Multifunctional connecting support

A multifunctional, supporting body technology, applied in the direction of supporting, clamping, positioning devices, etc., can solve the problems of inability to assemble, inability to locate and connect other components, single function, etc., and achieve the effect of increasing the space for conversion and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

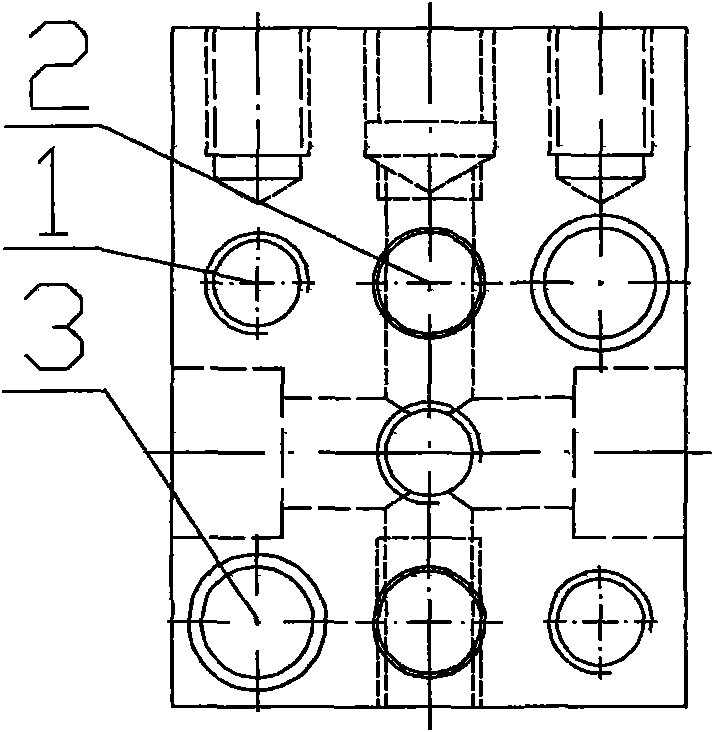

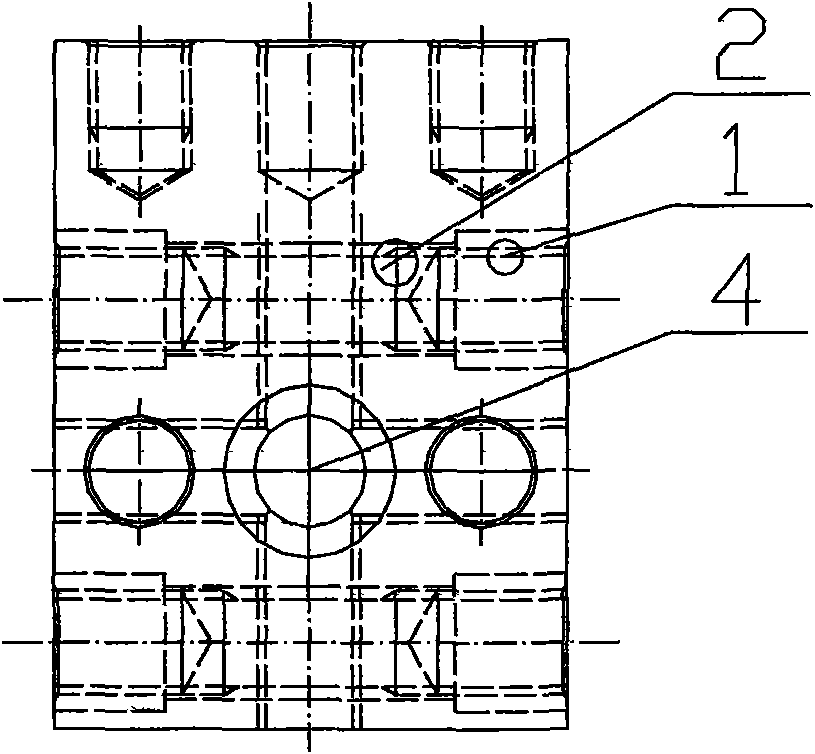

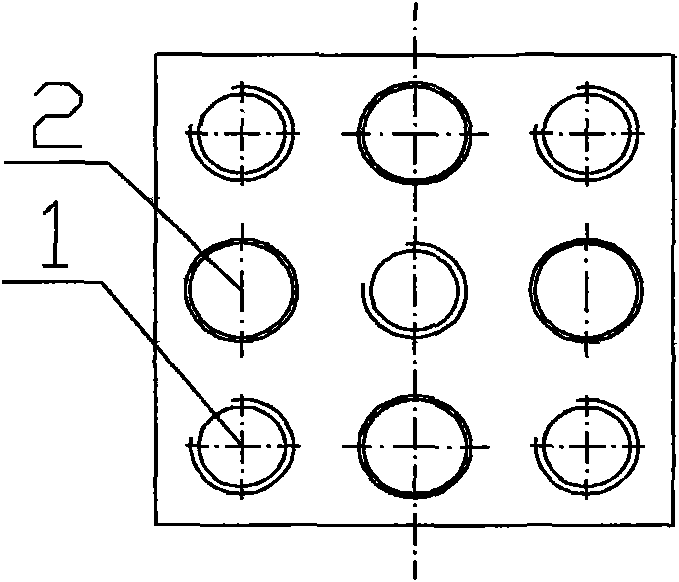

[0010] The multifunctional connection support includes a support body, which is characterized in that the support body is a rectangular parallelepiped, and the dimensions of the rectangular parallelepiped are 60mm, 60mm, and 80mm, and an M12, 80mm deep is made upward at the center of a short side 60mm and short side 60mm. Threaded through hole, on the plane axis of another short side 60mm and short side 60mm, make four Φ12H7 pin shaft blind holes with a distance of 40±0.01mm and a depth of 15mm in four directions, and four on the diagonal Make four M12 threaded blind holes with a distance of 40±0.01mm and a depth of 15mm in the direction, and make two distances on the axis of the upper and lower directions on the two symmetrical surfaces of 60mm on the short side and 80mm on the long side. For the 40±0.01mm pin shaft through hole, one M12 inner hexagon screw hole is made on the upper right side of the axis and the lower left side of the axis, and one M12, 15mm deep hole is made...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com