Automatic packaging production line control system

A pneumatic control system and technology of the control system, applied in the mechanical field, can solve the problems such as the unsatisfactory packaging machine, and achieve the effect of compact structure, fault detection and alarm function improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with drawings and embodiments.

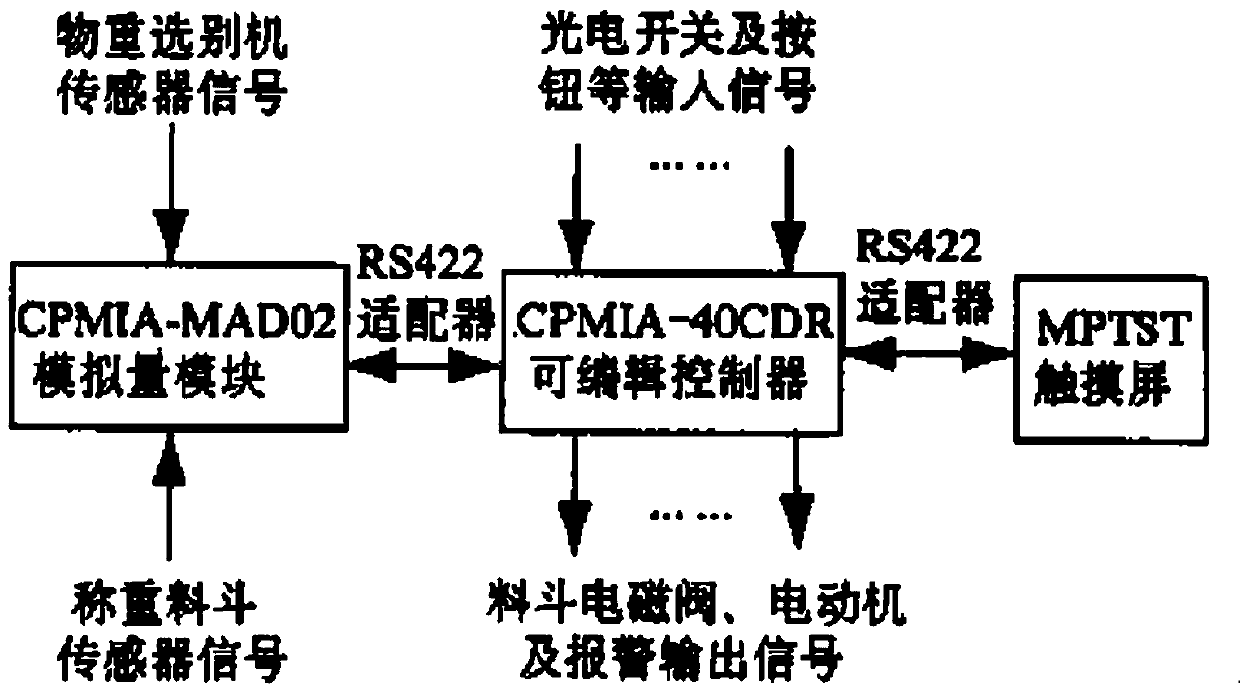

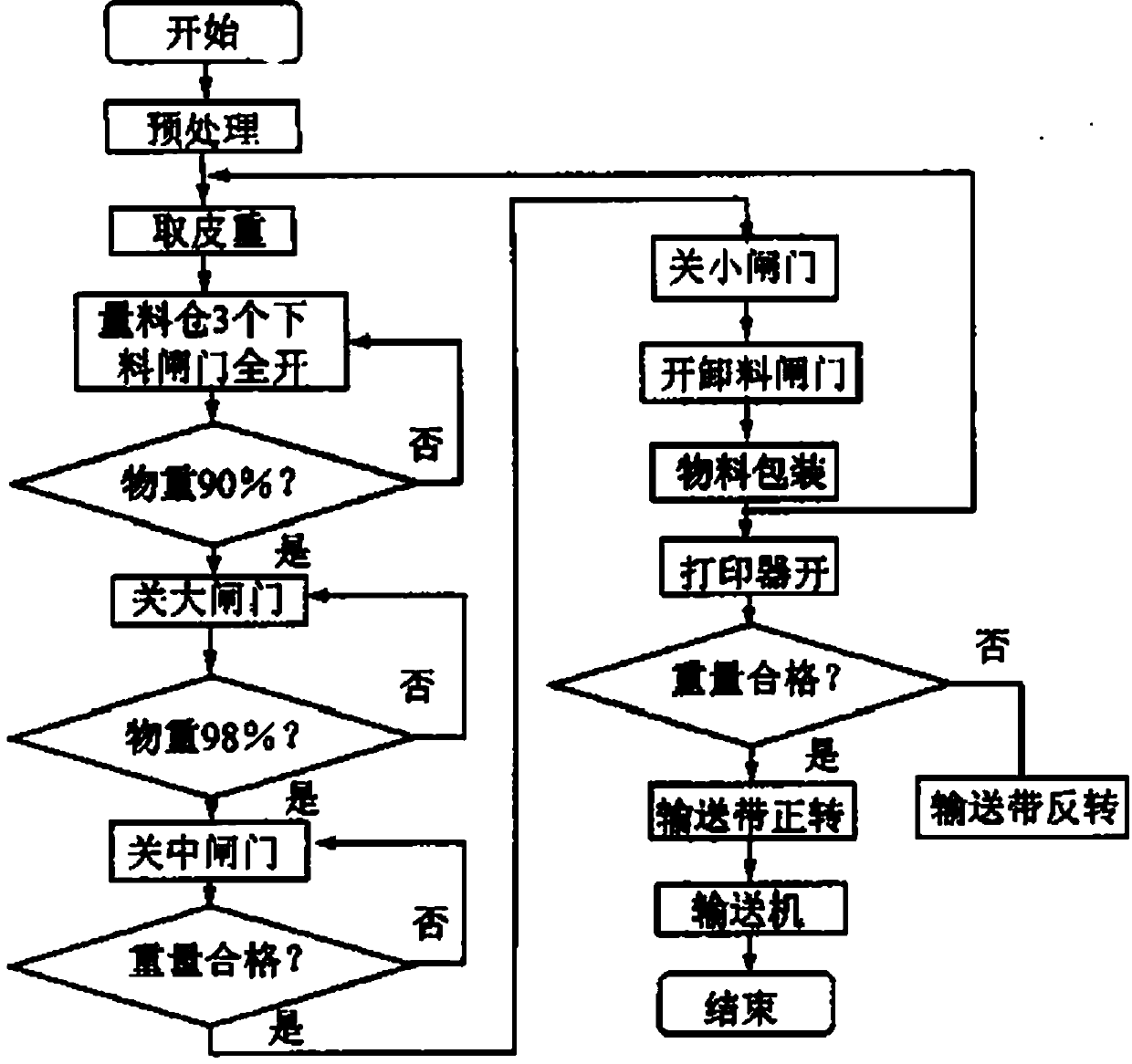

[0012] Such as figure 1 , The pneumatic control system is mainly composed of 7 two-position five-way electromagnetic reversing valves, 7 single-acting cylinders, 1 pressure reducing valve with pressure gauge, air filter and air compressor. In order to achieve high-precision dynamic weighing in the production line, the material bin is designed with a three-port feeding device. There are three large, medium and small gates installed at the bottom of the material bin of the weighing machine, which are controlled by three solenoid valves and three cylinders to complete the large and small. The opening and closing of the medium and small gates. The other cylinders respectively control the opening and closing of the weighing hopper door, the printing of the printer, the cutting of the seal of the horizontal sealer, and the withdrawal of the electric heating plate, etc.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com