Multifunctional high-frequency inversion direct-current electric welding machine realizing circuit

A high-frequency inverter, DC welding technology, applied in arc welding equipment, welding equipment, manufacturing tools, etc., to achieve the effect of perfect protection, high-quality welding, and lower production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

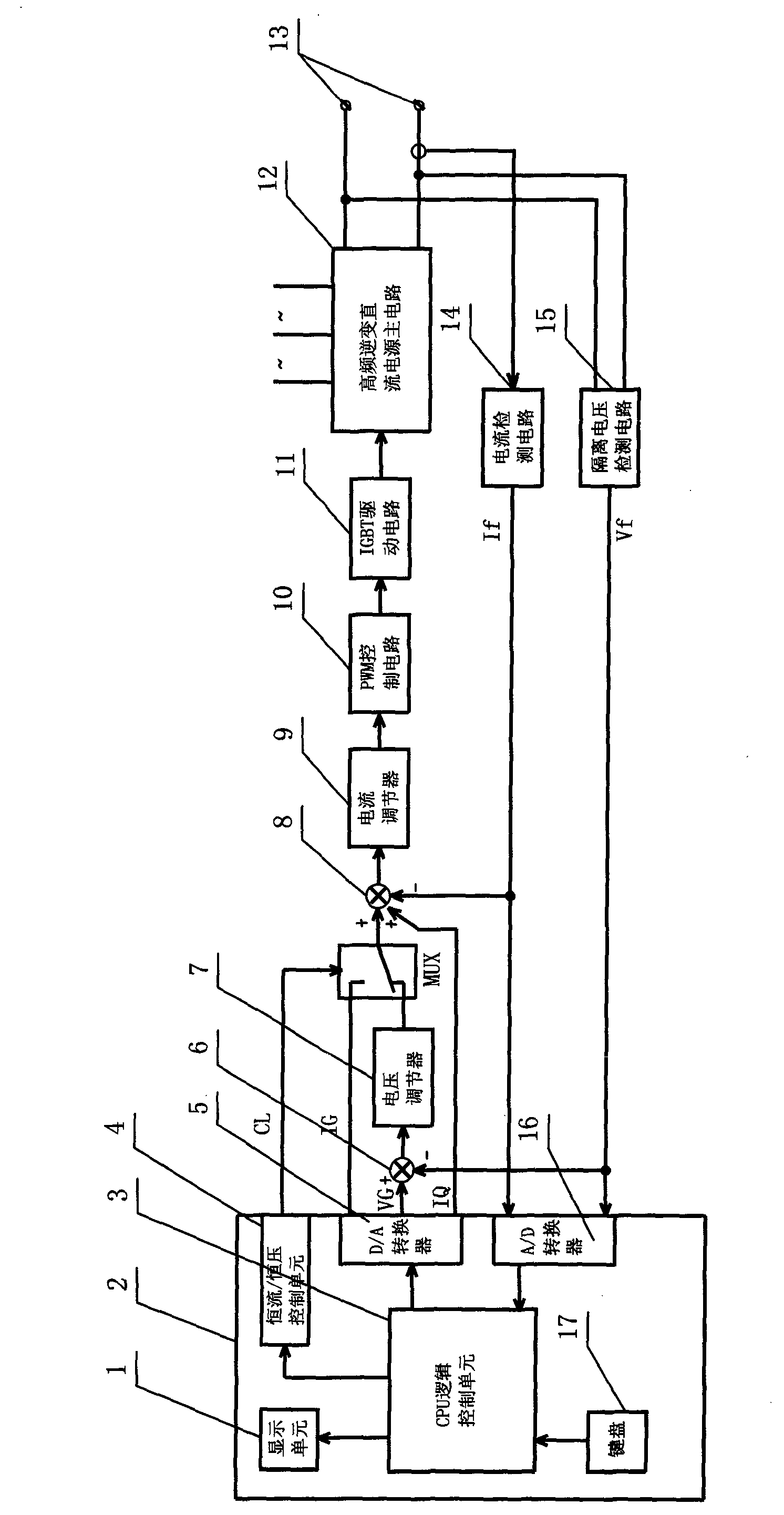

[0015]The welding machine control unit 2 sends a signal CL to control the selection switch MUX to determine the working mode of the multifunctional high-frequency inverter welding machine, that is, constant current / constant voltage control selection. When the signal CL is at a low level, the selector switch MUX is turned down (the connection state in the figure), the input of the current regulator 9 is provided by the voltage regulator 7, and the whole system forms a double-loop control structure with an inner current loop and an outer voltage loop. The machine output is a constant voltage characteristic. In the constant voltage mode, the control structure of the electric welding machine system is a double closed loop of voltage and current, which has a constant voltage characteristic and is suitable for MIG welding mode. If the output voltage is the no-load voltage value, it indicates that the welder is ready to strike the arc; if the output voltage begins to drop, it indicat...

Embodiment 2

[0017] The welding machine control unit 2 sends a signal CL to control the selection switch MUX to determine the working mode of the multifunctional high-frequency inverter welding machine, that is, constant current / constant voltage control selection. When the signal CL is at high level, the selection switch MUX is turned upward, the input of the current regulator 9 is provided by the control unit 2 of the electric welding machine, the whole system forms a single current loop structure, and the output of the electric welding machine is a constant current characteristic. In the constant current mode, the control structure of the electric welding machine system is a current single closed loop with constant current characteristics, which is suitable for TIG and MMA welding modes. If there is no output current, it indicates that the welding machine is in the state of preparing for arc striking; if there is output current and output voltage, it indicates that the welding machine is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com