Patents

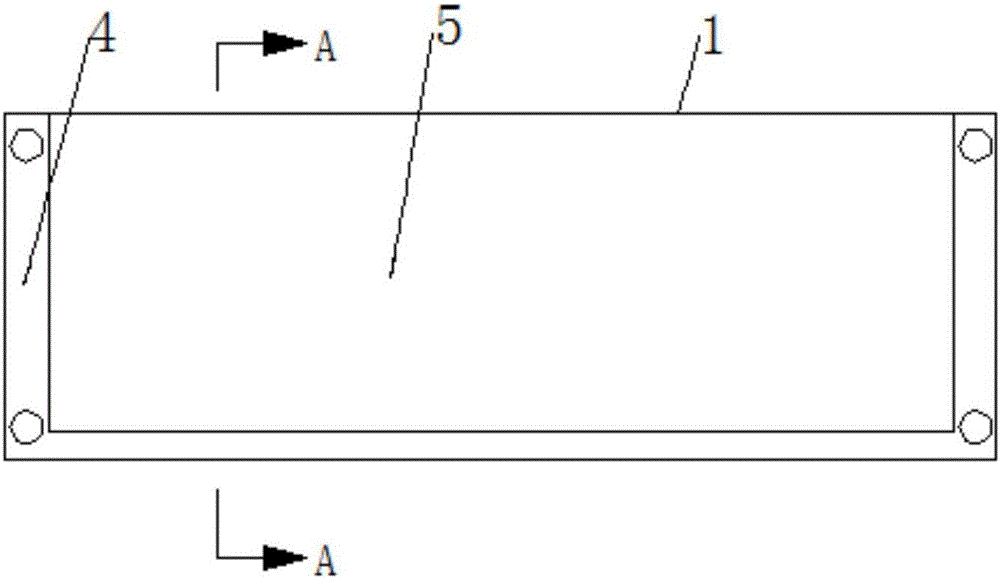

Literature

35results about How to "Efficient fit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

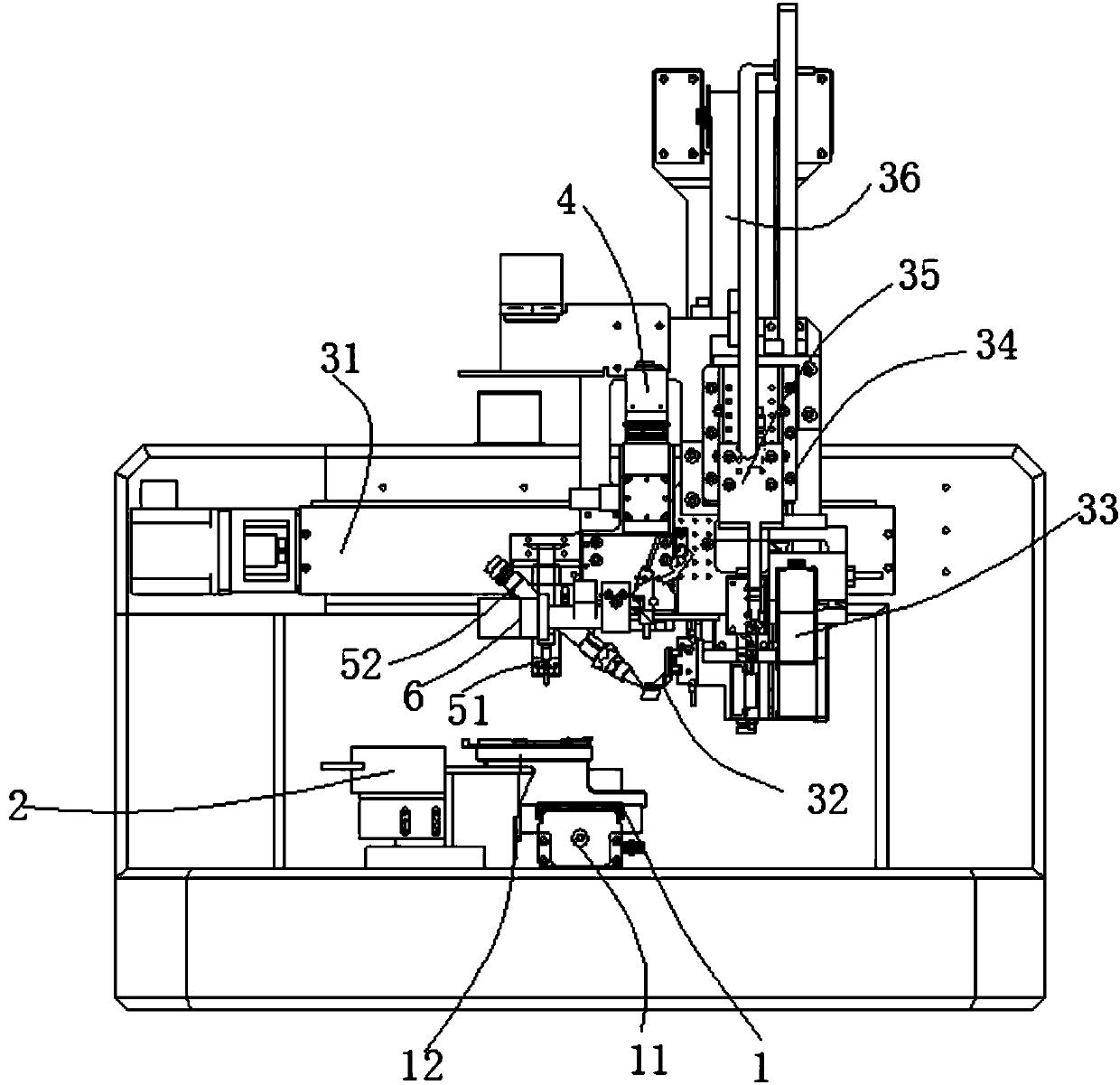

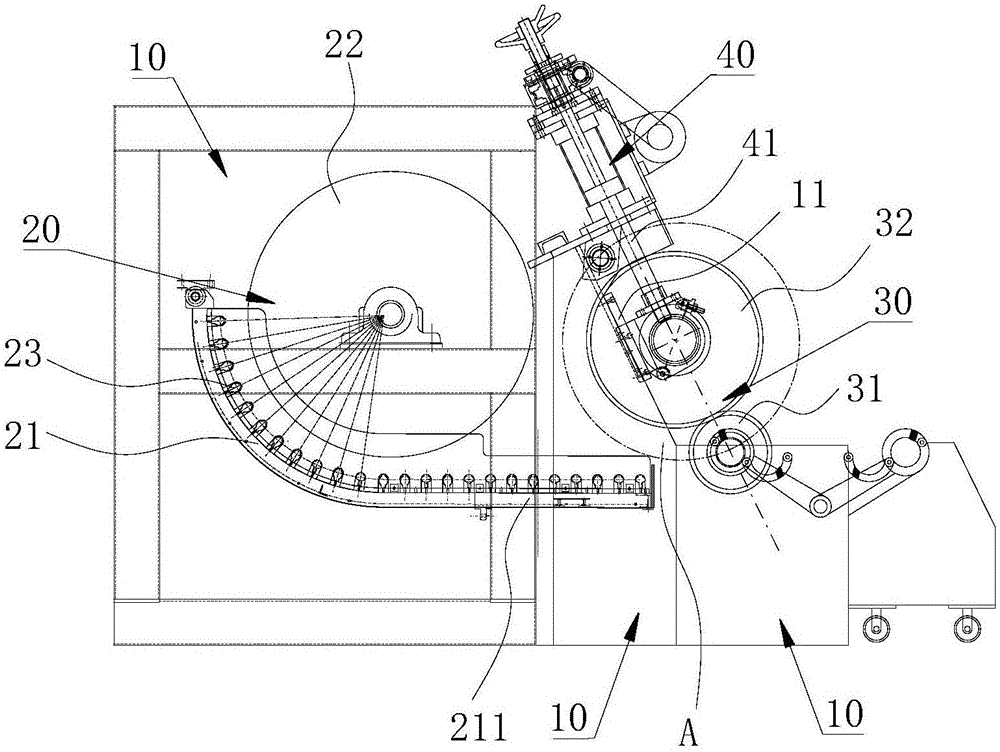

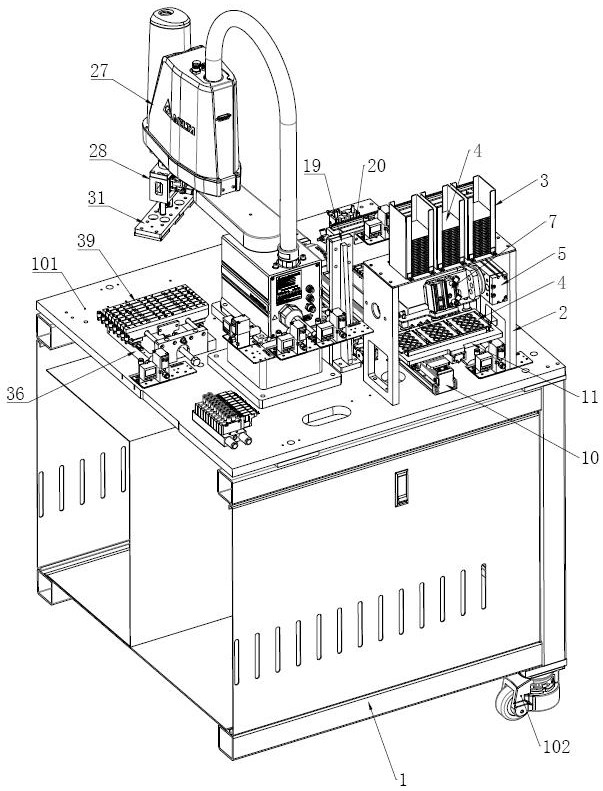

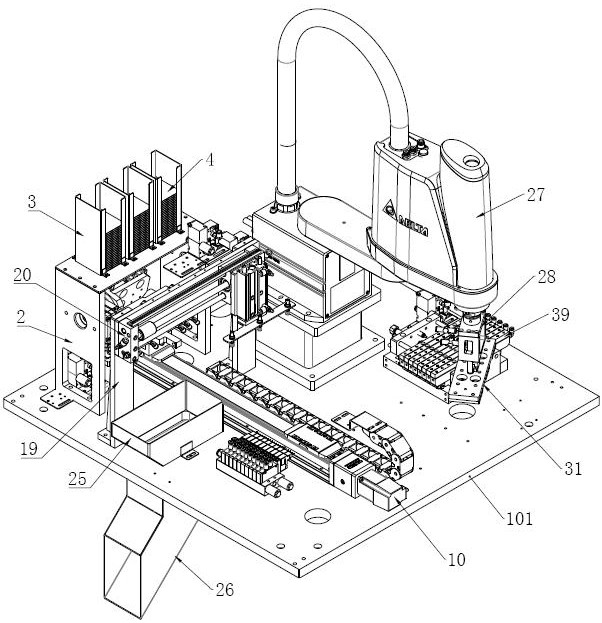

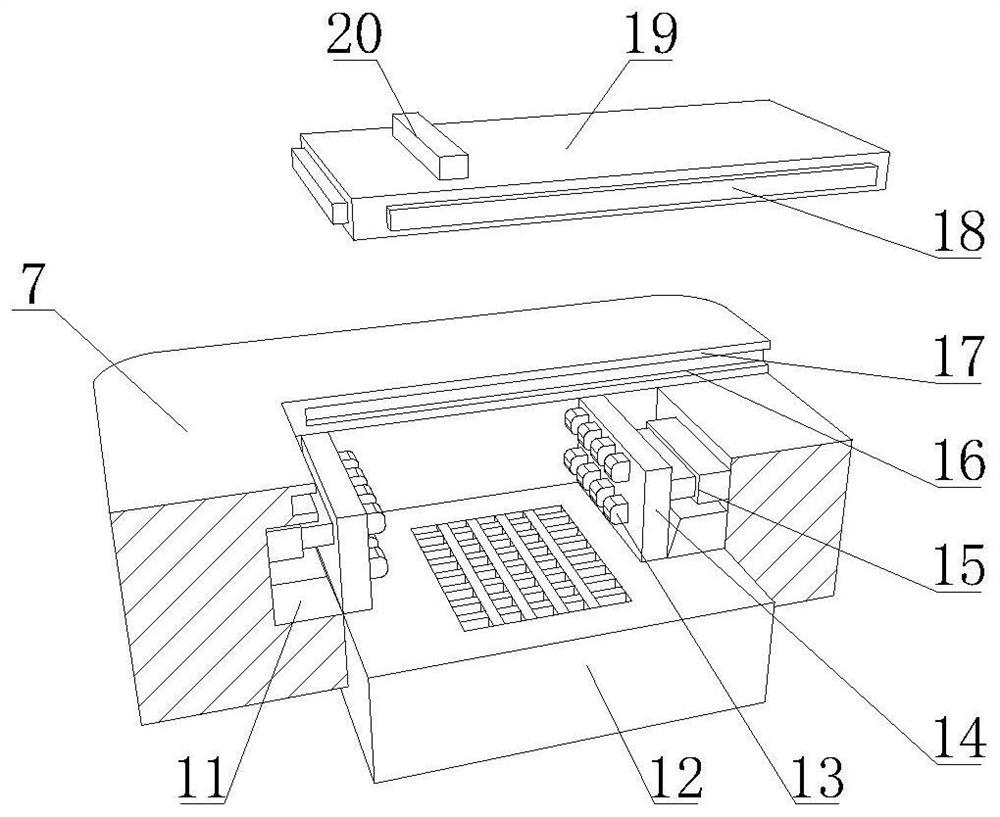

Glass lens laminator and automatic glass lens laminating method

The invention discloses an automatic glass lens laminating method which includes the steps: S1) loading a product A and a product B onto a vehicle component, and detecting the planar angles of the product A and the product B by a collimator; S2) grabbing the product A by a material taking suction head, detecting and adjusting the consistency of the planar angles of the product A and the product Bby the aid of a two-dimensional angle measuring device; S3) starting a light source, and simultaneously starting a monitoring camera; S4) dispensing glue at a fitting position on the product B by a UV(ultraviolet) dispensing and curing component; S5) driving the grabbed product A to fit with the fitting position on the product B by the grabbing component, and monitoring fitting conditions by themonitoring camera in fitting until a light interference ring is generated between the product A and the product B and the parallelism between the product A and the product B meets requirements; S6) detecting fitting pressure by a pressure feedback device in real time in fitting; S7) performing curing treatment by the UV dispensing and curing component.

Owner:SUZHOU MAKING INTELLIGENT EQUIP CO LTD

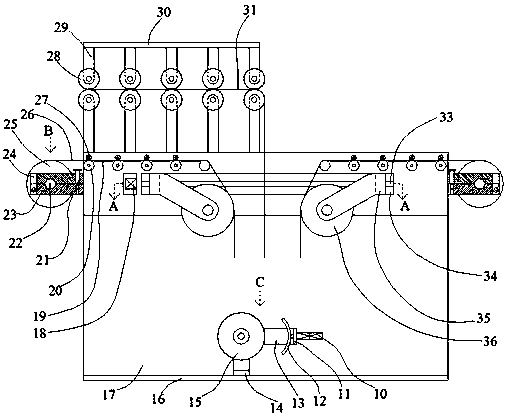

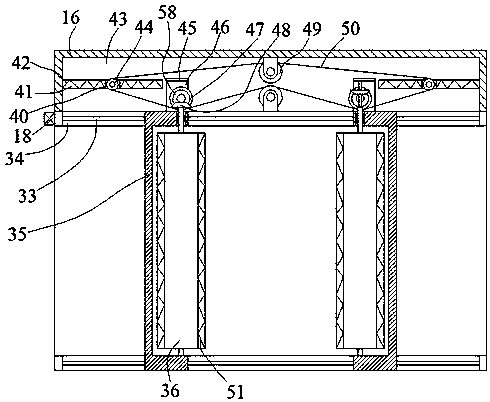

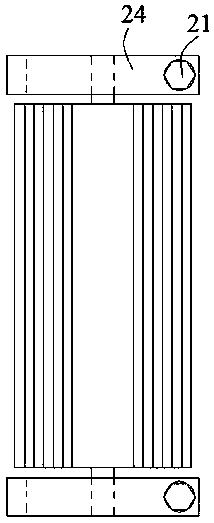

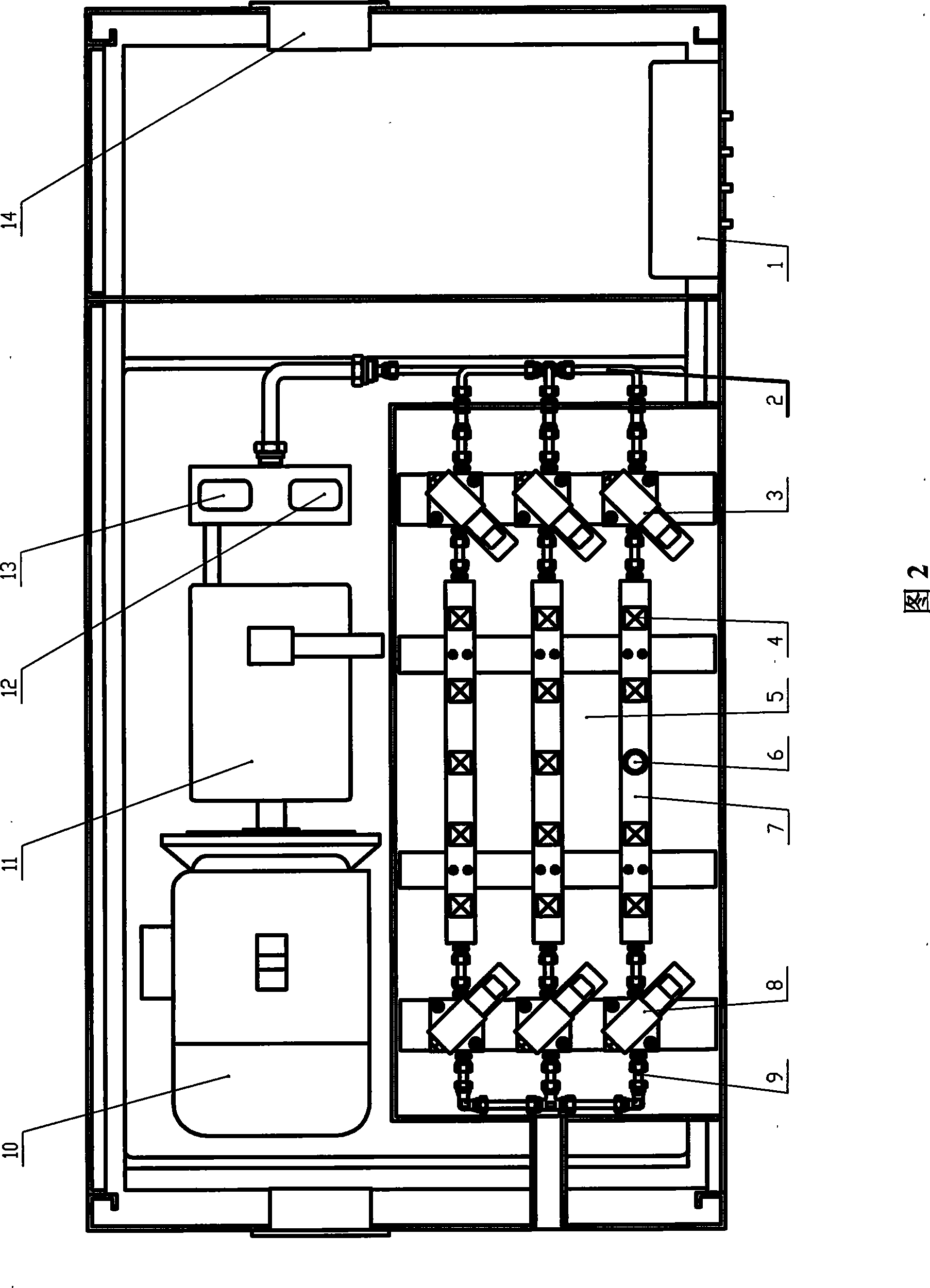

Thin film glue coating roller cleaning mechanism

ActiveCN106076960ASmooth rotationImprove cleaning efficiencyCleaning using toolsCleaning using liquidsHydraulic cylinderThin membrane

The invention discloses a thin film glue coating roller cleaning mechanism and belongs to the field of thin film machining mechanical equipment. The thin film glue coating roller cleaning mechanism comprises a fixed support, a lifting hydraulic cylinder, a cleaning support, cleaning hydraulic cylinders, cleaning brush plates, a roller cleaning tank and a glue coating roller containing mechanism; the roller cleaning tank is horizontally arranged on the lower side of the fixed support; the cleaning support is horizontally arranged on the lower side of the lifting hydraulic cylinder; the two ends of each cleaning supporting plate are correspondingly and symmetrically provided with the cleaning hydraulic cylinders in an inclined downward manner; the middle portions of the upper sides of the cleaning brush plates are connected with piston rods in a hinged manner; limiting springs are symmetrically arranged between the two sides of each cleaning brush plate and the corresponding piston rod correspondingly; the glue coating roller containing mechanism comprises a glue coating roller, a cleaning motor, a horizontal movement hydraulic cylinder, a fixed sleeve and a horizontal movement cylinder; and the two ends of the glue coating roller are horizontally arranged in the fixed sleeve and the horizontal movement sleeve correspondingly. The thin film glue coating roller cleaning mechanism is reasonable in structural design and capable of fast and efficiently cleaning thin film glue coating rollers in various size specifications, improving the cleaning efficiency and quality of the glue coating roller and meeting the requirement of production and use.

Owner:浙江耀阳新材料科技有限公司

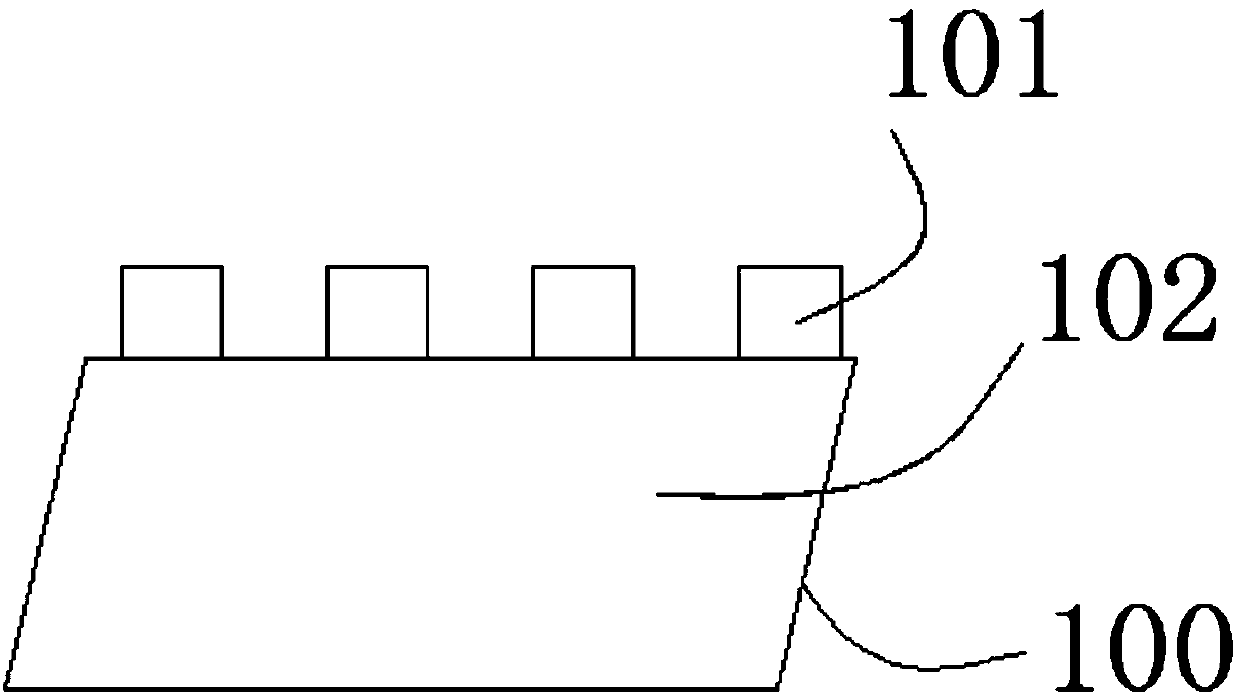

Dehydration-prevention gecko hydrogel application and preparation method thereof

The invention belongs to the field of medical high-molecular materials, and discloses a dehydration-prevention gecko hydrogel application and a preparation method thereof. The hydrogel application is prepared from the following raw materials in parts by weight: 0.25-1.55 parts of polyvinyl alcohol, 0.04-0.27 part of polyglutamic acid, 0.03-0.35 part of tannic acid, 0.05-0.12 part of glutaraldehyde having a mass concentration of 2-10 percent, 10-23 parts of water, and the balance of an acidity regulating agent. The gecko hydrogel application can adsorb and closely attach the surface of human skin since the application surface has tissues similar to the nano-sucker structure of gecko feet so as to effectively prevent falling off and effectively prevent hydrogel from being dehydrated. The hydrogel application can be well attached to skin to achieve a self-cleaning effect, and is applicable to wound protection and treatment of physical therapy, burning, scalds and traumatic wounds by cold application.

Owner:NANJING SHINEKING BIOTECH CO LTD

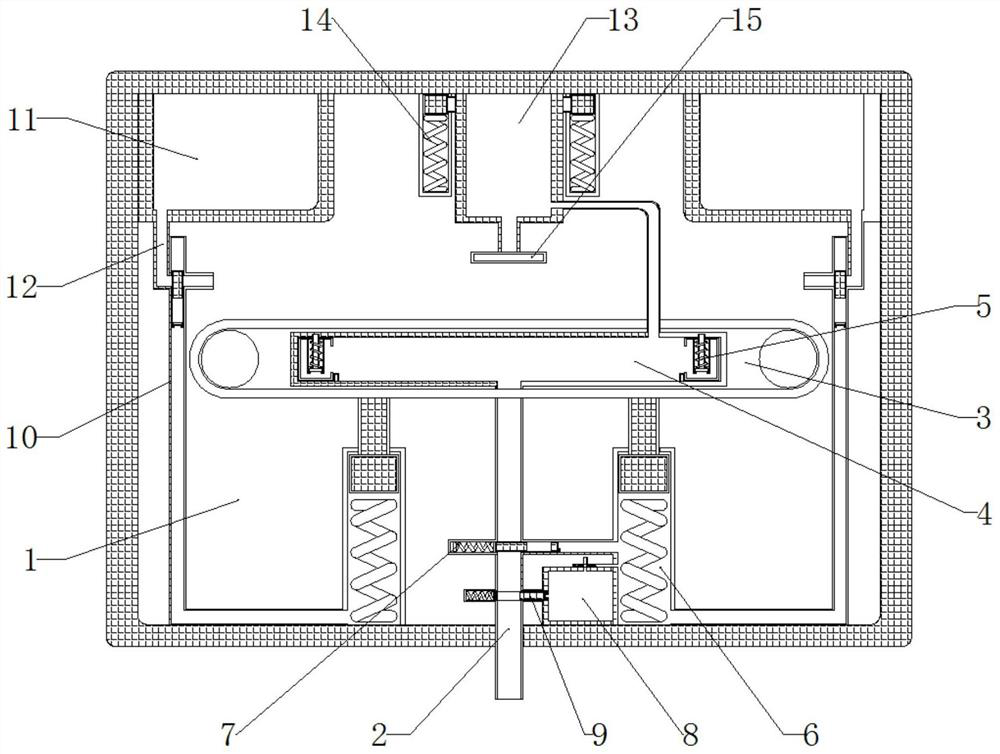

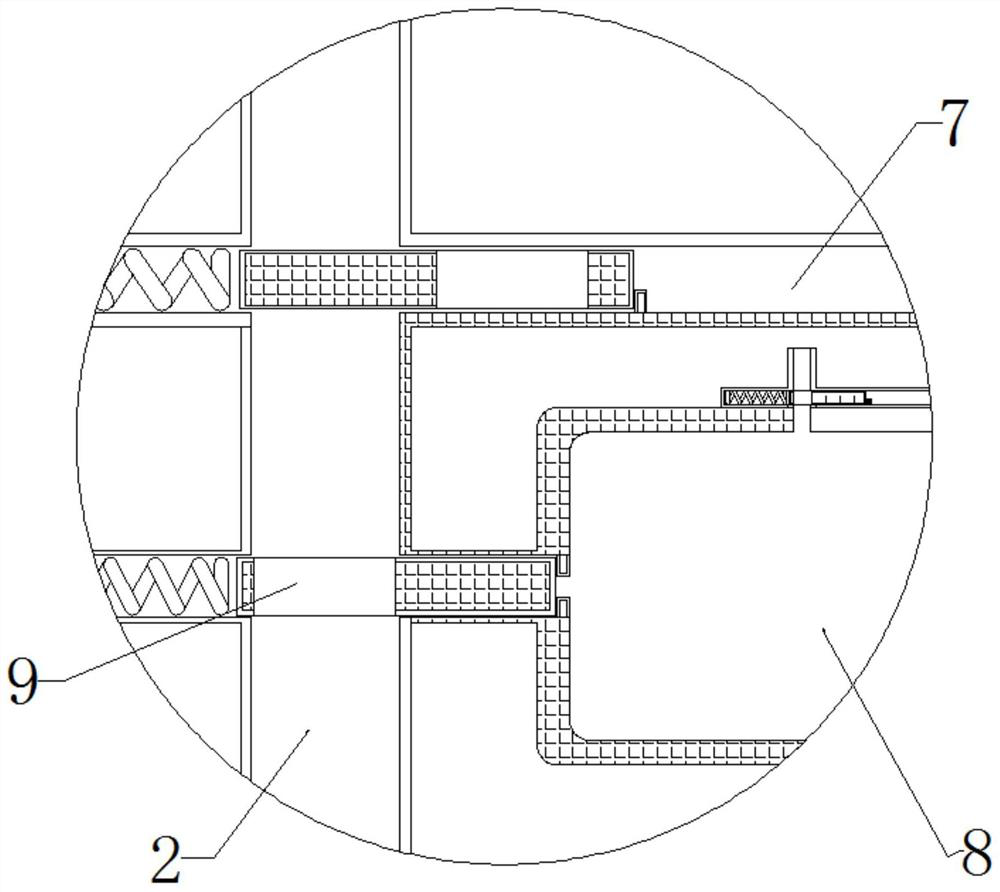

Shoe processing device capable of achieving constant-temperature rapid gluing through air bag extrusion

The invention relates to the technical field of shoe processing, and discloses a shoe processing device capable of achieving constant-temperature rapid gluing through air bag extrusion. The shoe processing device comprises a processing machine, an air inlet pipe is movably connected to the lower part in the processing machine, a working belt is movably connected to the interior of the processing machine, a cavity rail is movably connected into the working belt, clamping bins are movably connected to the two ends of the cavity rail, a supporting rail is movably connected to the bottom of the interior of the processing machine, an air inlet rail is movably connected between the supporting rail and the air inlet pipe, and a warm pressing bin is movably connected to the bottom of the interiorof the processing machine. A control sliding block is further pushed to move upwards, so that the position of a through hole of the control sliding block coincides with the position of a pipe openingof a drying pipe, heating gas in a constant-temperature bin is further sprayed out through the drying pipe, rapid drying is conducted for gluing, the effect of rapid gluing of shoes is achieved, and the processing efficiency is improved.

Owner:湖州瑞博鞋业有限公司

Textile chemical dyeing and finishing equipment

InactiveCN111038065APrevent oxidationOxidation achievedLaminationLamination apparatusMechanical engineeringDyeing

The invention discloses textile chemical dyeing and finishing equipment, which comprises a box body, wherein an open inner cavity is formed in the box body, sliding inner cavities symmetrically arranged front and back are formed in the rear end wall of the inner cavity in a communicating mode, a rear side cavity is formed in the rear end wall of the sliding inner cavity in the rear side in a communicating manner, the sliding inner cavities, the rear side cavity and the inner cavity are internally provided with movable extrusion devices capable of being adjusted left and right and extruding a textile cloth, release devices for releasing a protective film are arranged on the two sides of the box body, a bottom coiling device for further coiling the textile cloth attached with the protectivefilm is fixedly arranged in the lower end wall of the inner cavity, and the upper end surface of the box body is provided with a leading-in device for leading an textile cloth in an external space into the equipment. The equipment has smart structure, can protect a textile cloth and prevent the textile cloth from being oxidized compared with the equipment in the prior art, has the improved workingefficiency through the smart structure of the equipment, and has the prolonged service life.

Owner:储小英

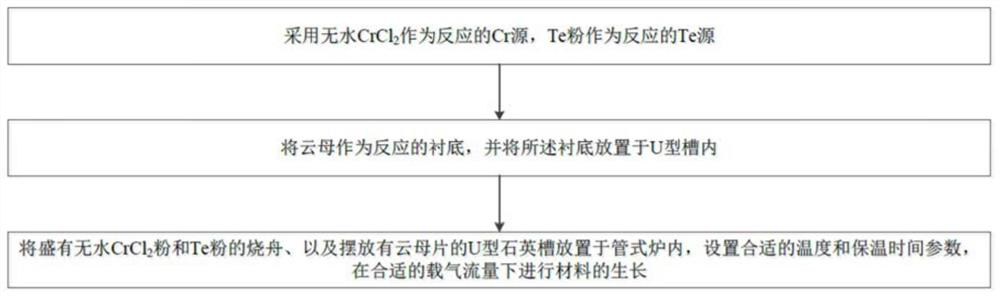

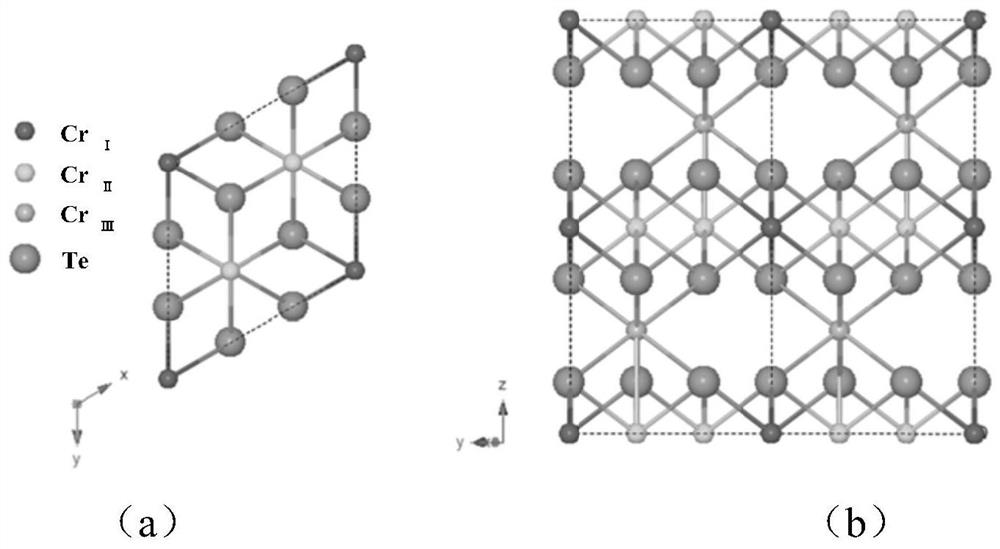

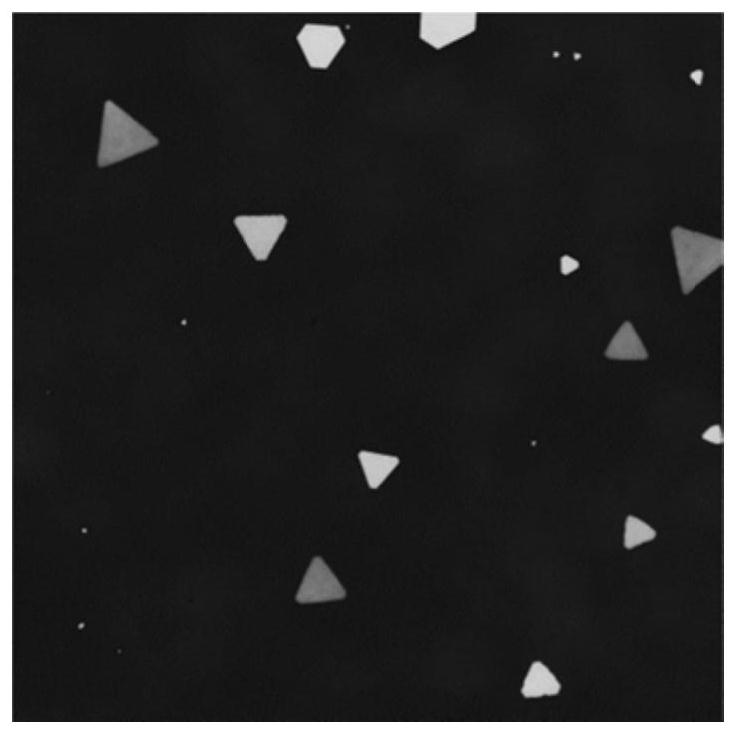

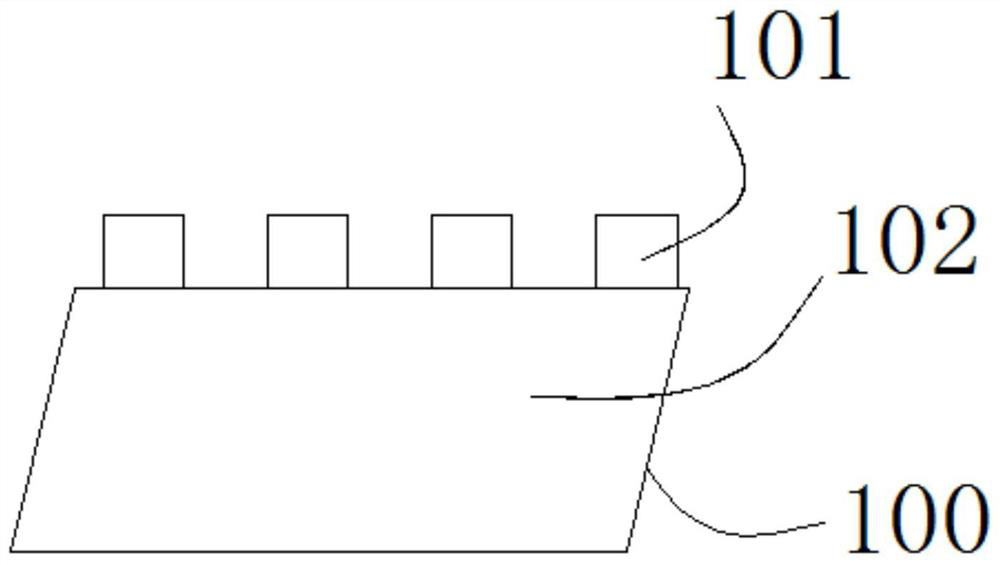

Strain-sensitive two-dimensional ferromagnetic Cr2Te3 nanosheet and preparation method thereof

InactiveCN113089100APromote growthGood for lateral migrationPolycrystalline material growthFrom chemically reactive gasesPhysical chemistrySingle crystal

The invention belongs to the related technical field of two-dimensional material preparation, and discloses a strain-sensitive two-dimensional ferromagnetic Cr2Te3 nanosheet and a preparation method thereof. The method comprises the following steps that firstly, a mica substrate is placed in a U-shaped groove; and then, the U-shaped groove, anhydrous CrCl2 powder and Te powder are arranged at intervals and heated, so the two-dimensional ferromagnetic Cr2Te3 nanosheet grows on the surface, close to the bottom surface of the U-shaped groove, of the mica substrate through chemical vapor deposition. According to the preparation method, the high-quality two-dimensional single crystal Cr2Te3 nanosheet is successfully grown on the lower surface of the mica substrate through a specific substrate and configuration in a proper temperature range and a proper source dosage, and the characteristic of strain sensitivity is proved through a variable-temperature Raman and bending stress applying method.

Owner:HUAZHONG UNIV OF SCI & TECH

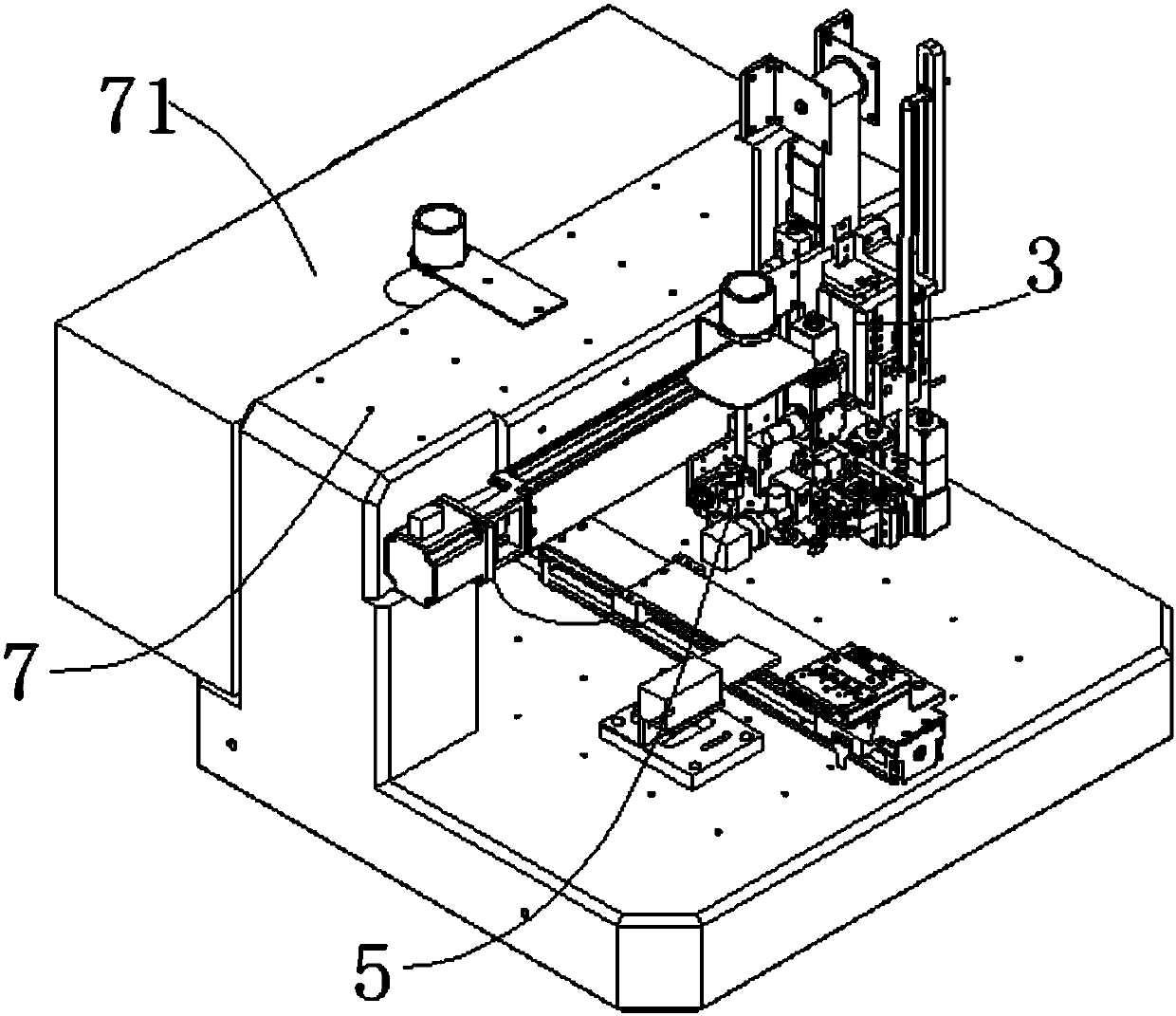

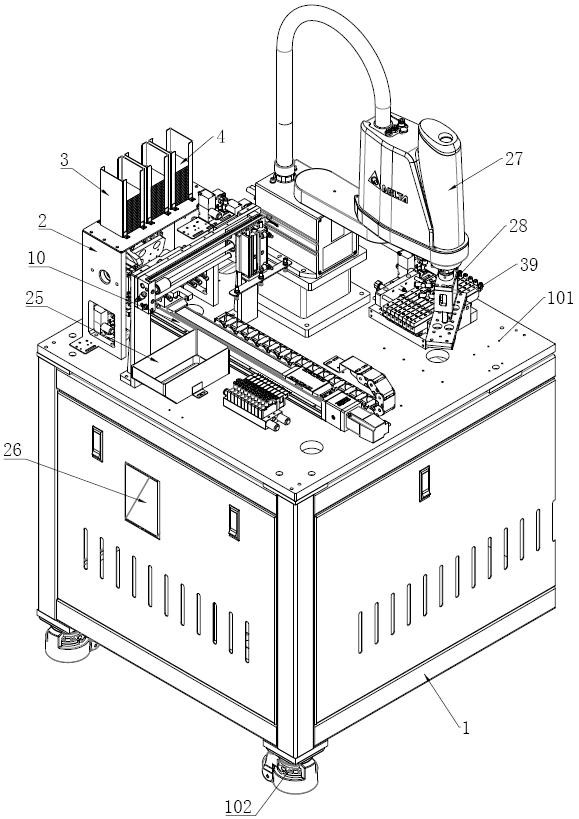

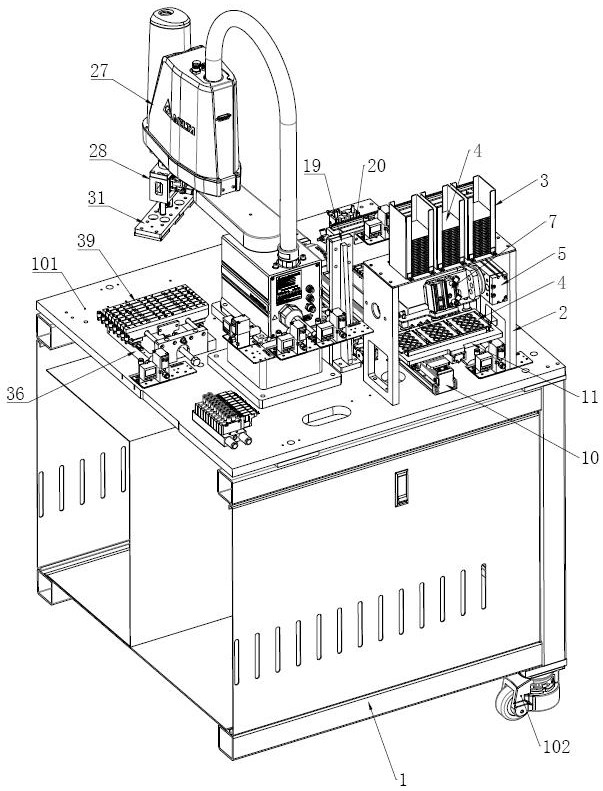

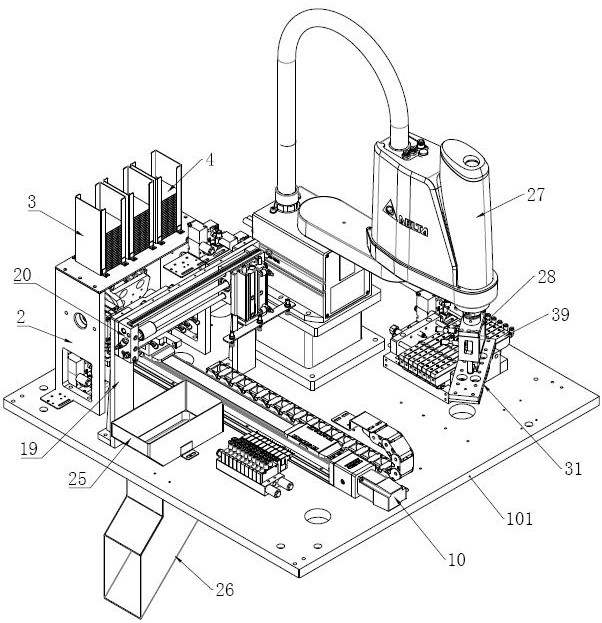

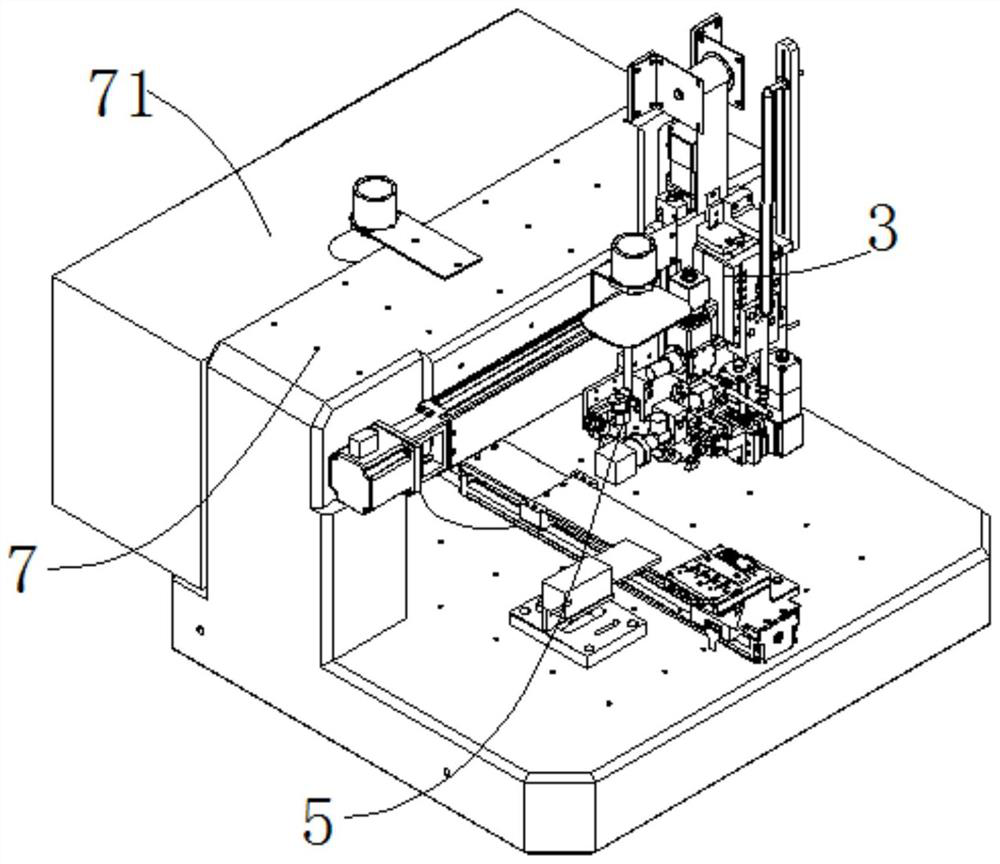

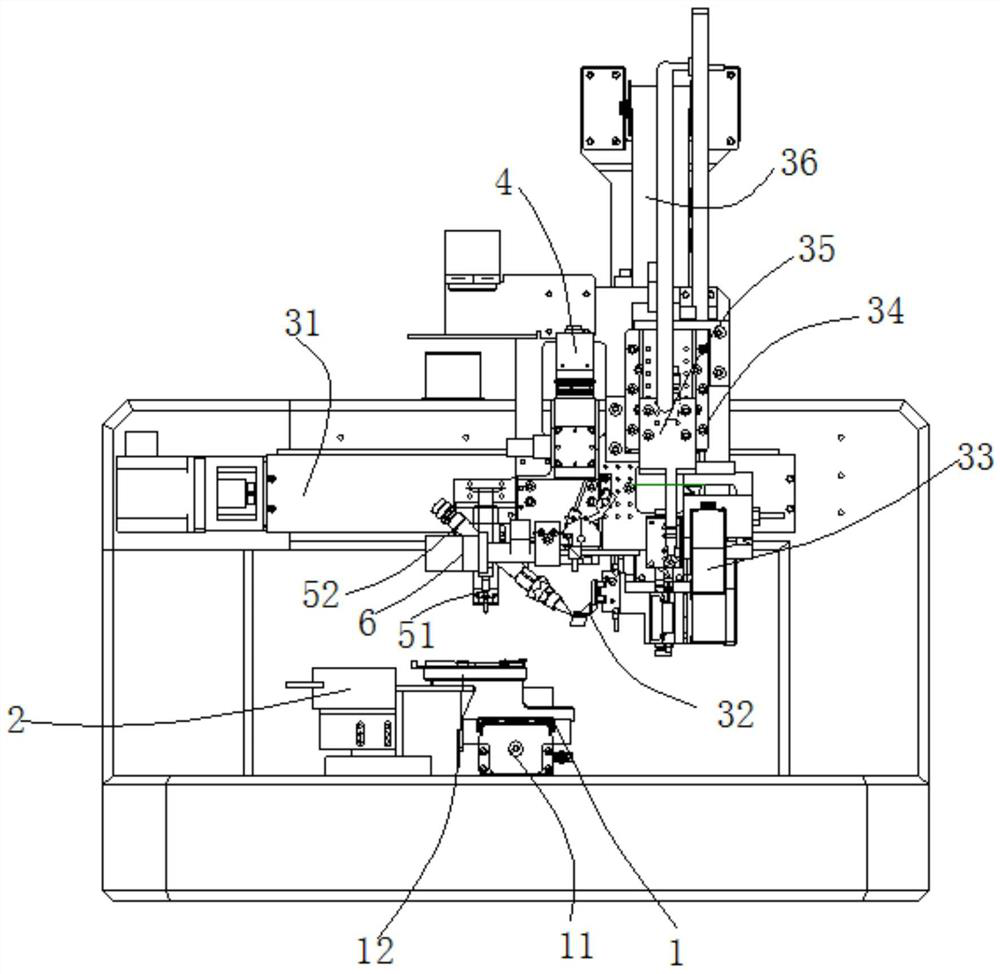

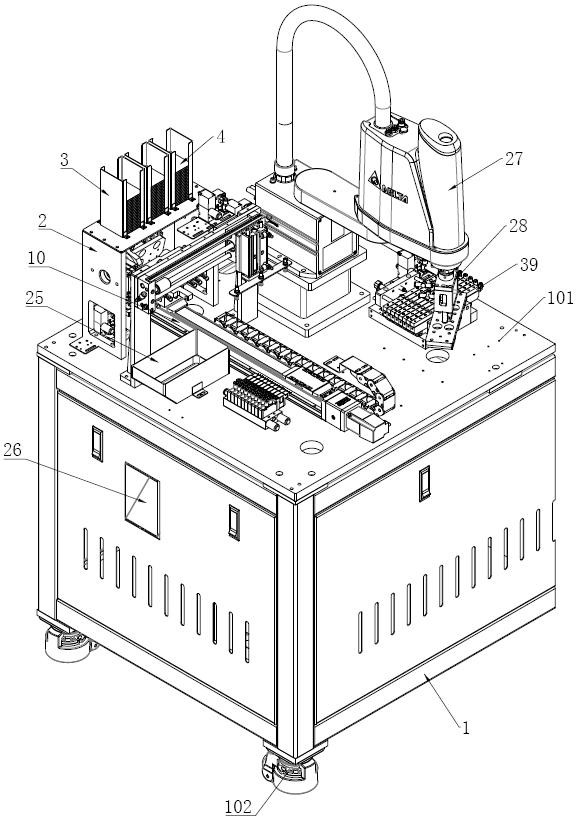

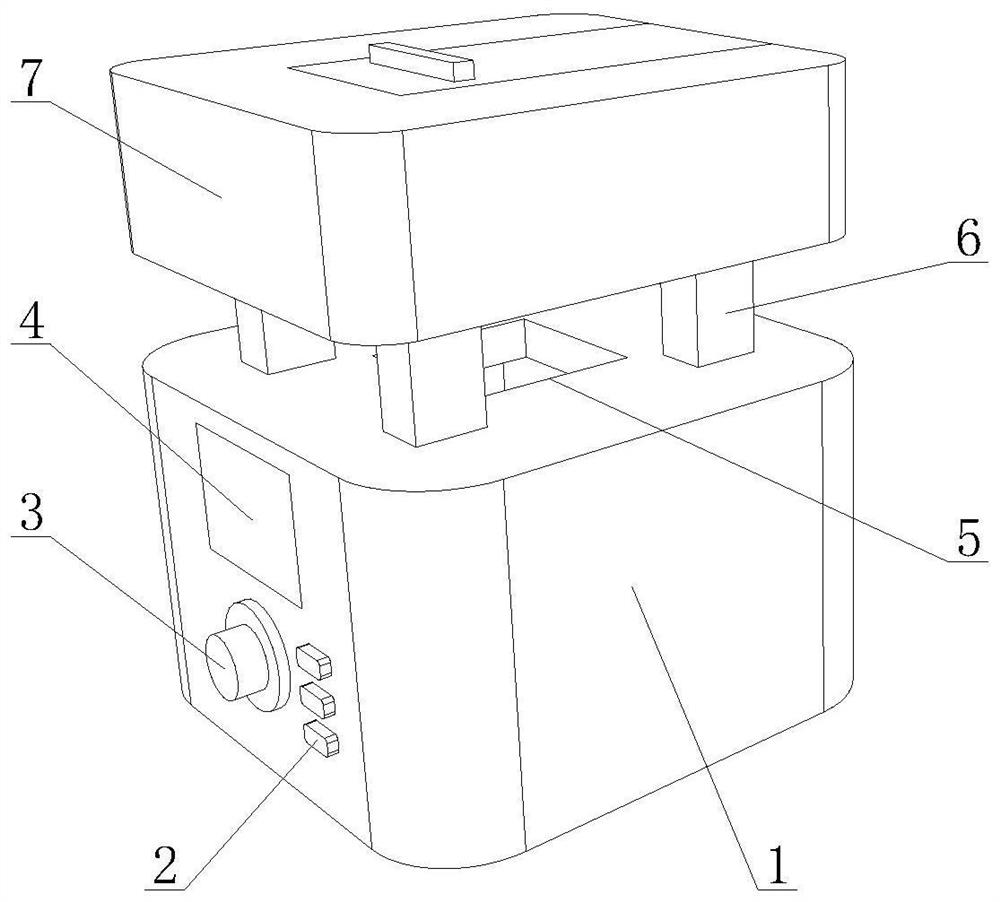

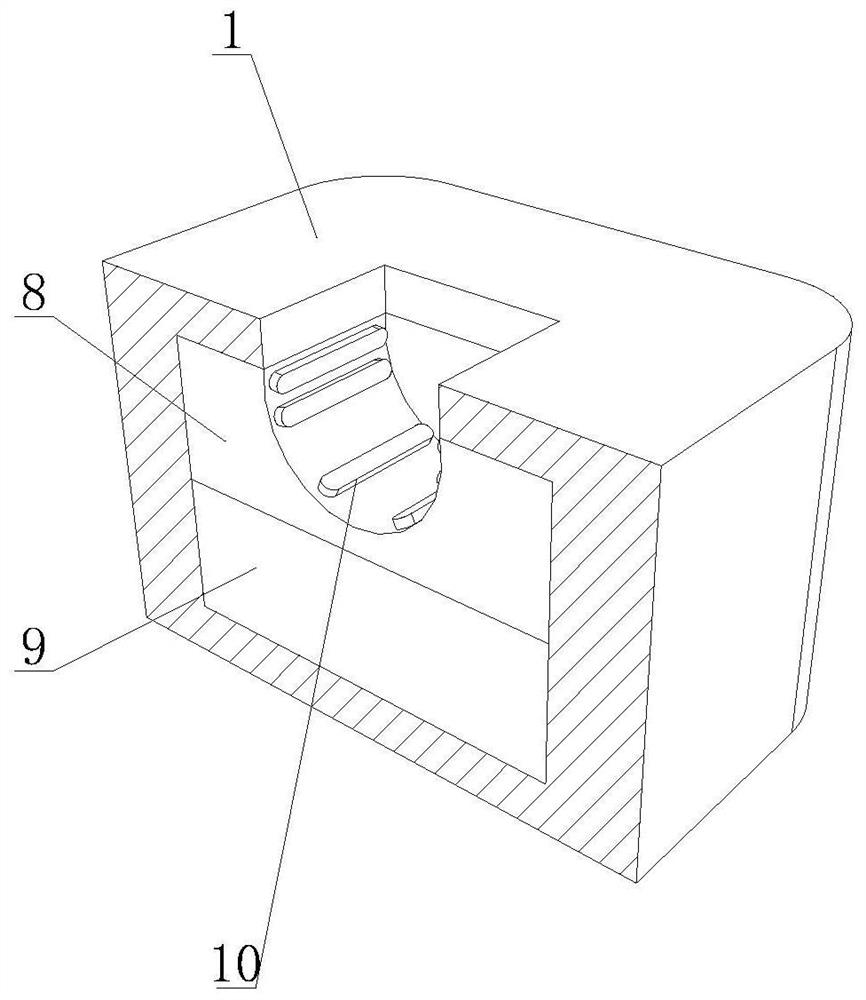

Automatic hydrogel slide feeding and patching device

The invention belongs to the technical field of micro-nano patching, and provides an automatic hydrogel slide feeding and patching device. The automatic hydrogel slide feeding and patching device comprises a machine frame, wherein a slide placing frame driven by an electric cylinder is arranged on a workbench of the machine frame, a slide positioning mechanism is arranged on the slide placing frame, and a slide bin and a film tearing mechanism are sequentially arranged on a workbench in the sliding direction of the slide placing frame; a slide feeding mechanism is correspondingly arranged below the slide bin; and a patching mechanical arm and a material sheet placing table are further arranged on the workbench, the material sheet placing table is located on one side of the patching end ofthe electric cylinder, the patching mechanical arm is located between the electric cylinder and the material sheet placing table, and a material taking and placing mechanism used for taking and placing material sheets is arranged at the end of a working shaft of the patching mechanical arm. According to the invention, automatic processing of hydrogel slide feeding, release film tearing and lamination of the material sheets on the hydrogel slide can be realized, so that the patching efficiency and the patching quality are greatly improved, the sanitation of the material sheets is not influencedin the processing course, and the produced patching product is ensured to meet the production requirement of sanitation standard.

Owner:SHANDONG NOVOSHINE OPTOELECTRONICS CO LTD

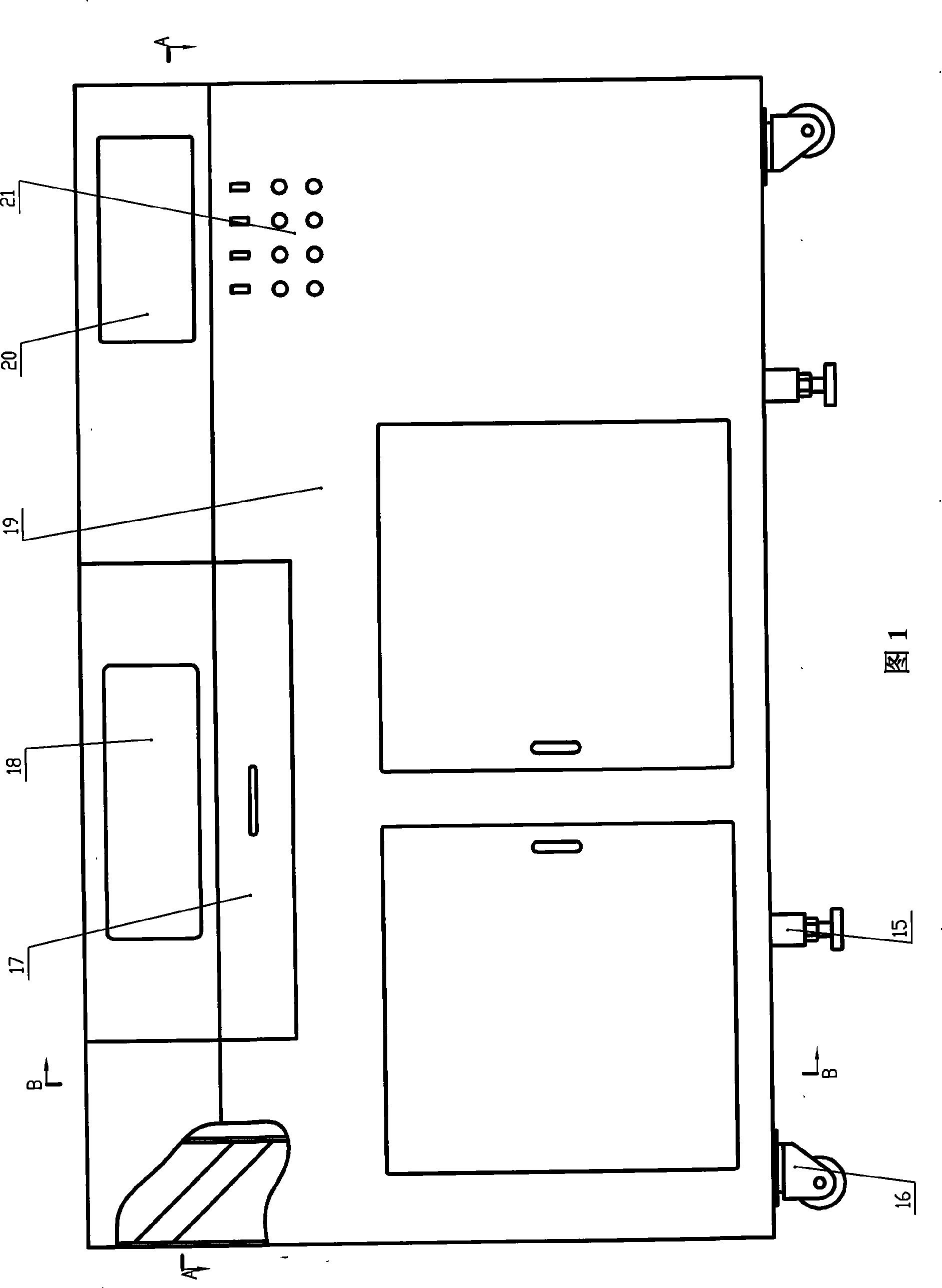

High-efficiency high-pressure sensor test machine

A high-efficiency high-pressure sensor testing machine comprises a bottom plate provided with a truckle, which has the technical point that: a cabinet and a pressure generating system is connected on the bottom plate, wherein the system comprises an oil tank fixedly arranged on the bottom plate, a motor and a variable pump are sequentially arranged on the upper part of the oil tank, the pressure outlet of the system is connected with a pipeline through an electromagnetic pressure regulator and a servo overflow valve, after being paralleled to be three-way, the pipeline is led to a testing area which is kept closed; an installation clamp is arranged in the testing area through conversion connection of a nested connector, each installation clamp is provided with two to eight installation positions, each of which is provided with a standard pressure sensor and a plurality of tested pressure sensor; a pressurized valve is serially connected to a pressure inlet end of the installation clamp, a cutoff valve is serially connected to a pressure outlet end of the installation clamp, and three-way pressure pipelines are paralleled to one way after the cutoff valve, and connected to a leakage discharge outlet at the lower part of the testing area; a panel computer and an electrical operation area are embedded into the upper part of the cabinet.

Owner:SHENYANG ACAD OF INSTR SCI

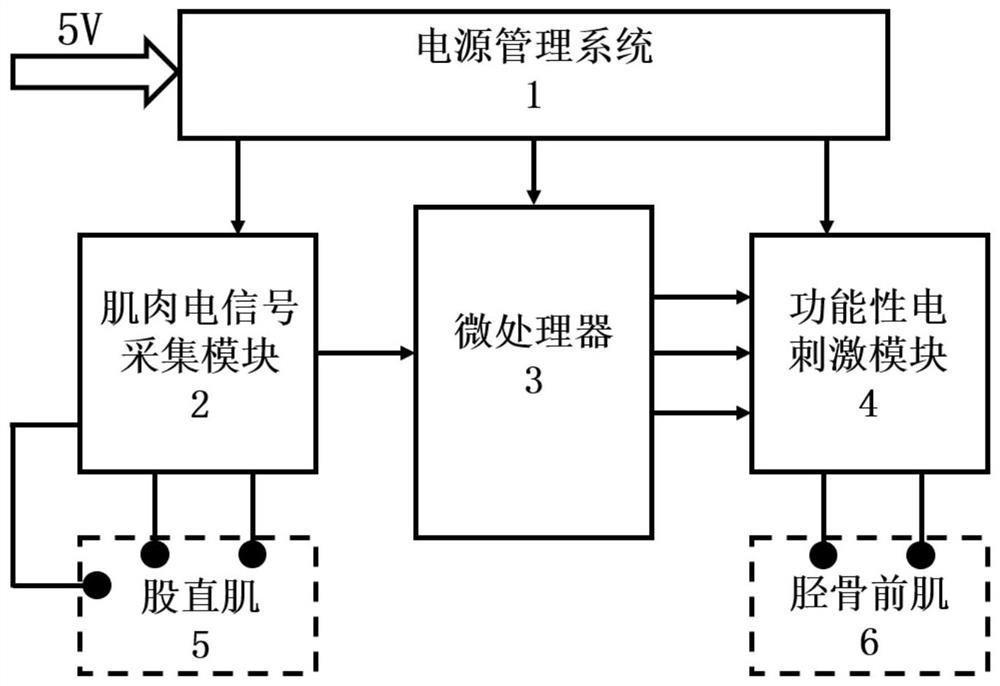

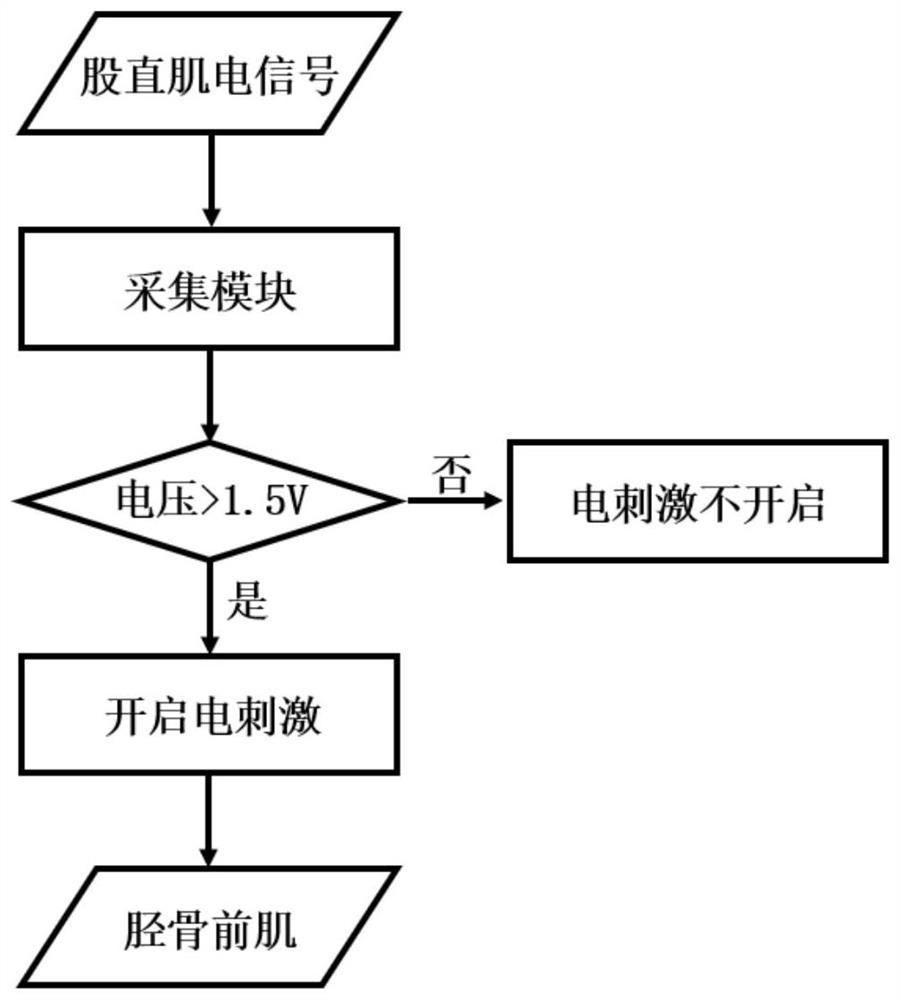

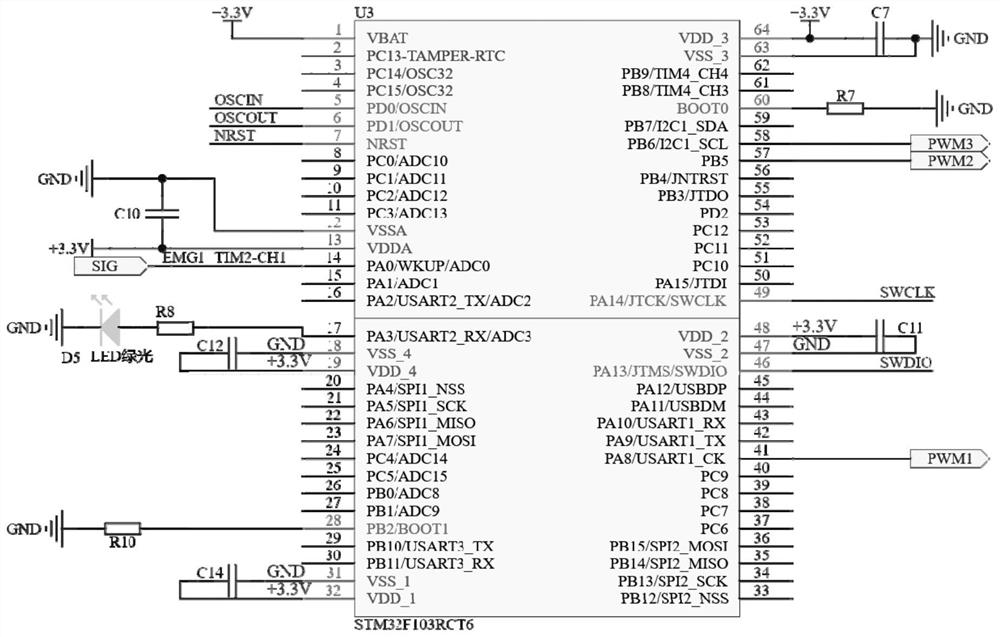

Wearable functional electrical stimulation system with electromyographic signal as control switch

PendingCN114344720AAvoid inaccuraciesEfficient fitDiagnostic recording/measuringSensorsStart timeSignal on

The embodiment of the invention discloses a wearable functional electrical stimulation system taking an electromyographic signal as a control switch, the movement of a shank is predicted by detecting the electromyographic signal on the skin surface of the thigh rectus femoris with the same time sequence as the gait of the shank, and the electromyographic signal greater than a certain threshold value is used as a switch for starting an electrical stimulation module, so that the movement of the shank is predicted. Therefore, the time sequence of pulse wave generation is controlled by the biological signal which is more fit with the consciousness of the patient, the problem of inaccuracy of the starting time of a traditional electrical stimulator is solved, muscle fatigue caused by redundant electrical stimulation is effectively avoided, and the stimulation time of the system is more efficiently fit with the walking gait of the foot drop patient.

Owner:长三角(嘉兴)纳米应用技术研究院 +1

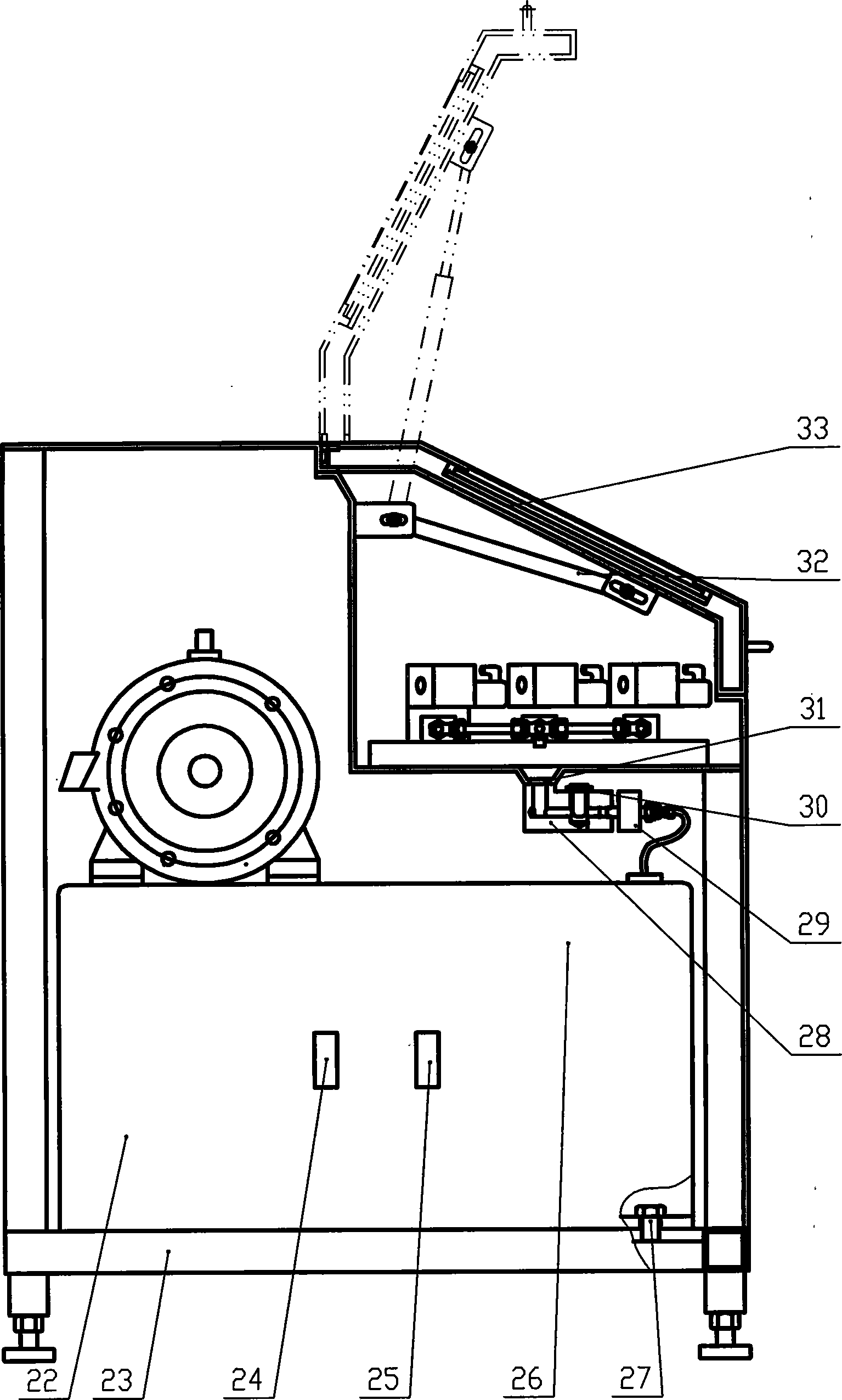

Reverse embossing machine

The invention discloses a reverse embossing machine. The reverse embossing machine comprises a machine frame, a heating device, an embossing device and a position-adjusting device. The heating device comprises a lampshade, a heat-conducting oil heating wheel used for preheating a non-embossing face and a heating lamp tube used for heating an embossing face; the heat-conducting oil heating wheel can be connected to the machine frame in a rotating mode; the heating lamp tube is installed below the heat-conducting oil heating wheel and wrapped by the lampshade; the lampshade is detachably and fixedly arranged on the machine frame; the embossing device comprises an embossing wheel used for pressing patterns and a pressure wheel used for clamping; the embossing wheel can be connected to the machine frame in a rotating mode; the pressure wheel is located above the embossing wheel and can be connected to the machine frame in a rotating mode; one end of the position-adjusting device is connected to the machine frame, the other end of the position-adjusting device is connected to the pressure wheel, and the position-adjusting device is used for adjusting the distance between the pressure wheel and the embossing wheel. The reverse embossing machine can effectively utilize hot gas and improve preheating energy efficiency.

Owner:QINGYUAN QILI SYNTHETIC LEATHER

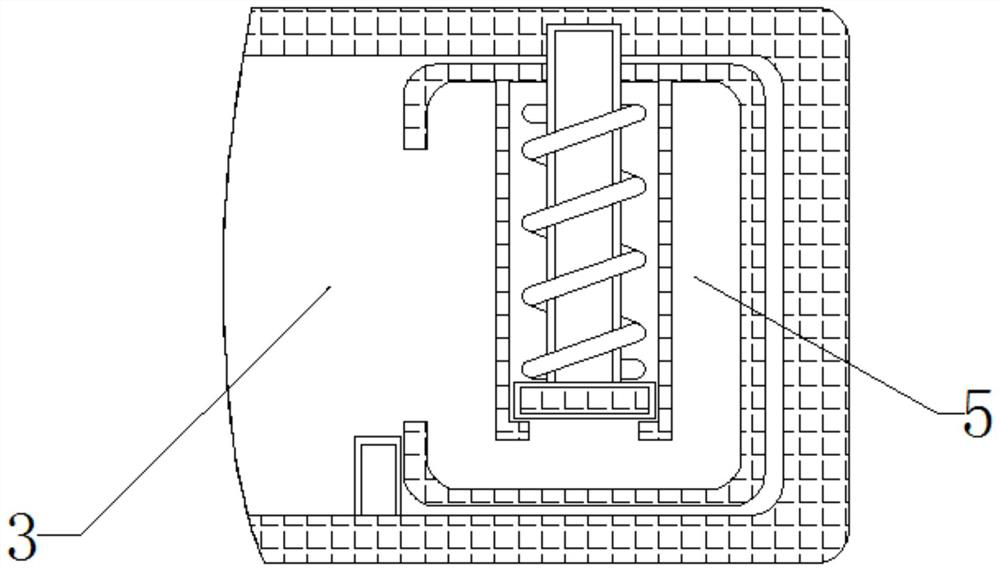

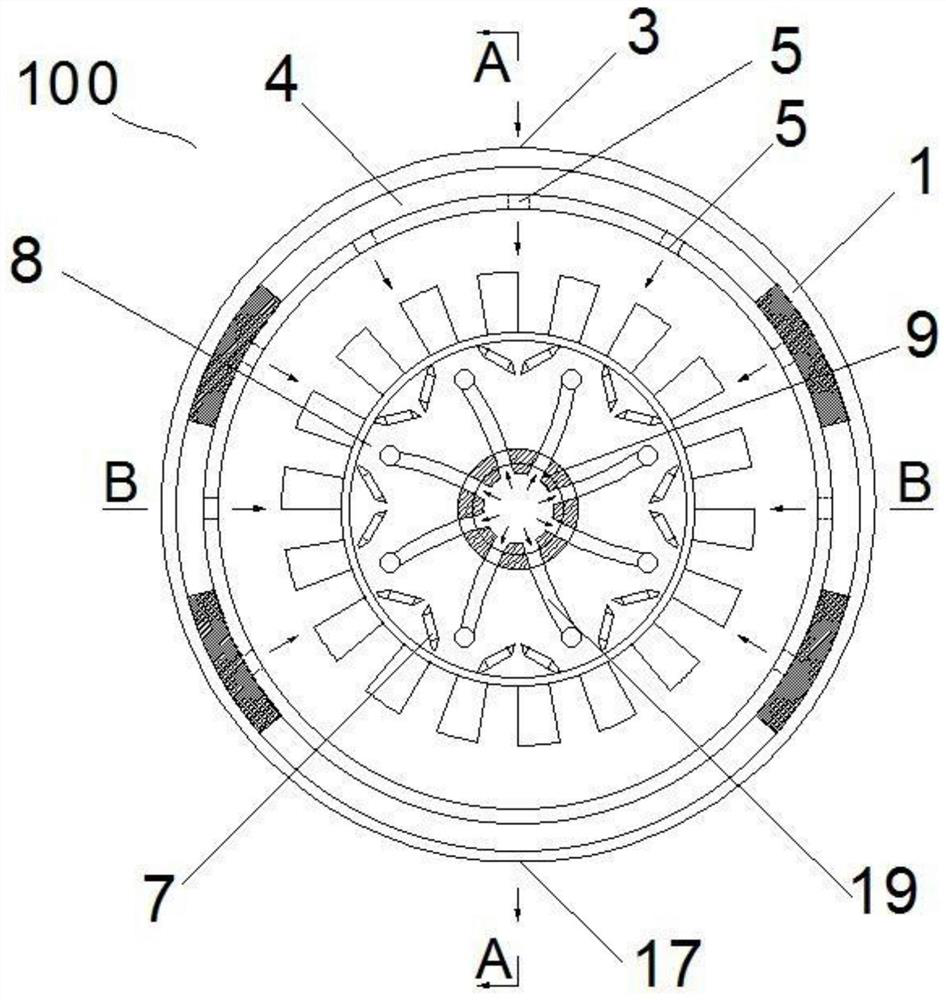

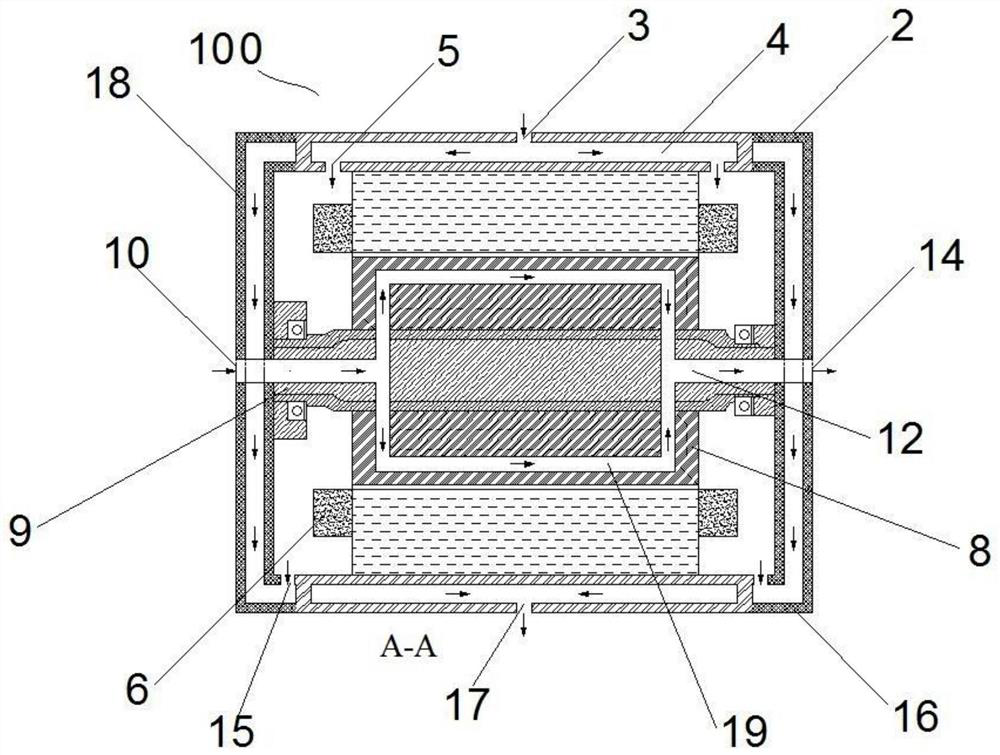

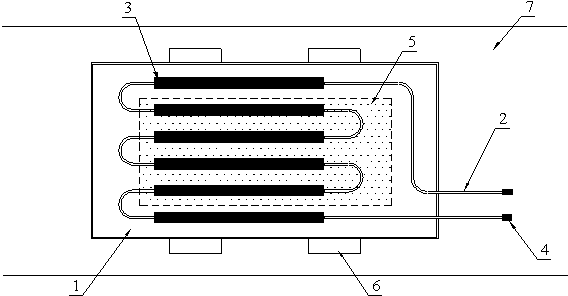

Motor cooling oil way structure

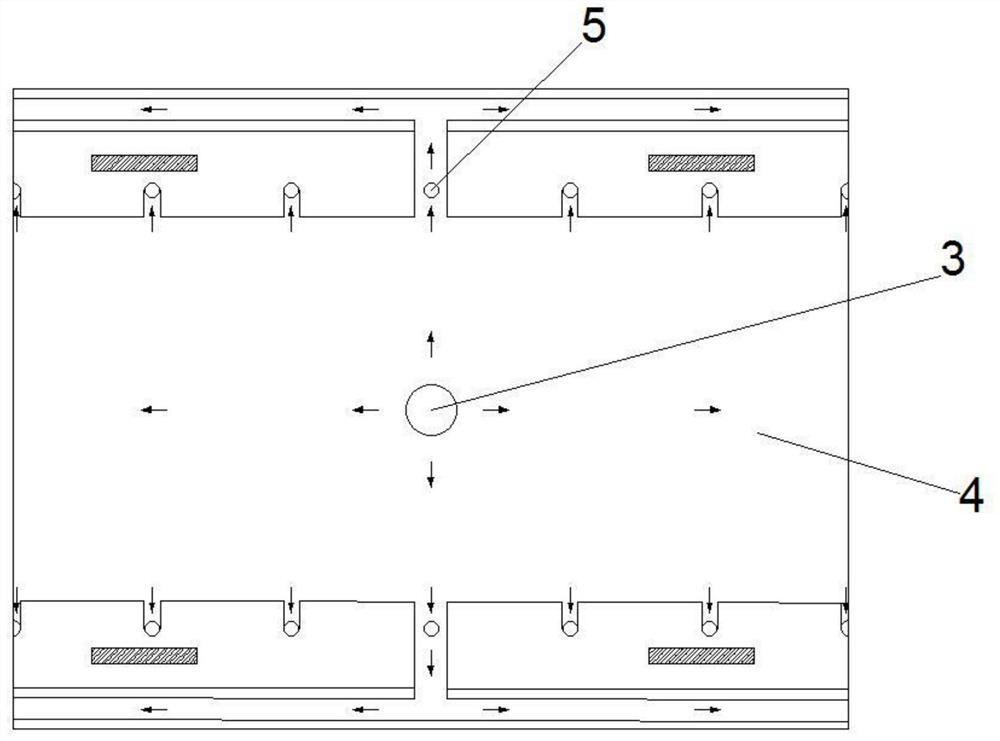

ActiveCN112865397AImprove cooling effectEfficient take awayElectric machinesCooling/ventillation arrangementThermodynamicsElectric machine

The invention discloses a motor cooling oil way structure. The motor cooling oil way structure comprises a shell oil way, two first cooling oil ways and a second cooling oil way; the shell oil way is arranged in the shell wall of a motor shell; two first cooling oil ways are arranged at the two ends of a rotating shaft of a motor respectively; the second cooling oil way is arranged in a rotor of the motor; the rotor is fixedly connected with the rotating shaft; The outer surface of the shell wall of the motor shell is provided with a first oil inlet and a first oil outlet; the inner surface of the shell wall of the motor shell is provided with a plurality of first oil injection holes and a plurality of first oil return holes; the first oil inlet, the first oil outlet, the first oil injection holes and the first oil return holes are communicated with the shell oil way; one end of each first cooling oil way is communicated with the second cooling oil way; a second oil inlet is formed in the other end of one first cooling oil way; and a second oil outlet is formed in the other end of the other first cooling oil way. The motor cooling oil way structure is good in cooling effect and low in cost; local hot spots do not exist; and oil in a gearbox is adopted as a cooling medium, so that cost is low.

Owner:JILIN UNIV

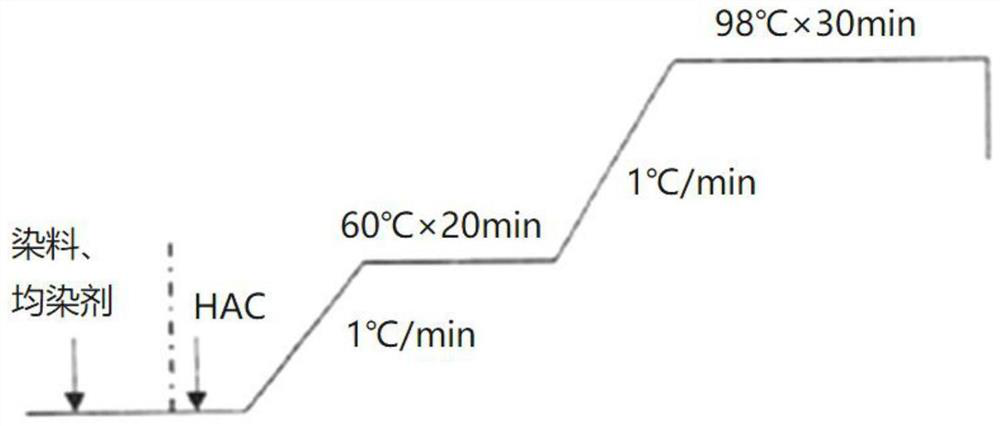

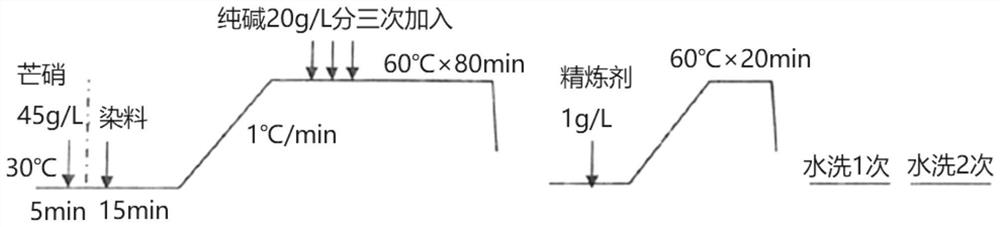

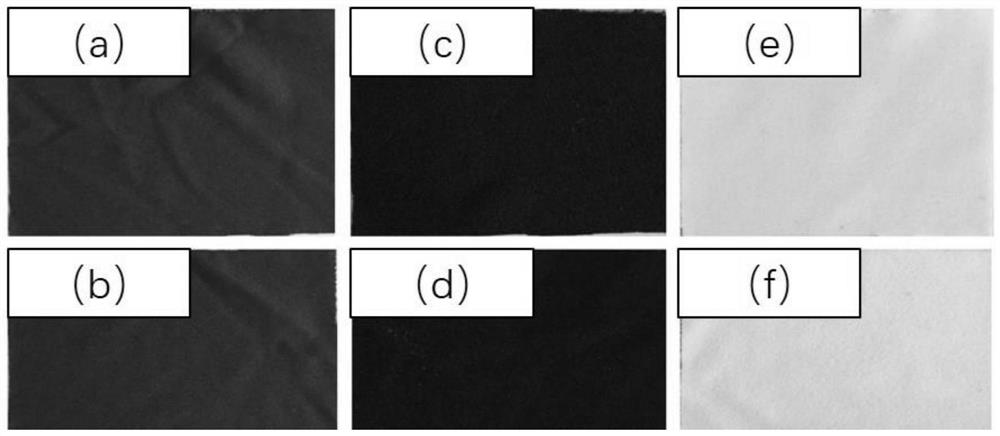

Silk protein coating solution and application thereof in surface modification of fibers or fabrics

PendingCN113106756AEasy to useHigh fitGrip property fibresVegetal fibresSurface modificationPolymer chemistry

The invention relates to a silk protein coating solution and application thereof in surface modification of fibers or fabrics. A silk protein surface modified fabric with the similar natural real silk effect, which is prepared by the invention, is obtained by finishing the silk protein textile coating solution in a setting and finishing link, wherein the silk protein textile coating solution mainly comprises silk protein, a structure inducer and water. The chemical fiber fabric or the non-natural real silk type natural fabric subjected to surface modification by using the silk protein in the silk protein-containing textile coating solution not only has the similar natural real silk effect and the functions of protecting the skin, resisting aging and the like, but also meets the daily wearing and washing stability requirements.

Owner:ZHEJIANG CATHAYA INT CO LTD +1

A kind of anti-dehydration gecko hydrogel application and preparation method thereof

ActiveCN106267316BWith self-cleaning effectEfficient fitAbsorbent padsBandagesPolyvinyl alcoholPolyglutamic acid

The invention belongs to the field of medical high-molecular materials, and discloses a dehydration-prevention gecko hydrogel application and a preparation method thereof. The hydrogel application is prepared from the following raw materials in parts by weight: 0.25-1.55 parts of polyvinyl alcohol, 0.04-0.27 part of polyglutamic acid, 0.03-0.35 part of tannic acid, 0.05-0.12 part of glutaraldehyde having a mass concentration of 2-10 percent, 10-23 parts of water, and the balance of an acidity regulating agent. The gecko hydrogel application can adsorb and closely attach the surface of human skin since the application surface has tissues similar to the nano-sucker structure of gecko feet so as to effectively prevent falling off and effectively prevent hydrogel from being dehydrated. The hydrogel application can be well attached to skin to achieve a self-cleaning effect, and is applicable to wound protection and treatment of physical therapy, burning, scalds and traumatic wounds by cold application.

Owner:NANJING SHINEKING BIOTECH CO LTD

Tire burst-proof rubber

InactiveCN106085307AEfficient fitImprove cold and heat resistanceMineral oil hydrocarbon copolymer adhesivesOil/fat/wax adhesivesHeat resistancePolystyrene

The invention discloses tire burst-proof rubber. The tire burst-proof rubber comprises the following components in percentage by mass: 20-35% of a main polymer, 30-60% of tackifying resin, 10-25% of a diluting agent and 0.2-0.5% of an additive, and a special polystyrene-isoprene-styrene block copolymer is used as a main raw material. Through grafting modification, the rubber has 10 or more branched chains, and has efficient attaching performance, and through a special tackifier, cold resistance and heat resistance are improved, and a burst-proof function is effectively realized.

Owner:东莞市成铭胶粘剂有限公司

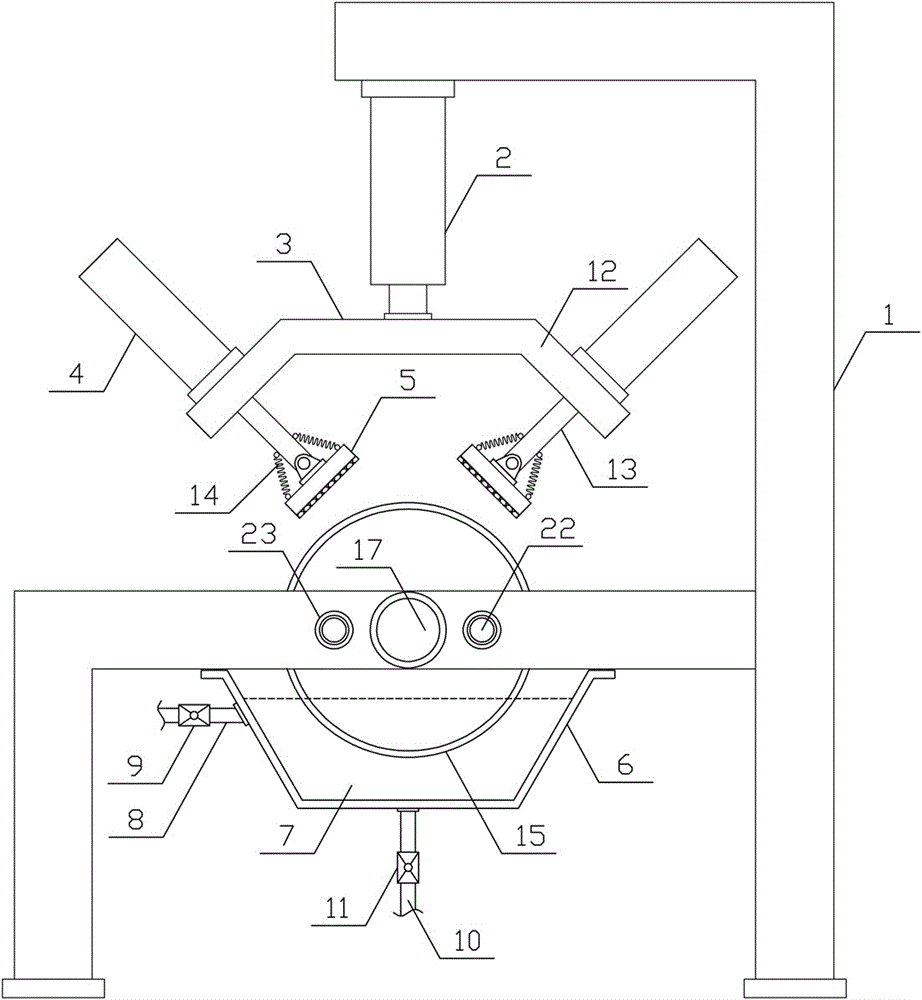

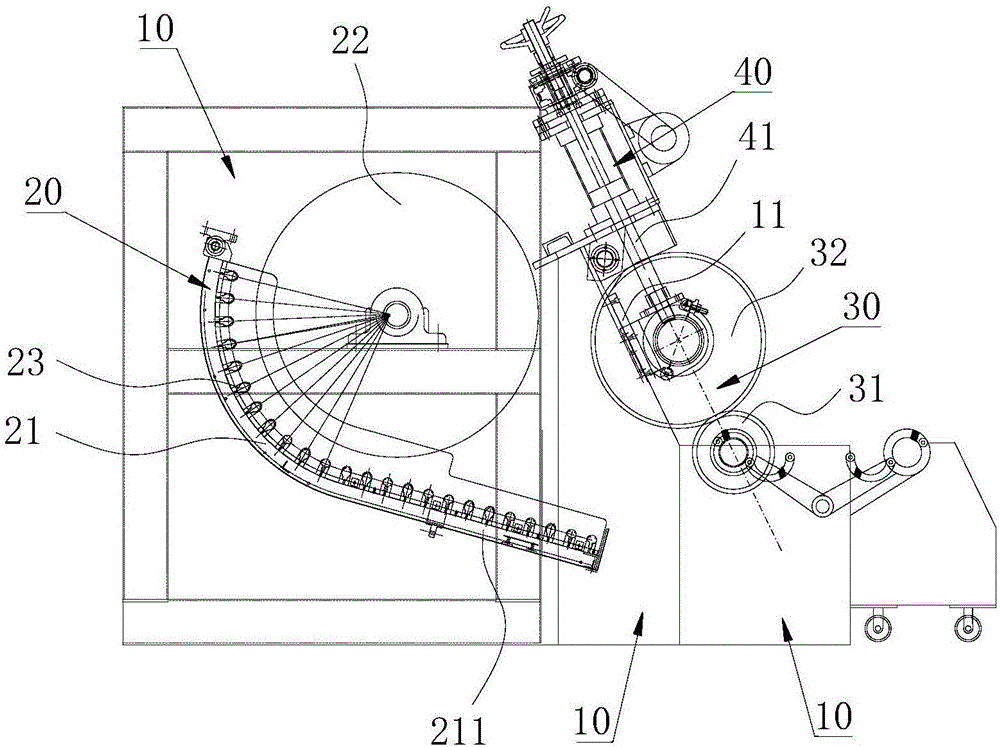

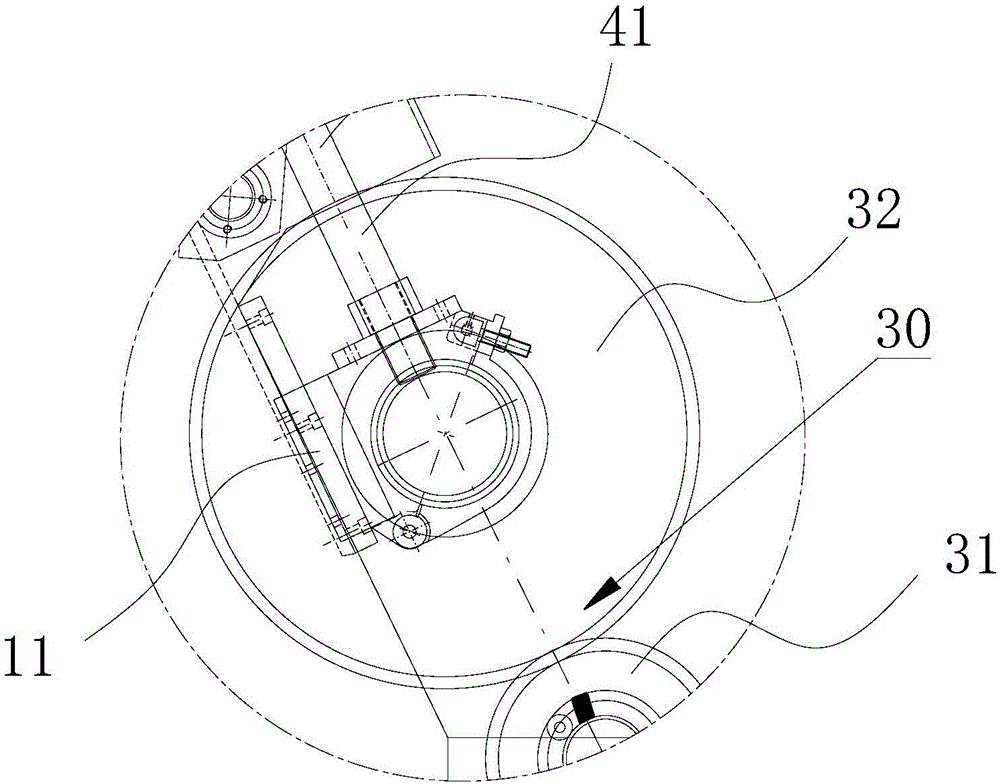

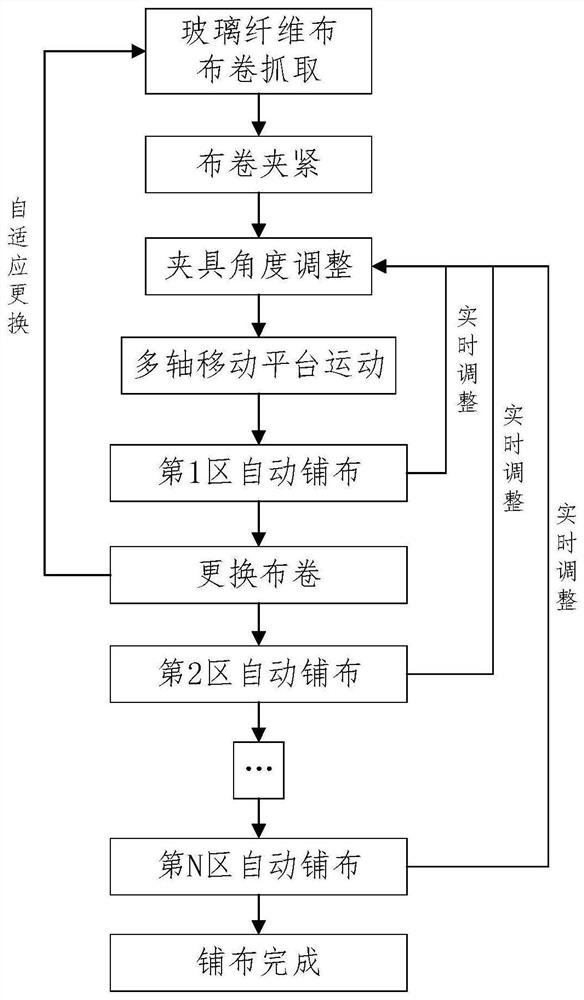

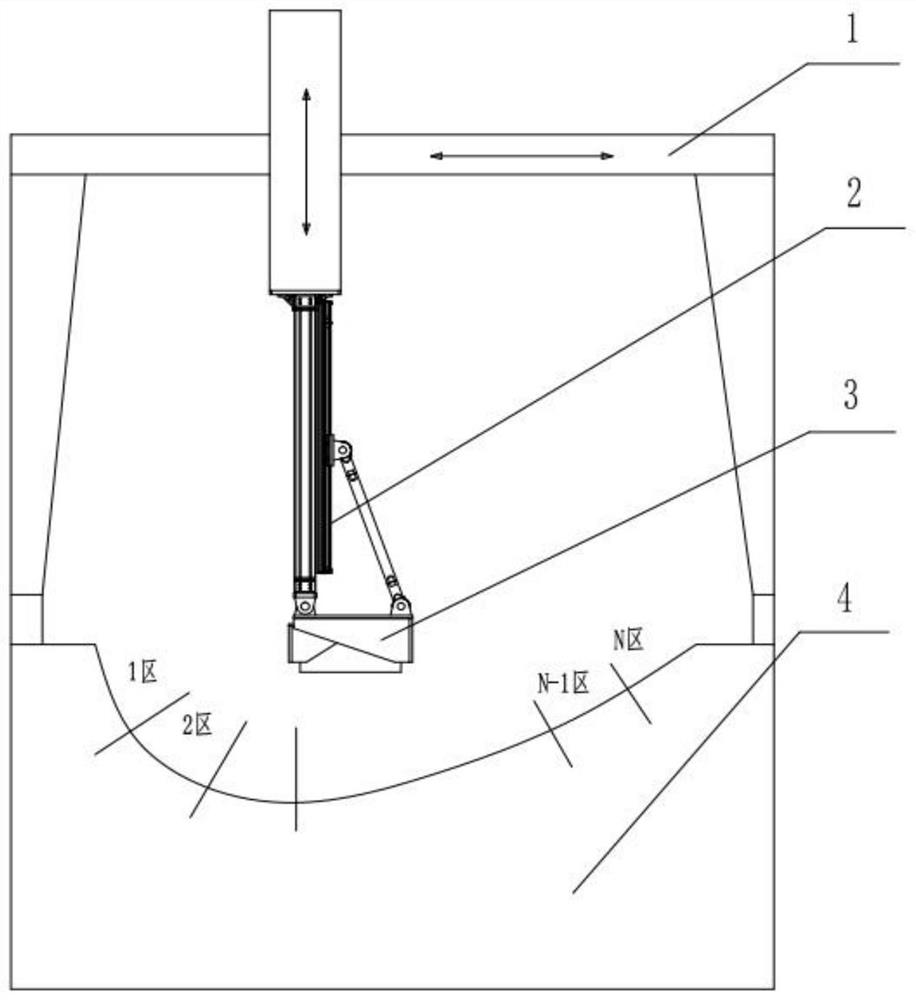

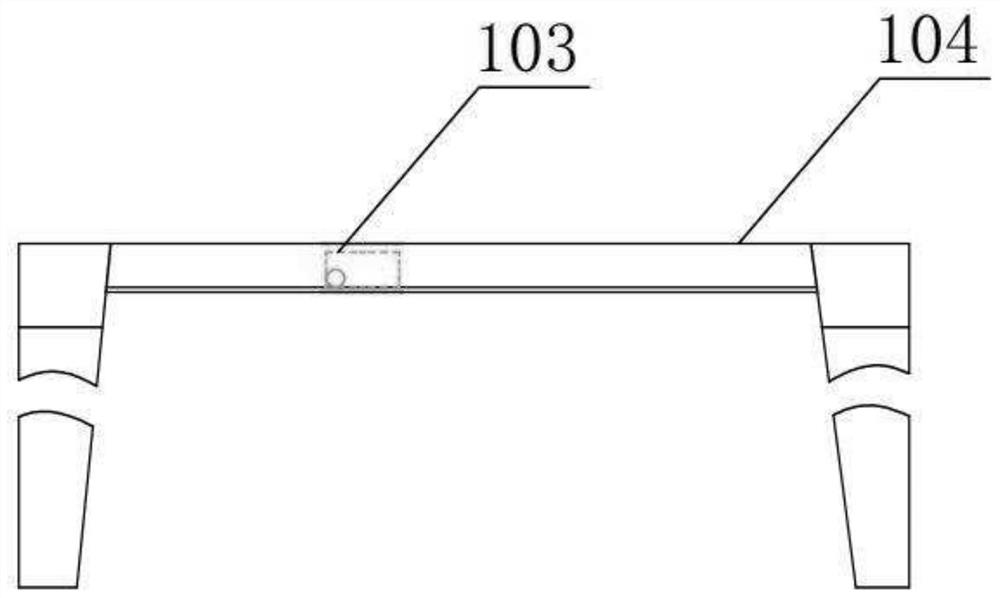

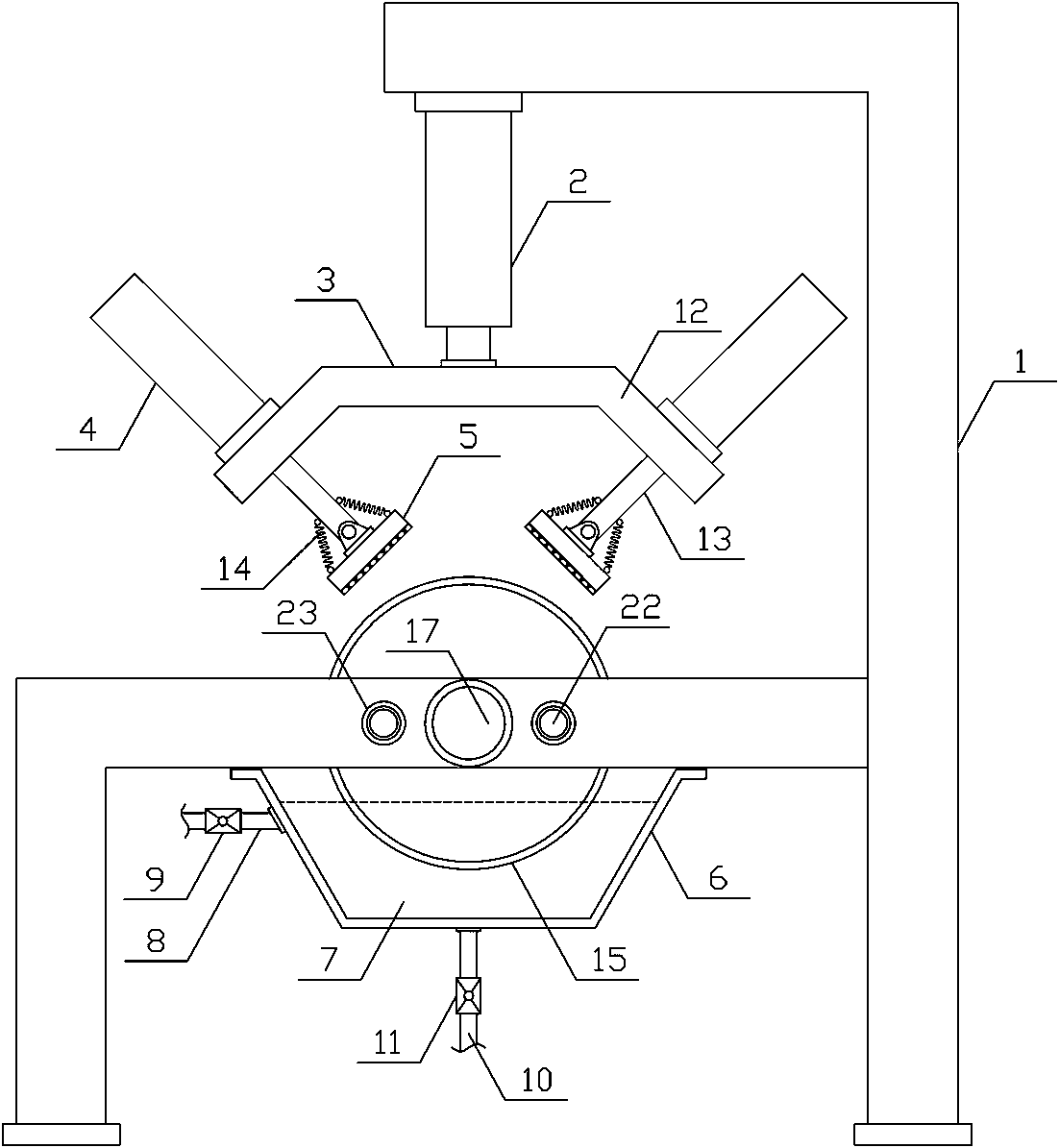

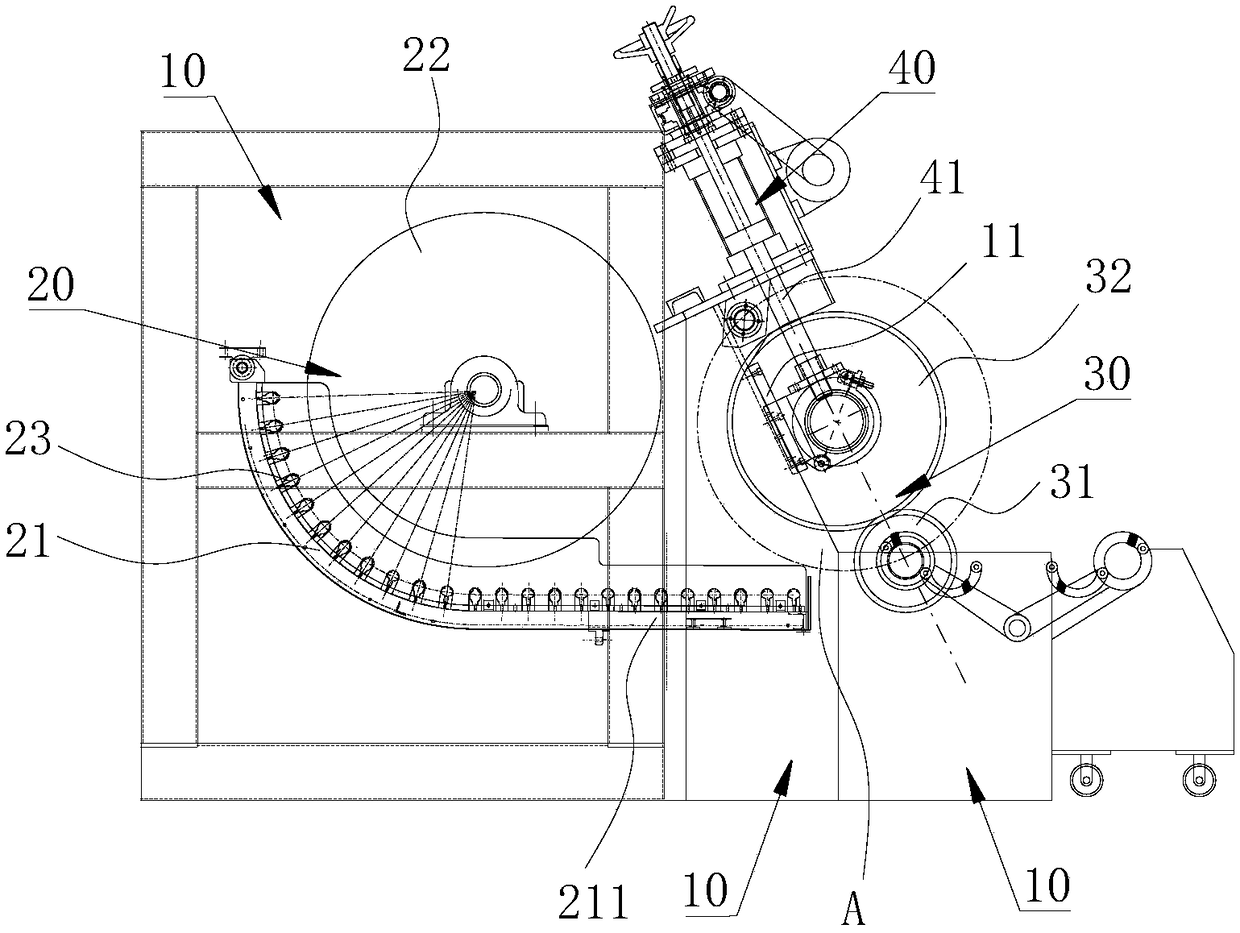

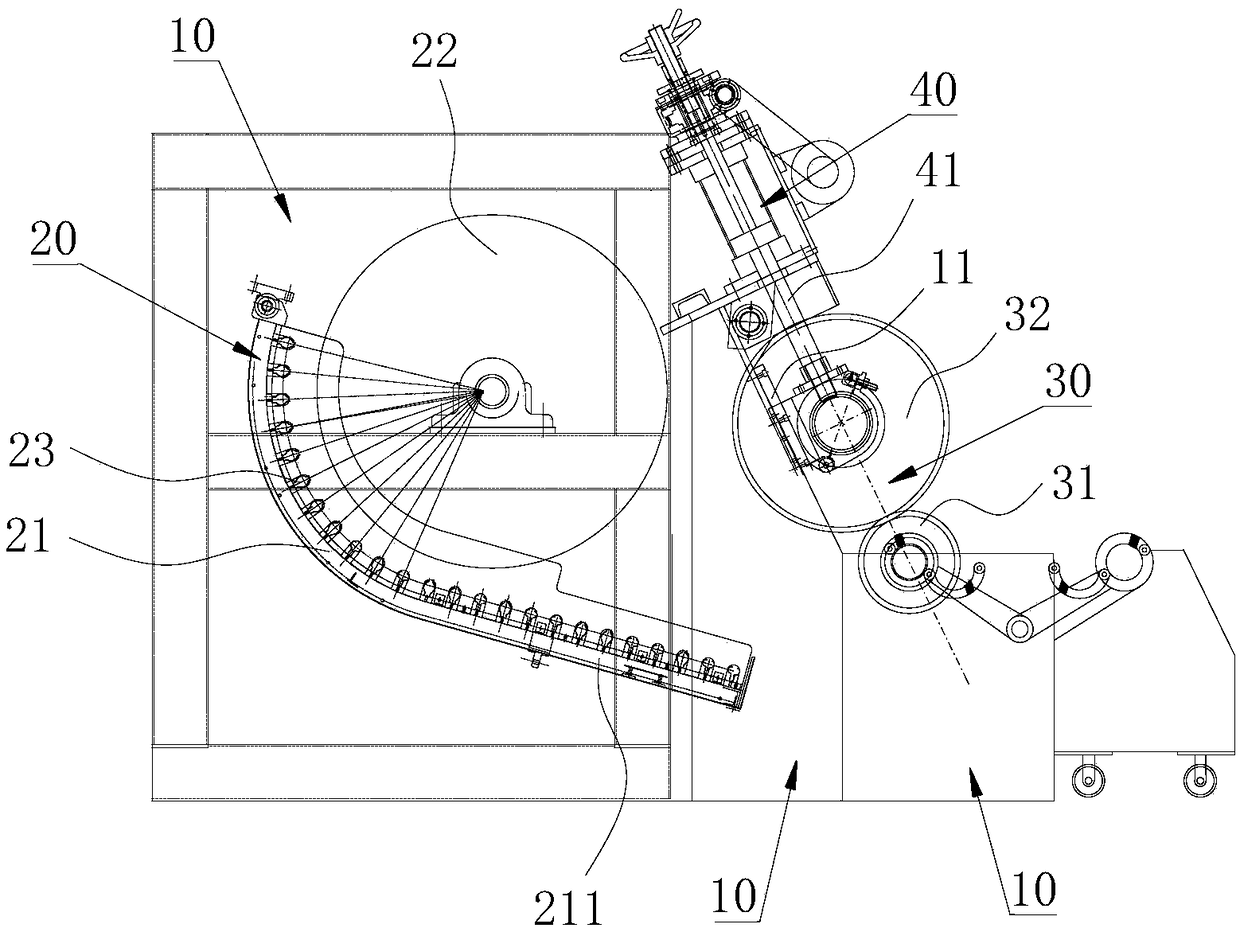

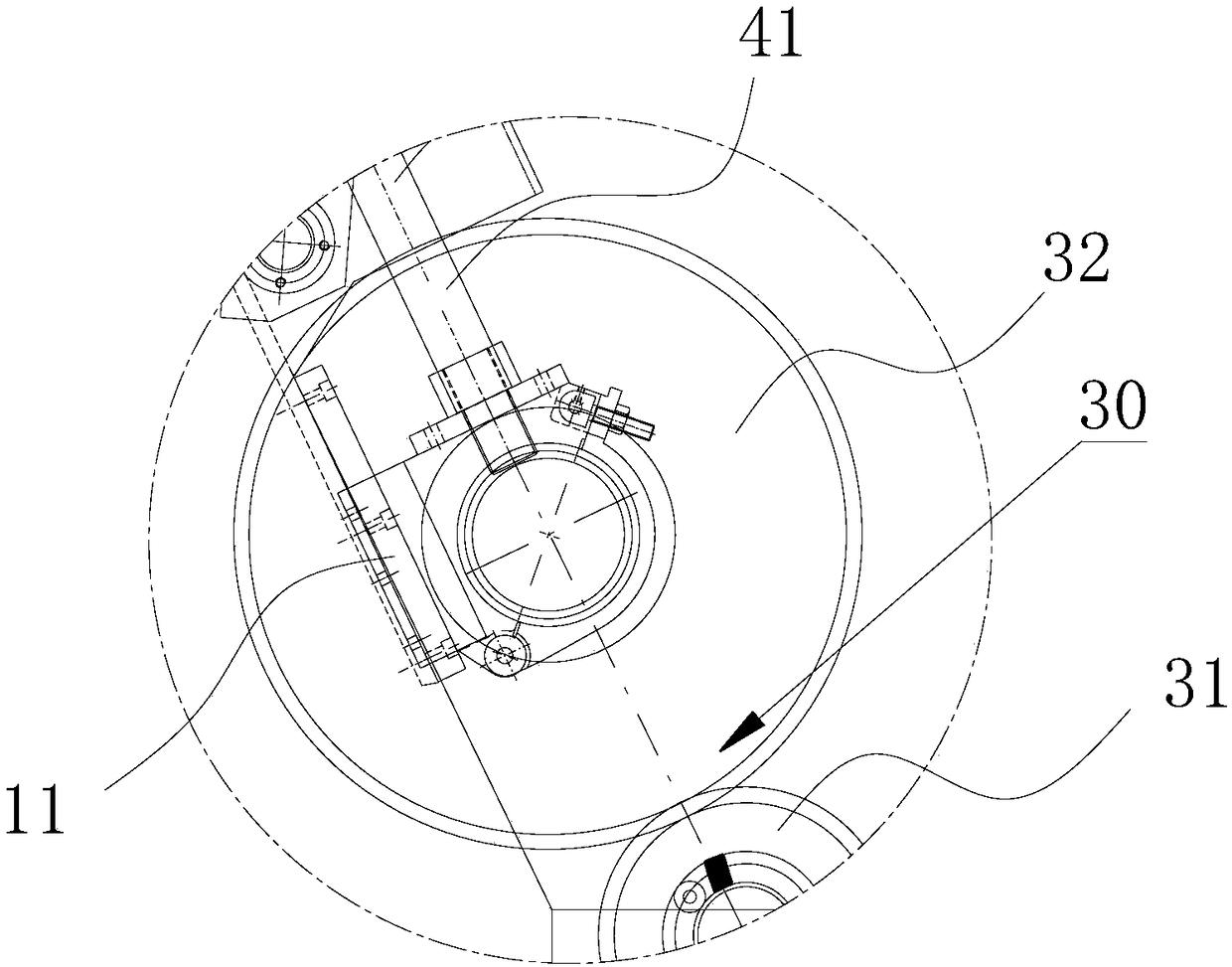

Laid cloth roll clamping mechanism for wind power blade mold and application of laid cloth roll clamping mechanism

PendingCN113134984AAddresses issues such as step-by-step changesRealize adaptive clampingGlass fiberEngineering

The invention discloses a laid cloth roll clamping mechanism for a wind power blade mold and application of the laid cloth roll clamping mechanism. The laid cloth roll clamping mechanism comprises a multi-axis moving platform, a laid cloth clamp supporting and adjusting mechanism and a glass fiber cloth roll clamp. One end of the laid cloth clamp supporting and adjusting mechanism is connected with the glass fiber cloth roll clamp, and the other end of the laid cloth clamp supporting and adjusting mechanism and the multi-axis moving platform are fastened. According to the mechanism, switching is carried out according to the models of different blades, laid cloth is attached to the curved surface of the blade mold, the problems of gradual changing of molded surfaces in the axis direction of the blades and the like are solved, an application method of the mechanism solves the problems that at present, laid cloth rolls are rapidly switched and molded surfaces are not attached, in the actual production process, the mechanism is effectively combined with manual work, repeated work in the manual cloth laying process is shared, productivity is liberated to a great degree, and the working efficiency is improved.

Owner:GURIT TOOLING (TAICANG) CO LTD

A film coating roller cleaning mechanism

ActiveCN106076960BSmooth rotationImprove cleaning efficiencyCleaning using toolsCleaning using liquidsHydraulic cylinderMechanical equipment

Owner:浙江耀阳新材料科技有限公司

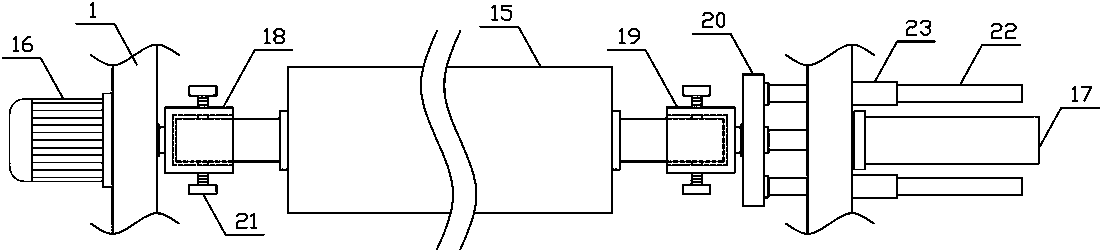

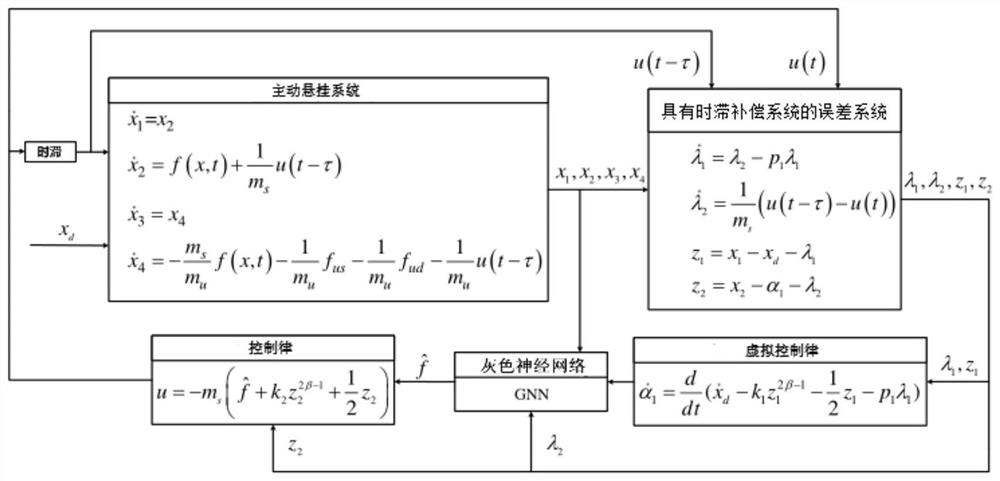

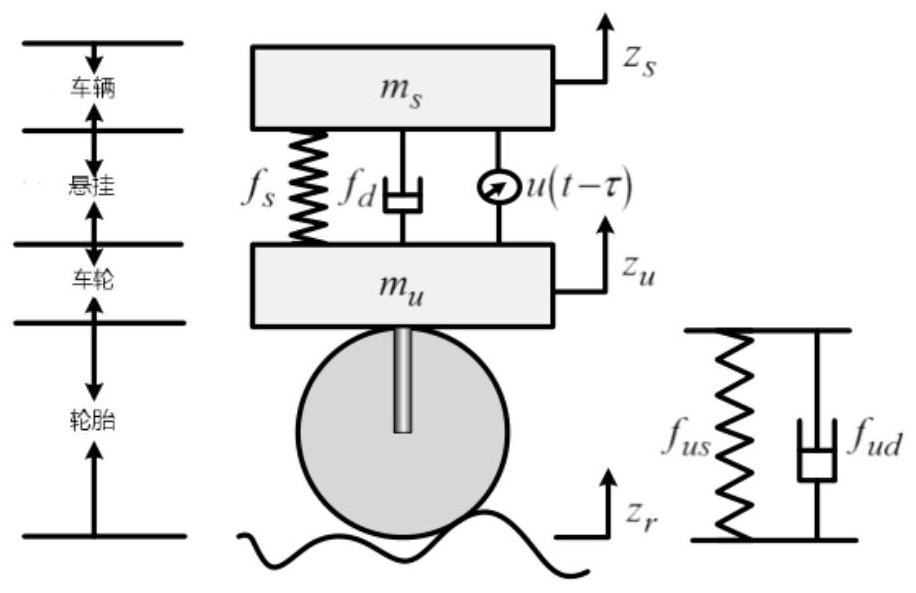

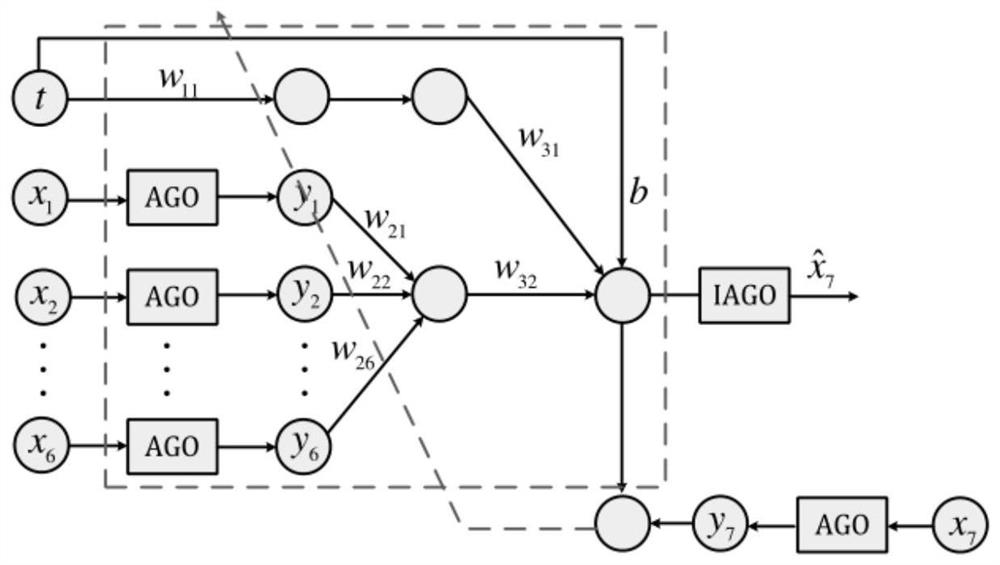

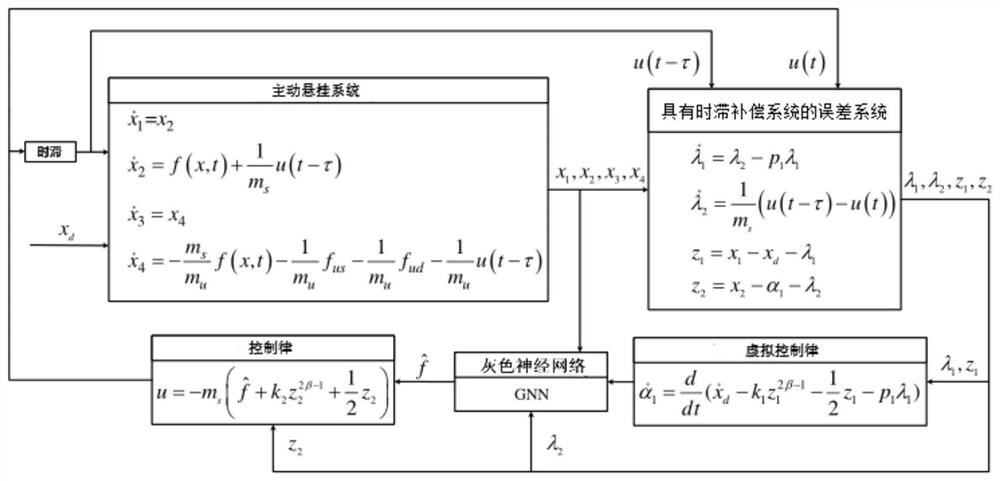

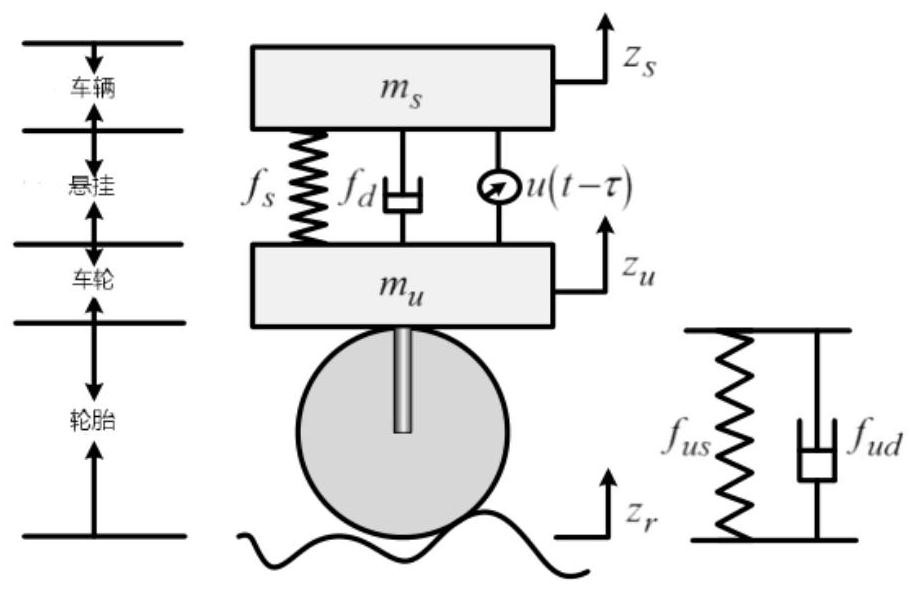

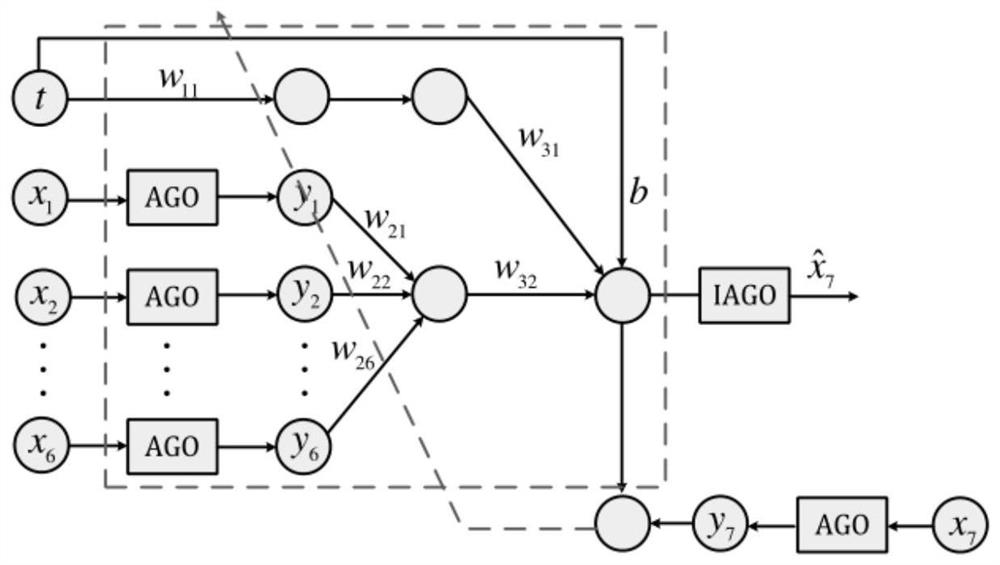

Method for realizing finite time control on nonlinear active suspension system

ActiveCN113110053ACompensation time lagImprove fitting accuracySustainable transportationAdaptive controlVirtual controlNon linearite

The invention discloses a method for realizing finite time control on a nonlinear active suspension system, which comprises the following steps of: firstly, establishing an active suspension system model equation, and analyzing a space state and a performance index needing to be improved of the active suspension system; and then establishing an error system with time delay compensation, and compensating the influence of time delay of the active suspension system through an auxiliary system; secondly, establishing a Lyapunov function relation through an error system, obtaining a virtual control law a1 and a control law u through an inversion technology, and improving corresponding performance indexes; performing training through a grey neural network to obtain an approximate nonlinear function of the compensated error system; and finally, after the control law u is used for correction, generating new smaller time lag influence of the active suspension system,repeatedly and continuously circulating the method within the finite time, therefore stable control over the active suspension system within the finite time is achieved.

Owner:GUANGDONG UNIV OF TECH

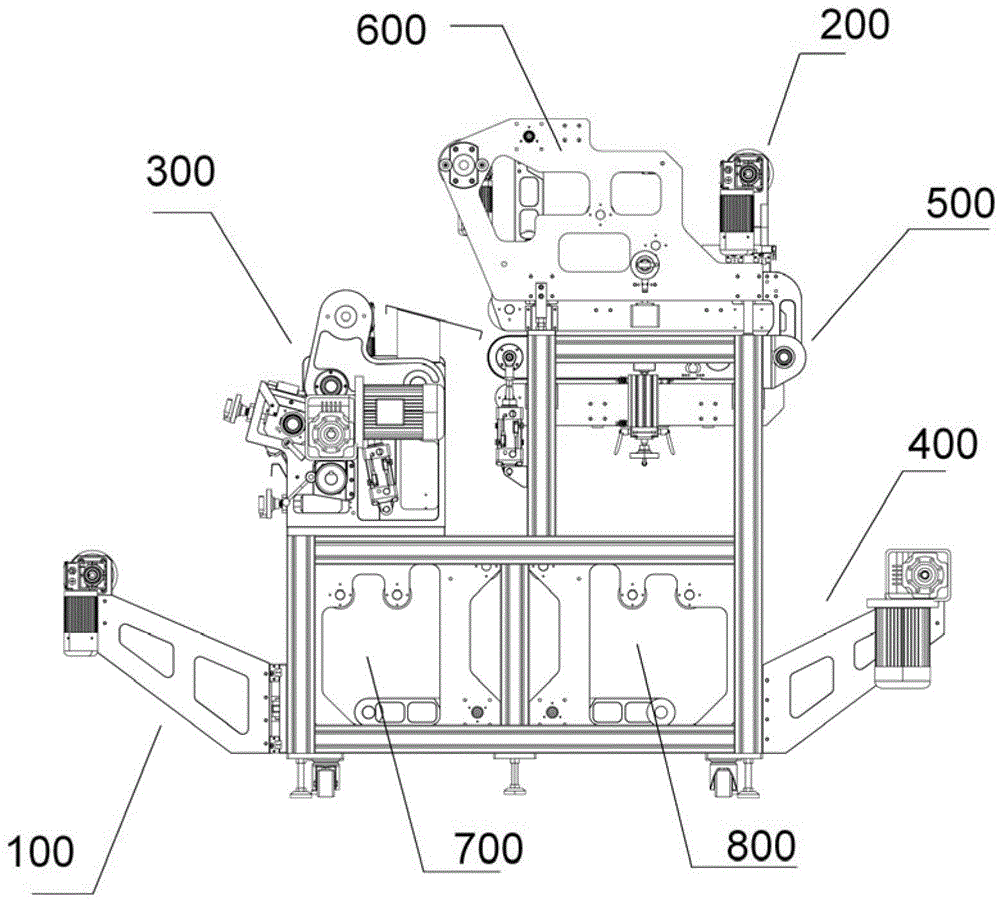

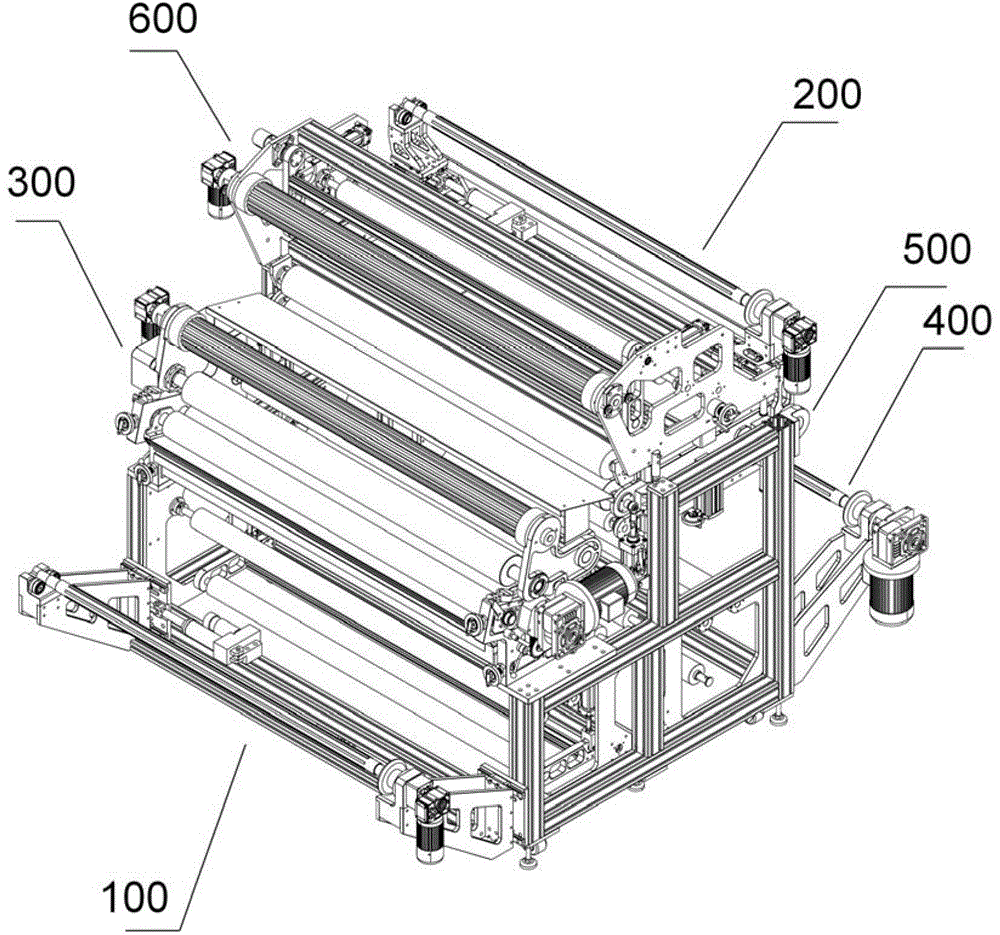

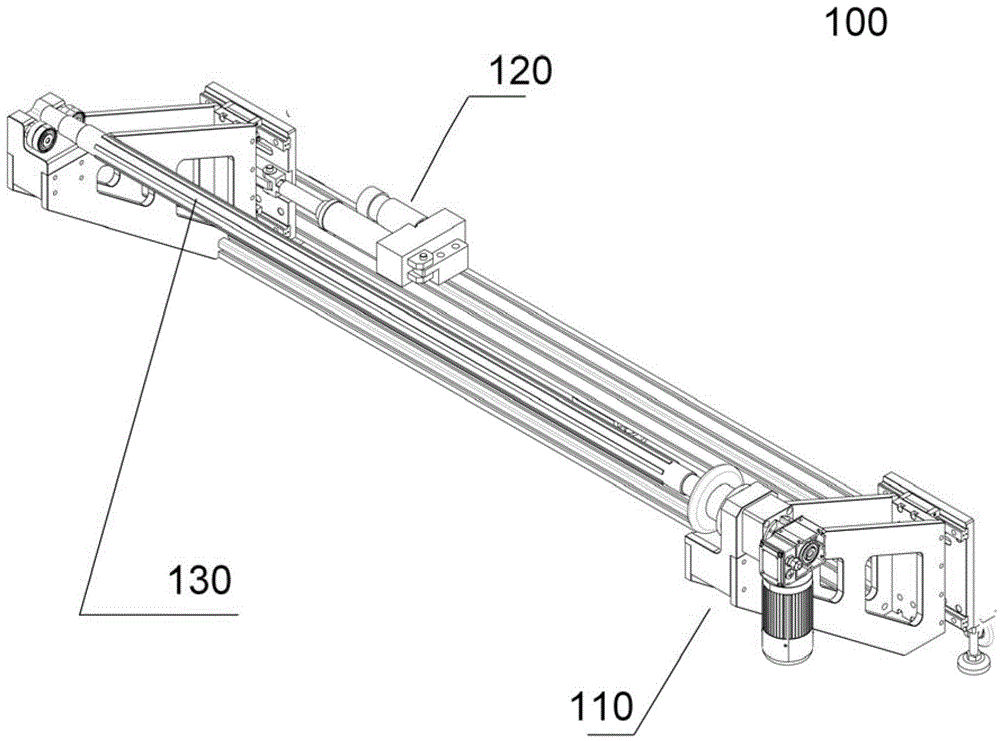

Glass lens bonding machine and glass lens automatic bonding method

The invention discloses an automatic glass lens laminating method which includes the steps: S1) loading a product A and a product B onto a vehicle component, and detecting the planar angles of the product A and the product B by a collimator; S2) grabbing the product A by a material taking suction head, detecting and adjusting the consistency of the planar angles of the product A and the product Bby the aid of a two-dimensional angle measuring device; S3) starting a light source, and simultaneously starting a monitoring camera; S4) dispensing glue at a fitting position on the product B by a UV(ultraviolet) dispensing and curing component; S5) driving the grabbed product A to fit with the fitting position on the product B by the grabbing component, and monitoring fitting conditions by themonitoring camera in fitting until a light interference ring is generated between the product A and the product B and the parallelism between the product A and the product B meets requirements; S6) detecting fitting pressure by a pressure feedback device in real time in fitting; S7) performing curing treatment by the UV dispensing and curing component.

Owner:SUZHOU MAKING INTELLIGENT EQUIP CO LTD

A Method for Realizing Finite Time Control of Nonlinear Active Suspension System

ActiveCN113110053BImprove fitting accuracyEfficient fitSustainable transportationAdaptive controlTime lagTime delays

Owner:GUANGDONG UNIV OF TECH

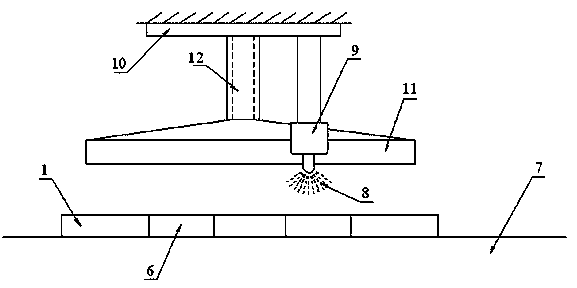

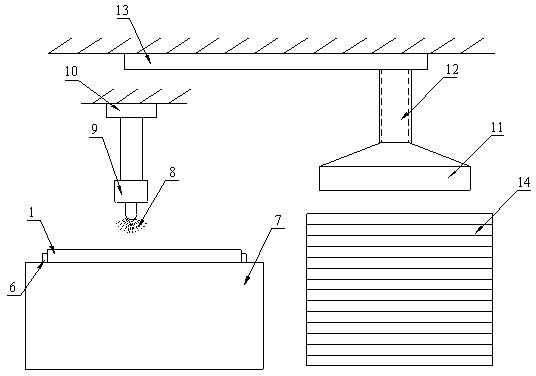

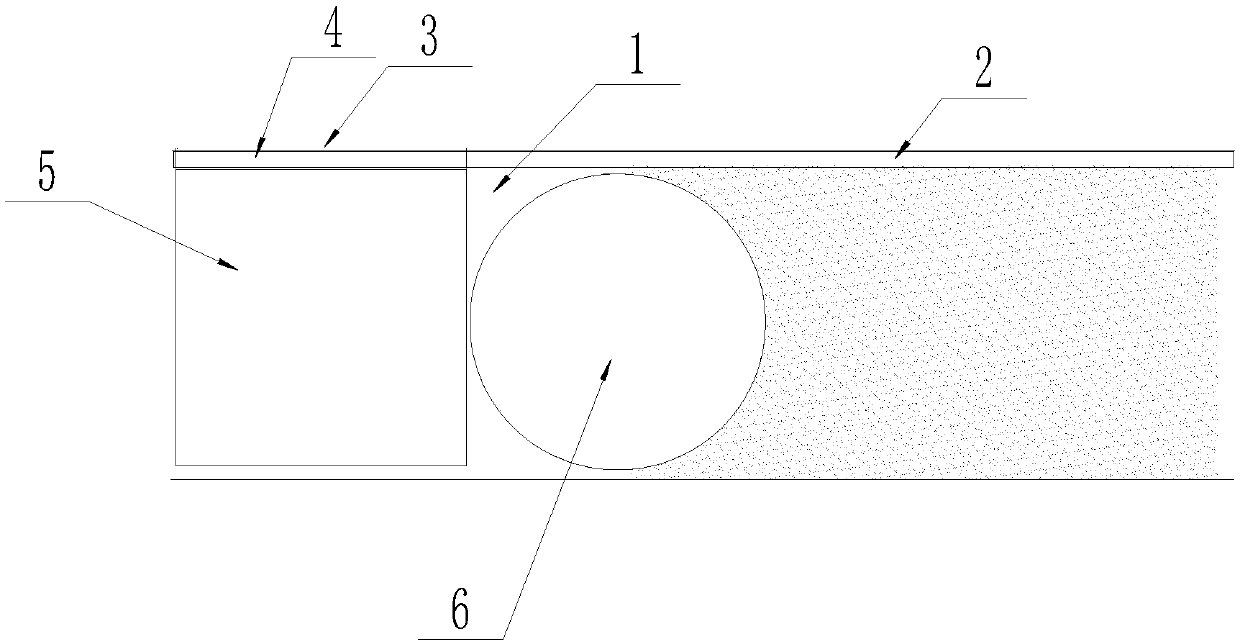

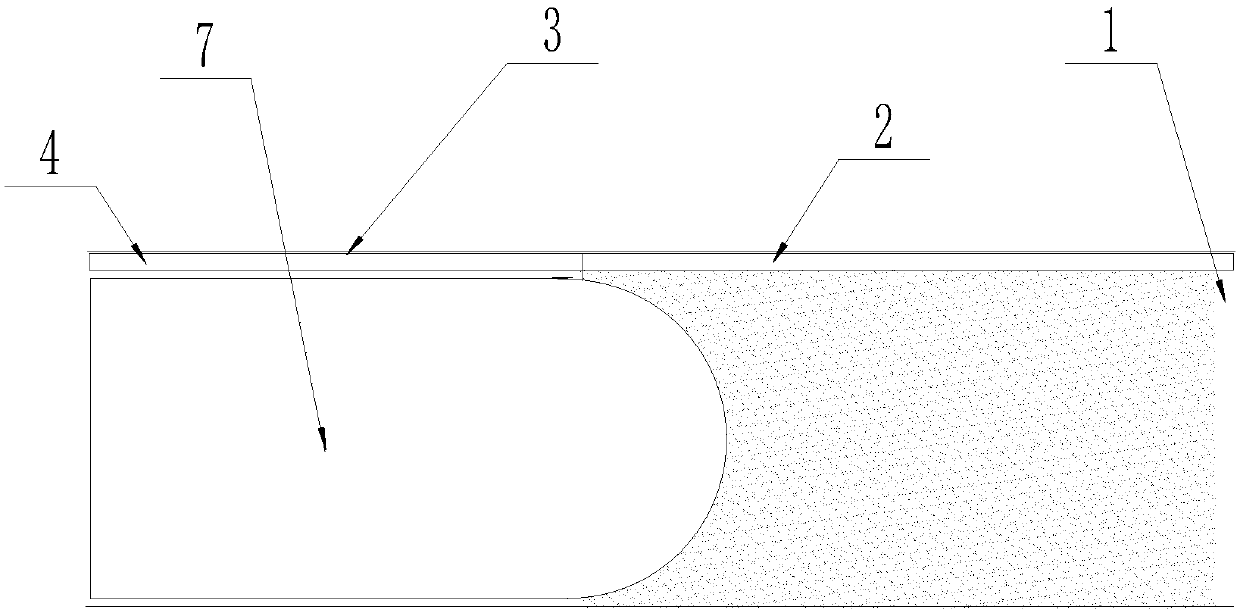

Device and method for sticking vacuum heat-insulating plate

InactiveCN102179990BStructure has no effectStructural influenceLaminationLamination apparatusEngineeringMechanical engineering

The invention relates to the technical field of refrigerators, in particular relating to a device for sticking a vacuum heat-insulating plate, and the device provided by the invention comprises a streamline platform (7) used for containing a refrigerator side plate, a spray gun head (9) arranged above the streamline platform (7), and a picking-up and pressing device (11) capable of picking up the vacuum heat-insulating plate from a material pile and moving and pressing the vacuum heat-insulating plate at a sticking position. A sticking method comprises the following steps: putting the refrigerator side plate provided with a condenser in a sticking manner on the streamline platform (7); evenly dispersing a proper amount of glue material on the sticking position on the refrigerator side plate by utilizing the spray gun head (9); picking up and moving the vacuum heat-insulating plate from the material pile to the sticking position by utilizing the picking-up and pressing device (11); pressing the vacuum heat-insulating plate by utilizing the picking-up and pressing device (11); and releasing by the picking-up and pressing device (11), thus finishing the sticking of the vacuum heat-insulating plate. According to the invention, the production efficiency is high, the heat-insulating property of the product is ensured, the refrigerator side plate is not influenced, and wide popularization and application values are achieved.

Owner:HISENSE RONSHEN GUANGDONG REFRIGERATOR

GCL vertical laying structural member and construction process thereof

PendingCN109930558AEfficient vertical layingImprove the quality of laying GCLFoundation engineeringMarine site engineeringArchitectural engineeringBuilding construction

The invention discloses a GCL vertical laying structural member and a construction process thereof. The construction process comprises excavating a groove for laying a vertical anti-seepage special GCL composite component layer; using a GCL composite component vertical laying device or a specially made lifting appliance to place the vertical anti-seepage special GCL composite component layer in the groove; rolling and attaching the laid vertical anti-seepage special GCL composite component layer to a groove wall by a rolling roller; lowering a joint box or a two-in-one joint box, wherein an overlapping area can be rolled for many times to ensure tight fit and improve the anti-seepage performance of the overlapping area. The GCL vertical laying structural member and the construction processthereof have the beneficial effects that the GCL vertical laying construction process is researched and developed according to practical engineering conditions such as the property of flexible anti-seepage coiled materials such as GCL, the construction characteristics of vertical laying and the construction characteristics of an anti-seepage wall, mechanized construction is adopted, the operationis simple and safe, and the construction efficiency is high.

Owner:TIANJIN ZHONGLIANGELIN SCI & TECH DEV CO LTD

An automatic loading and patching device for hydrogel slides

The invention belongs to the technical field of micro-nano patch, and provides an automatic loading and patching device for hydrogel slides. There is a slide positioning mechanism on the rack, and a slide magazine and a film tearing mechanism are arranged on the workbench along the sliding direction of the slide rack, and a slide feeding mechanism is provided under the slide magazine; It is equipped with a placement robot arm and a material placement table, the material placement table is located on the side of the patch end of the electric cylinder, the placement robot arm is located between the electric cylinder and the material placement table, and the working shaft end of the placement robot arm The part is equipped with a pick-and-place mechanism to realize the pick-and-place of the material. The present invention can realize the automatic processing of hydrogel loading, tearing off the release film, and lamination of the tablet on the hydrogel carrier, so that the patching efficiency and patching quality are greatly improved, and there is no damage to the patch during the processing. The sanitation of the material is affected, so as to ensure that the produced patch products meet the production requirements of hygienic standards.

Owner:SHANDONG NOVOSHINE OPTOELECTRONICS CO LTD

A fully automatic bread machine

The invention discloses a full-automatic fruit-added bread machine, which belongs to the technical field of food processing equipment. A baking timing shaft is fixedly installed on the left side, and a function button is fixedly installed on the left side of the bread machine main body and located on the side of the baking timing shaft, and the top of the bread machine main body is opened and penetrated with a fruit drop port . Through the delicate design, the present invention adopts the combination of fruit extrusion terminals, fixed connection plates, and fixed telescopic mechanisms, which is convenient to solve the problem that the existing fruit bread machine generally chops the fruit manually during the processing process, and the machine cannot cut the fruit. The problem of cutting fruit into granules can be achieved by the combination of the above structures, so that the equipment can actively squeeze the fruit into pieces, without manual chopping, avoiding manual waste of time cutting fruit, and effectively improving the use effect of the bread machine.

Owner:湖南大业食品有限公司

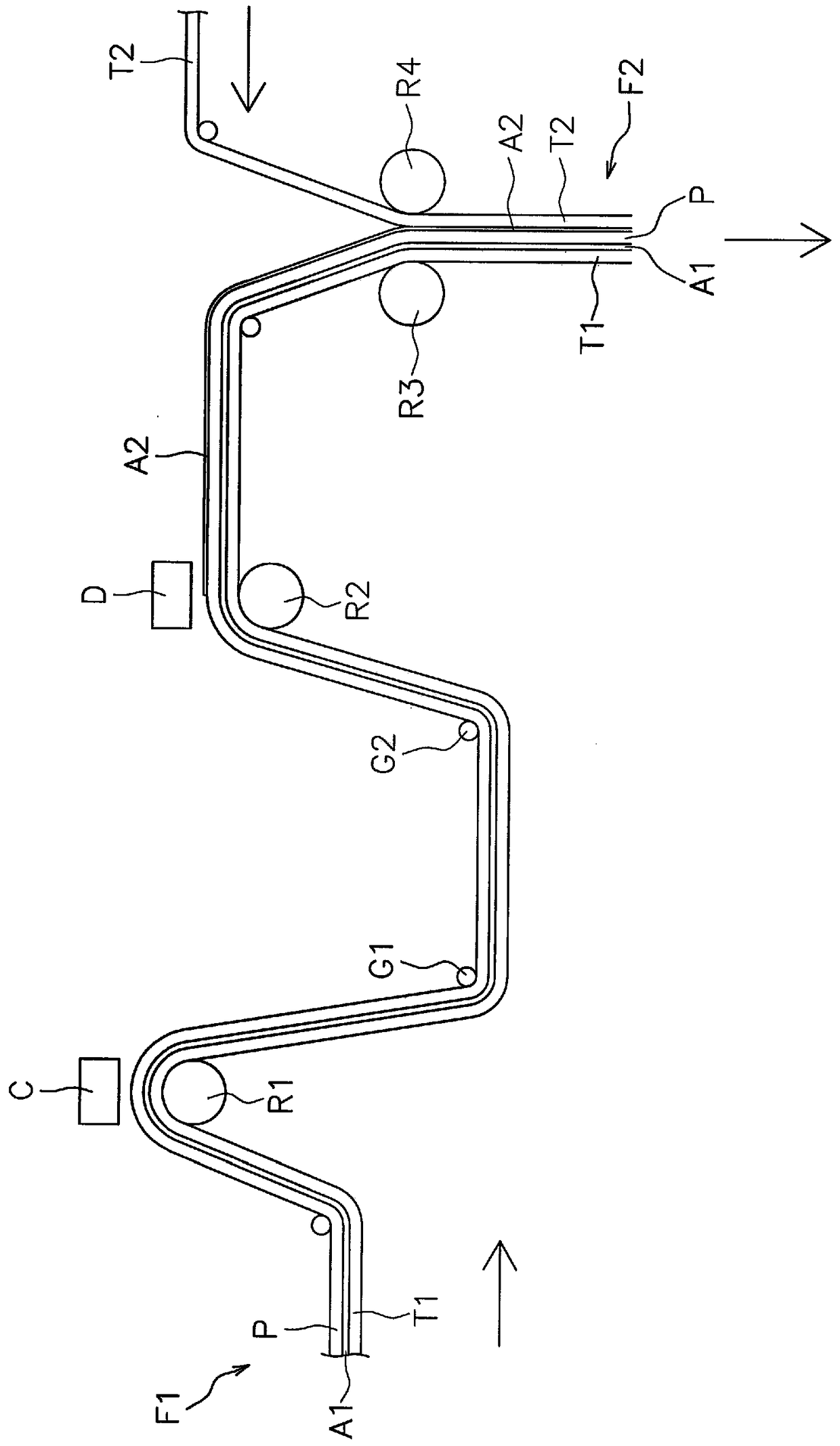

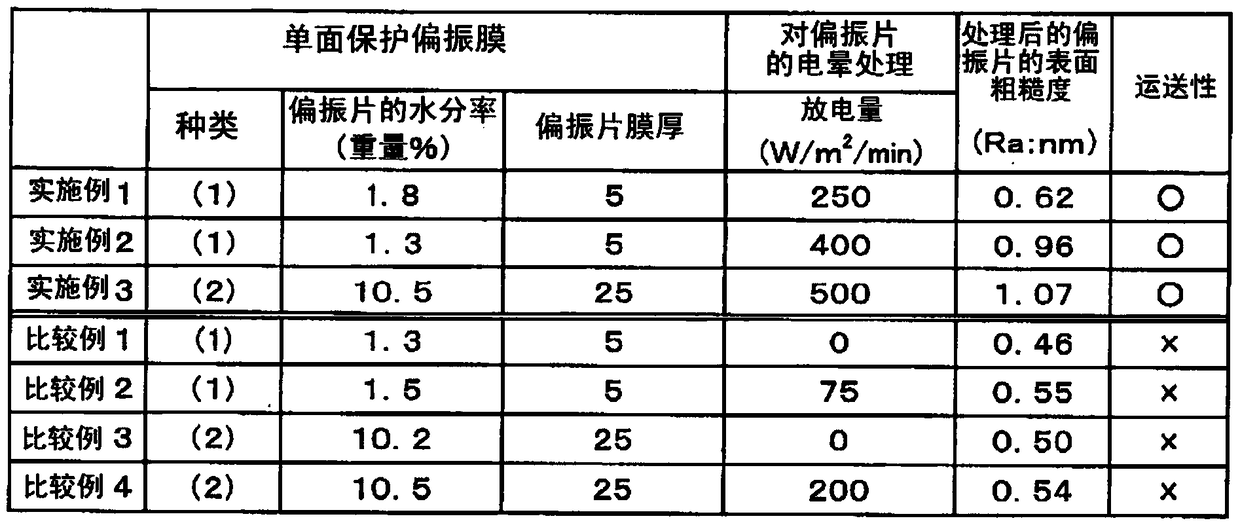

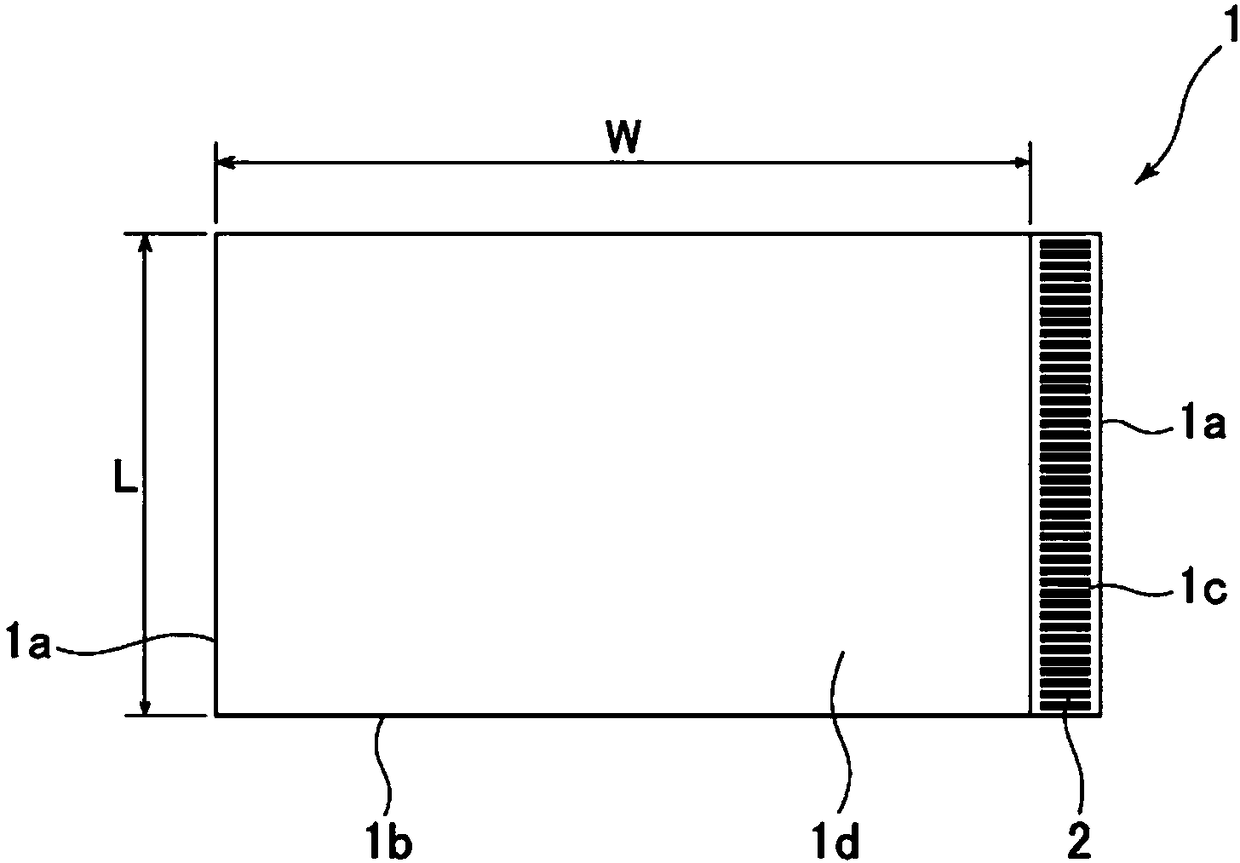

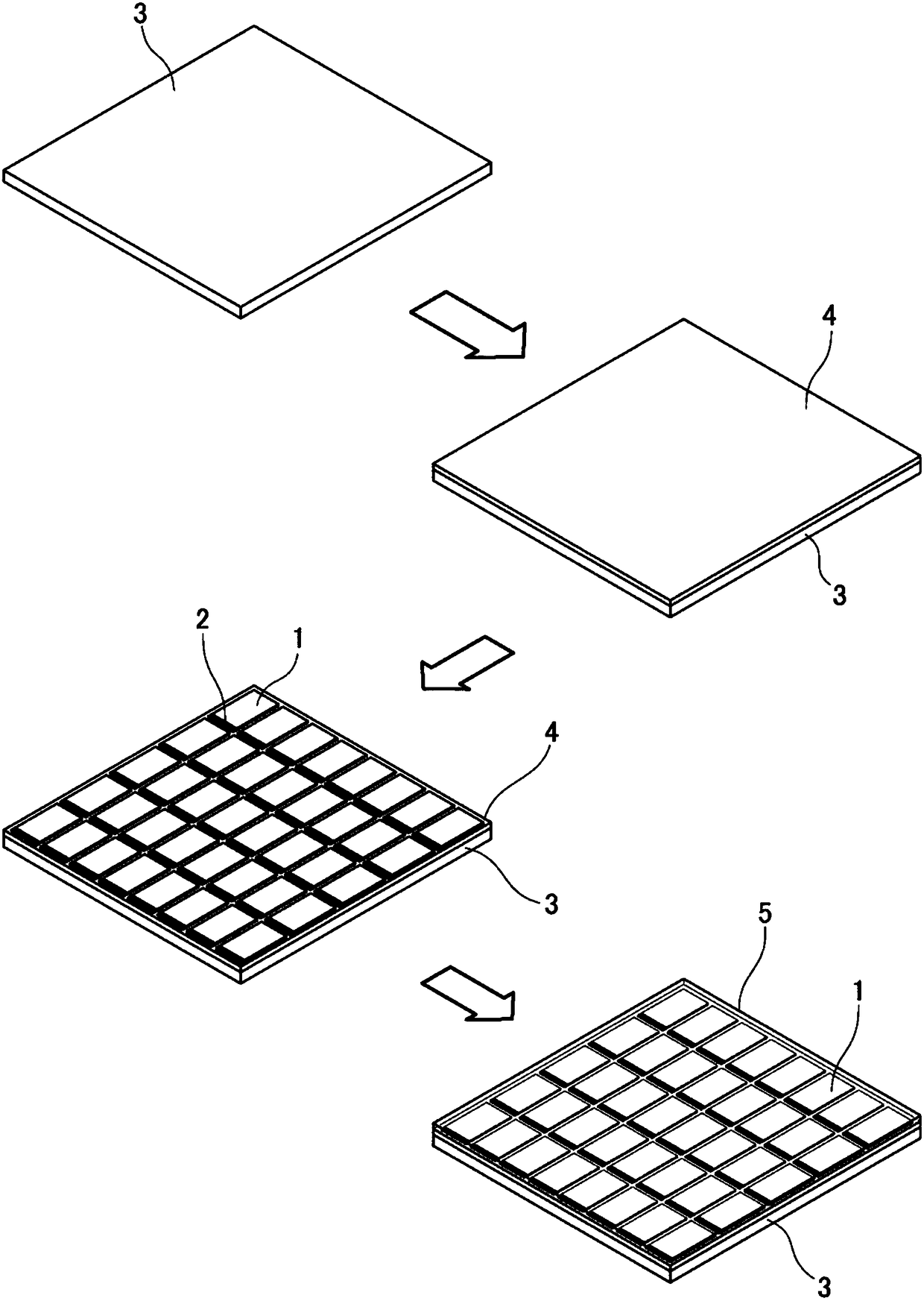

Manufacturing method of polarizing film

ActiveCN104854490BEfficient preparationImprove fitLamination ancillary operationsLayered product treatmentTectorial membraneAdhesive

This polarizing film production method is characterized by having: (1) a step in which an activation process is conducted on a polarizer having a moisture content of not more than 11 wt% so as to provide a surface roughness (Ra) of 0.6 nm or higher; (2) a step in which the polarizer is conveyed while the surface of the activated polarizer is in contact with a guide roll; (3) a step in which an adhesive is applied to the polarizer and / or a transparent protective film; and (4) a step in which the polarizer and the transparent protective film are bonded together via the adhesive. This production method enables a polarizing film to be produced with good conveying properties.

Owner:NITTO DENKO CORP

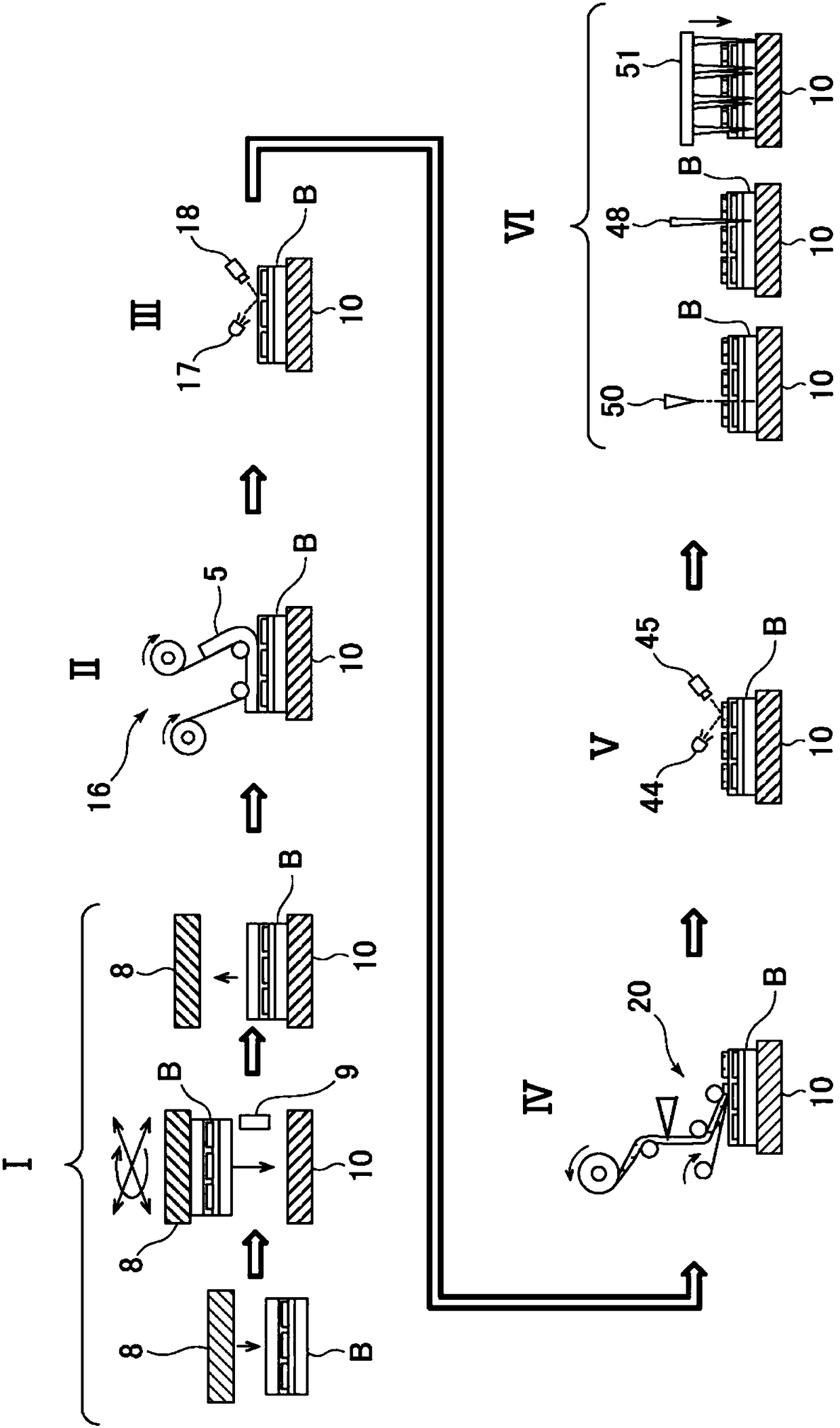

Method for attaching optical film sheet to optical display unit

ActiveCN105474293BEfficient fitEasy to adjustPolarising elementsNon-linear opticsEngineeringOptical membrane

The method of the present invention uses: a unit assembly motherboard (B), which vertically arranges a plurality of optical display units on a base material in a state in which the side with a terminal portion is located in a transverse direction; an optical film laminate roll (22), It is wound with an optical film laminate on which a carrier film (21e) is bonded via an adhesive layer, the optical film having a width corresponding to the lateral width of the optical display unit except for the terminal portion. width. The method includes the steps of: conveying the unit assembly motherboard to the bonding position; feeding the optical film laminate from a roll to the bonding position; , the optical film and the adhesive layer of the released optical film laminate are sequentially formed with cuts in the transverse direction to form a plurality of optical film sheets supported on the carrier film; The optical film sheet was peeled off from the carrier film while remaining on the optical film side, and bonded sequentially to the optical display surface of each optical display unit on the unit assembly motherboard except for the terminal portion.

Owner:NITTO DENKO CORP

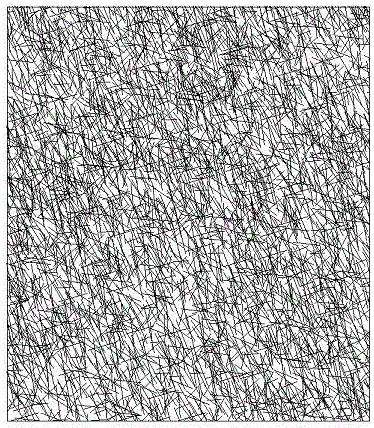

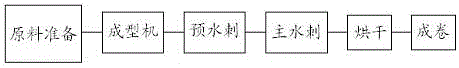

Highly flexible nonwoven fabric and method for producing the same

ActiveCN103437068BIncrease entanglementExtended service lifeNon-woven fabricsHigh pressureNonwoven fabric

Owner:HANGZHOU NBOND NONWOVENS

Reverse embossing machine

The invention discloses a reverse embossing machine. The reverse embossing machine comprises a machine frame, a heating device, an embossing device and a position-adjusting device. The heating device comprises a lampshade, a heat-conducting oil heating wheel used for preheating a non-embossing face and a heating lamp tube used for heating an embossing face; the heat-conducting oil heating wheel can be connected to the machine frame in a rotating mode; the heating lamp tube is installed below the heat-conducting oil heating wheel and wrapped by the lampshade; the lampshade is detachably and fixedly arranged on the machine frame; the embossing device comprises an embossing wheel used for pressing patterns and a pressure wheel used for clamping; the embossing wheel can be connected to the machine frame in a rotating mode; the pressure wheel is located above the embossing wheel and can be connected to the machine frame in a rotating mode; one end of the position-adjusting device is connected to the machine frame, the other end of the position-adjusting device is connected to the pressure wheel, and the position-adjusting device is used for adjusting the distance between the pressure wheel and the embossing wheel. The reverse embossing machine can effectively utilize hot gas and improve preheating energy efficiency.

Owner:QINGYUAN QILI SYNTHETIC LEATHER

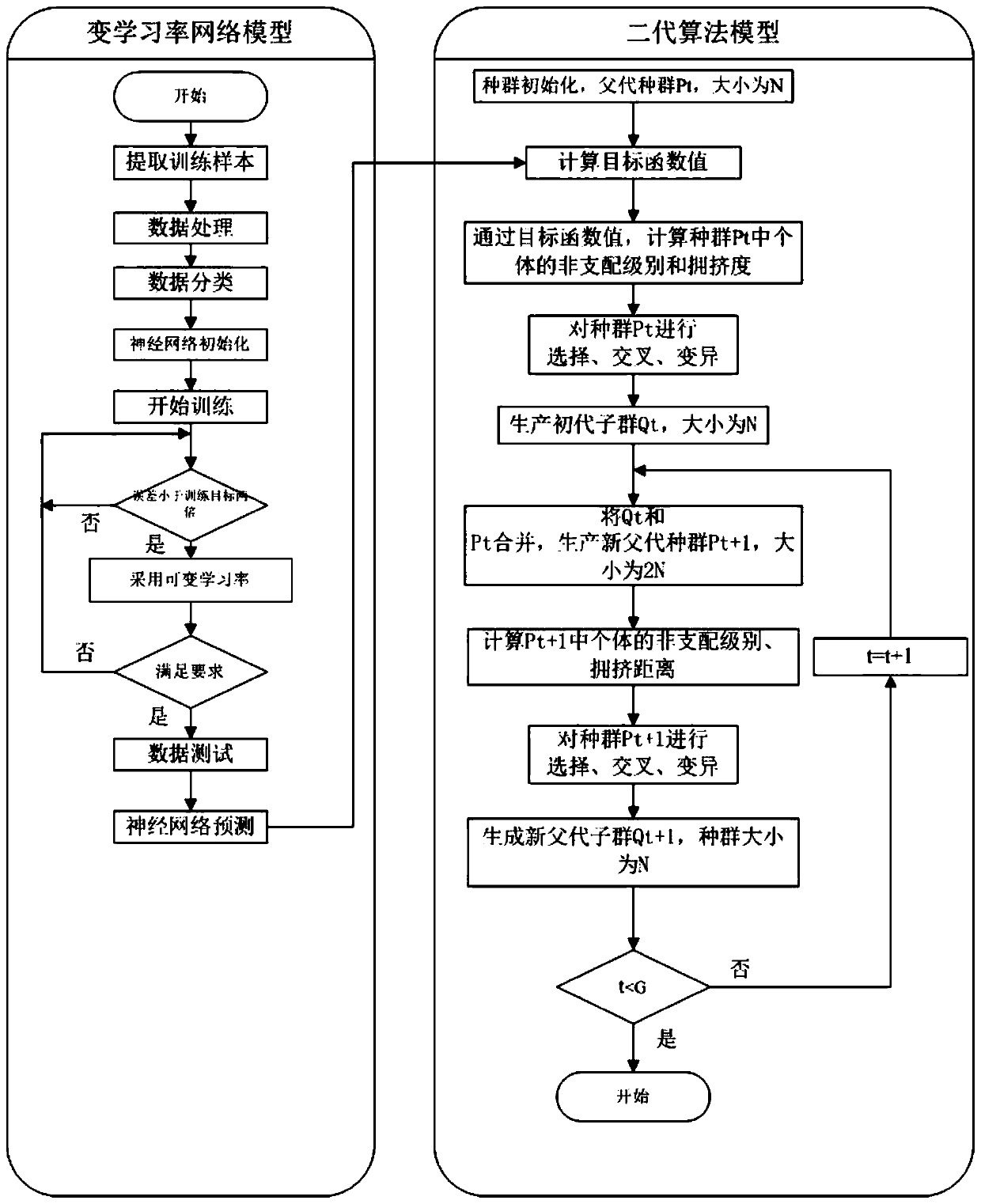

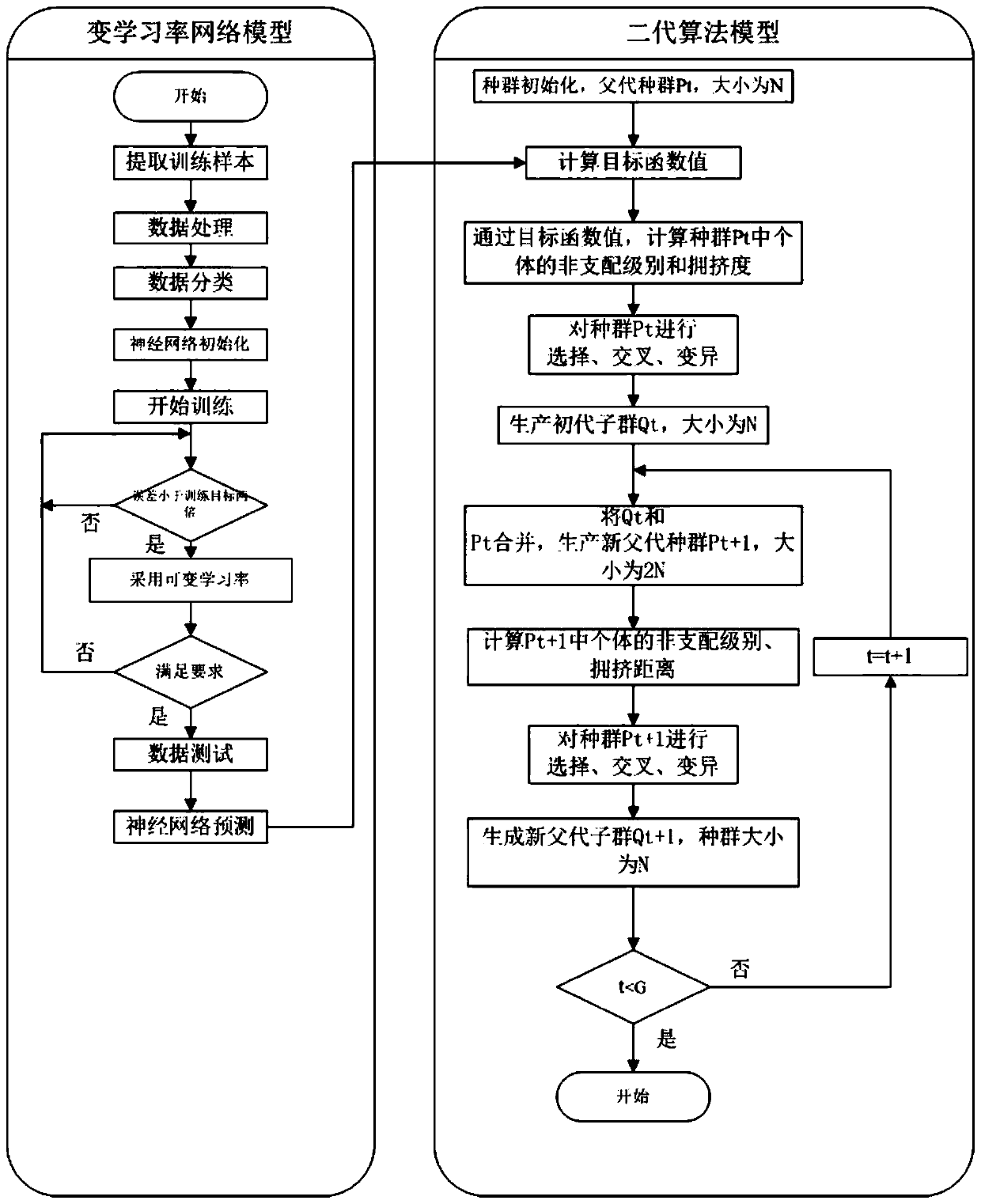

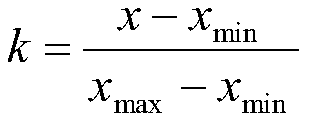

A fan design second-generation algorithm multi-objective optimization method based on variable learning rate network modeling

PendingCN109918749AEfficient mappingReduce oscillationNeural architecturesSpecial data processing applicationsLeading edgeAir volume

A fan design second-generation algorithm multi-objective optimization method based on variable learning rate network modeling comprises the following steps that 1, the wind pressure and the wind volume are given values, the efficiency and the cost are target variables, and data samples of the structure variables and the target variables are obtained through experiments; 2, taking the structure variable as an input variable and the target variable as an output variable, training the data sample to complete the establishment of a variable learning rate network model, and updating the weight andthe threshold value by adopting a variable learning rate method; Step 3, establishing a second-generation algorithm model, wherein a non-dominated sorting operator and an elitist strategy design operator are adopted; And 4, predicting the energy consumption and the cost of the fan through the established variable learning rate network, and using the predicted value to solve an objective function value in the second generation genetic algorithm model to obtain a pareto leading edge; And finally, applying the structure variable value subjected to the reverse normalization to the actual design ofthe fan. The method is comprehensive in target and high in precision.

Owner:BEIJING PICOHOOD TECH

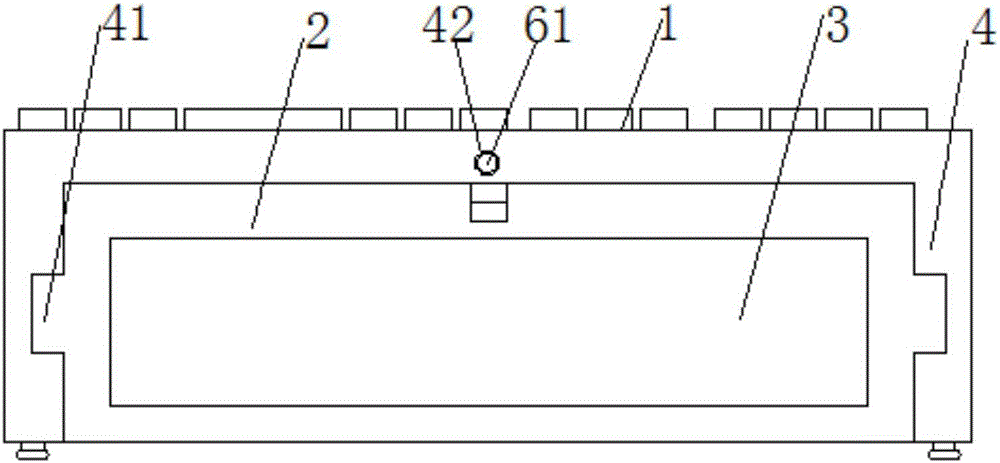

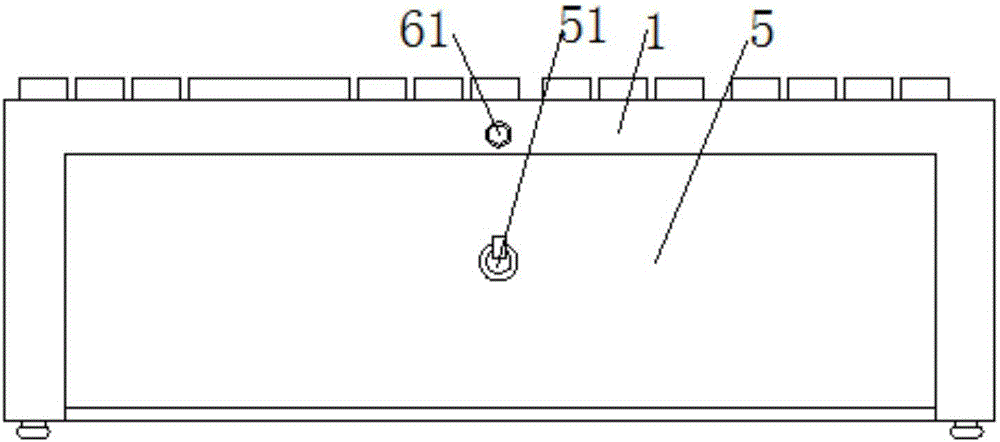

Computer keyboard with object storage function

InactiveCN106774954ASimple structureEasy to useInput/output for user-computer interactionUSBObject storage

The invention discloses a computer keyboard with an object storage function. The computer keyboard comprises a keyboard main body, wherein a U-shaped clamping strip is arranged at the bottom end of the keyboard main body; an elastic board with an L-shaped clamping rod is arranged in a clamping slot; the elastic board is connected into the clamping slot in a rotatable manner through a connection buckle; an object storage box is arranged in a sliding chute cavity. The computer keyboard is simple in structure; by the additional arrangement of the object storage box, the object storage function is added for the pure keyboard, and a small-sized part such as a USB flash disk can be stored in the object storage box conveniently, so that seeking and placement are facilitated; by the use of an iron core strip for attracting a permanent magnet strip, the keyboard main body can attract the object storage box conveniently to realize efficient fitting of the keyboard main body and the object storage box, and the attraction is preliminary fixing; an L-shaped locking rod is fastened into the L-shaped clamping rod on the elastic board, so that the keyboard main body can clamp the object storage box conveniently, and the clamping is secondary fixing; by the fixing of the two times, clamping for fastening between the keyboard main body and the object storage box is facilitated, so as to use the keyboard main body conveniently.

Owner:成都渔夫科技有限公司

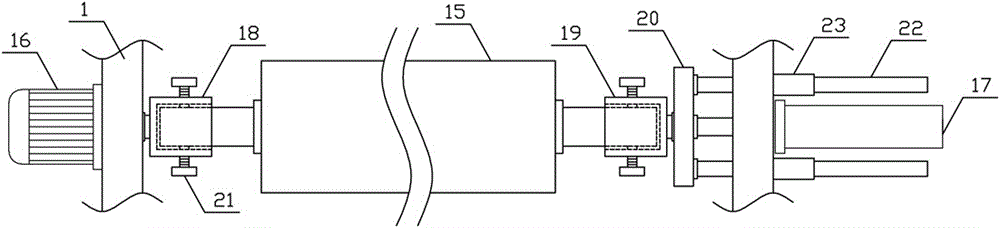

A roller laminating machine

InactiveCN103707607BReduce pollutionEfficient fitLamination ancillary operationsLaminationProcess engineeringHeating system

The invention relates to a roller laminating machine. The roller laminating machine comprises a first unreeling mechanism used for outwardly unreeling a first base material, a second unreeling mechanism used for outwardly unreeling a second base material, a gluing roller system used for transferring aqueous glue to the first base material, a flat heating system used for laminating the first base material coated with the aqueous glue to the second base material and heating to evaporate away water in the aqueous, and a reeling mechanism used for receiving the second base material laminated with the first base material. The roller laminating system can accurately coat the base material with the aqueous glue, and utilizes the flat heating system to control the evaporation capacity of the aqueous glue to realize low-pollution efficient lamination. The overall gluing process is simple, and there is no need to use extra ventilation systems, so the installation and the maintenance of the roller laminating machine are simple and convenient.

Owner:THE HONG KONG RES INST OF TEXTILES & APPAREL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com