Fully-automatic large-scale flat-plate type PECVD crystal silicon photovoltaic anti-reflection film preparation device

A flat, fully automatic technology, applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of long single production time and low output, and achieve easy maintenance and cleaning, excellent performance and price than the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

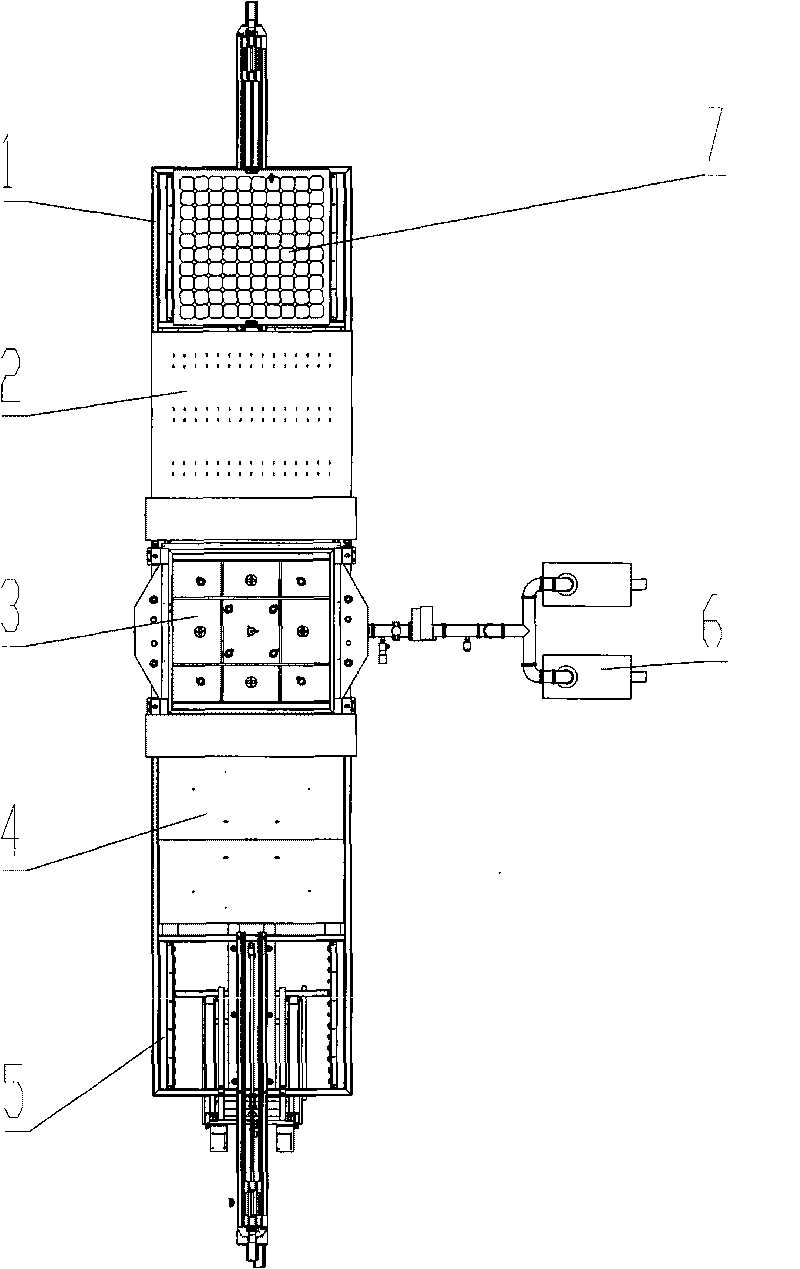

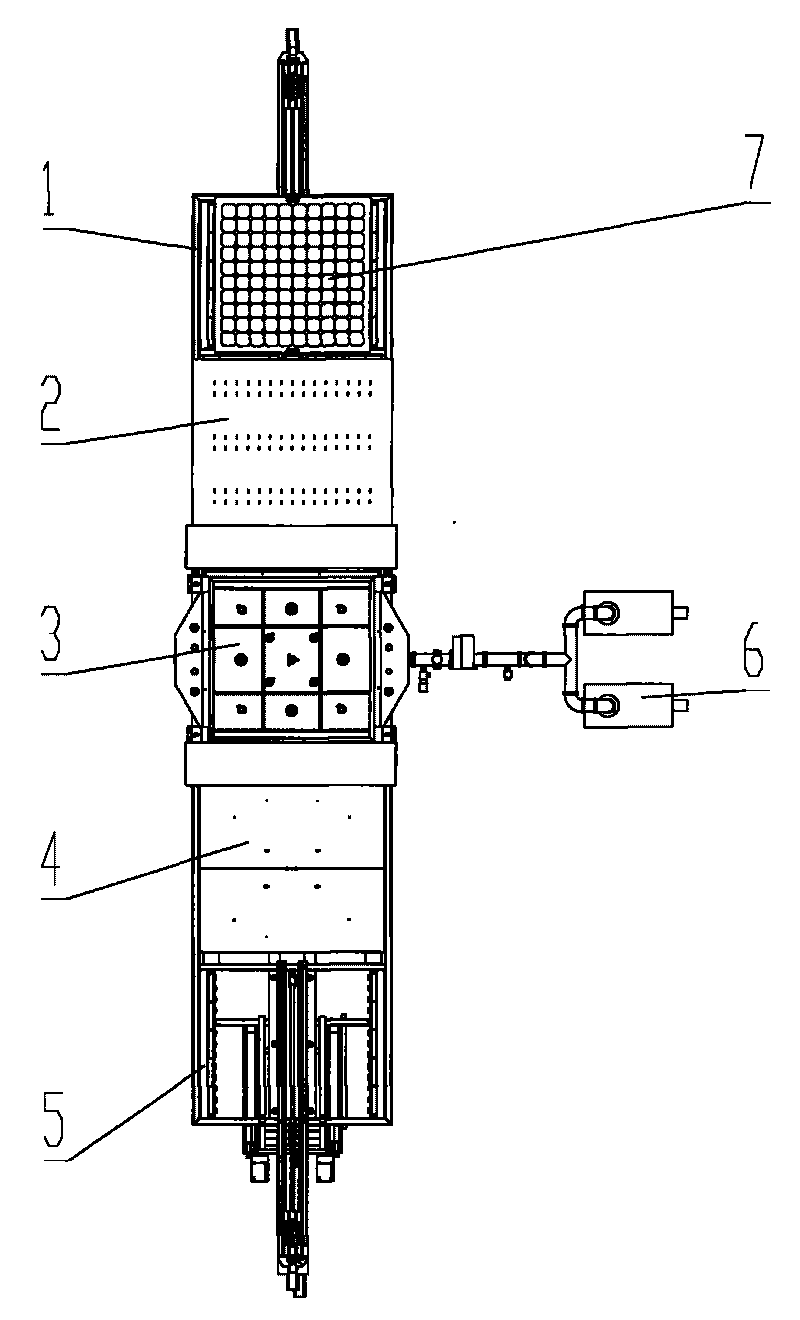

[0018] The structure and principle of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0019] Such as figure 1 As shown, the present invention adopts a fully automatic large-scale flat PECVD crystalline silicon photovoltaic anti-reflection coating equipment with a single chamber working under vacuum conditions, mainly including a loading platform 1, a preheating platform 2, a PECVD chamber 3, a cooling platform 4, an unloading Platform 5 and vacuum pumping system 6, etc. Wherein, the loading platform 1, the preheating platform 2, the PECVD chamber 3, the cooling platform 4 and the unloading platform 5 are sequentially arranged on the platform, and the loading platform 1, the preheating platform 2, the PECVD chamber 3, the cooling platform 4 and the unloading platform 5 are respectively It is connected with the respective benches by bolts, and the respective benches are connected by bolts. The preheating platform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com