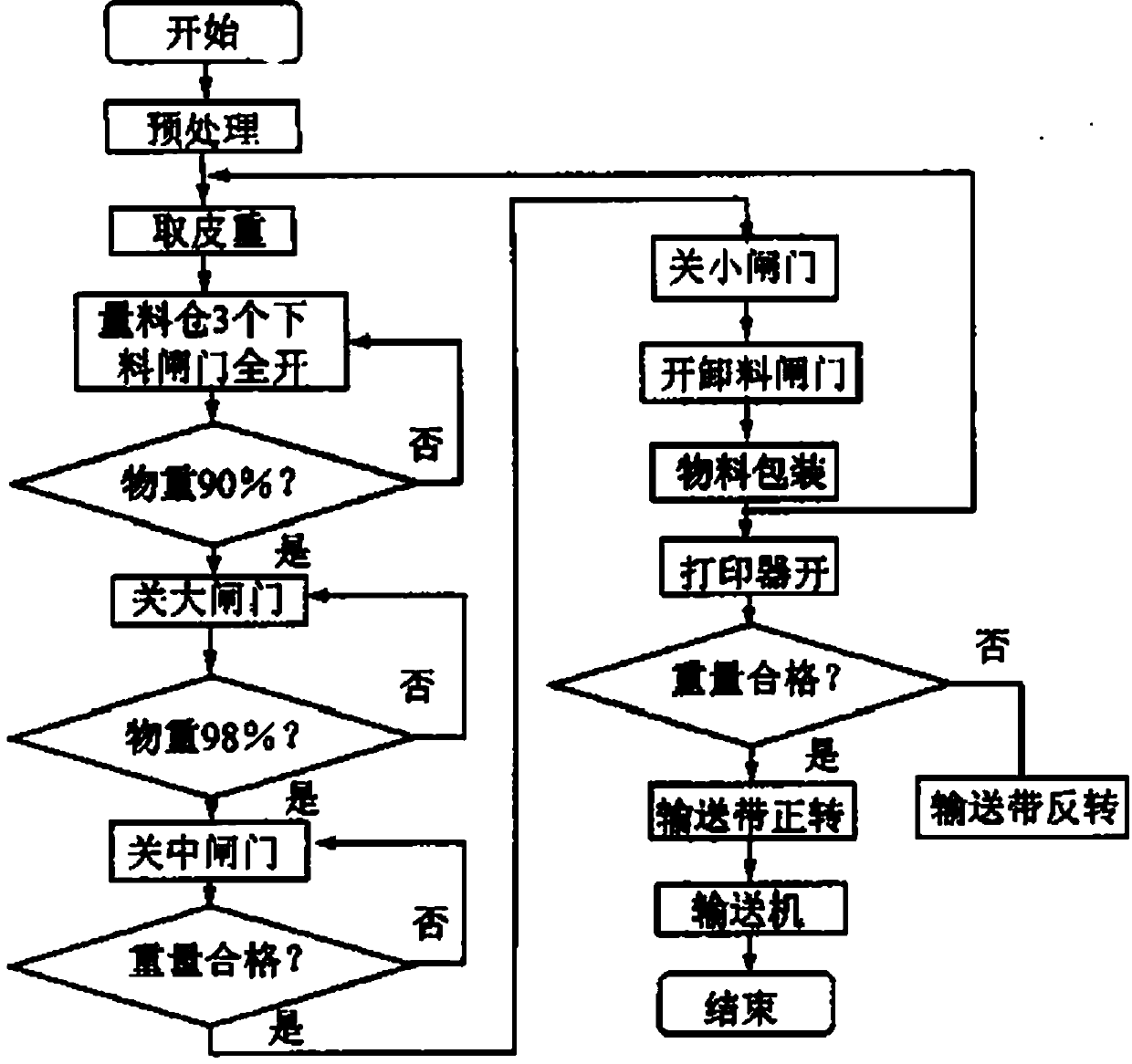

Automatic packaging production line control system

InactiveCN107776927ACompact structureComprehensive detection functionPackaging automatic controlSolid materialProduction lineHuman–machine interface

An automatic packaging production line control system, mainly composed of seven two-position five-way electromagnetic reversing valves, seven single-acting cylinders, one pressure reducing valve with a pressure gauge, an air filter and an air compressor. The control system uses PLC to coordinate the actions among the various equipment of the automatic line. The analog module and the man-machine interface detect and set the weighing weight to realize the automatic dynamic weighing and packaging of granules and powder materials. The actuator adopts pneumatic components. The entire automatic line has a compact structure, and the perfect fault detection and alarm functions improve the reliability and wide adaptability of the production line.

Owner:赵俭

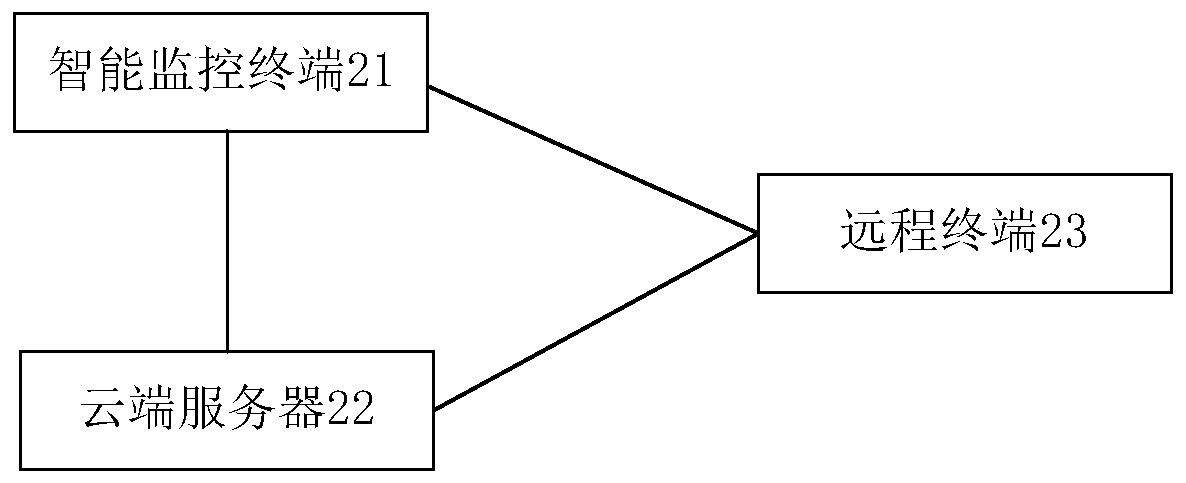

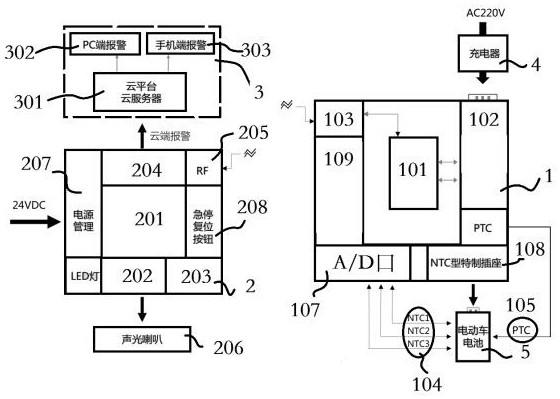

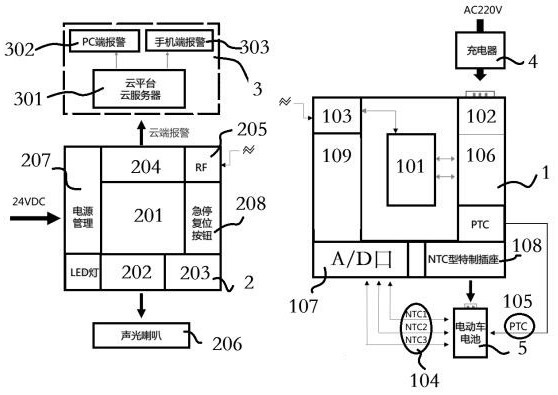

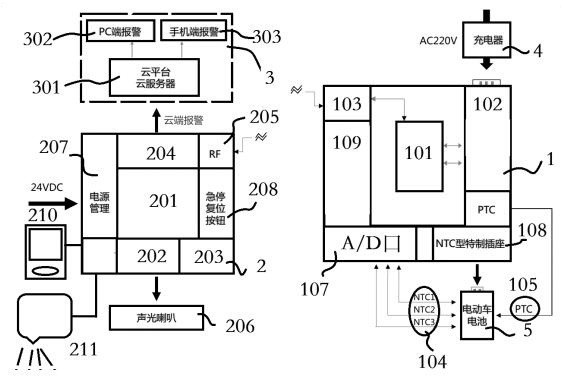

Electric vehicle fire alarm early warning system

PendingCN111775735AReduce volumeEasy to installCharging stationsParticular environment based servicesEarly warning systemCloud processing

The invention relates to a fire alarm early warning system, and particularly relates to an electric vehicle fire alarm early warning system. The system is characterized in that the system at least comprises an on-site detection unit fixed to an electric vehicle, a distributed processor and a cloud processing server, the on-site detection unit fixed to the electric vehicle and the distributed processor are in radio connection through an RF wireless module, and the distributed processor and the cloud processing server are electrically connected through a public communication network. The electric vehicle fire alarm early warning system provides an electric vehicle fire alarm early warning device small in size, convenient to install and complete in protection alarm function, so that the firealarm early warning position of the electric vehicle can be conveniently recognized, nearby personnel are reminded to pay attention to safety, personal safety is protected, and property loss is avoided.

Owner:深圳智慧动锂电子股份有限公司

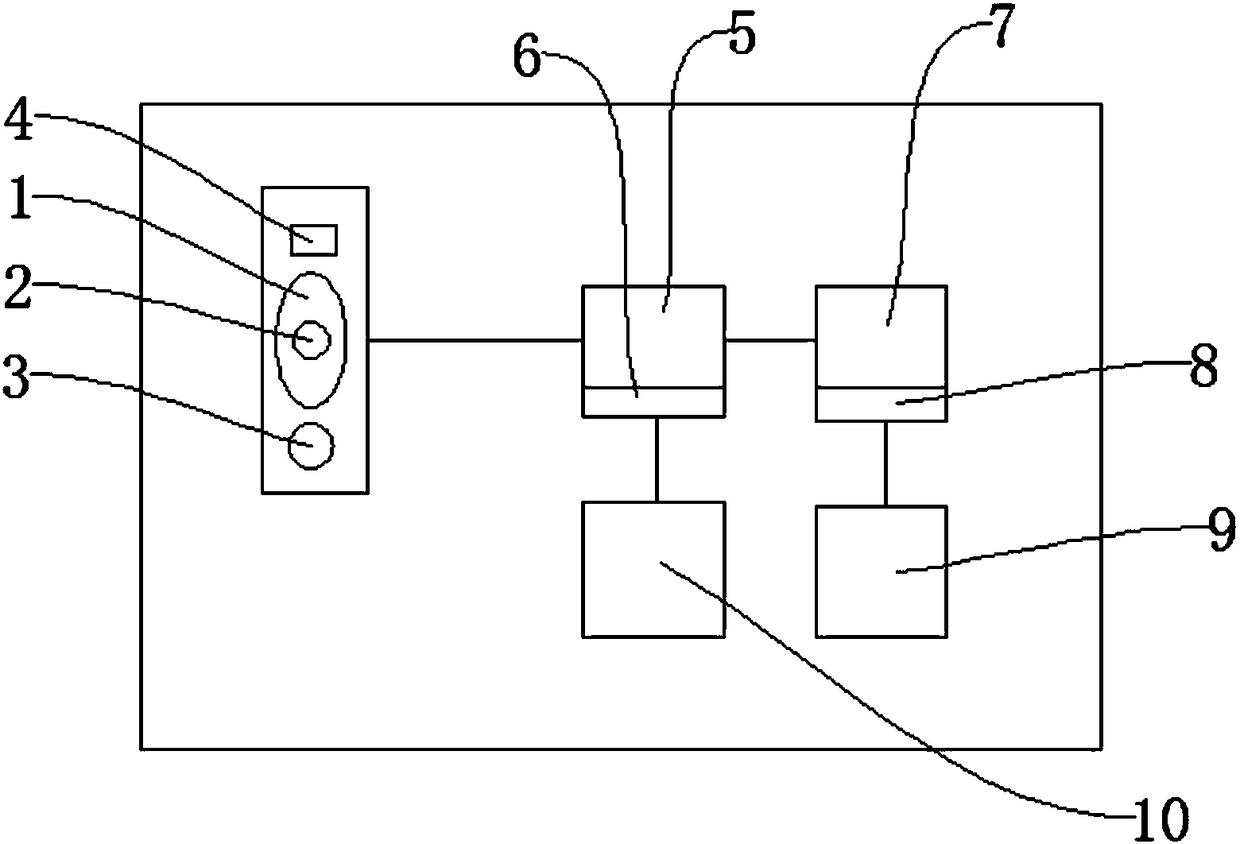

Intelligent alarm infrared monitoring camera device

InactiveCN108428327AIntelligent alarm functionIncrease profitClosed circuit television systemsAlarmsComputer modulePositioning system

The invention discloses an intelligent alarm infrared monitoring camera device which comprises a video collecting module, an infrared device, a communication module, an intelligent alarm module and anindoor monitoring module. The infrared device is installed above the video collecting module, an audio collecting module is installed below the video collecting module, a smoke alarm module is installed above the video collecting module, the communication module is installed at one side of a temporary storage module, and an alarm apparatus is installed below the communication module, a positioning system is installed at one side of the alarm apparatus, a touch display screen is installed inside the indoor monitoring module, a control module is installed at one side of the touch display screen, an intelligent alarm module is installed below the control module, and a manual alarm button is installed above the intelligent alarm module. The infrared audio and video function and the intelligent alarm function are integrated, the utilization rate of the device is increased, the alarm function is comprehensive and intelligent, and the alarm mode is more efficient.

Owner:WUHU CHAOYUANLI IND DESIGN CO LTD

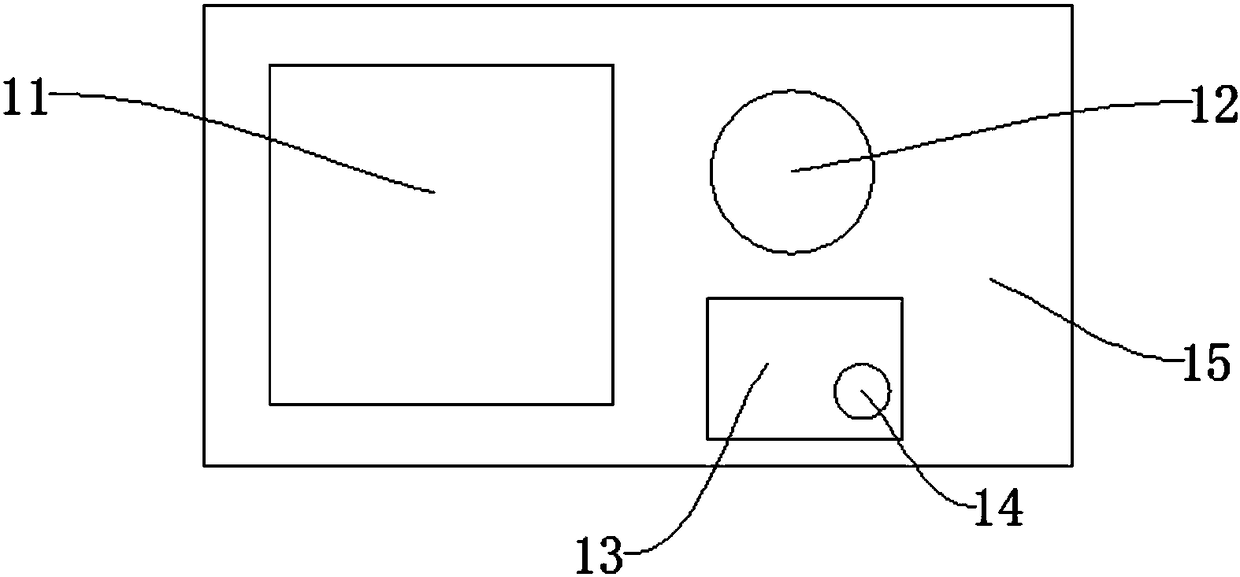

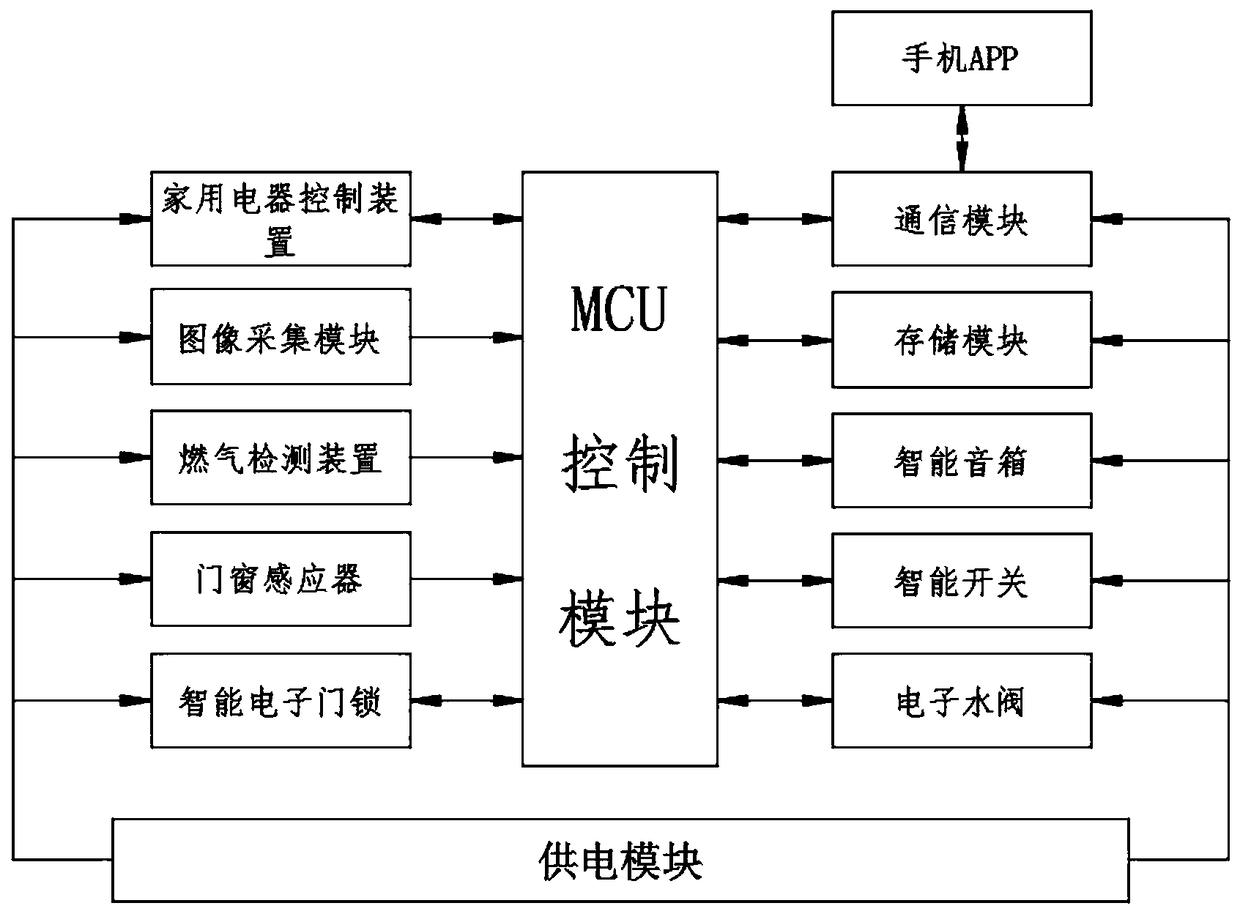

Smart human habitat device and system

InactiveCN109493563APerfect alarm functionHumanized alarm functionComputer controlAlarmsSmart switchEngineering

The invention discloses a smart human habitat system, and mainly relates to the field of smart home. The system is applied to convenient adjustment of family life and solves the problem of low intelligent degree of the smart home in the prior art. The system is characterized by comprising an MCU control module, a household appliance control device, an image acquisition module, a gas detection device, a door and window sensor, a smart electronic door lock, a communication module, a storage module, a smart loudspeaker, a smart switch, an electronic water valve and a power supply module; the household appliance control device, the image acquisition module, the gas detecting device, the door and window sensor, the smart electronic door lock, the smart loudspeaker, the smart switch and the electronic water valve are connected with the MCU control module through a family local area network. According to the system, the alarming function of the smart home is more complete through the double insurance of the door and window sensor and the image acquisition module, strangers and blacklist personnel are recognized through a portrait comparison function, and therefore the alarming function ofthe smart home is friendlier to human.

Owner:箱大大移动房屋(深圳)有限公司

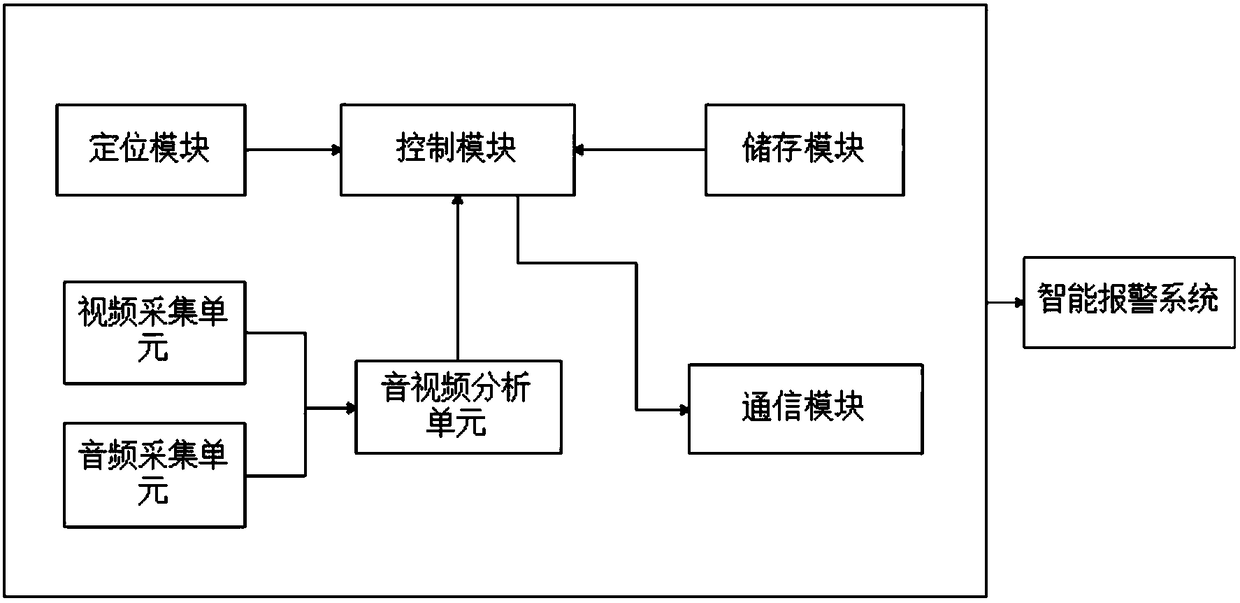

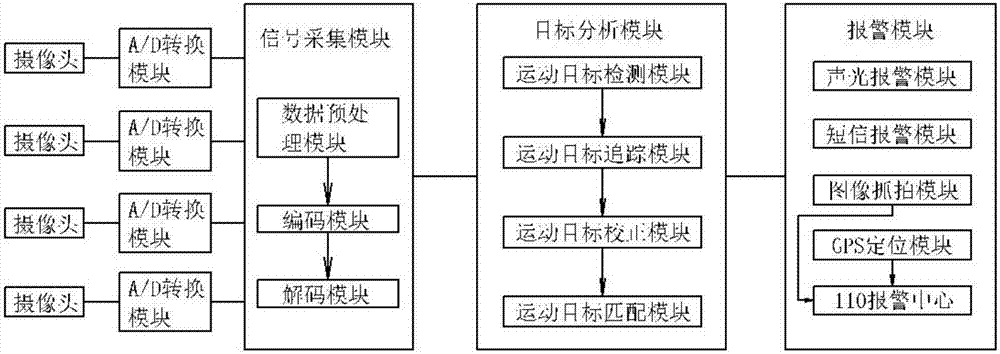

Intelligent monitoring system based on target tracking

InactiveCN107040763APerfect alarm functionImprove the effect of intelligent monitoringClosed circuit television systemsBurglar alarmCode moduleTarget analysis

An intelligent monitoring system based on target tracking comprises a plurality of cameras, each camera is connected with a signal collection unit through an A / D conversion module, the signal collection module comprises a data pre-processing module, and the data pre-processing module performs white balance regulation, noise elimination and elimination of other influences on video images of original data collected by the cameras and is suitable for channel transmission; the data pre-processing module is connected with a coding module, and the coding module is mainly configured to perform coding processing for video data; the coding module is connected with a decoding module, and the decoding module corresponds to the coding module; and the signal collection module is connected with a target analysis module. Compared to the prior art, the intelligent monitoring system based on the target tracking employs the target analysis module to realize target analysis such as detection, tracking, correction and matching so as to effectively improve the intelligent monitoring effect, and is provided with various alarm modules to allow the alarm functions of the monitoring system to be more perfect.

Owner:FUYANG NORMAL UNIVERSITY

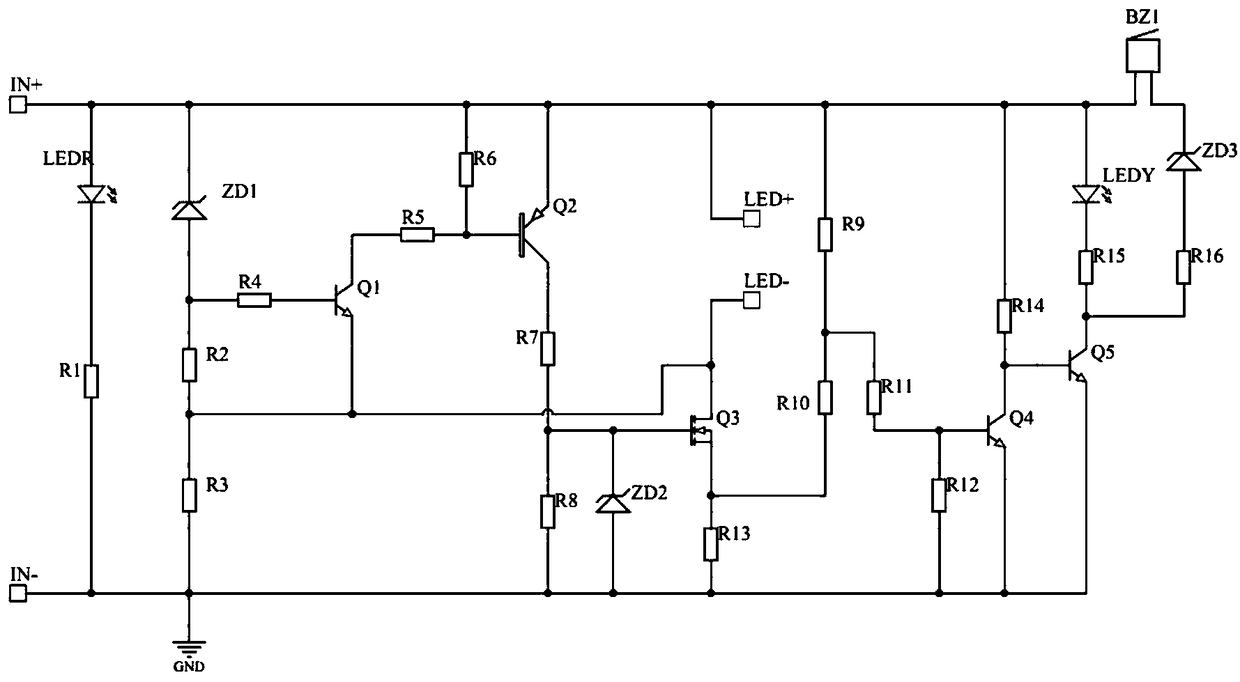

A light source abnormal alarm circuit for led lamps

ActiveCN106535422BIngenious designPerfect alarm functionElectrical apparatusElectroluminescent light sourcesEngineeringLight signal

The invention discloses a light source abnormal alarm circuit of an LED lamp, which is connected to a driving power supply of the LED lamp. The light source abnormal alarm circuit cuts off the light source circuit and outputs an indicator light signal when the light source is short-circuited or has a low conduction voltage drop. and buzzer alarm signal; when the light source current is lower than the preset value, output indicator light signal and buzzer alarm signal. The circuit of the invention is directly connected to the output end of the LED drive power supply, and outputs different processing results for different faults of the light source, thus having wide coverage and relatively perfect alarm function.

Owner:HANGZHOUSNGOOSE ELECTRICAL

Transmission system used in five-chamber automatic electron beam deposition system

ActiveCN104630737ASmall sizeReduce pumping timeVacuum evaporation coatingSputtering coatingAutomatic transmissionElectron beam deposition

The invention relates to the technical field of preparation of various films on glass, plastic and ceramic matrixes, and concretely relates to a transmission system used in a five-chamber automatic electron beam deposition system. The transmission system used in five-cavity automatic electron beam deposition system comprises an automatic transmission mechanism, an elevating cylinder, a sample support plate and a sample rack, the five chambers comprise a transmission chamber I, a loading chamber I, a technology chamber, a loading chamber II and a transmission chamber II which are connected in order, wherein an elevating cylinder, a sample support plate and a sample rack are arranged in the loading chamber I, the technology chamber and the loading chamber II, the sample rack is connected to a motor and is driven to rotate through the motor, the sample support plate is arranged on the sample rack, the elevating cylinder is capable of lifting or descending of the sample support plate, and the automatic transmission mechanism carries the sample support plate to move among chambers. According to the invention, the output is high, the air exhaust time in the technology chamber after the sample support plate is replaced can be saved, and process and pick-and-place of the sample support plate can be carried out simultaneously.

Owner:SHENYANG SCI INSTR RES CENT CHINESE ACAD OF SCI

Automatic large-scale flat-type pecvd crystalline silicon photovoltaic anti-reflection coating preparation equipment

ActiveCN101748392BRealize automatic controlGood price performanceChemical vapor deposition coatingShielding gasEngineering

Owner:SHENYANG SCI INSTR RES CENT CHINESE ACAD OF SCI

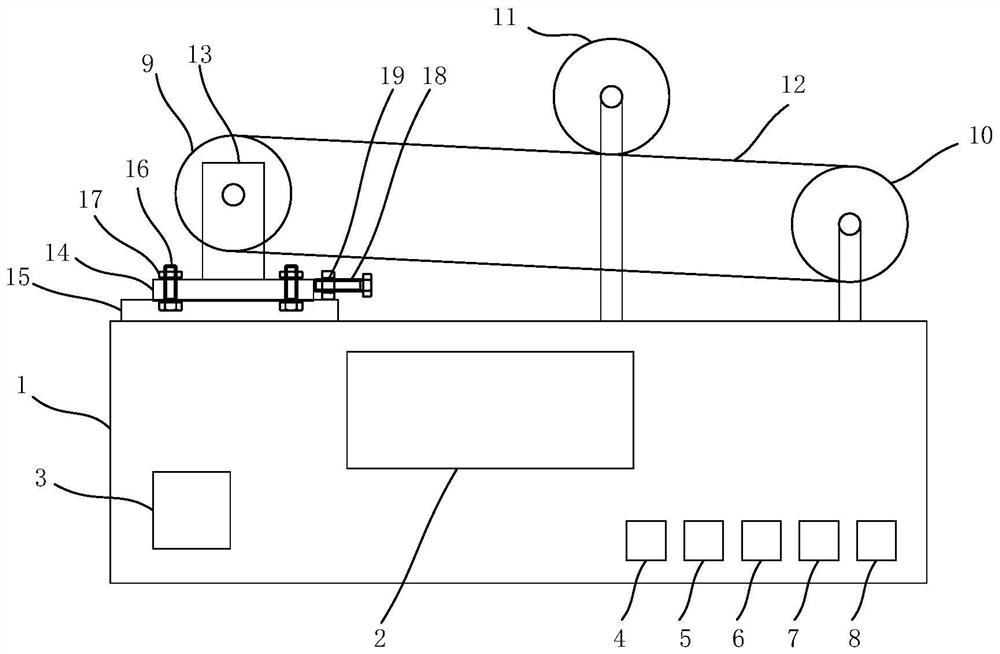

Adhesive tape machine system experiment platform

The invention provides an adhesive tape machine system experiment platform, and belongs to the field of adhesive tape machine protection. Comprising a control box and an adhesive tape conveying device, and the control box comprises a master controller, a power supply module used for supplying power to the master controller and a test interface used for connecting a sensor to be tested and the master controller. The rubber belt conveying device comprises a driving motor, a driving roller, a driven roller and a conveying belt, the driving motor is in transmission connection with the driving roller, and the driving roller is in transmission connection with the driven roller through the conveying belt; the test interface comprises a belt speed sensor interface; a driven wheel of the belt speed sensor is attached to the conveying belt. During testing, the belt speed sensor to be tested is connected with the belt speed sensor interface, the belt speed protection range of the conveying belt is set through the main controller, and the measurement result of the belt speed sensor displayed by the main controller and the alarm result of the main controller are observed by adjusting the relation between the belt speed of the conveying belt and the protection range. The problem that the protection function of the sealing-tape machine is difficult to test in a mine with a low ground space vacancy rate is solved.

Owner:YONGCHENG COAL & ELECTRICITY HLDG GRP

Log search method, log search device, and computer-readable storage medium

ActiveCN109492073BRealize the collectionRealize real-time monitoring and alarmText database queryingManagement toolEngineering

The present application relates to a log search method, a log search device and a computer-readable storage medium. The log search method includes: collecting and storing log data from multiple servers; regularly retrieving the log data, and locating the error log data in the log data; and obtaining the responsible person corresponding to the location information of the error log data Person information, and send alarm information according to the person in charge information. Through this log search method, the collection and storage of log data is realized. At the same time, the location and analysis of the error log data are located and analyzed through the distributed code version management tool, and the corresponding responsible person information is found, and through email, SMS, telephone, etc. In order to quickly respond to ongoing server failures and realize real-time monitoring and alarming of error logs.

Owner:BEIJING DAJIA INTERNET INFORMATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com